heat sink

A heat dissipation device and heat sink technology, which is applied in the direction of cooling/ventilation/heating transformation, etc., and can solve problems such as differences in the service life of electronic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

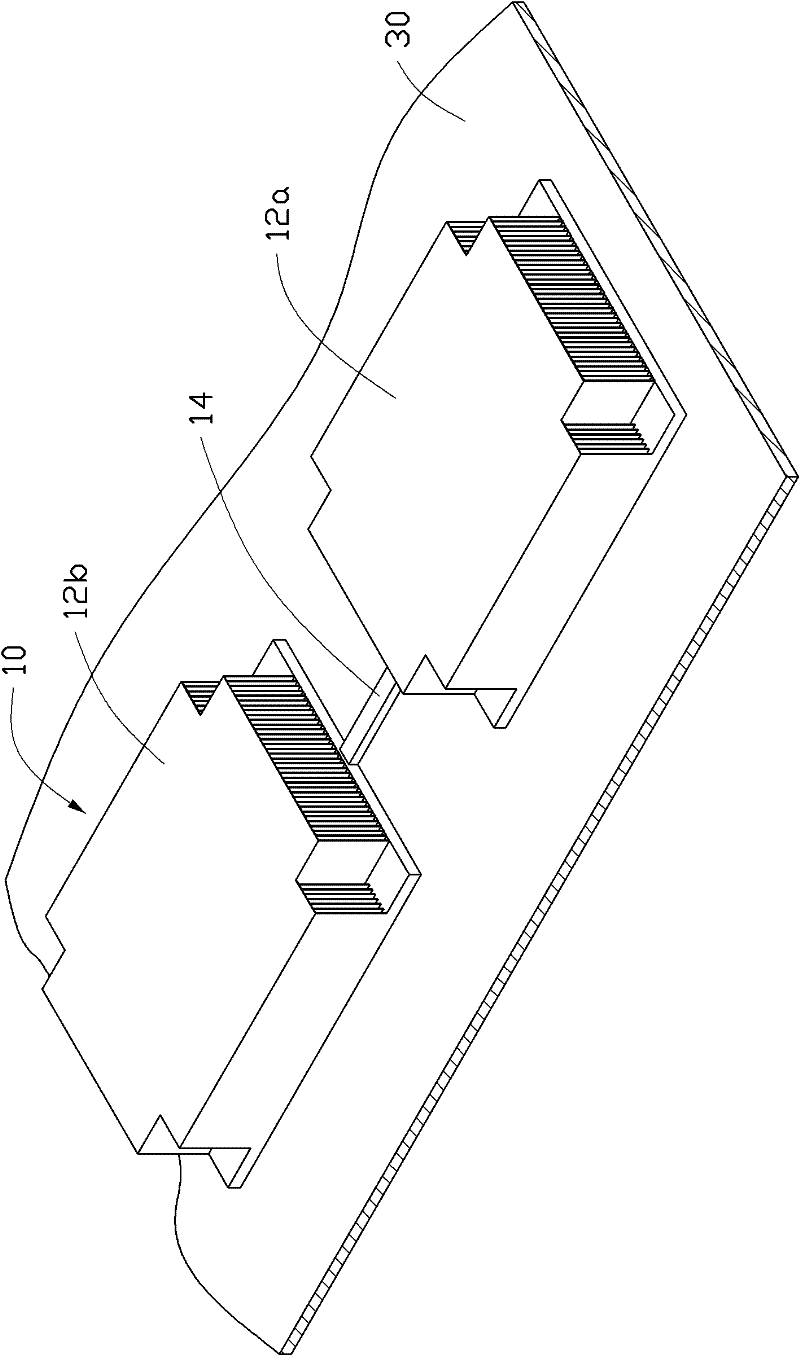

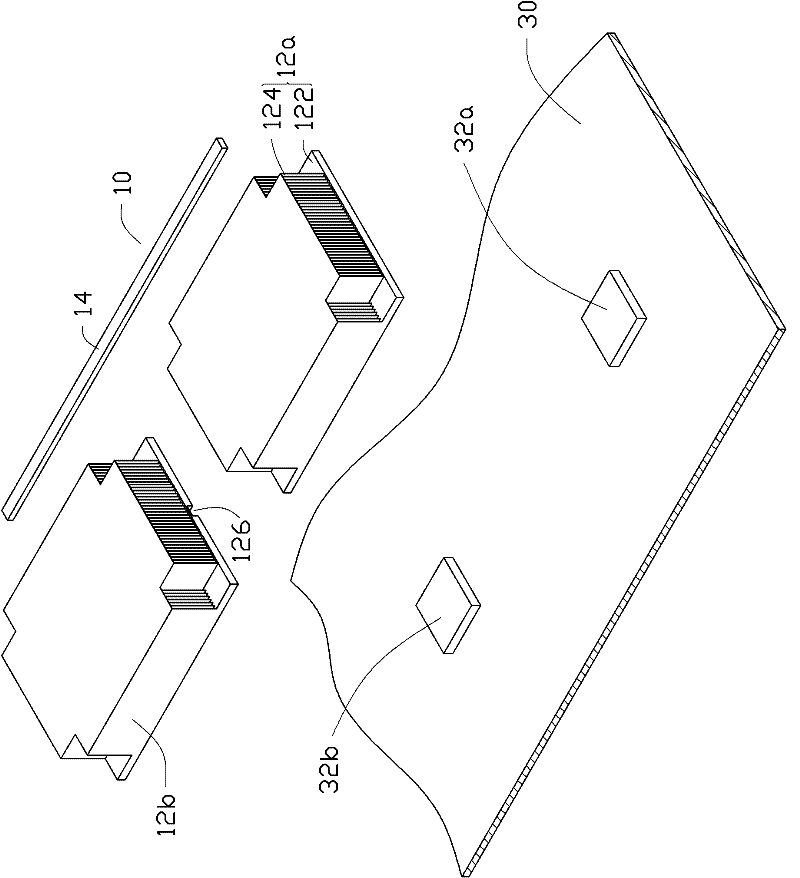

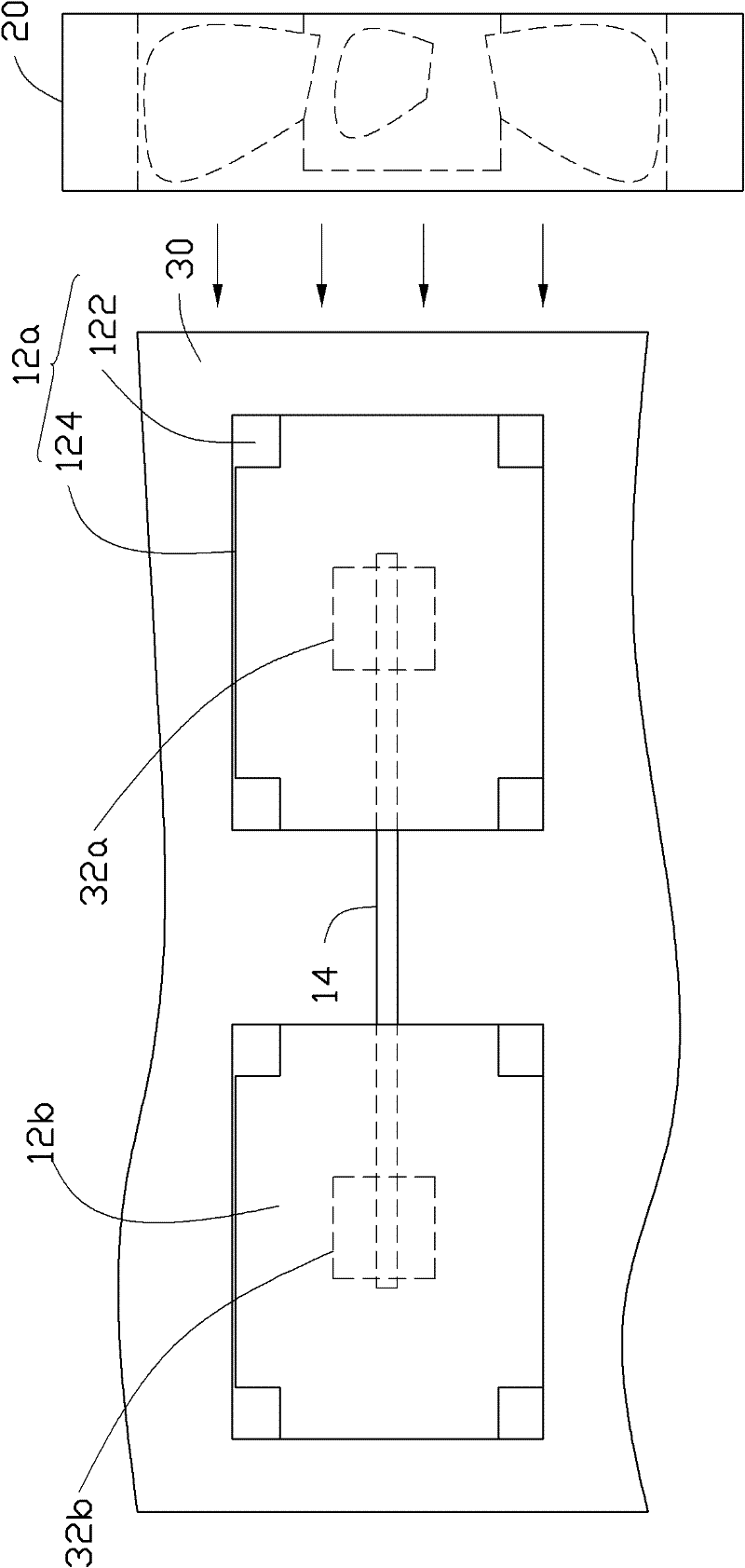

[0020] Such as figure 1 and image 3 As shown, the heat dissipation device 10 of a preferred embodiment of the present invention is used to simultaneously dissipate two electronic components 32a, 32b arranged at intervals on a motherboard 30 installed in an electronic device, which includes two components mounted on the motherboard 30 The upper radiators 12a, 12b, a heat pipe 14 thermally connected to the two radiators 12a, 12b, and a fan 20 arranged adjacent to one of the radiators 12a and away from the other radiator 12b.

[0021] Please also refer to figure 2 Each heat sink 12a, 12b is made of copper, aluminum and other thermally conductive materials. It includes a rectangular heat-conducting plate 122 and a plurality of heat-dissipating fins 124 extending vertically upward from the upper surface of the heat-conducting plate 122. The lower surface of the heat conducting plate 122 is in thermal contact with a corresponding electronic component 32a, 32b. A longitudinal groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com