Hydrogen gas storage buffering and filtering tank

A technology of buffer tanks and filter tanks, applied in the field of hydrogen gas storage buffer filter tanks, which can solve problems such as heat generation and inability to block solid particles, and achieve the effects of improving buffer performance, ensuring safety, and reducing impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

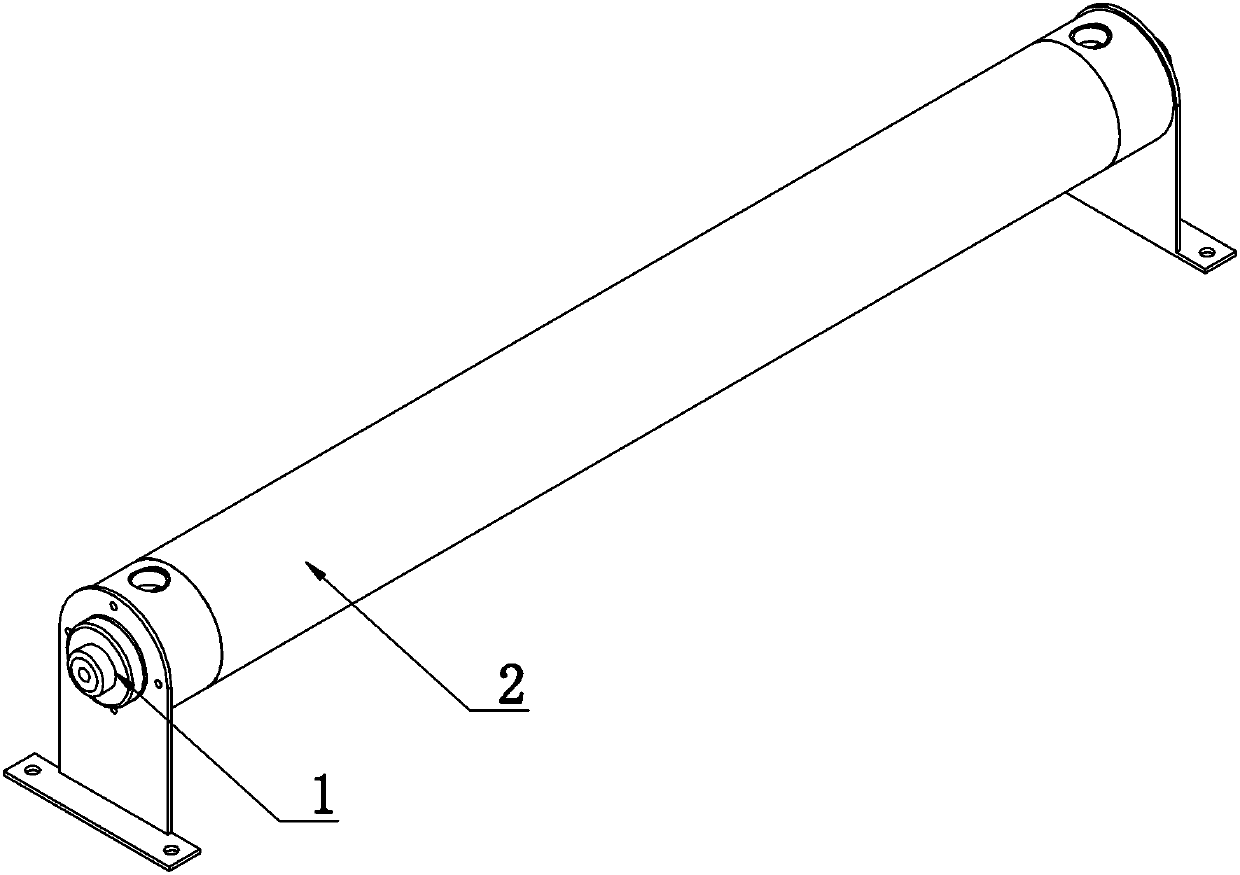

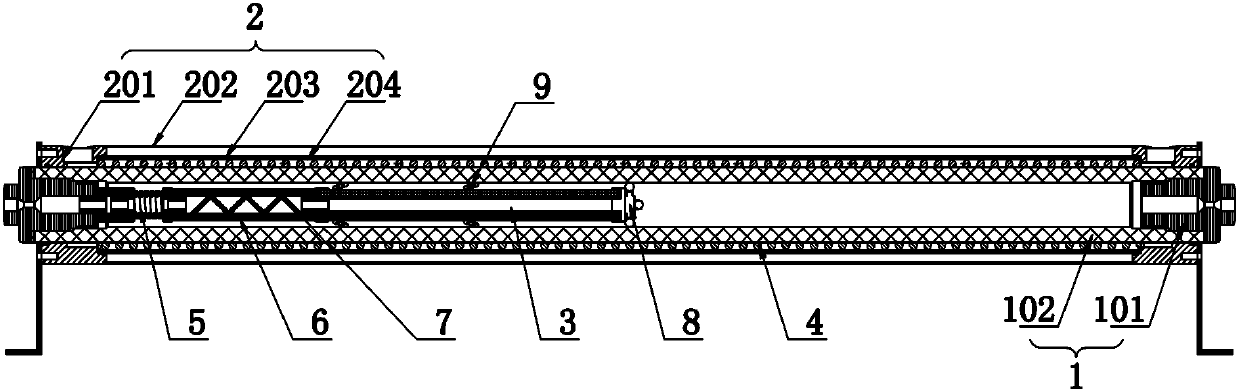

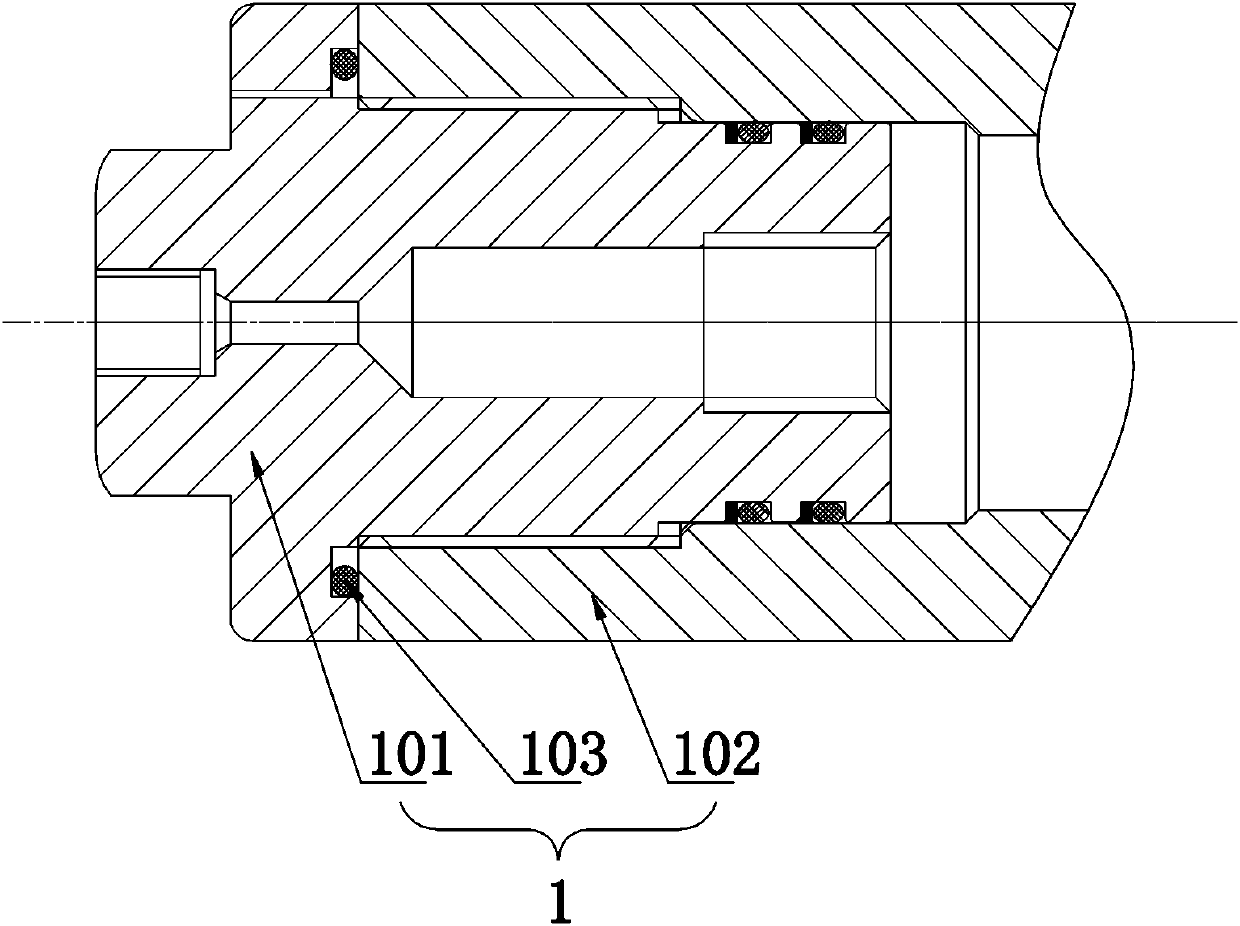

[0037] Such as Figure 1-4 As shown, a hydrogen gas storage buffer filter tank includes a buffer tank 1. The buffer tank 1 has a circular tube shape. Both ends of the buffer tank 1 are provided with an air inlet and an air outlet respectively. The buffer tank 1 includes a tank body 101 and a cover 102. , The tank body 101 is a round tube made of aluminum alloy material, and the two cover caps 102 are respectively located at the two ends of the tank body 101 and are screw-tightly connected with the tank body 101. A seal is provided between the inner end surface of the cover 102 and the end surface of the tank body 101. Ring 103, the cover 102 is provided with a side leakage hole corresponding to the sealing ring 103, one end of the side leakage hole is connected to the outer end surface of the cover 102, and the other end is connected to the inner end surface of the cover 102, and also includes a heat exchange shell 2 and a filter The cylinder 3 and the heat exchange shell 2 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com