A kind of porous silica gel particles loaded with graphitic phase carbon nitride, paper with same and preparation method thereof

A technology of porous silica and graphitic carbon nitride, which is applied in chemical instruments and methods, catalyst activation/preparation, separation methods, etc., can solve the problems such as the inability of formaldehyde molecules to emit, the poor effect of removing formaldehyde, and the overflow of formaldehyde molecules. , to achieve the effects of cheap raw materials, mild preparation conditions and uniform pore distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

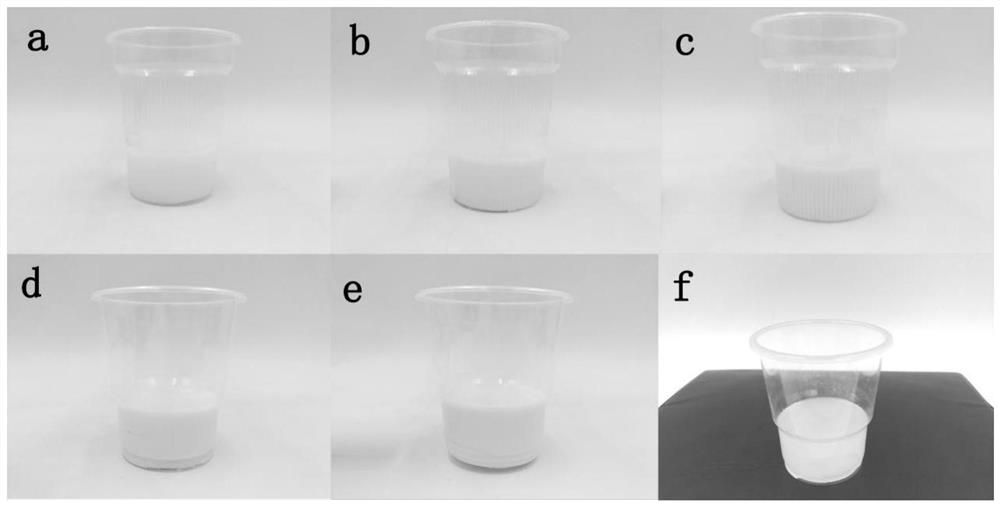

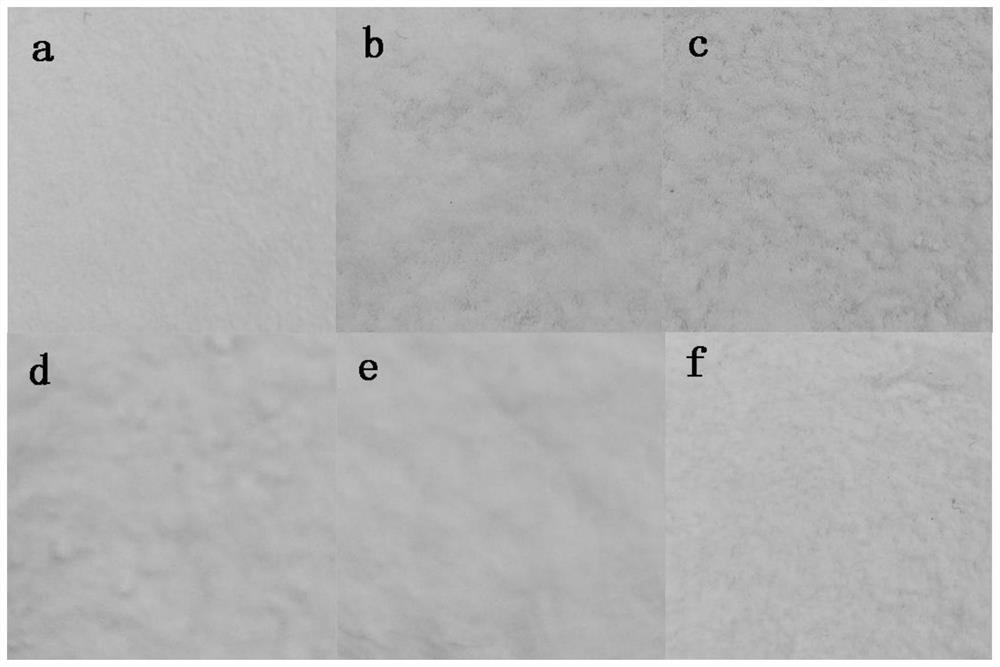

Embodiment 1

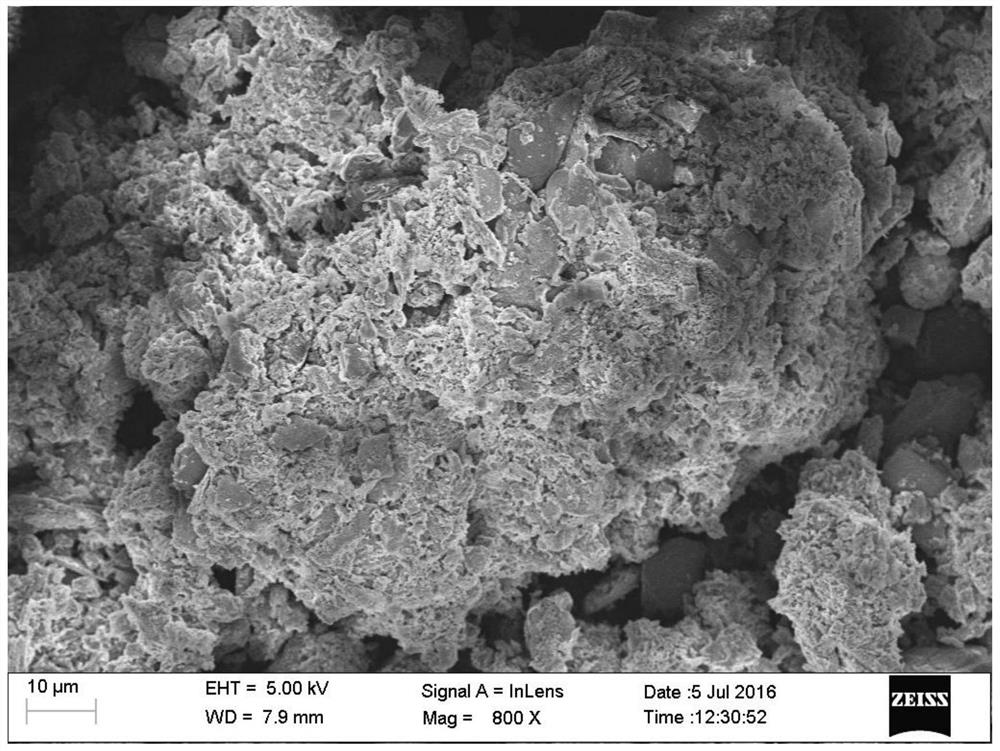

[0046] At room temperature, take 100mL tetraethyl orthosilicate aqueous solution and disperse it in absolute ethanol, stir for 30min to fully hydrolyze, then add 0.2g of g-C 3 N 4 , after stirring evenly, drop by drop the concentration less than 1mol L -1 The ammonia water was continuously stirred for 1h until the solution became viscous, then stood and aged, and after replacing the absolute ethanol in the system with deionized water for many times, the deionized water was poured out to obtain SiO 2 / g -C 3 N 4 gel system. SiO 2 / g -C 3 N 4 The gel system was frozen into a solid within 1 min, freeze-dried for 20 h, then calcined in a muffle furnace at 550°C for 2 h, and cooled naturally to room temperature to obtain porous silica gel particles loaded with graphite phase carbon nitride.

[0047] The obtained porous silica gel particles loaded with graphite phase carbon nitride were sieved to screen out silica microspheres with a particle size of 50 μm and ensure uniform ...

Embodiment 2

[0049] At room temperature, take 100mL tetraethyl orthosilicate aqueous solution and disperse it in absolute ethanol, stir for 30min to fully hydrolyze, then add 0.4g of g-C 3 N 4 , after stirring evenly, drop by drop the concentration less than 1mol L -1 The ammonia water was continuously stirred for 1h until the solution became viscous, then left to stand and aged, and methanol was used to replace the absolute ethanol and water in the system several times, then the methanol was poured off to obtain SiO 2 / g -C 3 N 4 gel system. SiO 2 / g -C 3 N 4 The gel system was frozen into a solid within 1 min, freeze-dried for 21 h, then calcined in a muffle furnace at 550°C for 2 h, and cooled naturally to room temperature to obtain porous silica gel particles loaded with graphite phase carbon nitride.

[0050] The obtained porous silica gel particles loaded with graphite phase carbon nitride were sieved to screen out silica microspheres with a particle size of 50 μm and ensure u...

Embodiment 3

[0052] At room temperature, take 100mL tetraethyl orthosilicate aqueous solution and disperse it in absolute ethanol, stir for 30min to fully hydrolyze, then add 0.6g of g-C 3 N 4 , after stirring evenly, drop by drop the concentration less than 1mol L -1 The ammonia water was continuously stirred for 1h until the solution became viscous, then stood and aged, and after replacing the absolute ethanol in the system with deionized water for many times, the deionized water was poured out to obtain SiO 2 / g -C 3 N 4 gel system. SiO 2 / g -C 3 N 4 The gel system was frozen into a solid within 1 min, freeze-dried for 22 h, then calcined in a muffle furnace at 550°C for 2 h, and cooled naturally to room temperature to obtain porous silica gel particles loaded with graphitic carbon nitride.

[0053] The obtained porous silica gel particles loaded with graphite phase carbon nitride were sieved to screen out silica microspheres with a particle size of 50 μm and ensure uniform mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com