Energy-saving far-infrared hot drying oven

A far-infrared, thermal baking technology, applied in heating devices, lighting and heating equipment, progressive dryers, etc., can solve the problems of uneven heating of the main body of the oven, inconsistent drying levels, and long time required to achieve The effect of improved baking time, high cleanliness and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

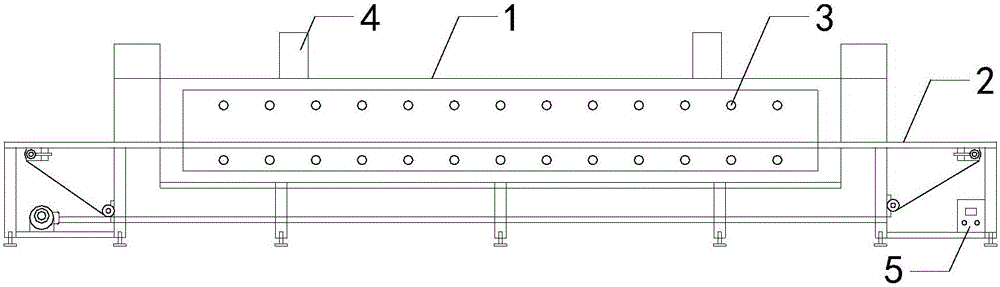

[0025] Such as figure 1 As shown, the energy-saving far-infrared heating oven of the present invention includes a box body 1 in a rectangular open structure, carbon fiber far-infrared heating tubes 3 are evenly arranged on the bottom and top inside the box body 1, and a conveyor belt with a tiled structure is adopted. 2. Pass through the middle of the casing 1 that is equipped with carbon fiber far-infrared heating tubes 3 at the bottom and top, and all carbon fiber far-infrared heating tubes 3 are connected with the control box 5.

[0026] After the power is turned on, the control box 5 adjusts the heat generation of the carbon fiber far-infrared heating tube 3 to the required range, and the baked objects placed on the conveyor belt 2 are heated by double radiation in the box body 1 through the bottom and top carbon fiber far-infrared heating tubes 3 , The internal temperature of the box 1 is balanced, there is no temperature difference, the heat energy is directly diffused t...

Embodiment 2

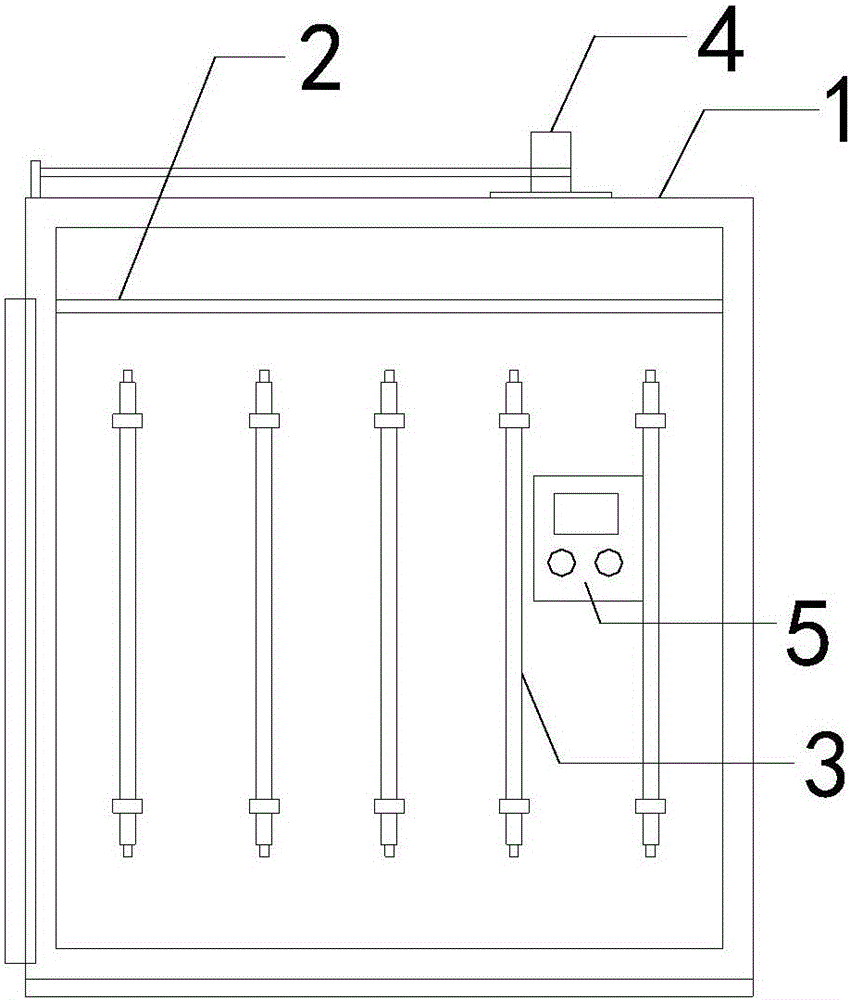

[0028] Such as figure 2 As shown, the energy-saving far-infrared heating oven of the present invention includes a box body 1 in a rectangular sealed structure, and the carbon fiber far-infrared heating tubes 3 are evenly arranged on the left side wall and the right side wall inside the box body 1. The conveyor belt 2 of structure is suspended in the middle of the casing 1 that carbon fiber far-infrared heating tube 3 is installed on the left side wall and the right side wall, and all carbon fiber far-infrared heating tubes 3 are connected with control box 5.

[0029] Due to the sealed structure, the equipment is small in size and low in construction costs, especially the far infrared drying tunnel can be shortened to half of the original one. Compared with microwave drying, high frequency drying and other equipment, far infrared equipment is simpler and cheaper. The drying quality is good, because the material molecules on the surface and inside of the coating absorb far-infr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com