Electrical connection assembly for contacting electronic module

A connecting device and conductive connection technology, which is applied in the direction of conductive connection, connection, fixed connection, etc., can solve problems such as impossible functional testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

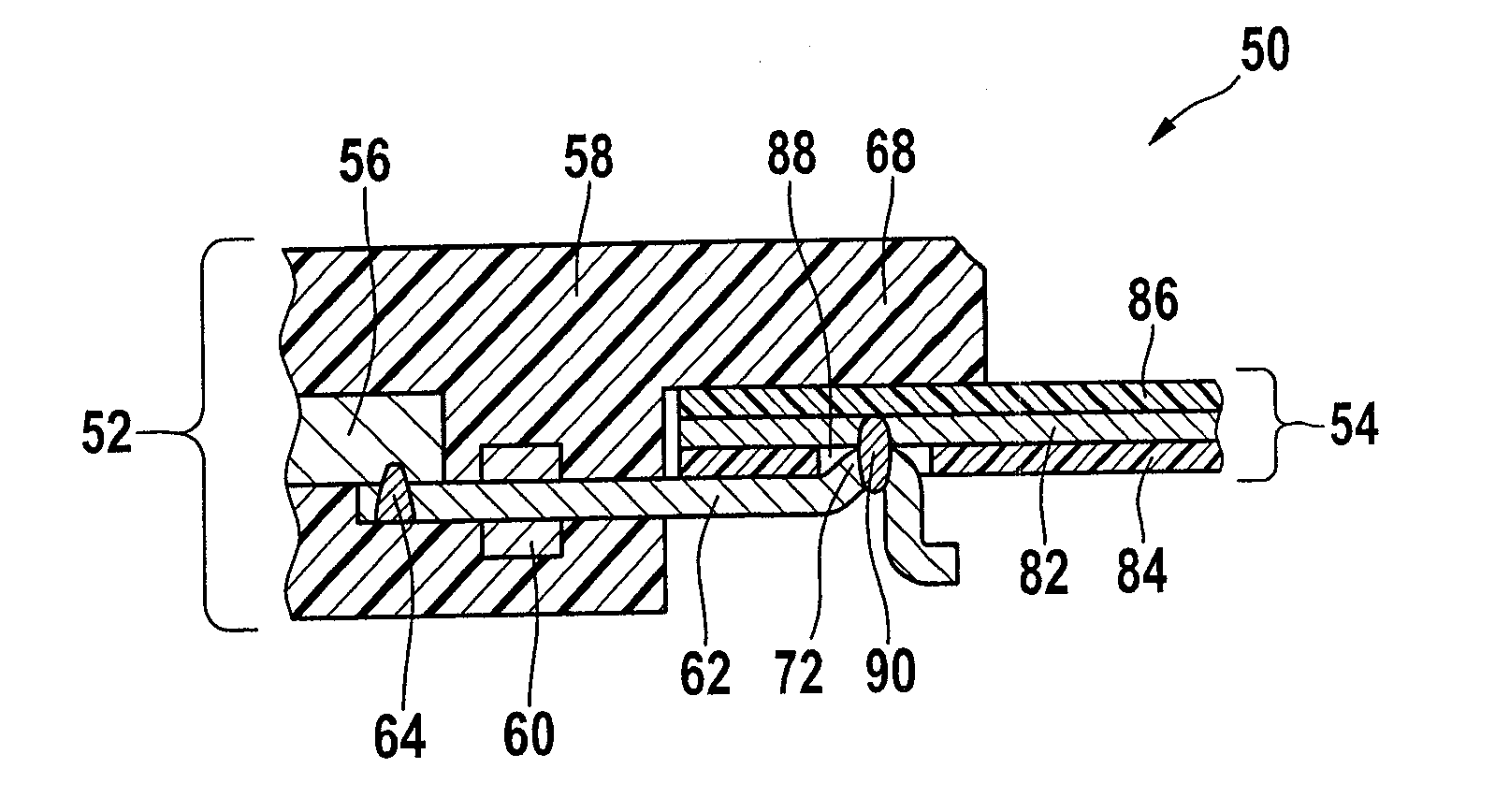

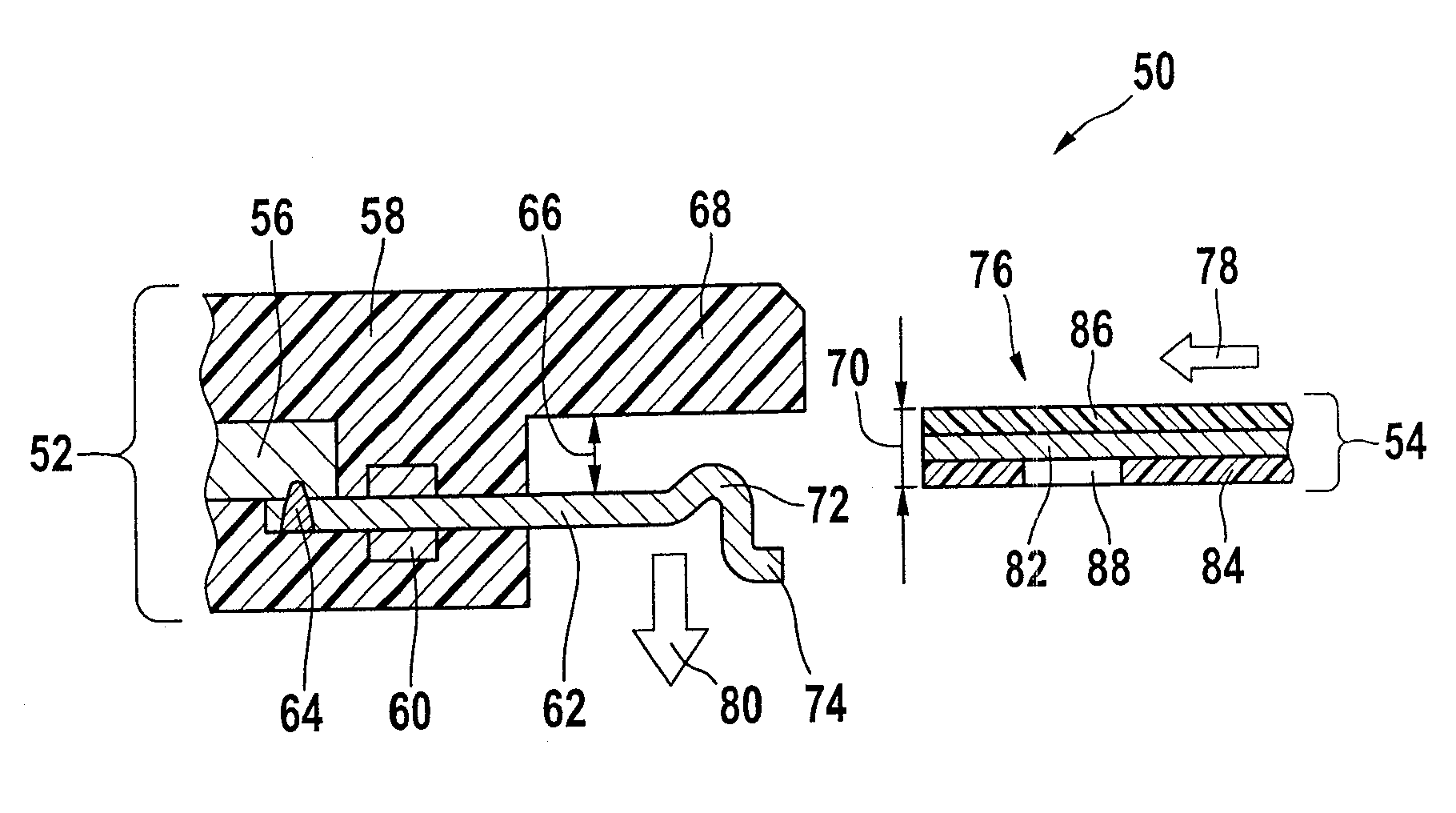

[0025] figure 1 A sectional view of the first embodiment of the electrical connection device according to the invention is shown with inserted flat conductors but not yet electrically contacted.

[0026] The connecting device 10 comprises in particular an electronic module 12 and a flexible flat conductor 14 which is plugged into the electronic module 12 . The line carrier 16 is integrated into a plastic housing 18 formed by extruding and encapsulating the line carrier 16 in all directions with a plastic material. Integrated into the plastic housing 18 is a contact lug strip 20 , which has a plurality of contact lugs, preferably evenly spaced and arranged side by side, of which a contact lug 22 can be seen. Electronic components (not shown) on circuit carrier 16 are electrically conductively connected via connection points 24 to contact lugs 22 inside plastic housing 18 . The contact lugs 22 are designed here as so-called flat pins. The inner connection point 24 can be prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com