Joint with anti-seismic slots for precast concrete piles

A technology for prefabricated concrete piles and prefabricated piles, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of fracture of prefabricated pile connection parts, dislocation and separation of upper and lower piles, connection method, complicated operation, etc., so as to save steel. , the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

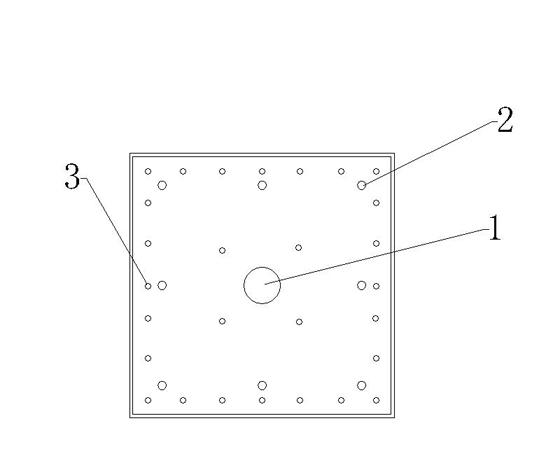

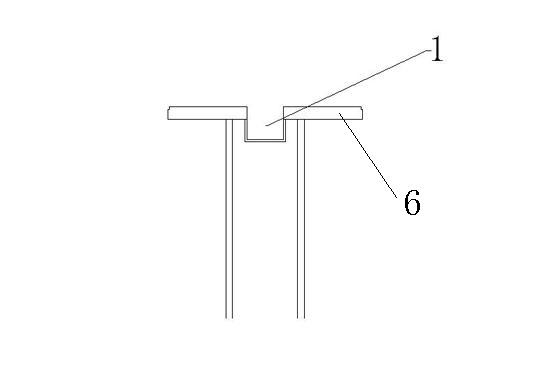

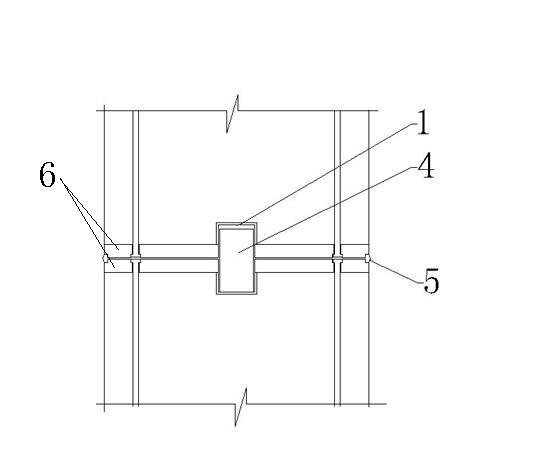

[0018] Such as figure 1 As shown, a concrete prefabricated pile joint with an anti-seismic groove, two square pile joints are provided with an end plate 6, and an anti-seismic groove 1 is arranged on the end plate 6 of each prefabricated pile joint, and the anti-seismic groove 1 is arranged on In the center of the prefabricated pile, the anti-seismic grooves on the joint surfaces of the two square piles correspond; image 3 shown. Since the anti-seismic slots of the two butted prefabricated piles correspond exactly to each other, the connecting bolts are placed in the anti-seismic slots, leaving a gap between the connecting bolts and the anti-seismic slots.

[0019] The anti-seismic groove is processed together with the prefabricated pile during the production of the prefabricated pile. In the preset position of the anti-seismic groove, the steel pipe of the required size is directly placed. When pouring concrete, the steel pipe will not be poured with concrete. Therefore, th...

Embodiment 2

[0022] Such as Figure 4 As shown, a concrete prefabricated pile joint with anti-seismic grooves, two prefabricated pile joints are provided with end plates 6, and four anti-seismic grooves 1 are arranged on the end plates 6 of each prefabricated pile joint, and the anti-seismic grooves 1 are all The anti-seismic grooves are distributed on the prefabricated piles, and the center of the anti-seismic groove is on the circle centered on the center of the prefabricated piles. The anti-seismic grooves on the joints of the two square piles correspond to each other; Connecting bolt 4 is arranged. Since the anti-seismic slots of the two butted prefabricated piles correspond exactly to each other, the connecting bolts are placed in the anti-seismic slots, leaving a gap between the connecting bolts and the anti-seismic slots.

[0023] The anti-seismic groove is processed together with the prefabricated pile during the production of the prefabricated pile. In the preset position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com