Copper-azole microporous crystalline material and preparation method thereof

A technology of crystal materials and pore crystals, applied in the field of porous crystalline materials and their preparation, can solve problems such as difficult to control structures, insufficient pore strength, and pore collapse, and achieve the effect of regular material structure and uniform pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

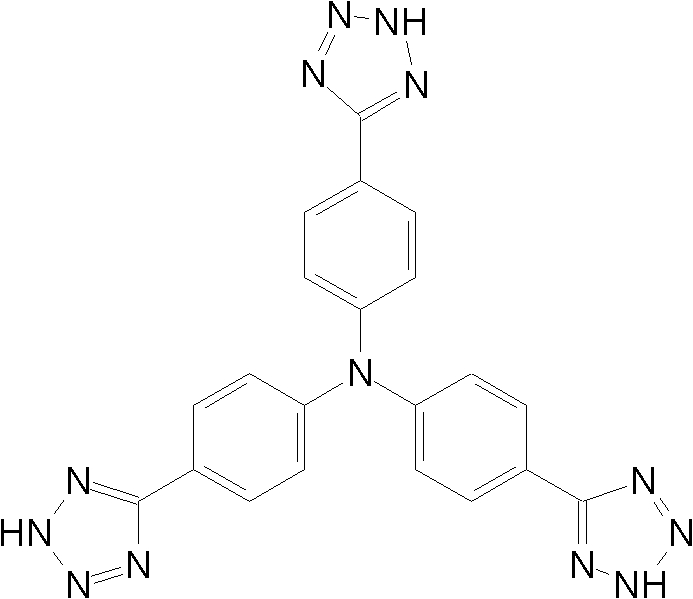

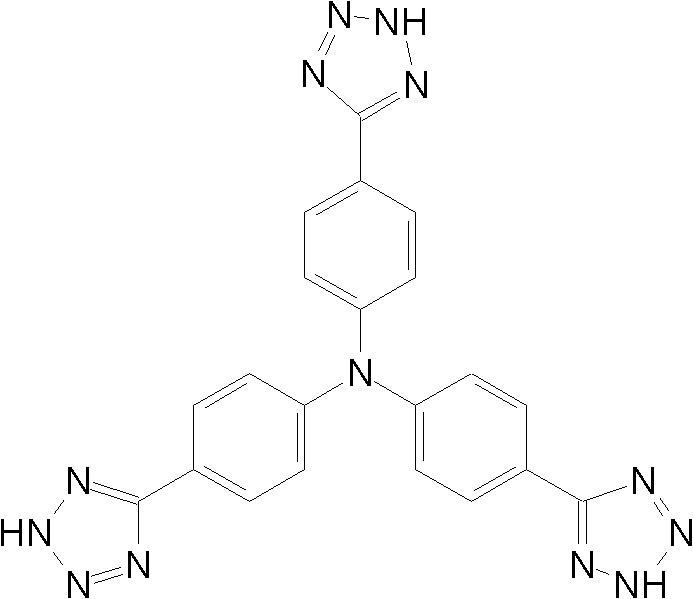

[0023] 0.1023g (0.6mmol) of CuCl 2 2H 2 O, 0.0449g (0.1mmol) of the ligand tris-(4-tetrazolylphenyl)amine (H 3 TCPZ) and 6mL N,N-dimethylformamide (DMF) were added to a 15mL autoclave, heated to 170°C in a closed manner and kept for 72 hours, and then cooled to room temperature at a rate not higher than 10°C / h. Filter, wash with water, and dry at room temperature to obtain 0.0404 g of bright yellow hexagonal prism crystals with a yield of 70%.

[0024] Confirmed by single crystal X-ray analysis, the product crystal prepared in the present embodiment, its structure is hexagonal crystal system, molecular formula is {[Cu(HTCPZ) 0.5 ]} ∞ , the specific parameters are listed in Table 1 below.

[0025] Table 1 Porous crystalline materials {[Cu(HTCPZ) 0.5 ]} ∞ parameter

[0026]

[0027]

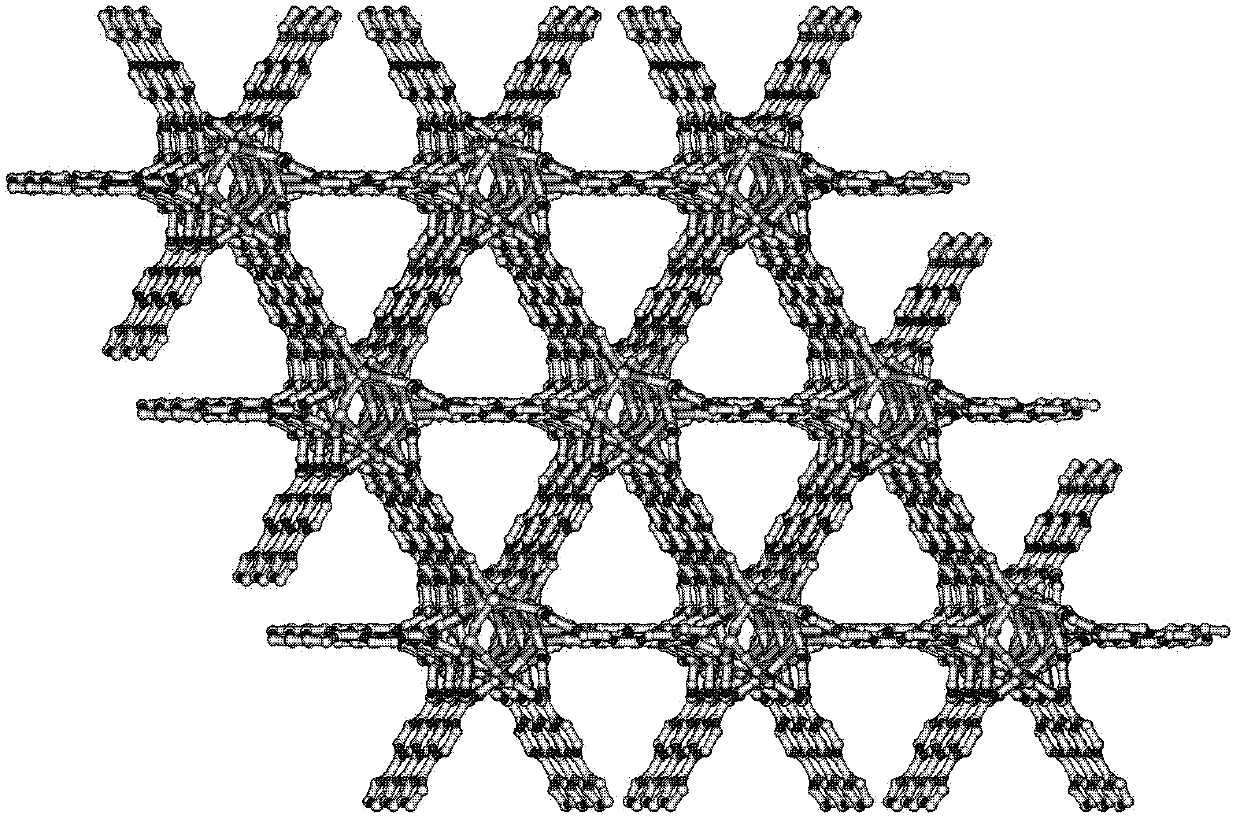

[0028] figure 1 Is prepared catalyst {[Cu(HTCPZ) in the present invention 0.5 ]} ∞ A schematic diagram of the crystal structure, the crystal material is a porous material, and its p...

Embodiment 2

[0034] 0.1023g (0.6mmol) of CuCl 2 2H 2 O, 0.0449g (0.1mmol) of the ligand tris-(4-tetrazolylphenyl)amine (H 3 TCPZ) and 6mL N,N-dimethylformamide (DMF) were added to a 15mL autoclave, heated to 170°C in a closed manner and kept for 72 hours, and then cooled to room temperature at a rate not higher than 10°C / h. Filter, wash with water, and dry at room temperature to obtain 0.0346 g of bright yellow hexagonal prism crystals with a yield of 60%. Single crystal X-ray analysis confirmed that its structure is hexagonal system, molecular formula is {[Cu(HTCPZ) 0.5 ]}∞ .

[0035] The solvent used in the above examples can be selected from N,N-dimethylformamide, N,N-diethylformamide, N,N-dimethylacetamide or water.

[0036] The copper salt may be selected from copper chloride, copper bromide, copper iodide, cuprous chloride, cuprous bromide, cuprous iodide or hydrates thereof; divalent copper salts may be preferred, particularly preferably chlorinated copper.

[0037] The molar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com