Patents

Literature

47results about How to "Appropriate porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bracket material for bone tissue engineer and preparation method thereof

InactiveCN101417145AImprove mechanical propertiesGood biocompatibilityProsthesisDrug biological activityProtein C

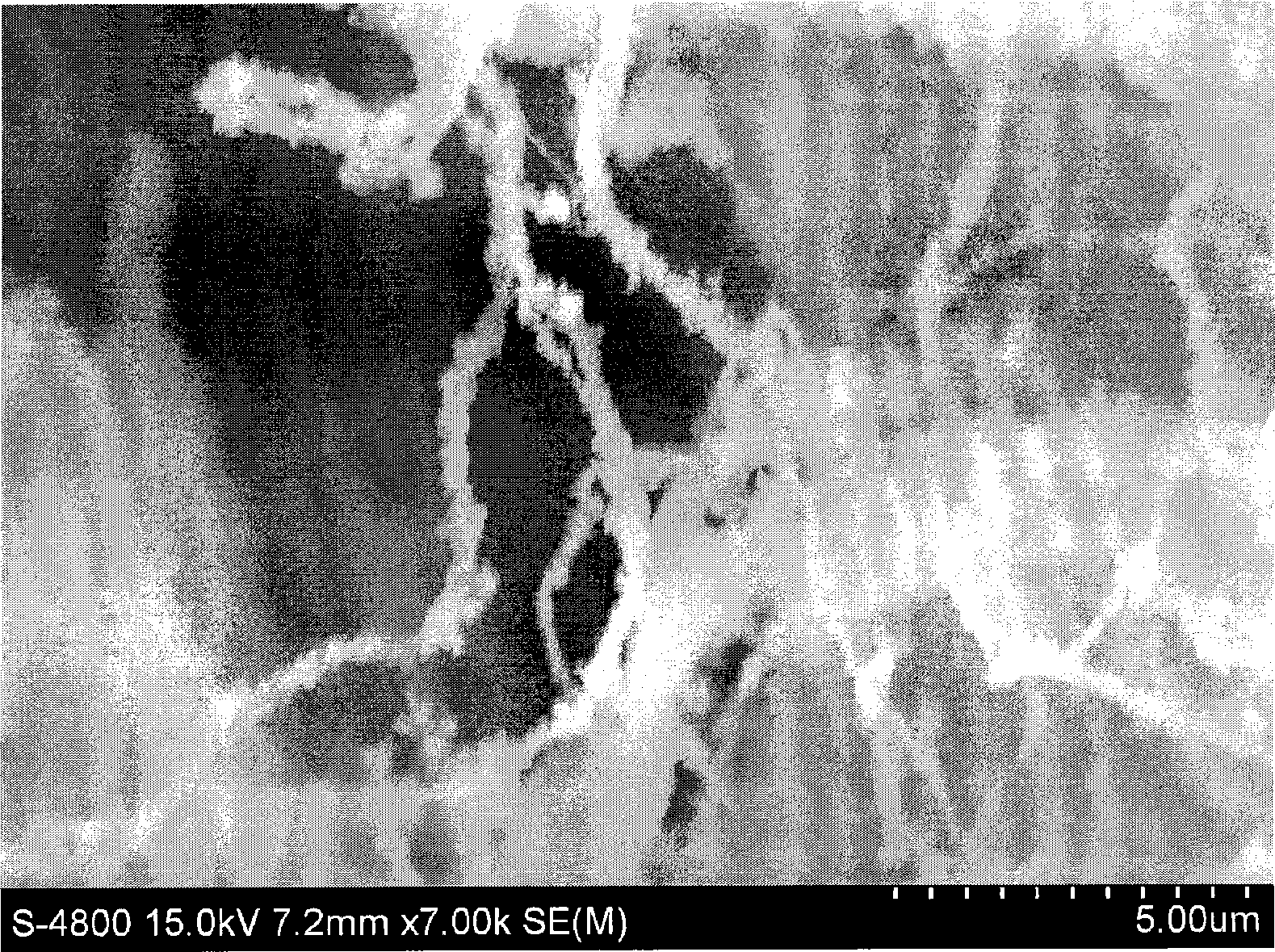

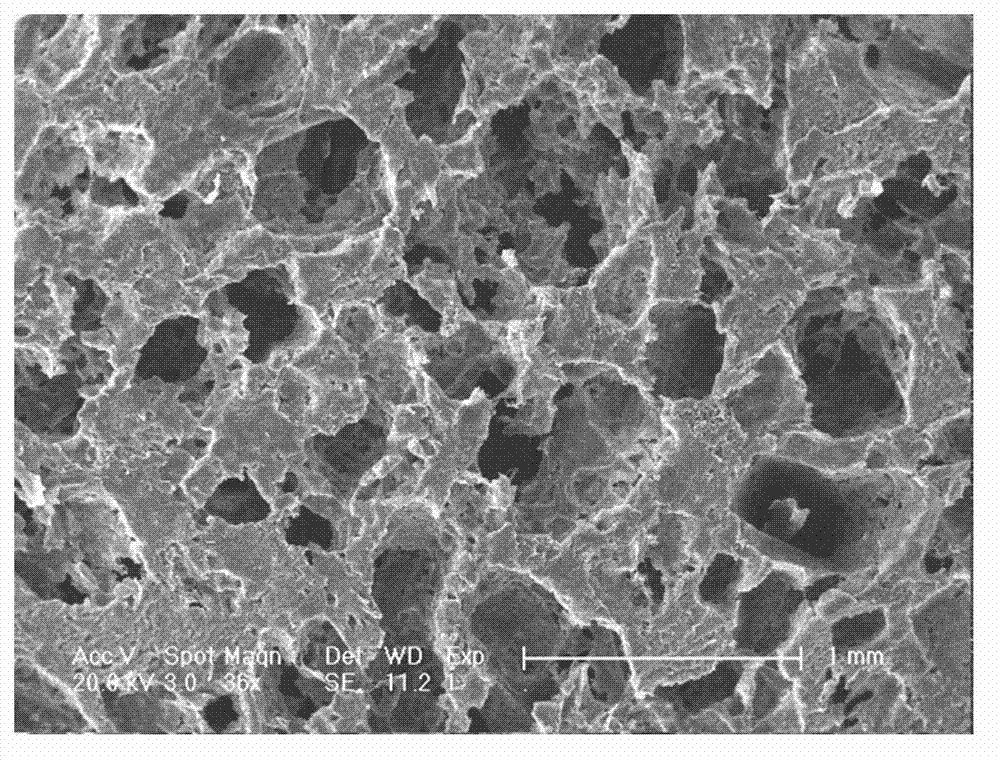

The invention relates to a bracket material used for an osseous tissue project, and a preparation method thereof. Firstly, the bracket of a type I collagen is extracted from a small fresh pigskin by a mature extracting technique. Then, the bracket is further expanded in a Tris cushion liquid, the pH of which is equal to 8.8 to obtain a natural porous collagen bracket by the treatments of freezing and drying. The bracket is respectively and repeatedly mineralized in a CaCl2 liquid and in (NH4)2HPO4 liquid or mineralized in simulated body fluid for a long period to lead the weakly crystallized HA to be uniformly settled into the collagen bracket; and then a pigskin collagen-hydroxyapatite ossein is obtained by the treatments of freezing and drying to replace the natural bracket material. The invention not only maintains the natural bracket structure of the collagen in an organism, but also has the advantages of low material cost, simple devices, short period and easy operation. The obtained compound bracket material used for the pigskin collagen-hydroxyapatite osseous tissue project has the characteristics of high intensity, large toughness, non-antigenicity, higher biological activity as well as degradation and releasing control.

Owner:SHANDONG UNIV

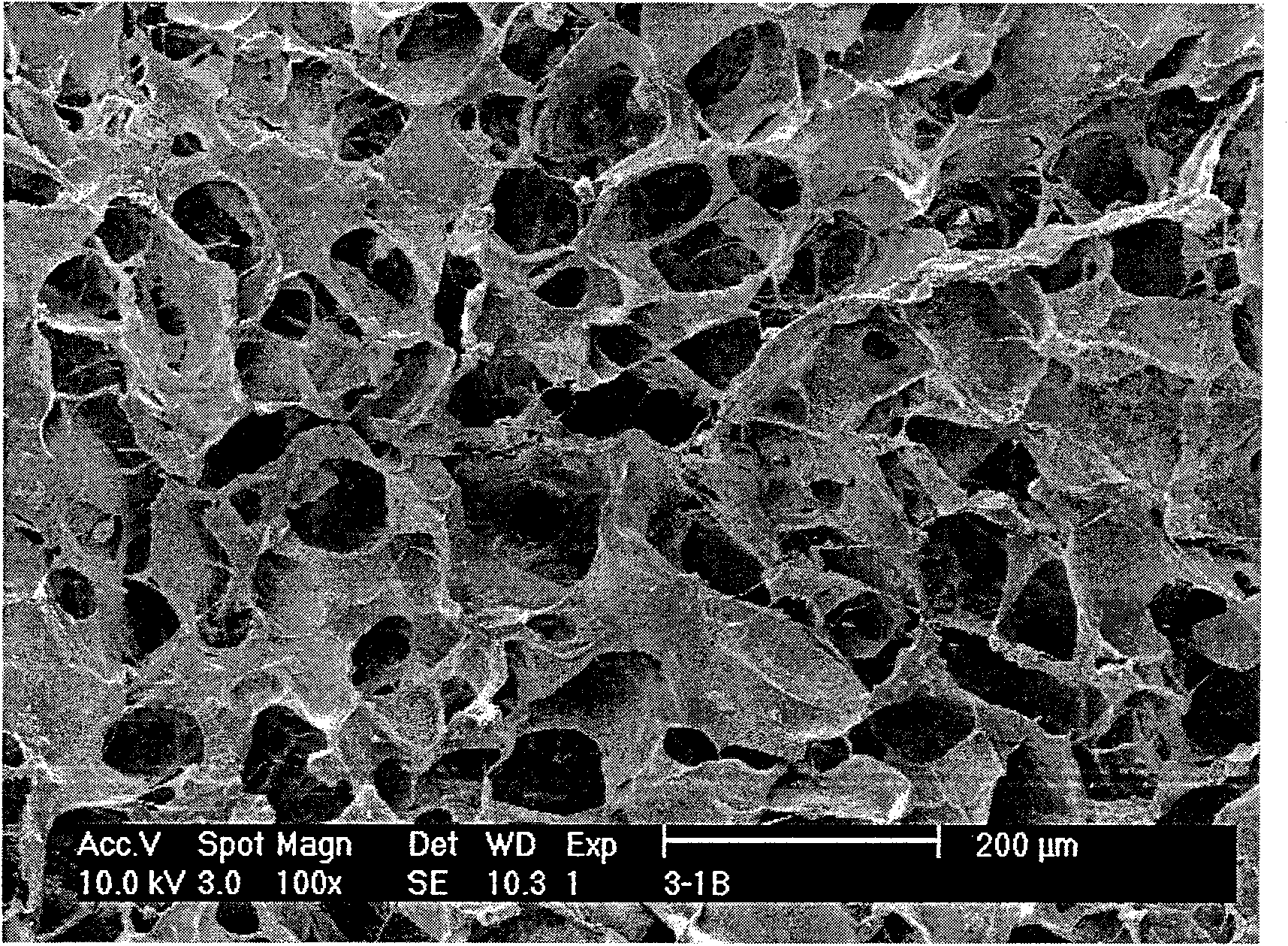

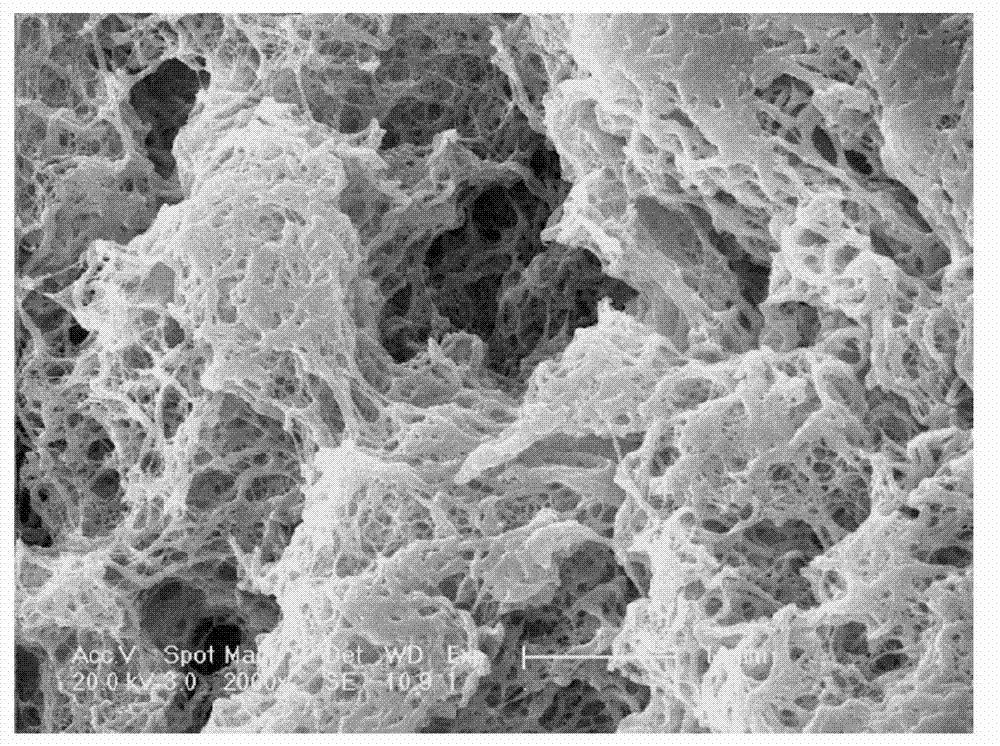

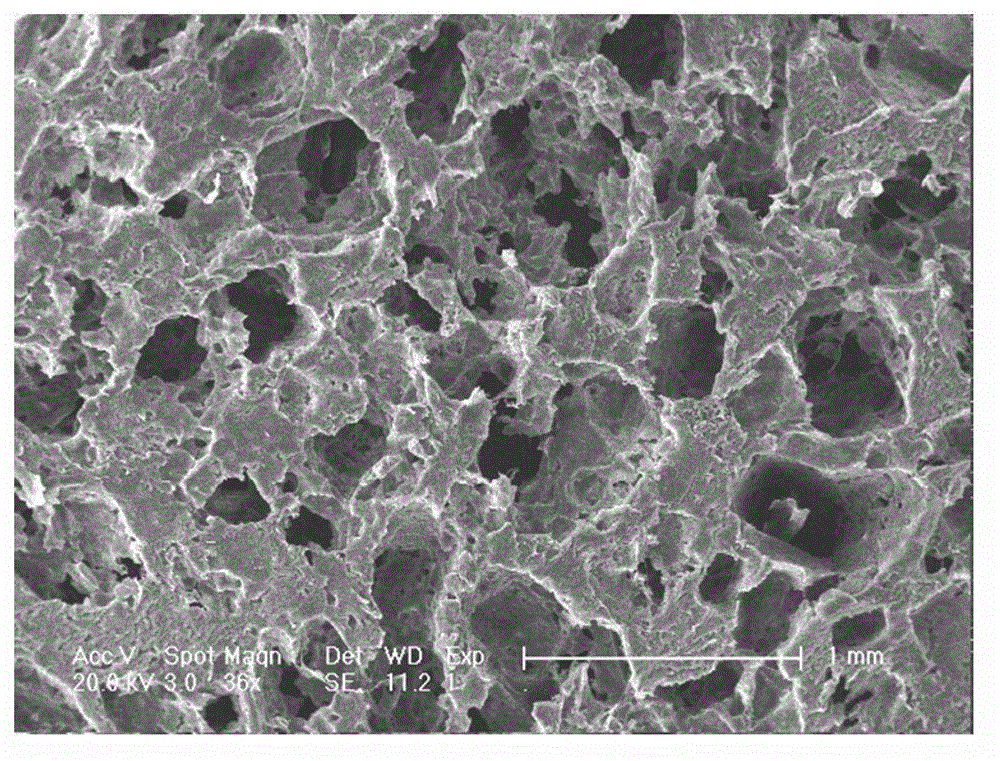

Cartilage cell epimatrix three-dimensional porous sponge stent for tissue engineering and preparation method thereof

ActiveCN101496913AFacilitate in vitro constructionPromotes regeneration in the bodyBone implantCartilage cellsCell-Extracellular Matrix

The invention discloses a three-dimensional porous cartilage extracellular matrix sponge scaffold made of natural cartilage, which can compound cells further to construct tissue engineered cartilage, and can be used for clinically repairing cartilage defects. In the invention, conditions which can fully perform cell extraction and form a porous scaffold matrix are provided by processing cartilage into cartilage microfilaments, and then the cell extraction and solidification and / or strengthening treatment are performed to obtain the three-dimensional porous cartilage extracellular matrix sponge scaffold which is completely decellurized. The antigenicity and cell components are removed in the natural cartilage, and an extracellular matrix component of the cartilage is retained to obtain the scaffold with appropriate pore diameter and porosity, suitable degradation rate, good biocompatibility and certain biomechanical strength. The scaffold has the advantages of broad material sources, low cost, simple and feasible preparation technology, and good repetitiveness; and the scaffold can be widely applied in the field of tissue engineering and has good clinical application prospect.

Owner:GENERAL HOSPITAL OF PLA

Method for synthesizing composite material of organic - inorganic bentonite

InactiveCN101003374AOvercome the disadvantage of easy falling offStrong forceSilicon compoundsPorositySodium Bentonite

This invention discloses a method for synthesizing organic-inorganic bentonite composite. The method comprises: utilizing bentonite as the main material, performing inorganic modification through cation-exchange reaction by using hydroxyl aluminum aqueous solution, torrefying to obtain hydroxyl-containing aluminum-pillared bentonite with high porosity and high specific surface area, and reacting between the hydroxyls and silylation agent to graft silane groups onto aluminum-pillared bentonite and obtain organic-inorganic bentonite composite. The organic-inorganic bentonite composite has both the advantages of inorganic pillared bentonite such as high porosity and high specific surface area, and those of organic bentonite such as high organic carbon content and high hydrophobicity thus can be used to treat organic waste gases and wastewater with a good effect by surface adsorption as well as distribution.

Owner:ZHEJIANG UNIV

Remediation of groundwater

ActiveUS20090184058A1Appropriate porosityMinimize impactWater contaminantsContaminated soil reclamationGroundwater remediationSlurry

A groundwater remediation method for treating acidic or alkaline groundwater containing divalent and trivalent metal cations includes the step of injecting a slurry or suspension of solid alkaline material into the ground, the slurry or suspension being injected into one or more regions such that the groundwater contacts the solid alkaline material and the divalent and trivalent metal cations react to form a layered double hydroxide (LDH) material.

Owner:COMMONWEALTH SCI & IND RES ORG

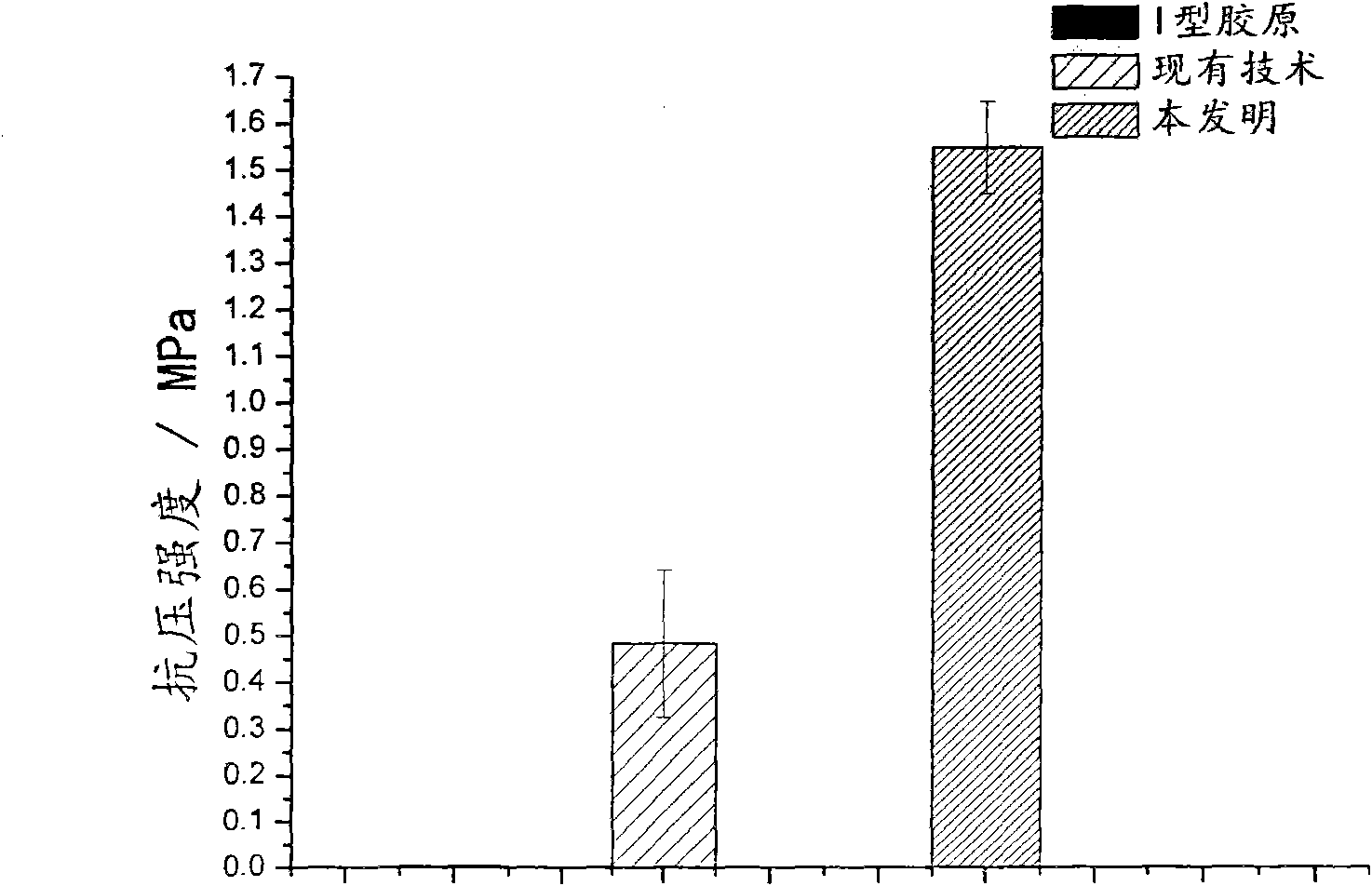

Method for preparing collagen/bioglass/hyaluronic acid tissue repairing materials

The invention discloses a method for preparing collagen / bioglass / hyaluronic acid tissue repairing materials, comprising the following steps: combining I-type collagen and bioglass, static layering, filtering, adjusting pH value, adding hyaluronic acid, cross linking, molding, freezing and drying and the like. In the process of preparing the collagen / bioglass / hyaluronic acid tissue repairing materials, the diameter of the collagenous fiber bundle composing the network structure of the tissue repairing materials is increased by adjusting the ratio of the I-type collagen and bioglass and the pH value of the combined solution, and the microstructure of the materials is adjusted, thus achieving the aim of improving mechanical strength thereof. The collagen / bioglass / hyaluronic acid tissue repairing materials prepared by the invention has improvement in mechanical property and degradation performance, can be widely used in medical field, also can be used in tissue engineering scaffolds and bone defects and soft tissue injuries repairing.

Owner:SOUTH CHINA UNIV OF TECH

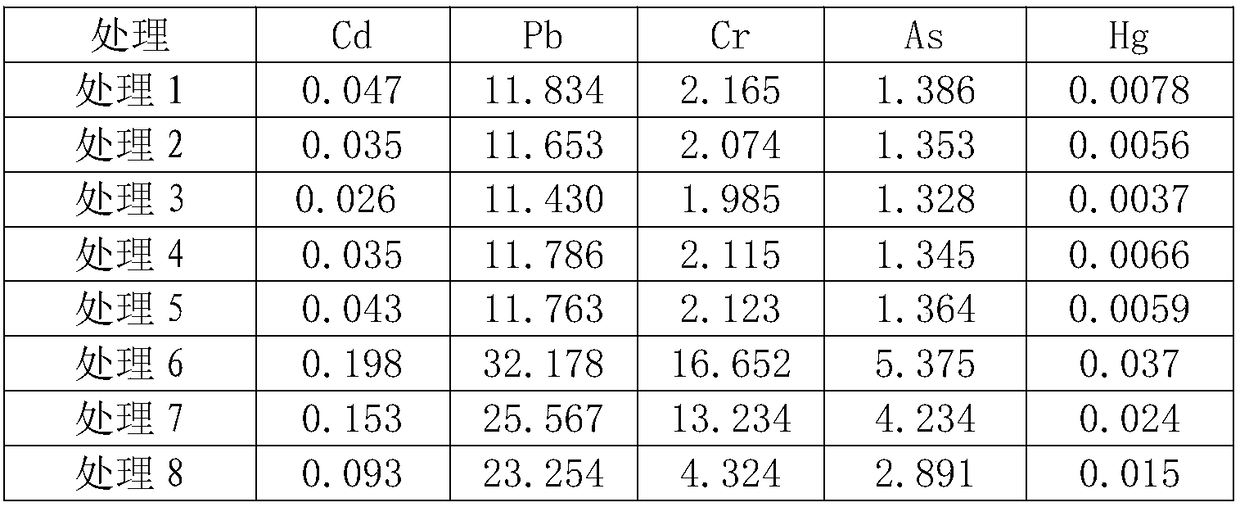

Soil conditioner capable of reducing activity of heavy metal in soil and preparation method thereof

InactiveCN108410474AReduced activityImprove fertilityAgriculture tools and machinesOther chemical processesSoil scienceHeavy metal chelation

The invention discloses a soil conditioner capable of reducing activity of heavy metal in soil and a preparation method thereof. The soil conditioner is prepared from sulfydryl modified plant straw powder, an inorganic porous material, caustic dross, humic acid mineral powder, a compound microbial fertilizer and a heavy metal chelating agent. According to parts by weight of the sulfydryl modifiedplant straw powder, the inorganic porous material, the caustic dross, the humic acid mineral powder, the compound microbial fertilizer and the heavy metal chelating agent, the sulfydryl modified plantstraw powder is 3 to 7 parts, the inorganic porous material is 15 to 45 parts, the caustic dross is 1 to 5 parts, the humic acid mineral powder is 20 to 40 parts, the compound microbial fertilizer is2 to 8 parts, and the heavy metal chelating agent is 0.5 to 3 parts. The soil conditioner disclosed by the invention can effectively reduce activity of the heavy metal in acidic heavy metal contaminated soil and further has the advantages of low cost, easiness in implementation, greenness and environmental friendliness.

Owner:张鑫

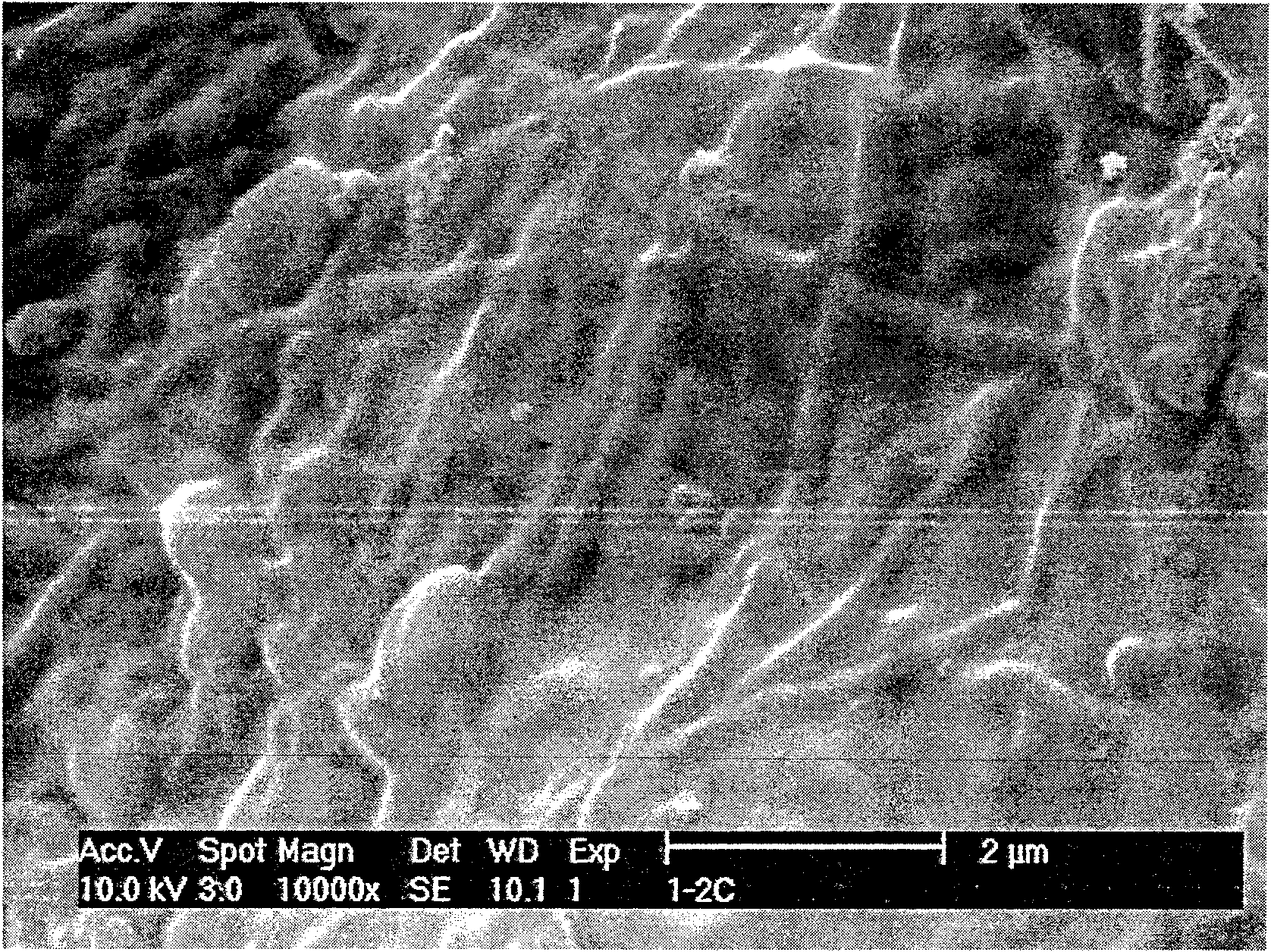

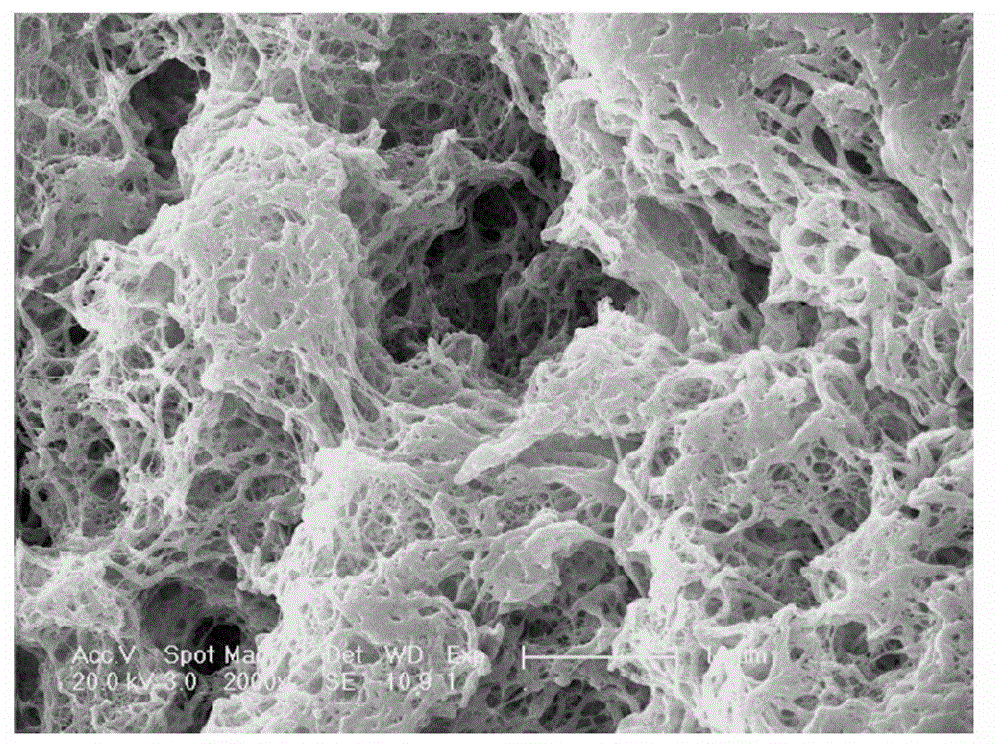

Method for preparing microfiber hemostatic collagen sponge

InactiveCN104558675AHas advantagesEfficient use ofAbsorbent padsBandagesSurgical operationProtein solution

The invention relates to a method for preparing microfiber hemostatic collagen sponge. The method comprises the following steps of: aggregating collagen molecules by the charge effect by adjusting pH, temperature and the salt concentration of collagen protein solution, freeze-drying the obtained and assembled collagen, then preparing into the collagen protein sponge, and then carrying out thermal crosslinking to obtain the microfiber hemostatic collagen sponge. The microfiber hemostatic collagen sponge prepared by adopting the method has uniform porous structure, good hydrophilic performance, high mechanical strength and degradation resistance and good hemostatic performance, and the defects that the traditional collagen sponge is easy in degradation, poor in mechanical property, easy in collapse in the application process and difficult in maintenance of the inherent form and the like are solved. The preparation method is simple and feasible, and is stable in process, and the prepared microfiber hemostatic collagen sponge can be widely applied in hemostasis and restoration of wounds of burns, traumas and surgical operation, and has good application prospect.

Owner:无锡贝迪生物工程股份有限公司

Method for preparing polyalcohol stephanoporate bracket for tissue project by poragen agglutinating filtering off method

InactiveCN101176799AAvoid wrappingAppropriate apertureCoatingsProsthesisPorosityPolymer solution casting

The invention relates to a preparation method of porous polymer scaffolds used for tissue engineering by means of pore-forming agent bonding and filtering method, comprising two steps: firstly, a mold containing pore-forming agent is positioned in the environment with certain temperature and certain humidity, and the pore-forming agent in the mold then can bond together; secondly, polymer solution is cast into the mold, the pore-forming agent in the mold is filtered out after the solvent volatilizing, and a porous polymer scaffold can be obtained. The invention has the advantages of simple equipment, easy operation, controllable aperture, high porosity, excellent connectivity, and fitness for three-dimension porous cell scaffolds in tissue engineering and other application fields.

Owner:TONGJI UNIV

Chitosan artificial nerve graft containing neurotrophic factor and preparation method thereof

InactiveCN102343112AImprove adsorption capacityEasy to transportProsthesisGlial cell line-derived neurotrophic factorCross-link

The invention discloses a chitosan artificial nerve graft containing a neurotrophic factor and a preparation method thereof. The chitosan artificial nerve graft is prepared by processing chitosan into a nerve conduit with a porous structure and high tensile strength by virtue of weak acid dissolution, mold injection, freezing formation, neutralization and immobilization, cleaning, lyophilization and other processes under a condition of not adding any foaming agent or cross linking agent. The cell factor with a treatment effect in the nerve conduit is one or more of a basic fibroblast growth factor (bFGF), a brain derived neurotrophic factor (BDNF), a neurotrophic factor 3 (NT-3), a basic fibroblast cell growth factor (bFGF) and a glial-cell-line derived neurotrophic factor (GDNF) and the like. The product provided by the invention contains the neurotrophic factor, adopts degradable materials, and has excellent biocompatibility with a human body. The prepared product does not contain exogenous toxic or side-effect substances brought by a preparation process.

Owner:JIANGSU YITONG BIOTECHNOLOGY CO LTD

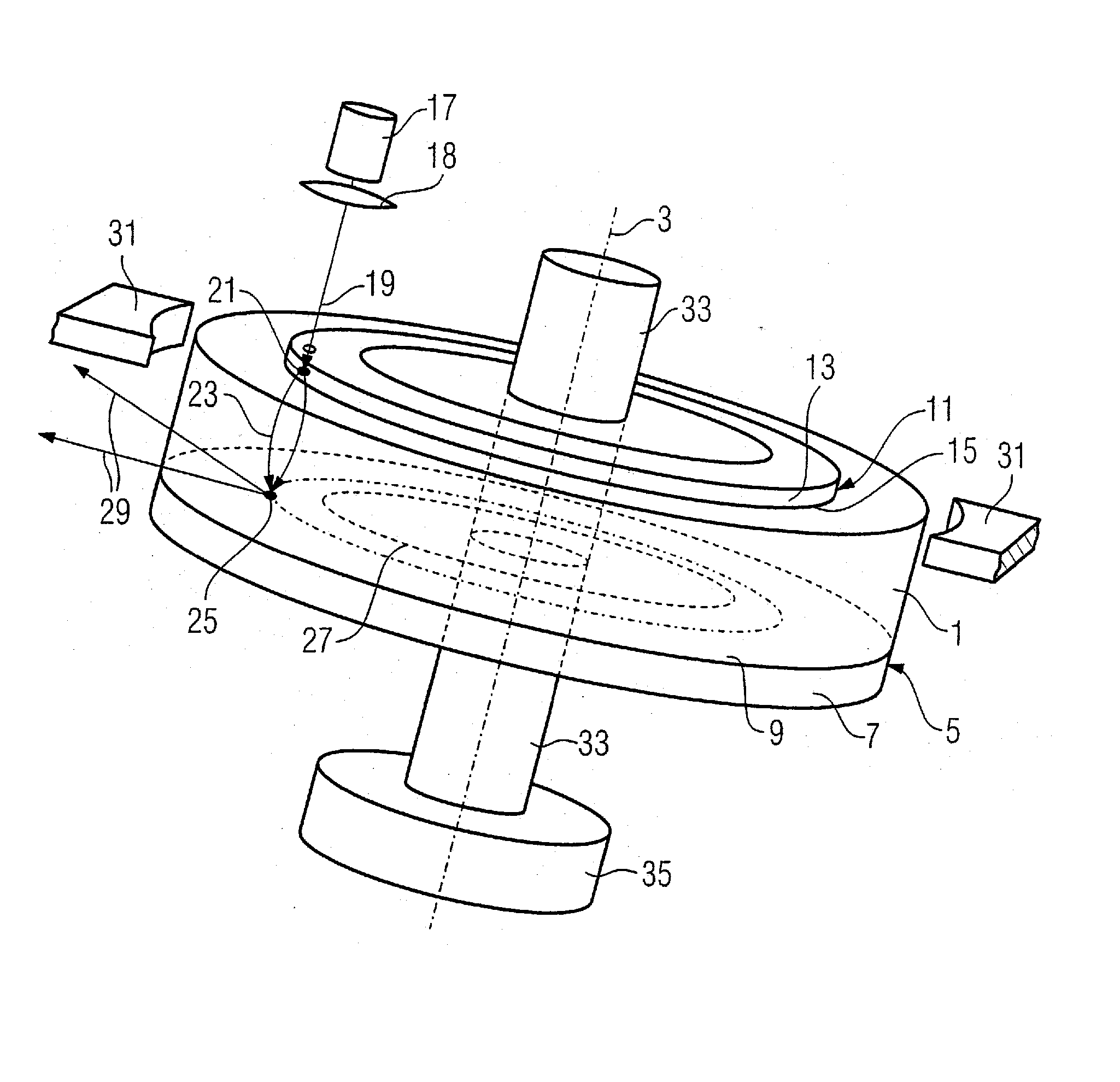

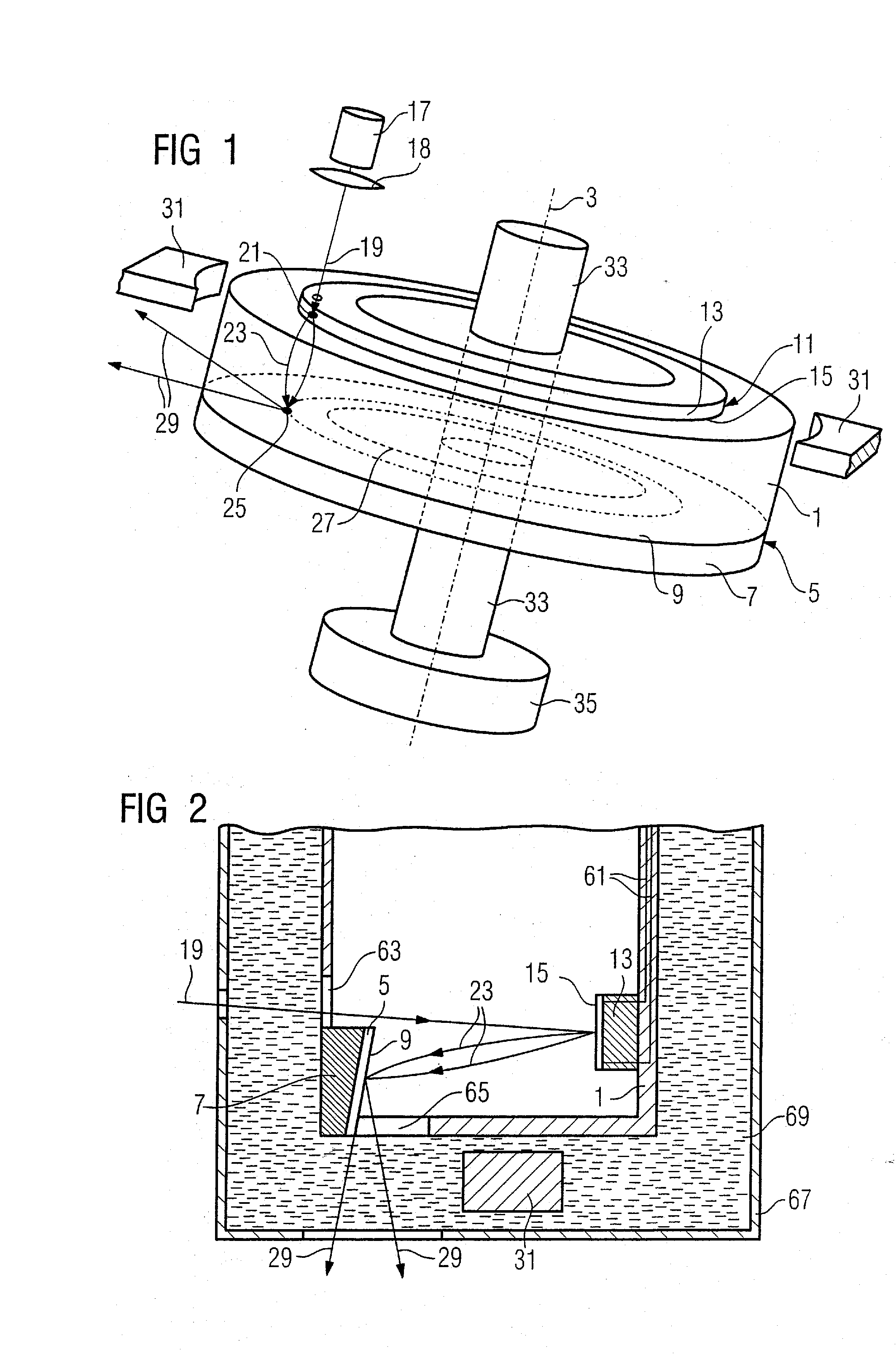

X-ray radiator with a thermionic photocathode

InactiveUS20070274454A1Reduce laser powerImprove vacuum stabilityX-ray tube electrodesX-ray tube vessels/containerPhotocathodeX-ray

An x-ray radiator has an anode that emits x-rays when struck by electrons, a cathode that thermionically emits electrons upon irradiation thereof by a laser beam, a voltage source for application of a high voltage between the anode and the cathode for acceleration of the emitted electrons towards the anode to form an electron beam. A surface of the cathode that can be irradiated by the laser beam is at least partially roughened and / or doped and / or is formed of an intermetallic compound or vitreous carbon.

Owner:SIEMENS AG

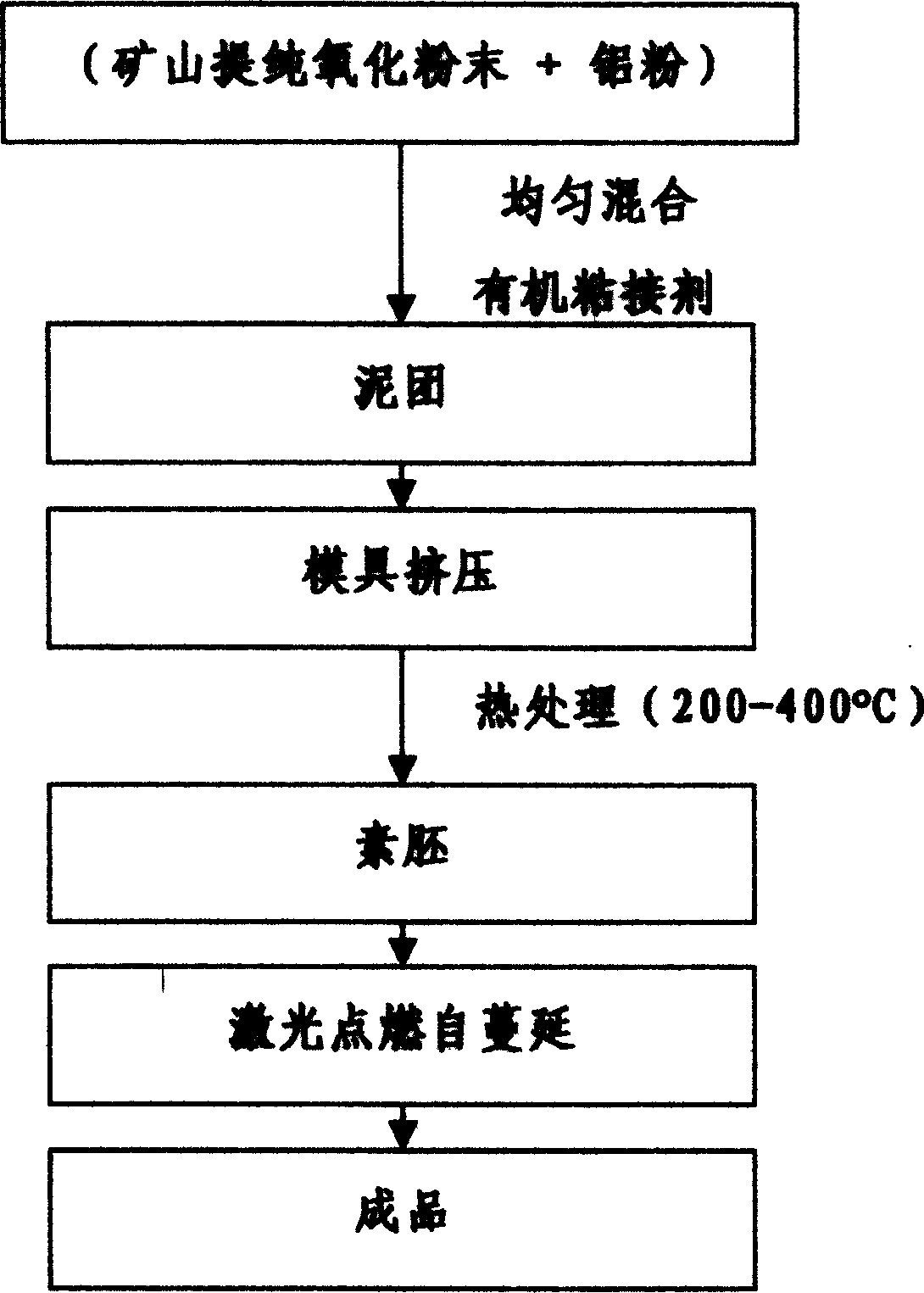

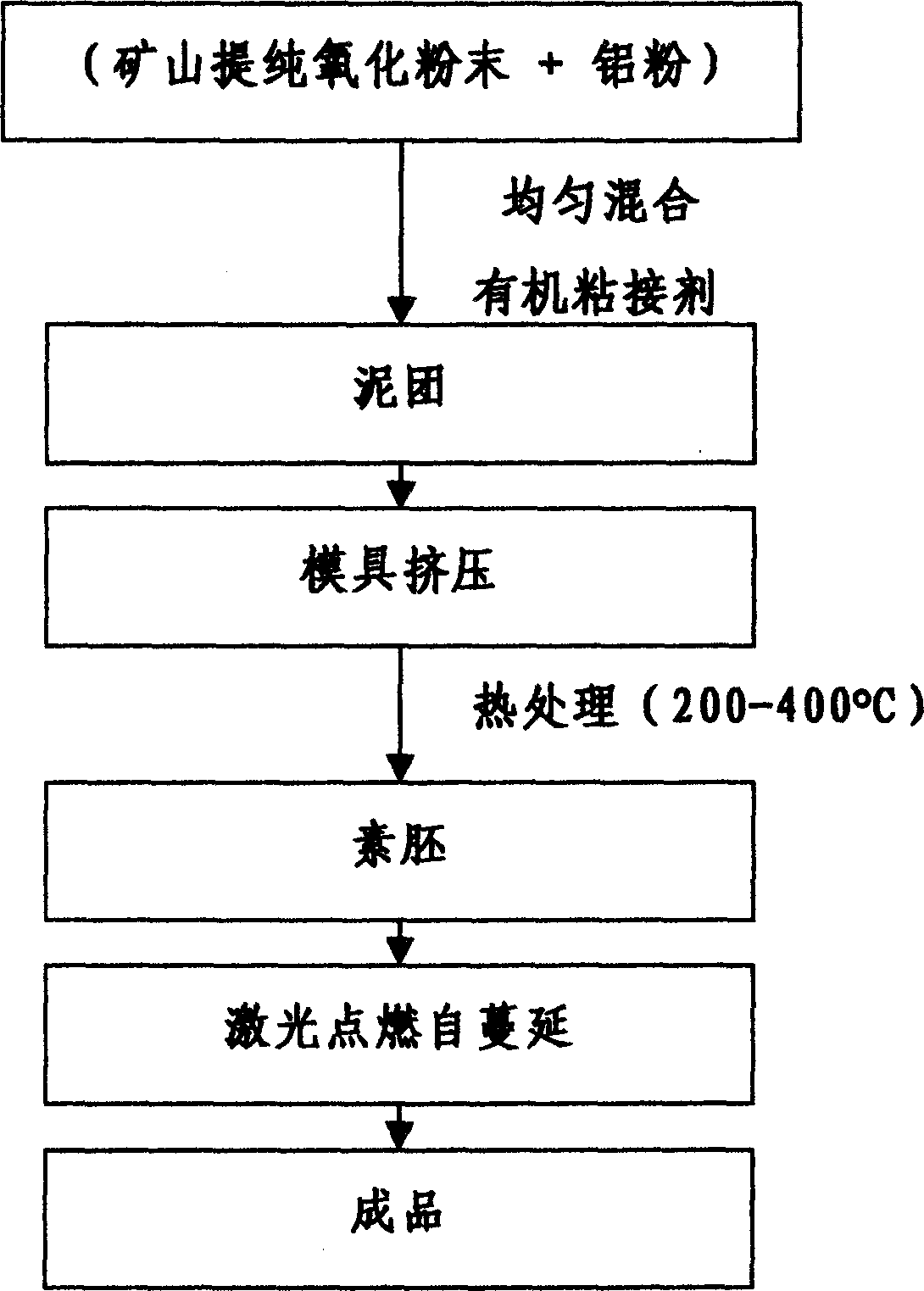

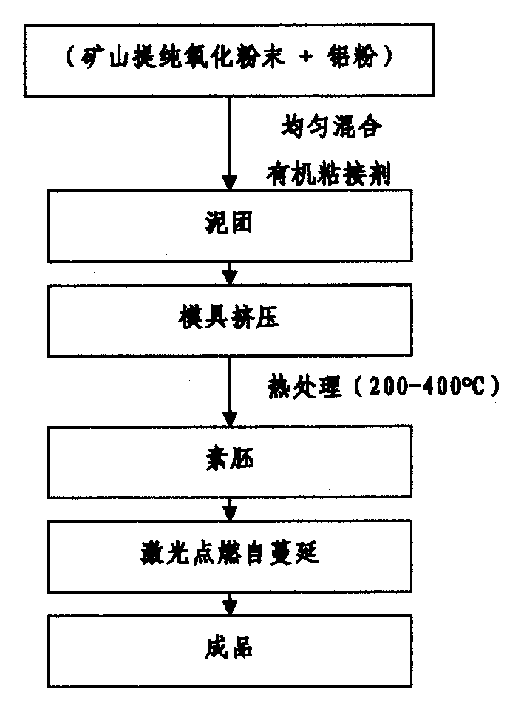

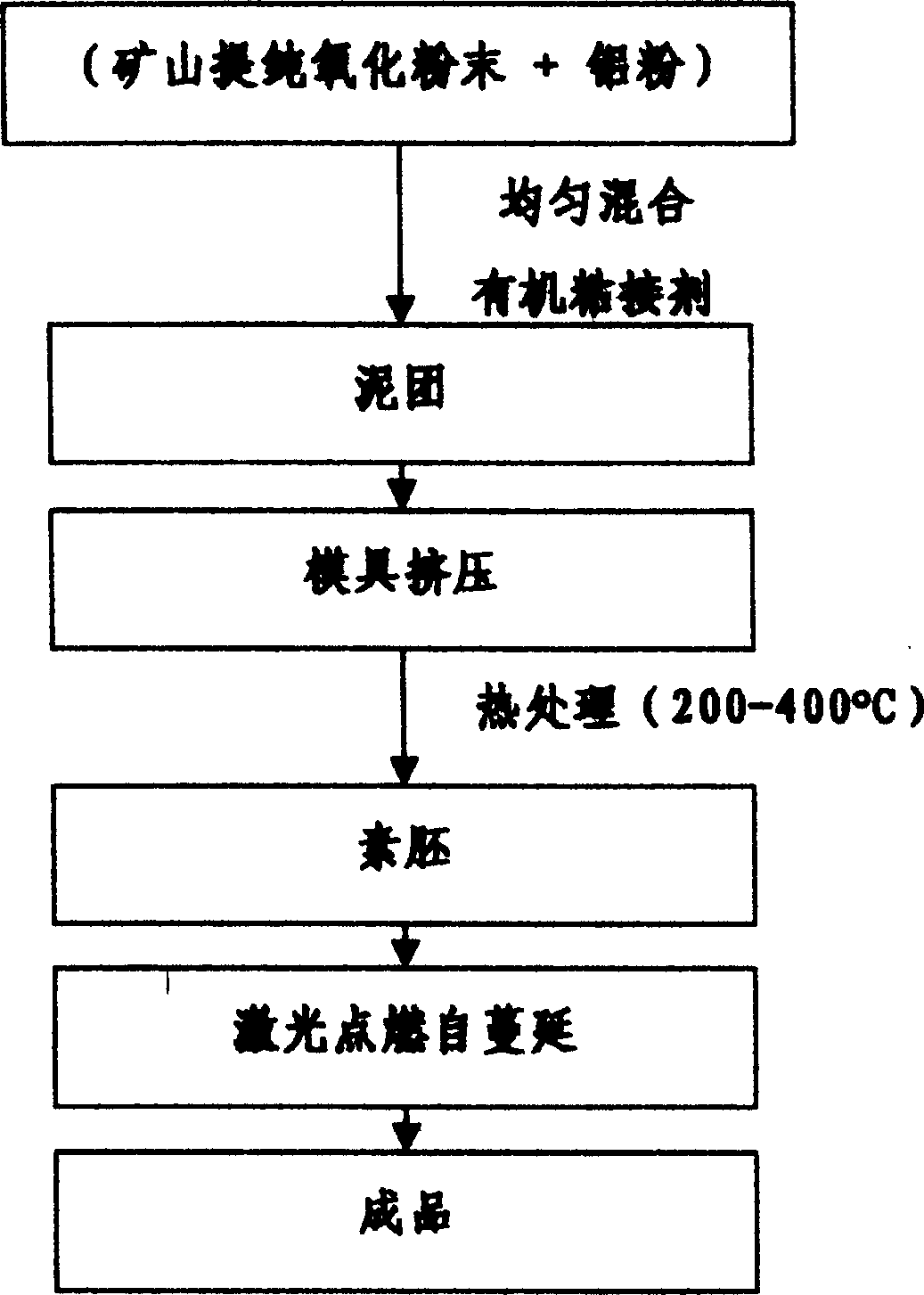

Conductive honey comb ceramic catalyst carrier and its preparation method

InactiveCN1651143AProperly conductiveAppropriate heat conductionCatalyst carriersAl powderSelf-propagating high-temperature synthesis

An electrically conductive cellular ceramic as the carrier of catalyst used for car is prepared from purified titanium oxide or Ti powder, graphite powder and pure Al powder through proportionally mixing, adding organic adhesive, stirring, die pressing, heat treating, igniting and self burning for high temp synthesis.

Owner:KUNMING UNIV OF SCI & TECH

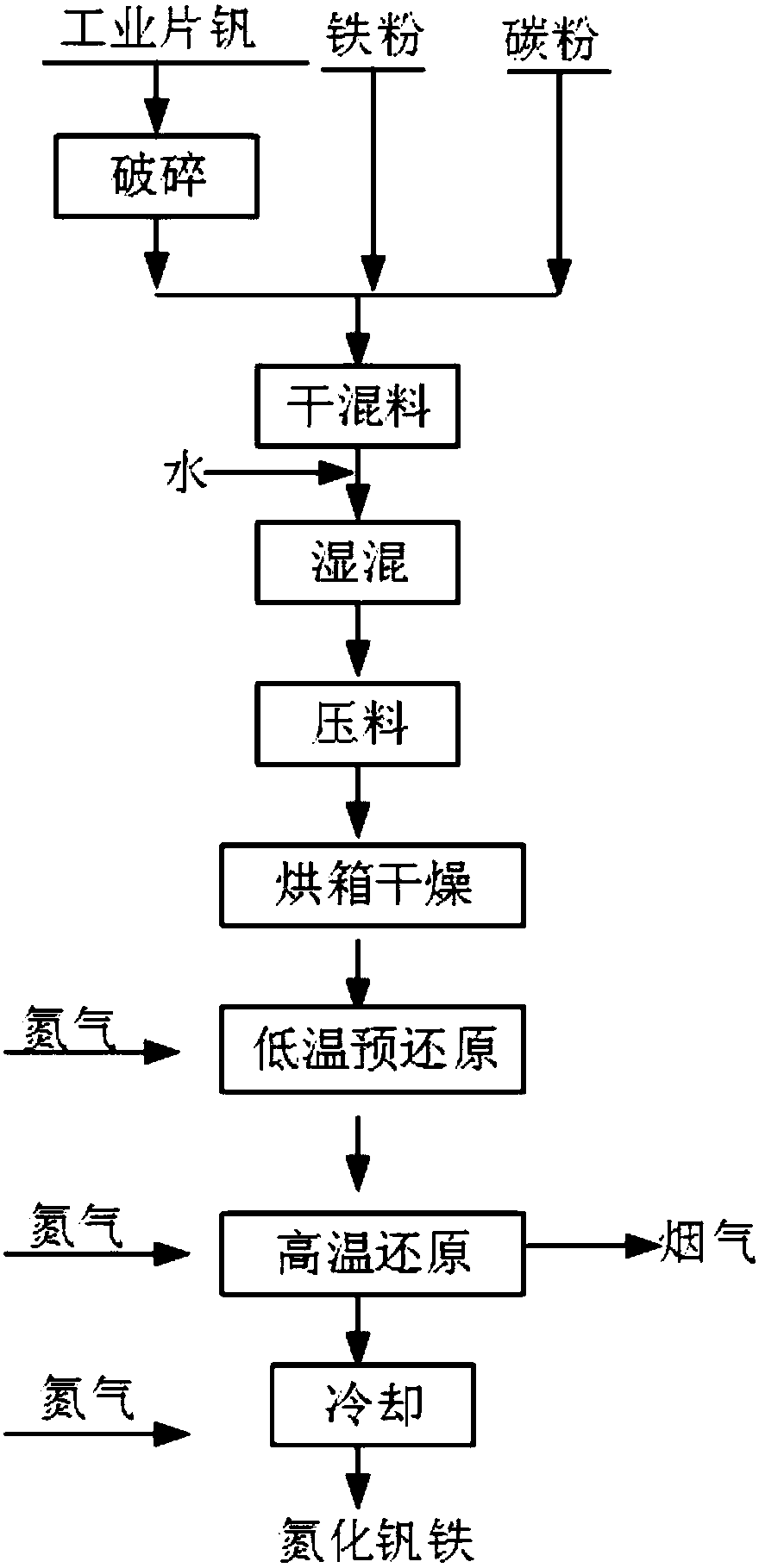

Method for preparing nitrided ferrovanadium

The invention discloses a method for preparing nitrided ferrovanadium. The method comprises the following steps that (1), a sample fabricated by uniformly mixing and pressing vanadium oxide powder, iron powder and carbon powder is subjected to prereduction through the nitrogen gas in a heating furnace, in the prereduction process, the temperature in the heating furnace is 650 + / -20 DEG C, the nitrogen gas flow is 150-180 L / h, and the heat preservation time of the heating furnace is 3-5 hours; (2), after heat preservation in step (1) is finished, the temperature of the heating furnace is then increased to 1200-1500 DEG C to perform final reduction on the sample, in the final reduction process, the nitrogen gas flow in the heating furnace is 150-180 L / h, and the heat preservation time of theheating furnace is 2-3 hours; (3), after heat preservation in step (2) is finished, the sample is cooled along with the furnace in the atmosphere of the nitrogen gas, and an obtained product is the nitrided ferrovanadium. According to the method, the vanadium oxide powder serves as the raw material, the iron powder serves as the iron source, the carbon powder serves as a reducing agent, the nitrogen gas is introduced into the heating furnace for reaction, and the method has the advantages that the procedure is simple, no vanadium slag is generated, the vanadium utilization rate is high, resources are saved, the environment is protected, and the production cost can be lowered.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method for synthesizing composite material of organic - inorganic bentonite

InactiveCN100429146CIncrease the areaImprove thermal stabilitySilicon compoundsPorositySodium Bentonite

This invention discloses a method for synthesizing organic-inorganic bentonite composite. The method comprises: utilizing bentonite as the main material, performing inorganic modification through cation-exchange reaction by using hydroxyl aluminum aqueous solution, torrefying to obtain hydroxyl-containing aluminum-pillared bentonite with high porosity and high specific surface area, and reacting between the hydroxyls and silylation agent to graft silane groups onto aluminum-pillared bentonite and obtain organic-inorganic bentonite composite. The organic-inorganic bentonite composite has both the advantages of inorganic pillared bentonite such as high porosity and high specific surface area, and those of organic bentonite such as high organic carbon content and high hydrophobicity thus can be used to treat organic waste gases and wastewater with a good effect by surface adsorption as well as distribution.

Owner:ZHEJIANG UNIV

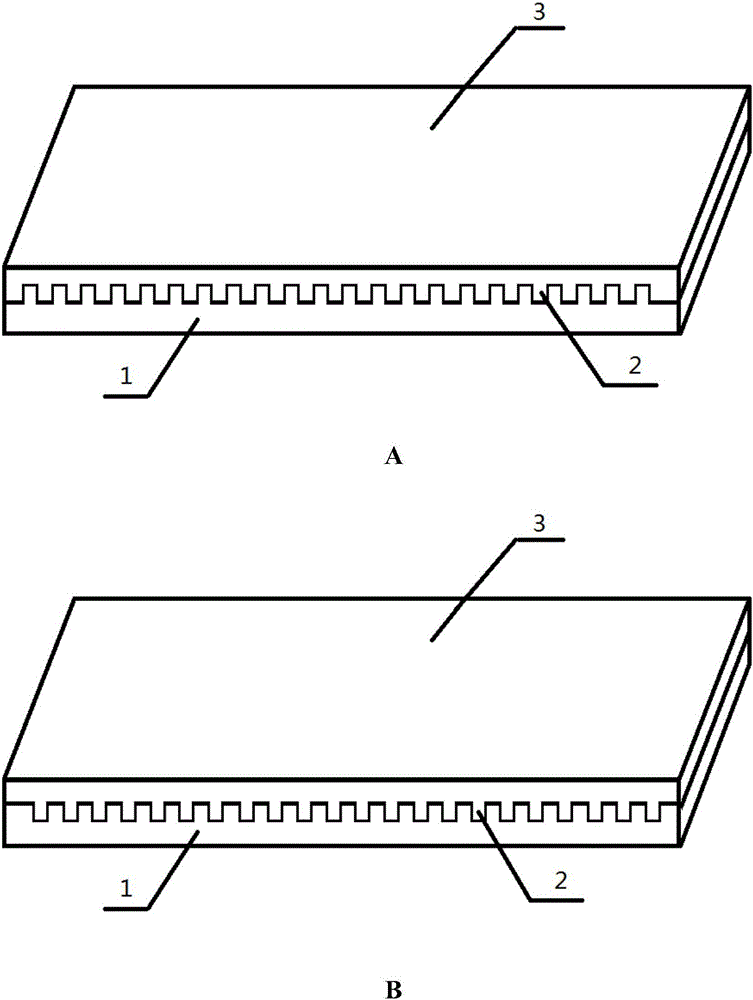

Biological patch for tissue damage restoration

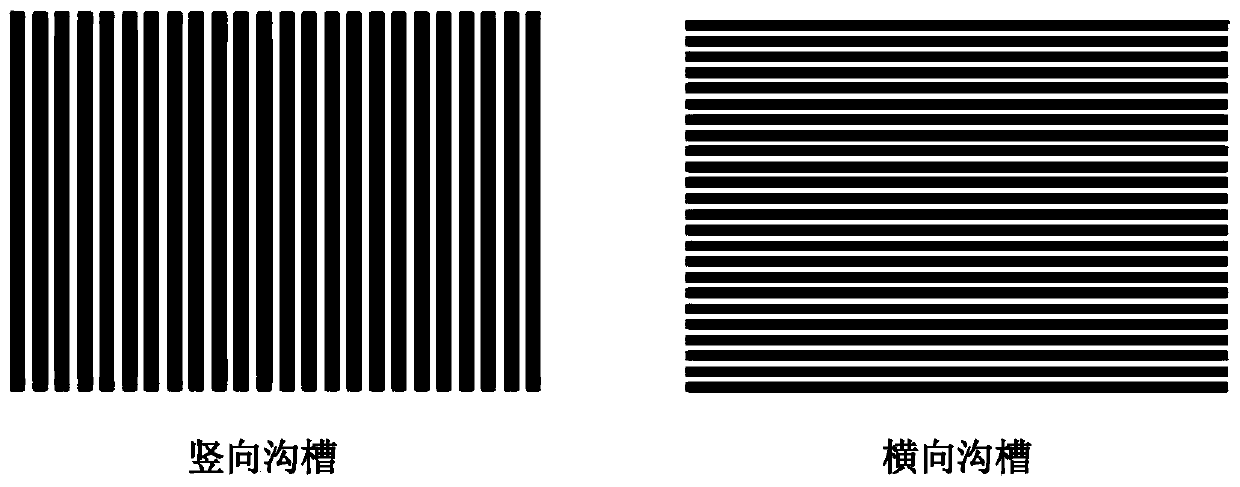

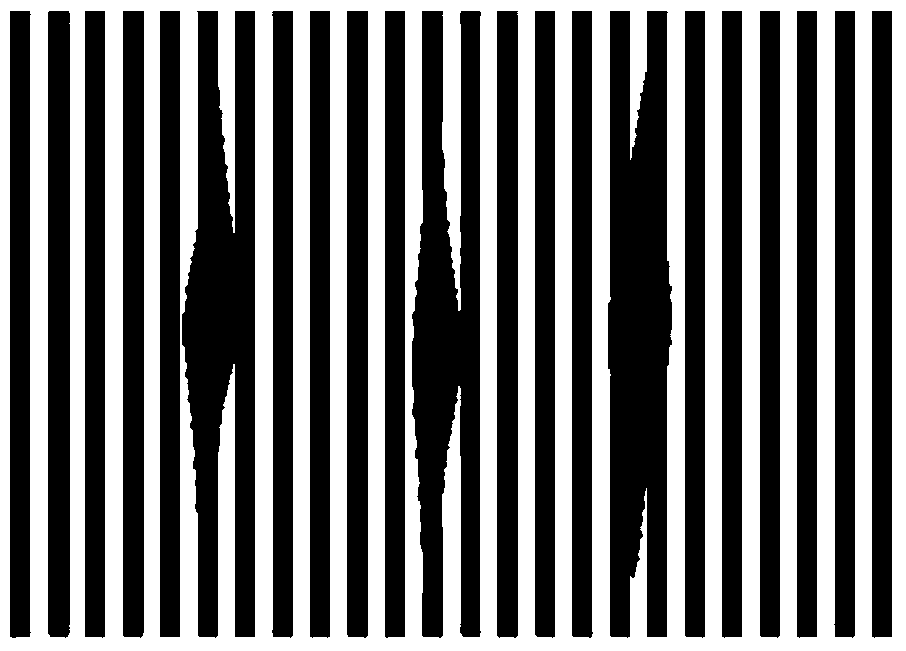

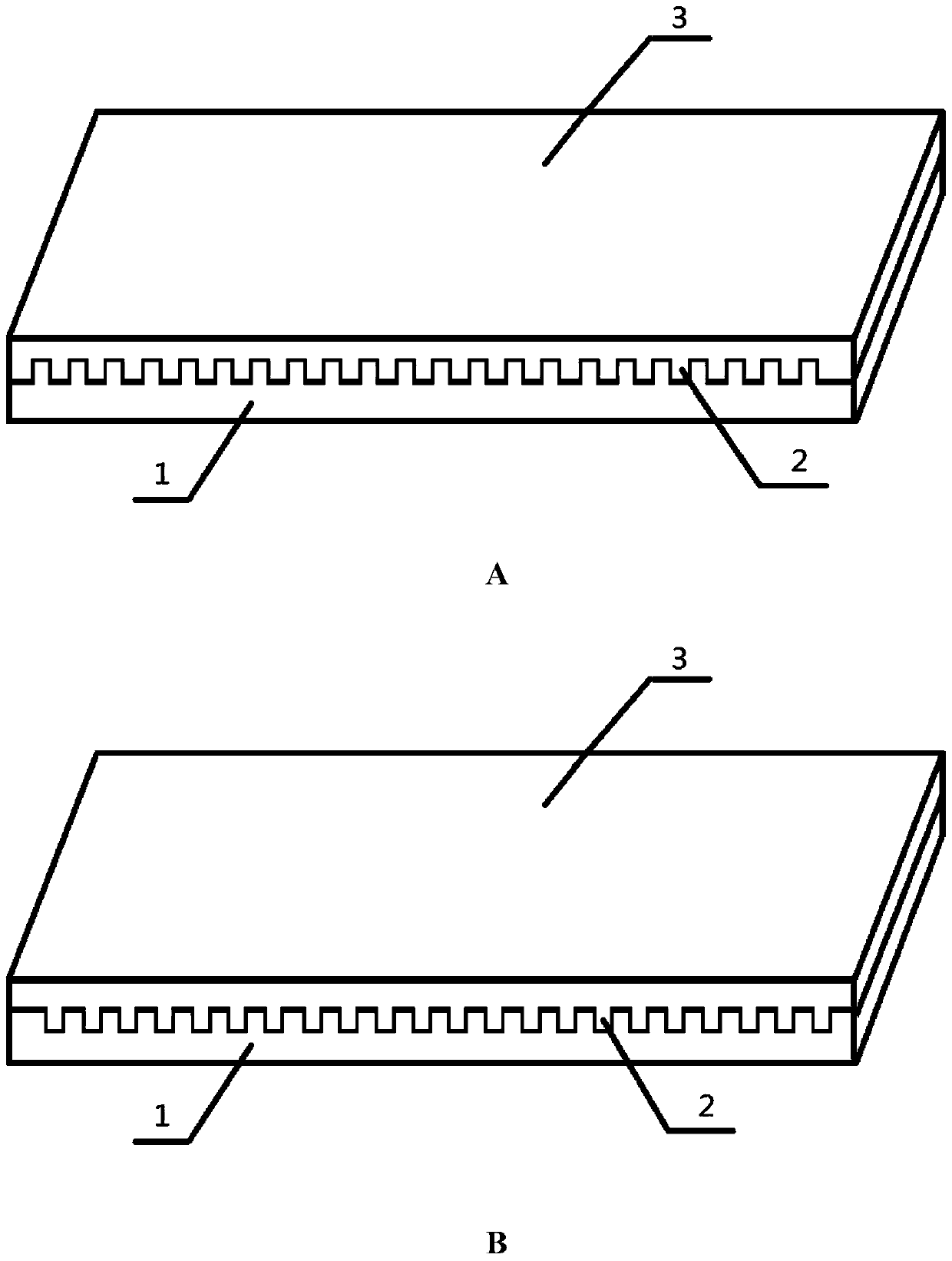

ActiveCN105769381AImprove the growing environmentImprove adhesionProsthesisTissue repairNormal tissue

The invention discloses a biological patch for tissue damage restoration. The biological patch comprises a biological material substrate layer and a cell substrate layer, wherein the substrate layer is attached onto the substrate layer; and a plurality of parallel grooves are formed in the contact surface of the substrate layer and the cell substrate layer. The substrate layer of the biological patch is simultaneously provided with porous and groove vein structures; the orientation growth and distribution of cells can be regulated and controlled; the cell substrate layer can be well attached onto the substrate layer through the mechanical property of the groove vein structures; and the falling is avoided. A product of the biological patch has the advantages that the structure is stable; the pore diameter, the porosity and the permeability are proper; the normal tissue structure can be simulated; the tissue growth pipeline and cell substrates can be provided; and cells favorable for tissue restoration and regeneration can be carried.

Owner:NANTONG UNIVERSITY

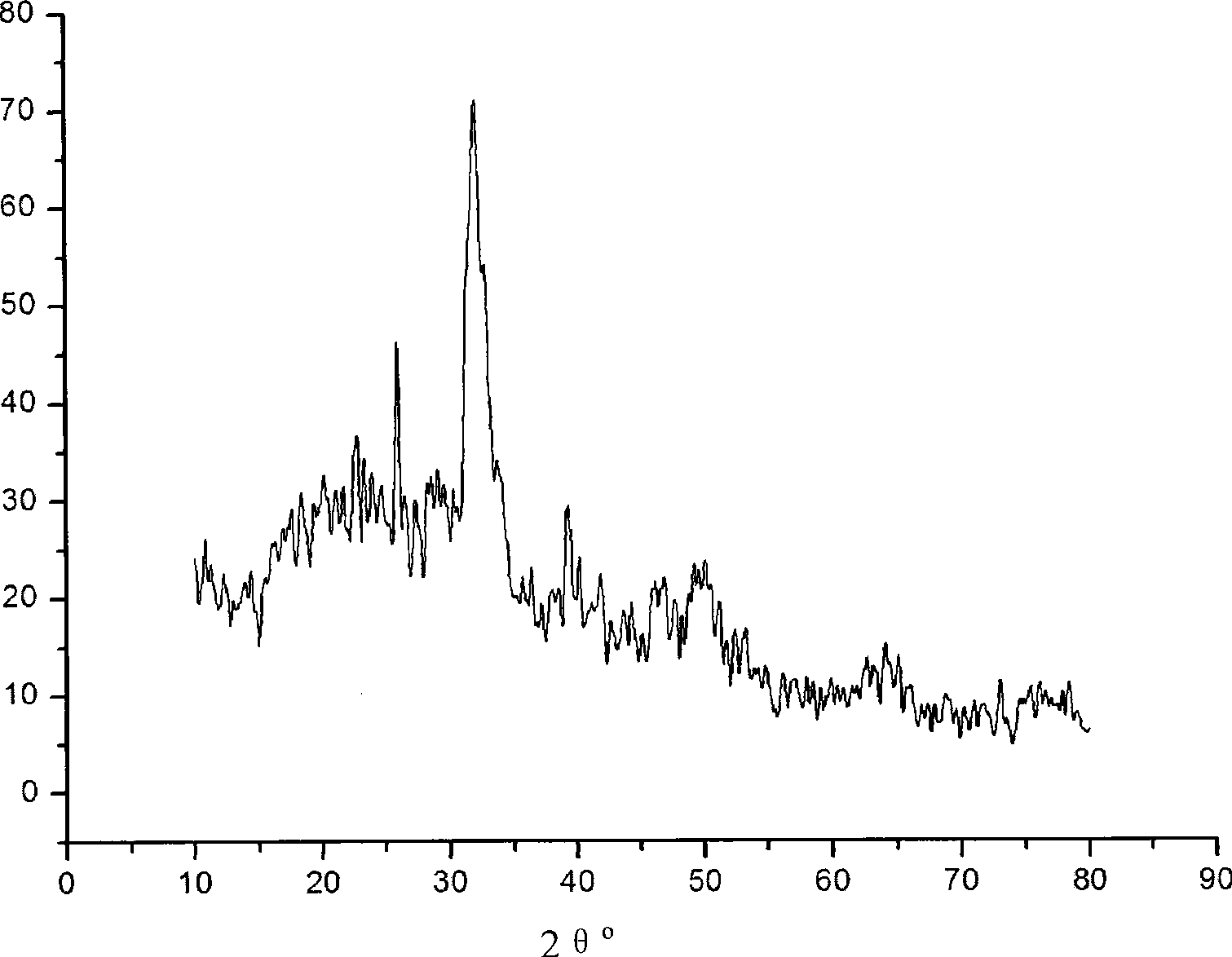

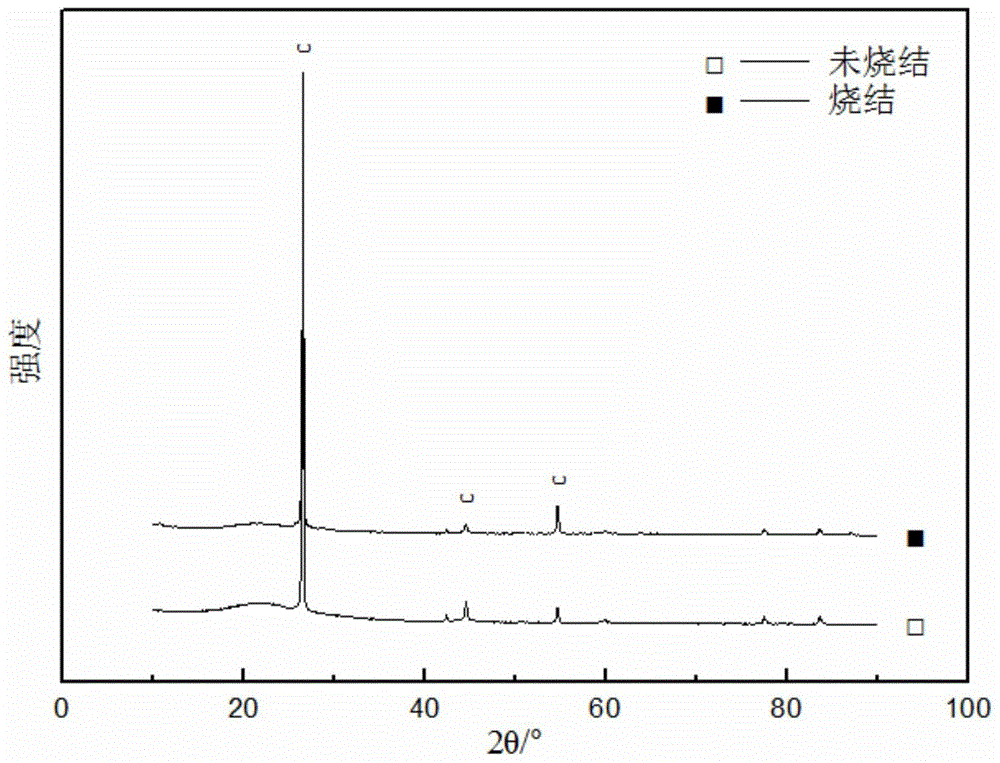

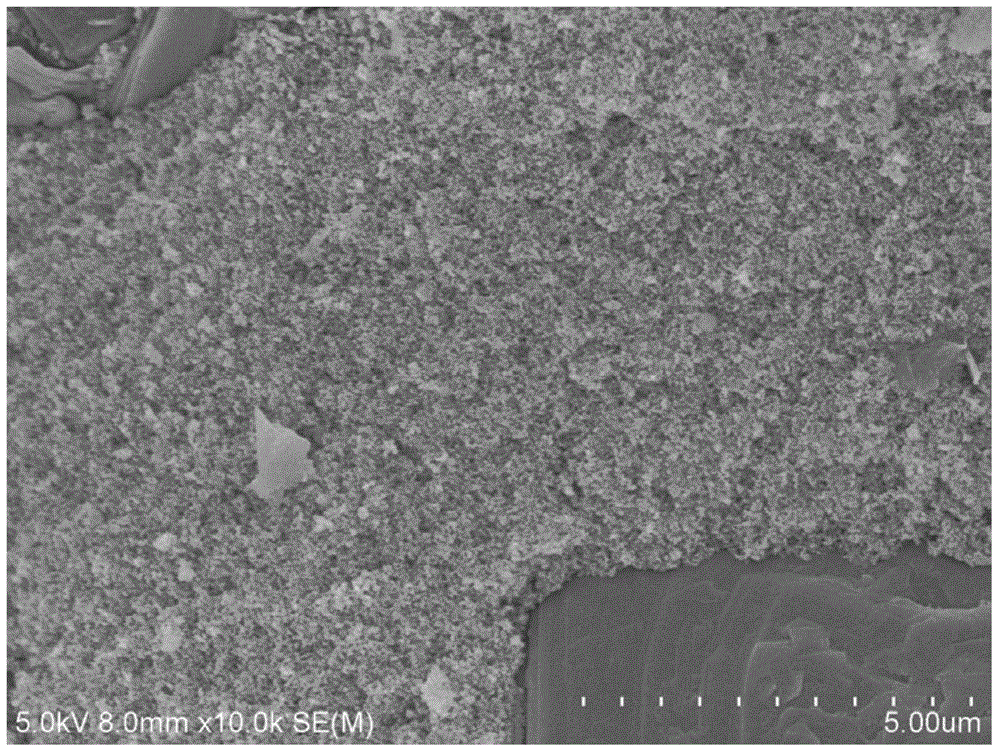

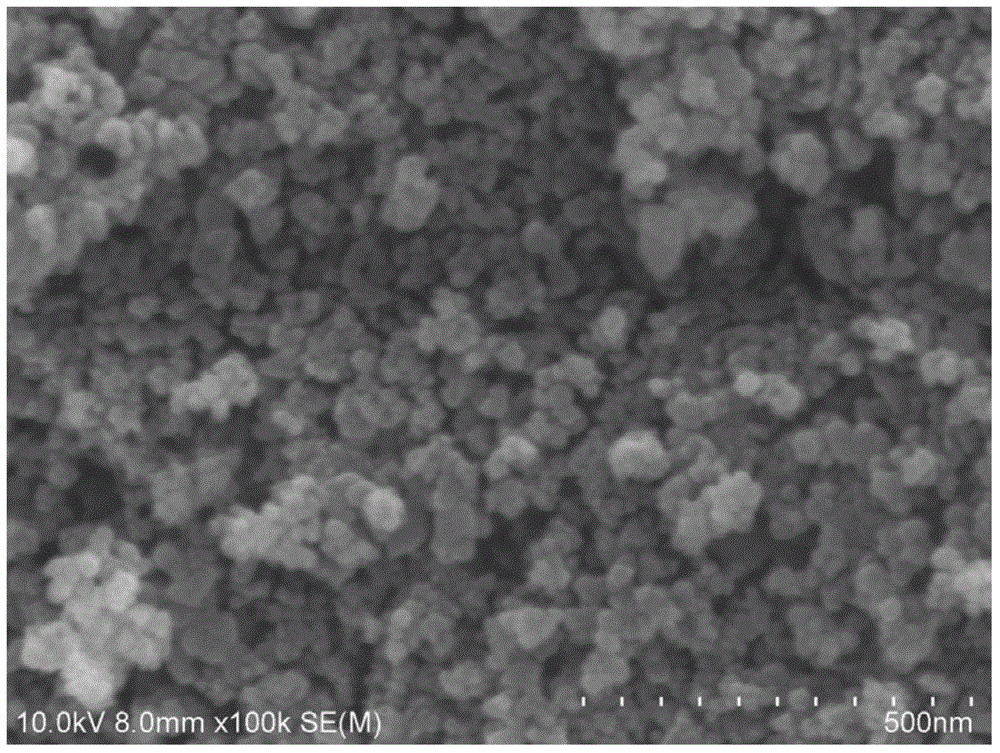

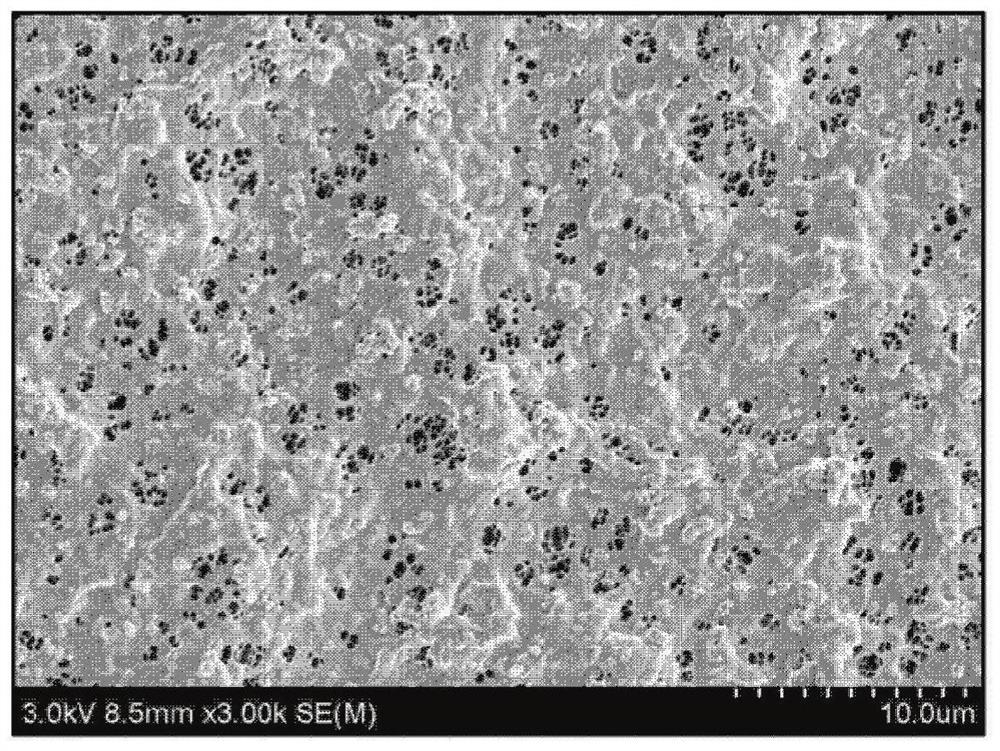

Crystal silicon dioxide/carbon porous composite material and preparation method thereof

ActiveCN105018956ATightly boundLow resistivityPolycrystalline material growthElectrode shape/formsSilica particleTetragonal crystal system

The invention discloses a crystal silicon dioxide / carbon porous composite material and a preparation method thereof. Three-dimensional network-shaped crystal silicon dioxide is evenly distributed on the surfaces of carbon particles, so that the crystal silicon dioxide / carbon porous composite material is formed. The silicon dioxide is tetragonal crystals and belongs to a P41212 space group, a=b=4.973, and c=6.924. The porosity of the crystal silicon dioxide / carbon porous composite material is 40%-80%, the peso-position hole diameter is 100-2000 nm, and the electrical resistivity is 0.10-80 ohmcm. The crystal silicon dioxide / carbon porous composite material comprises, by mass, 30%-90% of silicon dioxide and 10%-70% of carbon materials. The preparation method at least includes the following steps of mixing, forming and sintering. According to the step of mixing, the silicon dioxide particles, the carbon materials and a fluxing agent are evenly mixed, so that a powder-like mixture is obtained. According to the step of forming, the powder-like mixture is formed so that a porous block body can be obtained. According to the step of sintering, the obtained porous block body undergoes high-heat treatment in an inert atmosphere, and after the fluxing agent is removed, the three-dimensional network-shaped crystal silicon dioxide / carbon porous composite material is obtained.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Carrier of catalyst in conducting typed honeycomb ceramics and its preparation method

InactiveCN1446634AProperly conductiveAppropriate heat conductionCatalyst carriersSelf-propagating high-temperature synthesisAdhesive

An electrically conductive honeycomb ceramics as the carreir of catalyst for car is prepared from purified titanium oxide powder, or Ti powder or iron oxide powder, B2O3 or graphite powder, and pure aluminium powder through mixing, adding organic adhesive, die pressing, heat treating and high-temp synthesis by self combustion.

Owner:KUNMING UNIV OF SCI & TECH

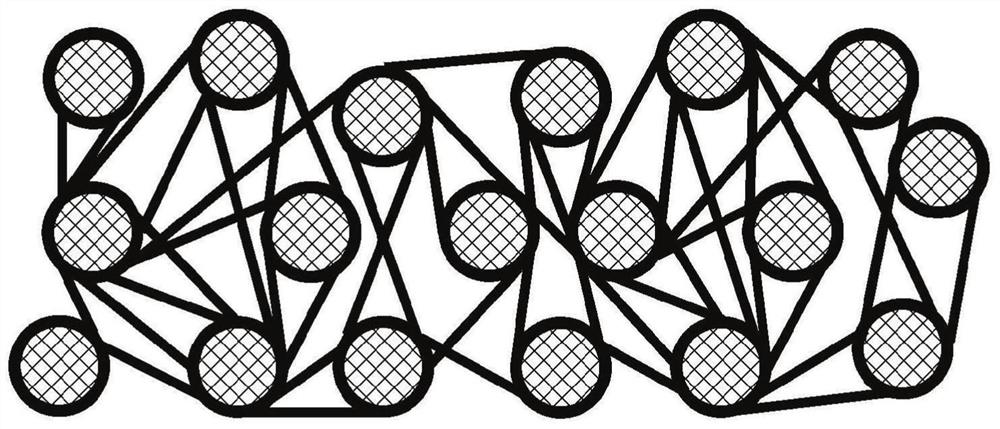

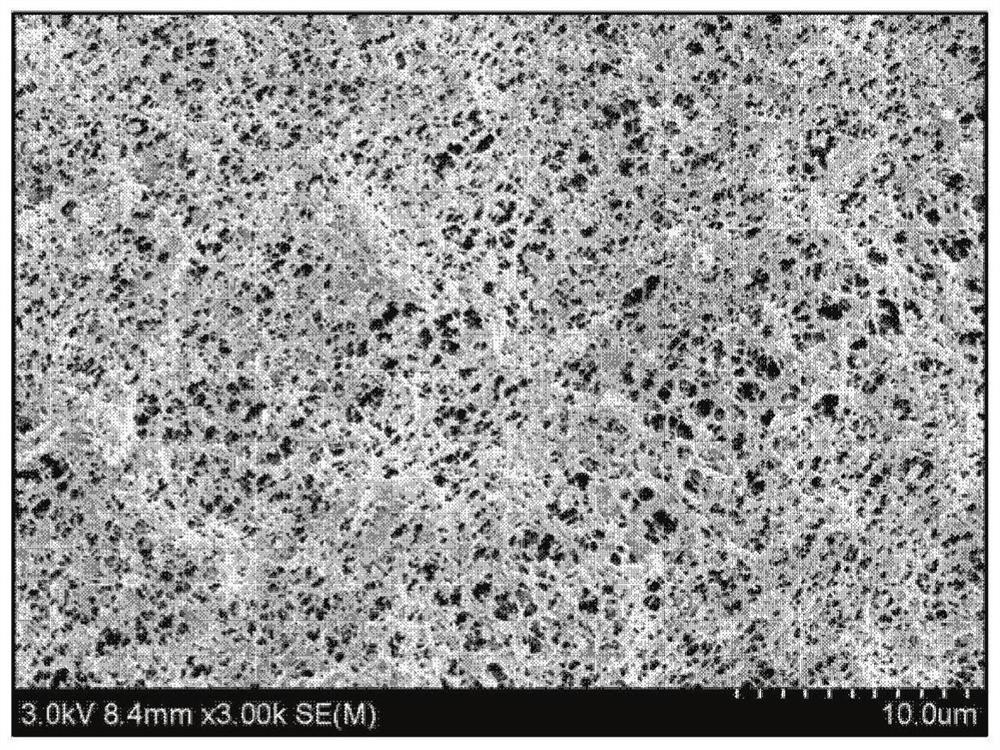

Electrochemical element separation membrane including low-resistance coating layer, and method for manufacturing same

ActiveCN112106223AGuaranteed heat resistanceLower resistanceSecondary cellsCell component detailsPorous substratePolymer resin

A separation membrane according to the present invention ensures heat resistance and simultaneously has low resistance, appropriate air porosity and electrolyte retention. The separation membrane according to the present invention includes a porous substrate and a low-resistance coating layer formed on at least one surface of the porous substrate, wherein the low-resistance coating layer includes:a node (nodes) including inorganic particles and a polymer resin for coating at least a part of the surfaces of the inorganic particles; and filament(s) having a thread-like shape and coming out fromthe polymer resin of the nodes, wherein one or more filaments extends from one node, and the filaments are arranged to connect one node with another node.

Owner:LG CHEM LTD

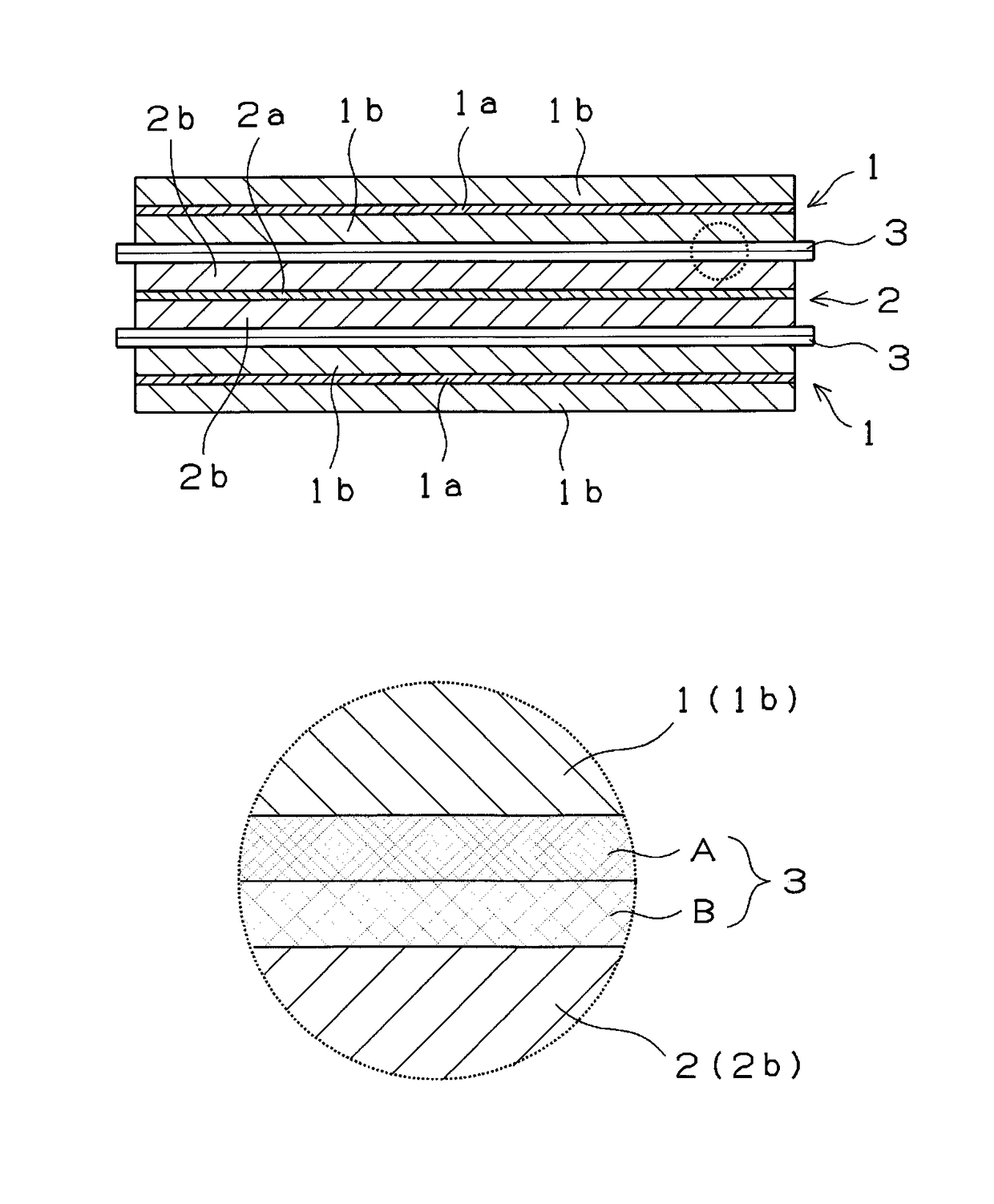

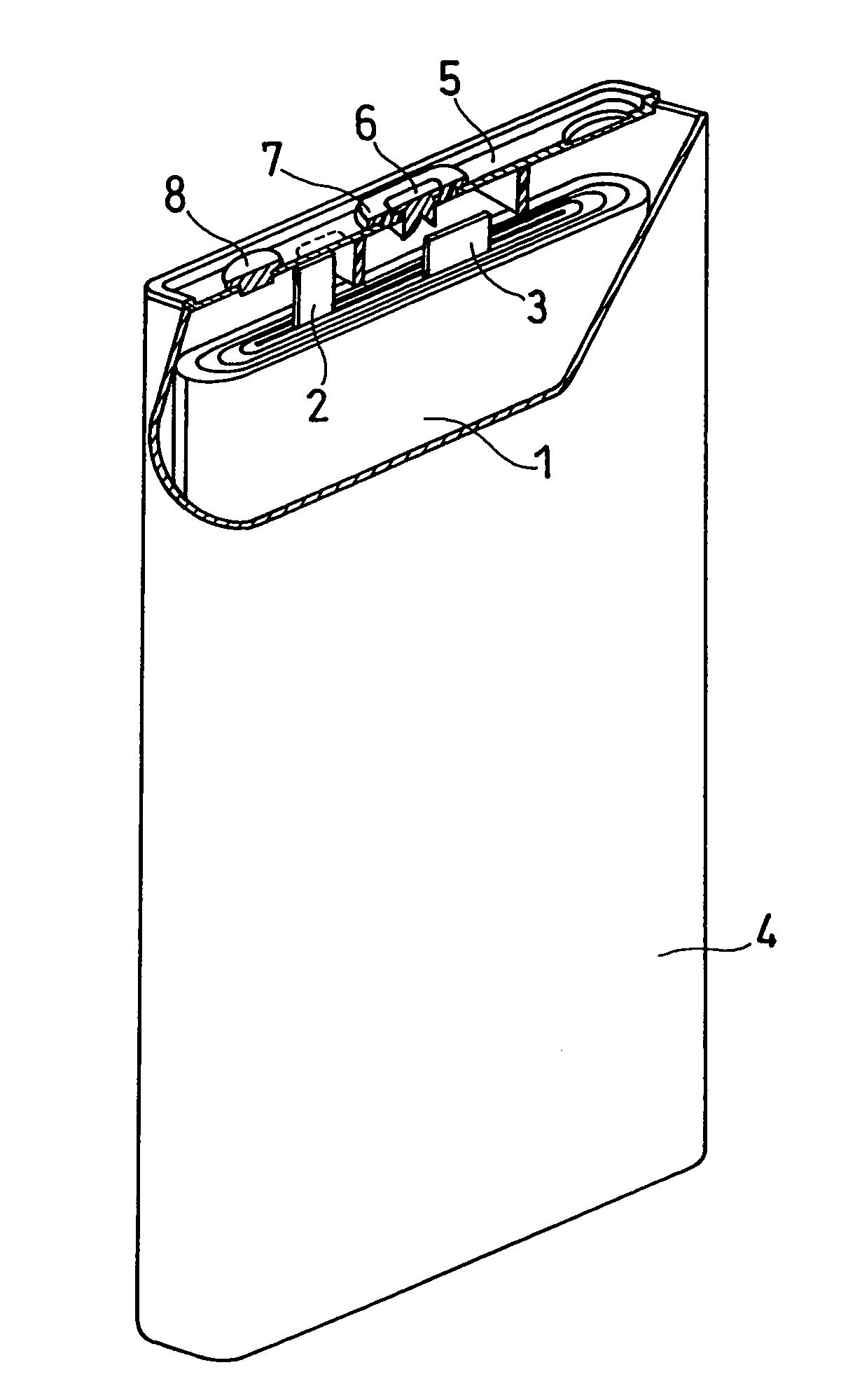

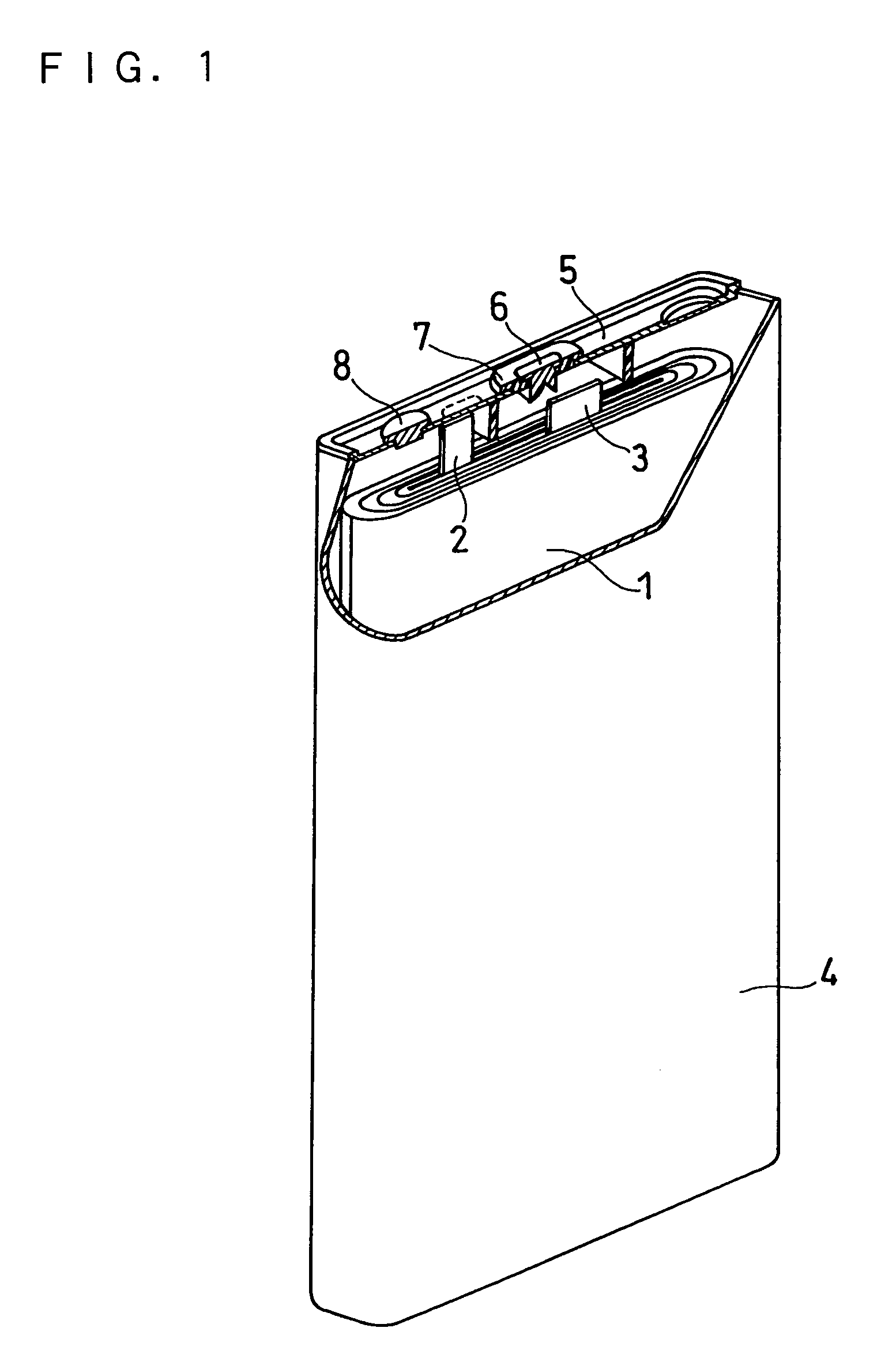

Electrolyte holder for lithium secondary battery and lithium secondary battery

ActiveUS10230089B2Easy to migrateAvoid it happening againFinal product manufactureWound/folded electrode electrodesPorosityCellulose fiber

The present invention provides an electrolyte holder for a lithium secondary battery capable of holding an electrolytic solution inside electrodes or at an interface between the separator and each of the electrodes, preventing electrolyte shortage inside the electrodes, and restraining dendrite from precipitating and growing and also provide the lithium secondary battery, using the electrolyte holder, which is capable of achieving a cycle life to such an extent that the lithium secondary battery can be used for industrial application. An electrolyte holder (3) for use in the lithium secondary battery consists of a multi-layer structure having at least two hydrophilic fibrous layers (A, B) having different porosities. The electrolyte holder (3) is composed of an electrode group formed by winding a cathode (2) and an anode (1) or laminating the cathode (2) and the anode (1) one upon another with an electrolyte holder (3) serving as a separator interposed between the cathode (2) and the anode (1). The organic electrolytic solution is permeated into the electrode group or the electrode group is immersed in the organic electrolytic solution. A porosity (40% to 80%) of the fibrous layer (A) disposed at an interface between the fibrous layer (A) and the anode (1) is set smaller than a porosity (60% to 90%) of the fibrous layer (B) disposed at an interface between the fibrous layer (B) and the cathode (2). An average porosity of the entire fibrous layer is set to not less than 50%. The fibrous layers are formed by using cellulose fibers as a main material thereof. An active substance for use in the anode (1) is a carbon material.

Owner:SEI CORP +1

Processing method for delaying spicy strip ageing

InactiveCN107212282AWater absorption index decreasedLow water absorptionFood shapingSwelling capacityPulp and paper industry

The invention belongs to the technical field of spicy strip processing and specifically relates to a processing method for delaying spicy strip ageing. The dosing material contains structuring lipid of which the weight is 12-18% of the wheat weight and 3-7 parts of hydrophobic bletilla polysaccharide. The extruding cooking condition is as follows: the water content of the material is 18-21%, the pore diameter of the adopted front mold is 5-6mm, the width of a threaded slot of a double-end screw rod is 14-17mm, the rotating speed of the screw rod is 120-160 rpm and the temperature of the cylinder is at 140-160 DEG C. Compared with the prior art, the processing method has the advantages that the swelling capacity and the water absorption index of the spicy strip prepared under the condition according to the invention are both reduced, but the influence on the taste of the spicy strip is less, and meanwhile, due to the recombination of starch and protein in the product, the stability of the hydrogen bond between starch and water molecule is enhanced, the starch ageing is delayed, the nanometer gel particle can further increase the water molecule and can separate from the starch and the stability of the product taste can be promoted.

Owner:含山县长通食品制造有限公司

Preparation method of tissue engineering scaffold material

The invention provides a preparation method of a tissue engineering scaffold material. The preparation method comprises the following steps: mixing biocompatible polyester with a non-polar solvent to get a first solution; adding a phase inversion solvent into the first mixed solution to get a second solution; and removing the non-polar solvent and the phase inversion solvent of the second solution in a mold through a liquid-gas phase conversion process or / and a liquid-solid phase conversion process, and drying a solute, thus obtaining the tissue engineering scaffold material. According to the method for preparing the tissue engineering scaffold material, a tissue engineering scaffold has high porosity on the basis of good mechanical properties.

Owner:CHANGCHUN SINOBIOMATERIALS

Matrix for cultivating straw biomass charcoal with high ventilating performance

InactiveCN107333636AModerate pHPromote growthGrowth substratesCulture mediaFiberMonosodium glutamate

The invention discloses a matrix for cultivating straw biomass charcoal with high ventilating performance, and the process comprises, amounts by weight, 8-12 parts of perlite powder, 4-6 parts of coconut bran, 1-2 parts of large-leaf sophora; 0.5-0.8 parts of peanut seedling; 0.1-0.3 parts of alfalfa, 0.2-0.3 parats of vegetable sponge of luffa fiber, 1-2 parts of dandelion, 1-2 parts of potato stem leaf, 1-2 parts of grape skin slag; 0.1-0.2 parts of EM inocula, 1-2 parts of soybean meal, 0.1-0.2 parts of calcium hydrogen phosphate, 30-50 parts of rice straw, 60-80 parts of corn straw, 0.2-0.3 parts of lauroyl monosodium glutamate, 0.2-0.3 parts of ore oil, 0.2-0.4 parts of alkyl glucosides and 0.1-0.2 parts of rapeseed oil.

Owner:安徽帝元现代农业投资发展有限公司

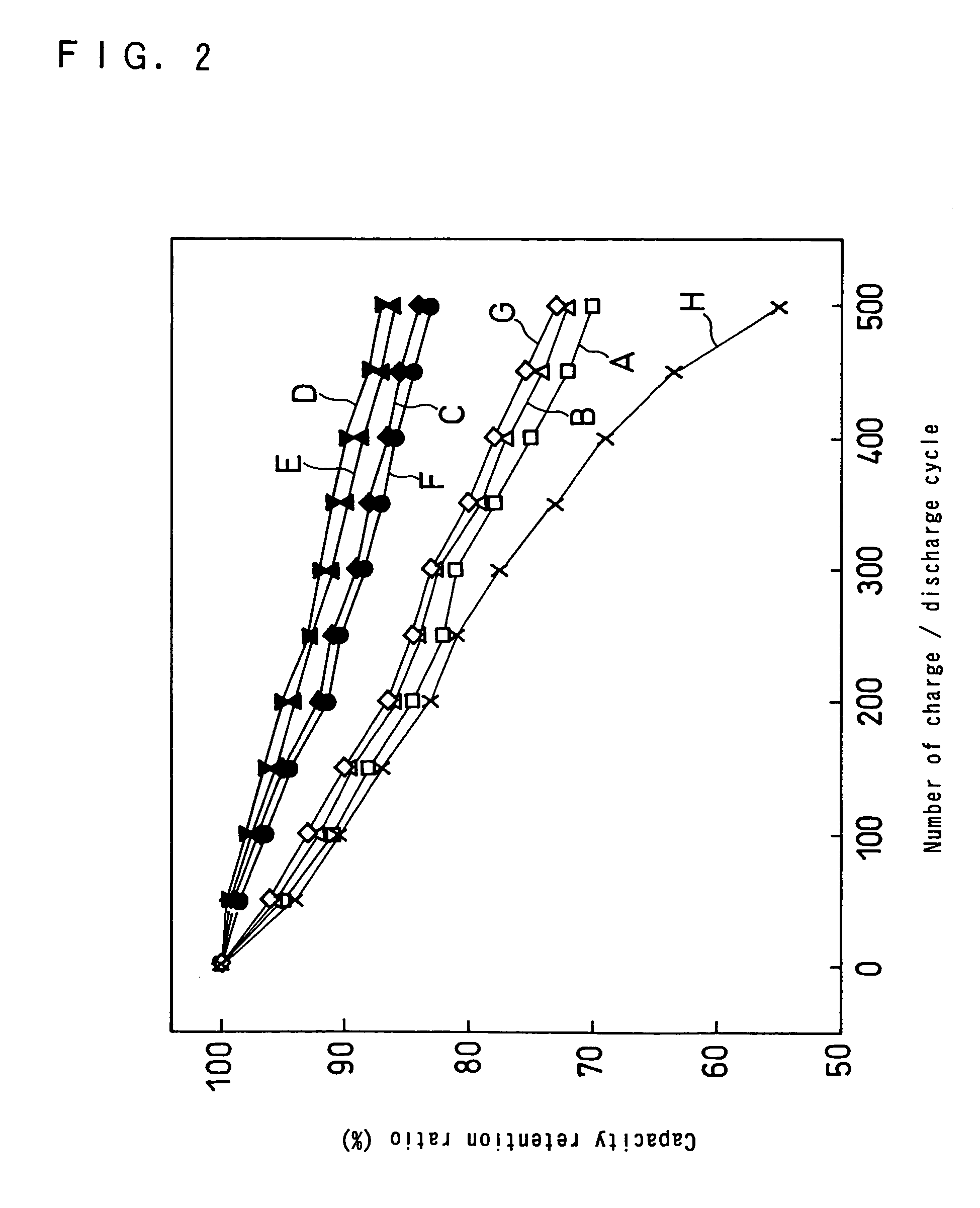

Lithium-ion rechargeable battery with negative electrode material mixture comprising graphite and carbon nano-tubes

ActiveUS7550232B2Improved cycle life characteristicsImprove cycle lifeMaterial nanotechnologyNon-aqueous electrolyte accumulatorsCarbon nanotubeGraphite

A lithium-ion rechargeable battery, comprising a positive electrode capable of absorbing and desorbing lithium ions, a negative electrode capable of absorbing and desorbing lithium ions, a separator interposed between the positive electrode and the negative electrode, and a non-aqueous electrolyte, wherein the negative electrode comprises a negative electrode current collector and a negative electrode material mixture layer carried on the negative electrode current collector, the negative electrode material mixture layer comprises graphite and carbon nano-tubes, and an amount of the carbon nano-tubes in the negative electrode material mixture layer is not smaller than 0.1 part by weight and not larger than 10 parts by weight, per 100 parts by weight of the graphite.

Owner:PANASONIC CORP

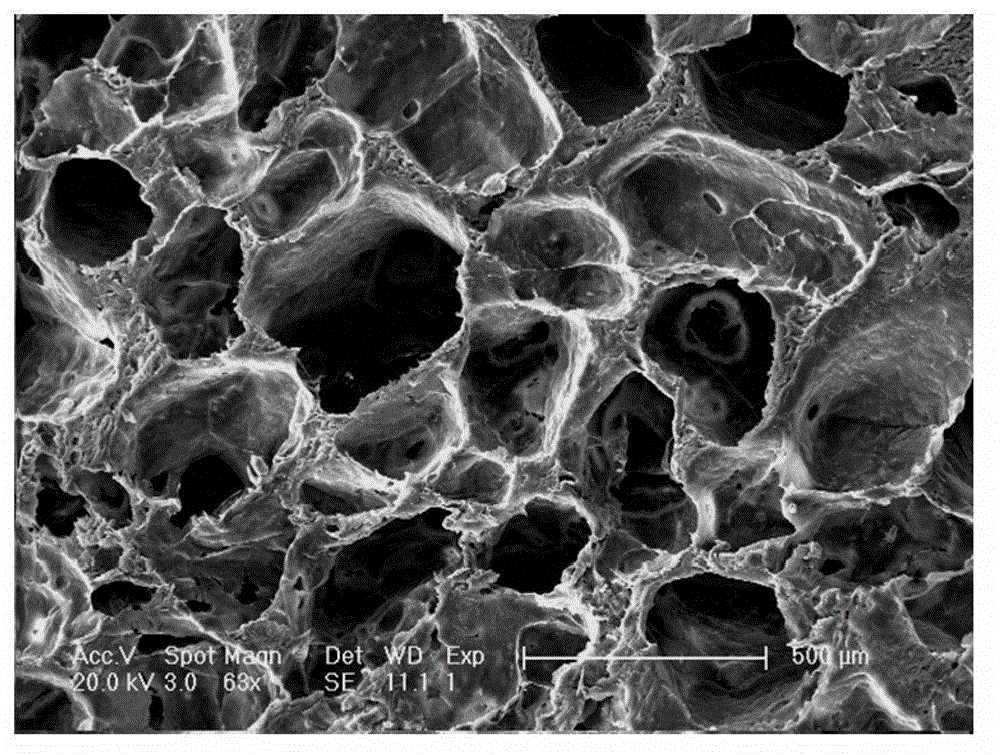

Artificial dermal scaffold and production method thereof

The invention discloses an artificial dermal scaffold and a production method thereof. The artificial dermal scaffold comprises a porous scaffold produced from oxycellulose and a cross-linking agent, the amount of porosity of the porous scaffold is 85-96%, the average aperture is 50-200[mu]m, the water absorption rate is 17-28 times the self weight of the porous scaffold, and the saturated water content is 90-97%. The artificial dermal scaffold is similar to human body skins in softness, can keep good three dimensional form and strength in a wet state, can cling to wounds, has good adhesiveness and breathability, can absorb human body diffusate and has no untoward effects. The artificial dermal scaffold has appropriate aperture size and porosity amount, can effectively promote wound healing, and also can promote generation of granulation tissues and new vessels. The artificial dermal scaffold also has an appropriate degradation time, and can reduce formation of scars.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

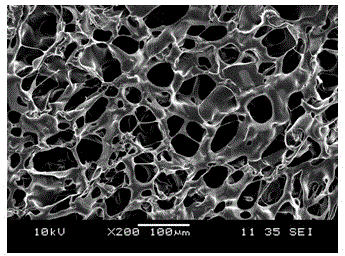

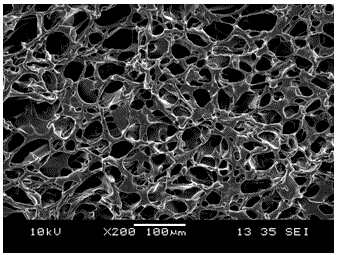

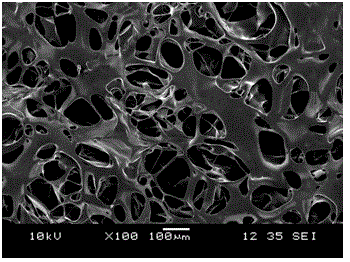

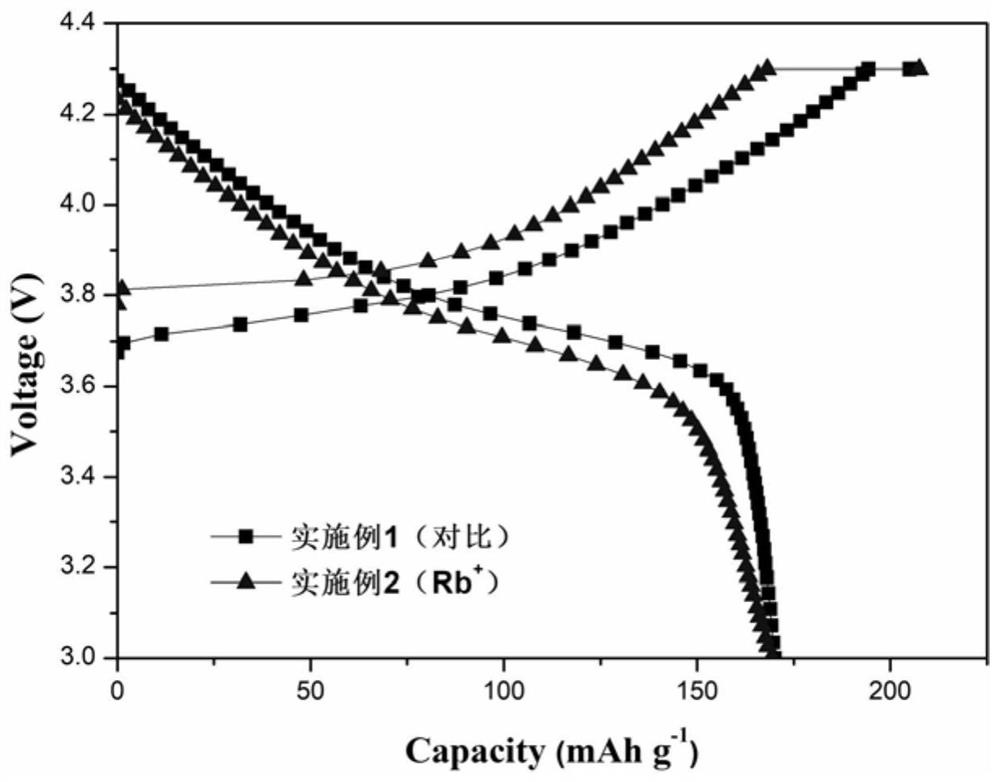

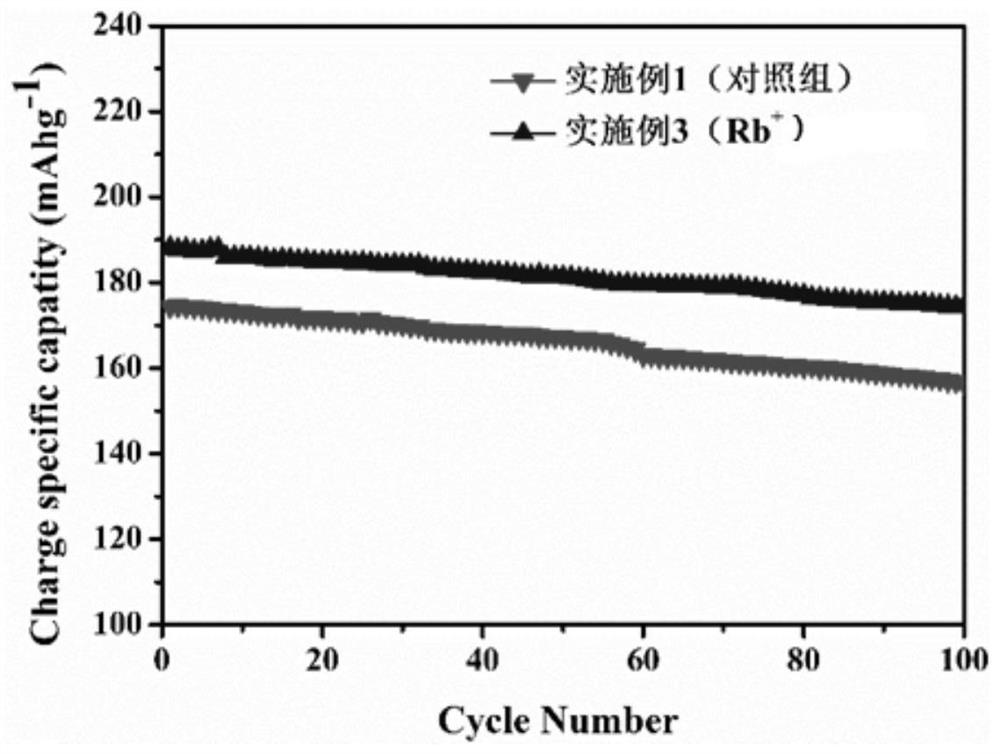

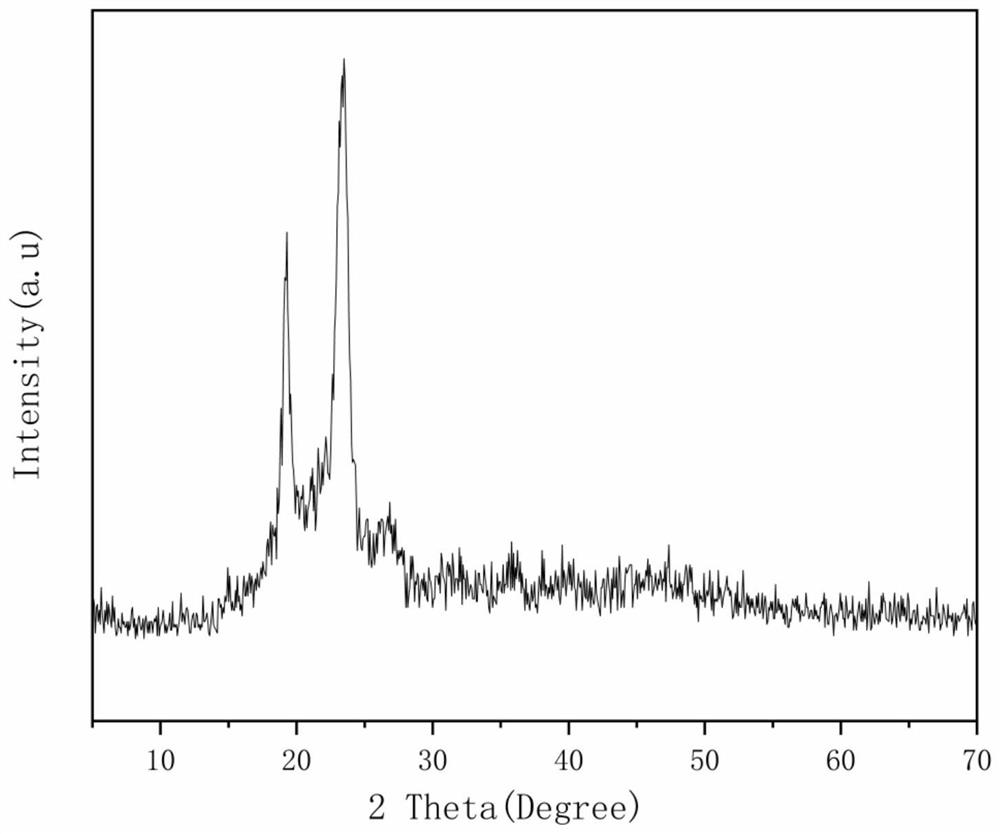

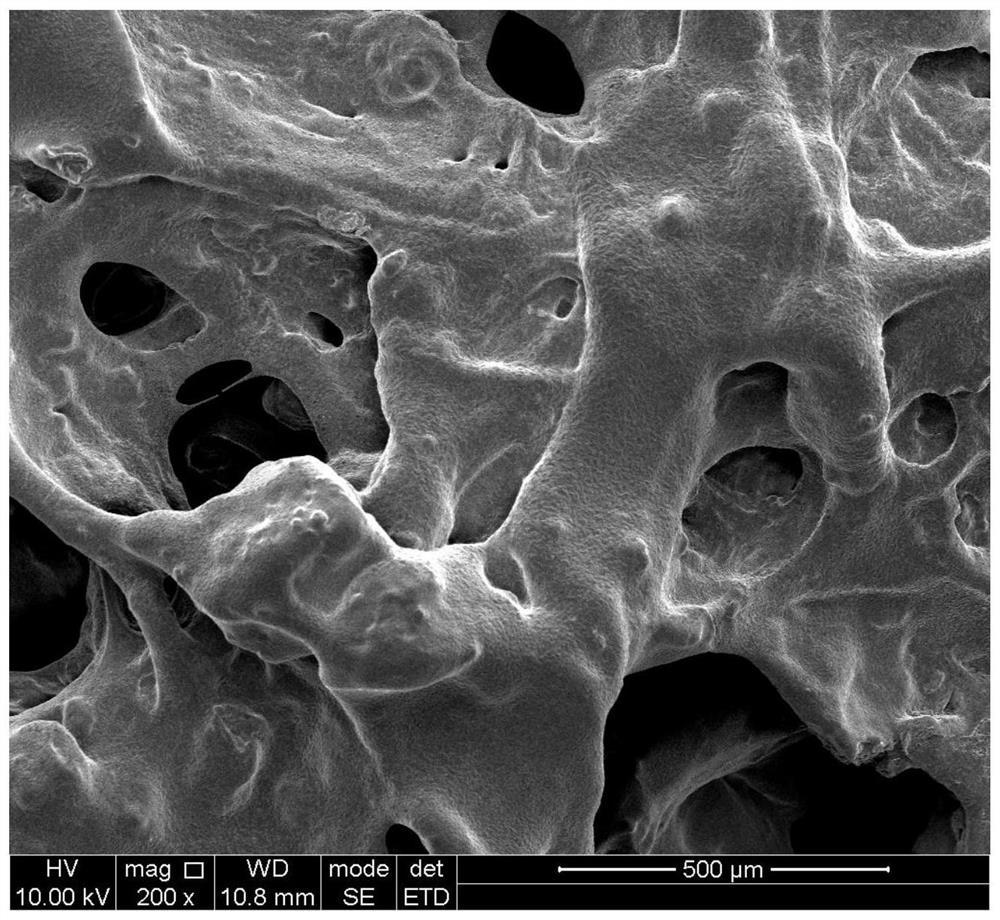

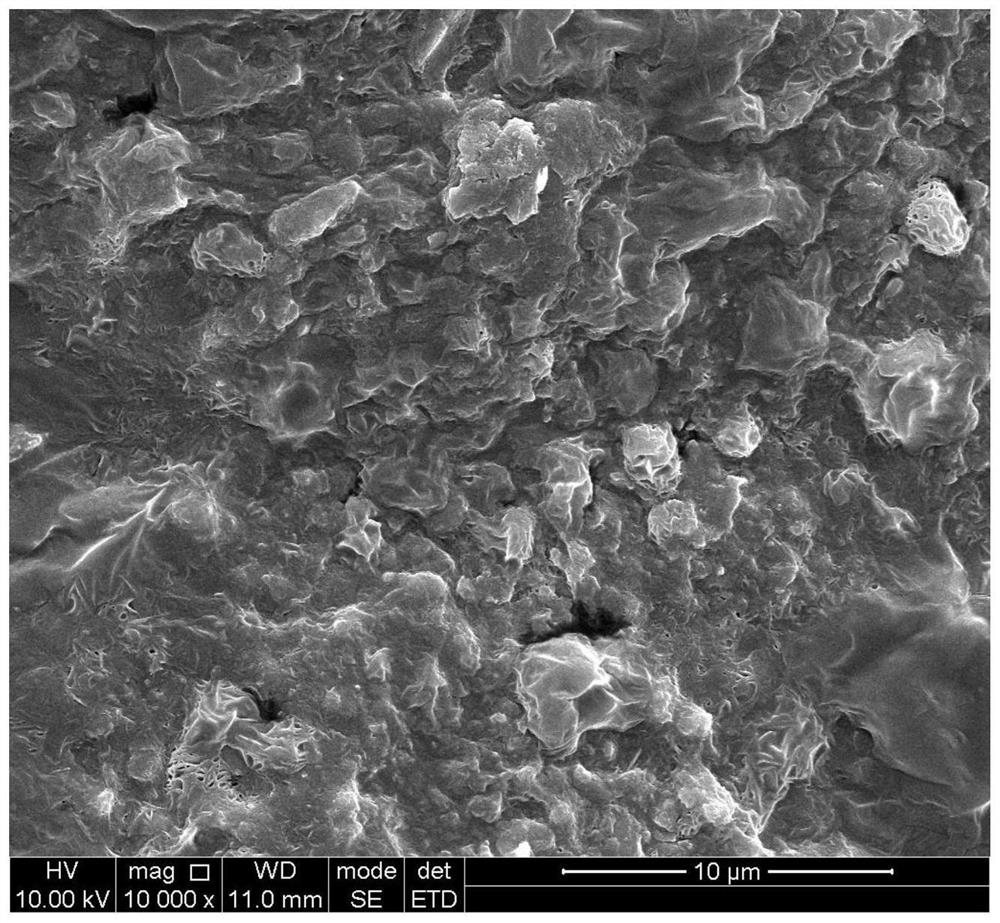

Preparation method of rubidium-doped inorganic-organic lithium battery composite coating type diaphragm

PendingCN112271401AImprove safety performanceGuaranteed pore size uniformitySecondary cellsCell component detailsPolyolefinLithium electrode

The invention discloses a preparation method of a rubidium-doped inorganic-organic lithium battery composite diaphragm, which mainly comprises the following steps: (1) mixing an inorganic precursor with an ethanol-water mixed solvent and rubidium salt, regulating the pH value to 2-10, testing the Zeta potential to be 0, continuing to add an HCl solution until the Zeta potential is -40 mV, and crystallizing to form a colloidal solution; (2) adding polyacrylic acid into the dispersing solvent to form a viscous solution; (3) pouring the colloidal solution obtained in the step (1) into the viscoussolution obtained in the step (2), and adding a binding agent and a dispersing agent to form double-solution coating slurry; and (4) coating the surface of the porous polyolefin diaphragm with the coating slurry, and drying to obtain the rubidium-doped inorganic-organic lithium battery composite diaphragm. According to the rubidium-doped lithium ion battery composite diaphragm disclosed by the invention, due to the doping of rubidium ions, the space between crystal lattices is enlarged, the lithium ion conduction coefficient of the lithium ion battery diaphragm is facilitated, and the first effect and the cycle performance of lithium ions are further improved.

Owner:光鼎铷业(广州)集团有限公司

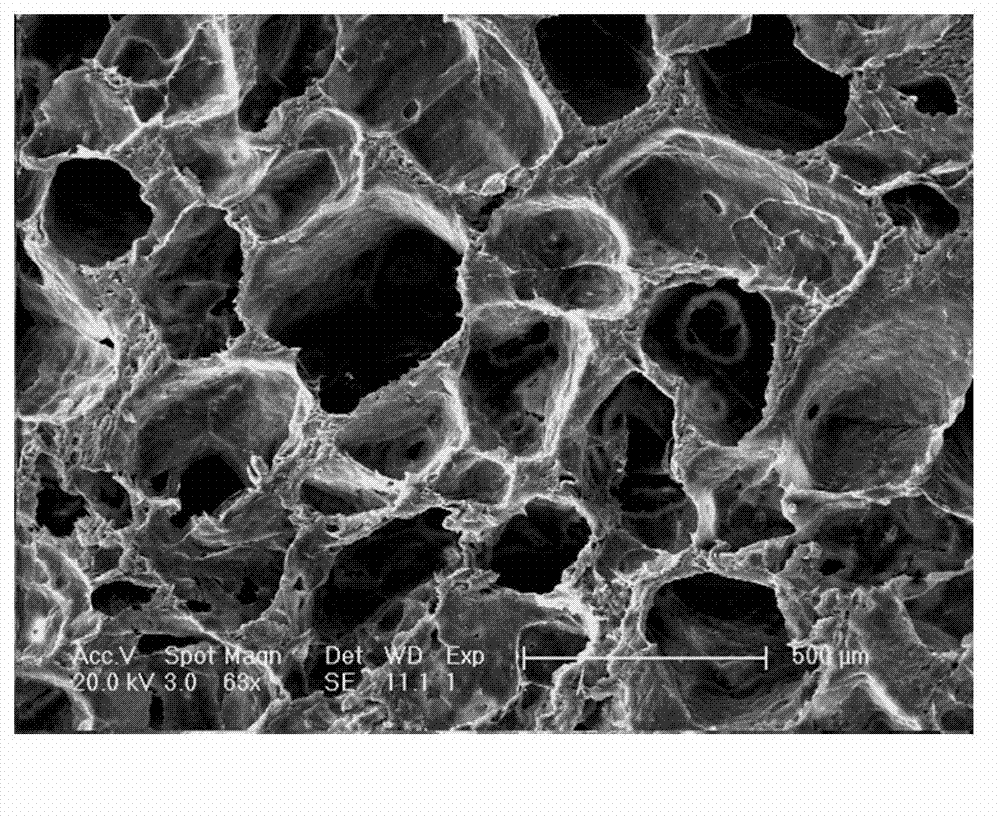

Shape memory polyurethane bone scaffold prepared by gas foaming method and application thereof

InactiveCN113262326AImprove mechanical propertiesPromote growthPharmaceutical delivery mechanismTissue regenerationPolyethylene glycolChemistry

The invention belongs to the field of biomedical bone tissue engineering, and particularly relates to a shape memory polyurethane bone scaffold prepared by a gas foaming method and application of the shape memory polyurethane bone scaffold. The invention provides the preparation method of the shape memory polyurethane bone scaffold prepared by using the gas foaming method. According to the invention, hydrophilic polyethylene glycol can provide a good environment for the growth and adhesion of cells and tissue, and can quickly swell in a body fluid environment to accelerate the conversion of the material from a temporary shape to a permanent shape; amorphous calcium phosphate and organic calcium salt, namely calcium citrate cooperate with each other, so calcium supply can be continuously provided for a bone repair material; the shape memory polyurethane bone scaffold prepared by the gas foaming method can be processed into a bone scaffold required for treating bone defects and the like; and the scaffold has good shape memory performance, can complete transformation from a temporary shape to a permanent shape at a temperature close to a physiological temperature, and well meets the requirements of minimally-invasive surgery. The invention provides a feasible and effective novel shape memory polyurethane bone scaffold for the field of biomedical bone tissue engineering.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Base fertilizer for interplanting chilies and radishes and preparation method thereof

InactiveCN108191535AImprove drainage and ventilationImprove nutrient utilizationBio-organic fraction processingMagnesium fertilisersAdditive ingredientBran

The invention belongs to the technical field of agricultural planting, and particularly discloses base fertilizer for interplanting chilies and radishes and a preparation method thereof. The base fertilizer for interplanting chilies and radishes is prepared from the following raw material ingredients in parts by weight: 4 to 9 parts of silt, 4 to 10 parts of pig manure, 2 to 5 parts of sheep manure, 3 to 6 parts of medical stone, 2 to 6 parts of furnace clinker, 2 to 4 parts of plant ash, 3 to 5 parts of a traditional Chinese medicine mixture, 2 to 5 parts of bagasse, 1 to 5 parts of peanut brans and 2 to 4 parts of compound fertilizer. The traditional Chinese medicine mixture is prepared from certain weight parts of exocarpium citri rubrum, humifuse euphorbia herb, ternate buttercup roots, radix et rhizoma rhei, herba houttuyniae, litchi rind and longan peel; the raw material ingredients are subjected to crushing, mixed fermentation and drying; the base fertilizer can be obtained. Thebase fertilizer provided by the invention has the advantages that the preparation method is simple; the prepared base fertilizer has good physical property; the fertilizer effect release realizes thefast and slow combination; the growth and the yield increase of the chilies and the radishes can be promoted; in addition, the sterilization and bacteriostasis effects can be achieved; the disease rate of the chilies and the radishes can also be effectively reduced.

Owner:宜州市怀远镇诚信辣椒种植专业合作社

A biological patch for repairing tissue damage

The invention discloses a biological patch for tissue damage restoration. The biological patch comprises a biological material substrate layer and a cell substrate layer, wherein the substrate layer is attached onto the substrate layer; and a plurality of parallel grooves are formed in the contact surface of the substrate layer and the cell substrate layer. The substrate layer of the biological patch is simultaneously provided with porous and groove vein structures; the orientation growth and distribution of cells can be regulated and controlled; the cell substrate layer can be well attached onto the substrate layer through the mechanical property of the groove vein structures; and the falling is avoided. A product of the biological patch has the advantages that the structure is stable; the pore diameter, the porosity and the permeability are proper; the normal tissue structure can be simulated; the tissue growth pipeline and cell substrates can be provided; and cells favorable for tissue restoration and regeneration can be carried.

Owner:NANTONG UNIVERSITY

Conductive honey comb ceramic catalyst carrier and its preparation method

InactiveCN1268430CProperly conductiveAppropriate heat conductionCatalyst carriersAl powderSelf-propagating high-temperature synthesis

An electrically conductive cellular ceramic as the carrier of catalyst used for car is prepared from purified titanium oxide or Ti powder, graphite powder and pure Al powder through proportionally mixing, adding organic adhesive, stirring, die pressing, heat treating, igniting and self burning for high temp synthesis.

Owner:KUNMING UNIV OF SCI & TECH

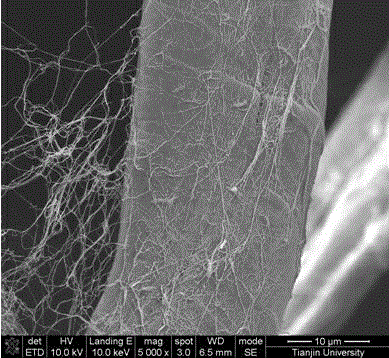

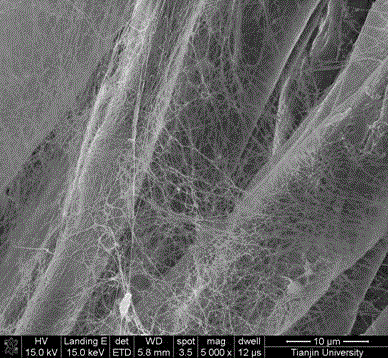

A kind of micro-nano fiber tissue engineering scaffold and preparation method thereof

InactiveCN103691005BWide variety of sourcesHigh degree of bionicProsthesisMicrobiology processesPorosityFibers tissue

The invention relates to the technical field of biological materials, in particular to a micro-nanofiber tissue engineering scaffold and a preparation method thereof. The micro-nanofiber tissue engineering scaffold comprises microfibers, bacterial cellulose nanofibers, micropores and bacterial cellulose micropores, wherein the microfibers are 5-500 microns in diameter, the bacterial cellulose nanofibers are 10-100 nm in diameter, the micropores are 200-500 microns in diameter, and the bacterial cellulose micropores are 10-100 nm in diameter. Compared with the prior art, the micro-nanofiber tissue engineering scaffold is high in bionic degree, stable in structure and proper in porosity and aperture, and can provide a proper external environment for cells; the preparation method is simple and easy to implement, low in cost, wide in raw material source, environment-friendly and pollution-free.

Owner:EAST CHINA JIAOTONG UNIVERSITY

A preparation method of tissue engineering scaffold material

A method for preparing a tissue engineering scaffold material comprises: a) mixing biocompatible polyester and a non-polar solvent to obtain a first solution; b) adding a phase transformation solvent into the first solution to obtain a second solution; c) placing the second solution in a mold, removing the non-polar solvent and the phase transformation solvent through a liquid-vapor phase transformation process or / and a liquid-solid phase transformation process, and drying a solute to obtain the tissue engineering scaffold material. The tissue engineering scaffold material has good mechanical properties and high porosity.

Owner:CHANGCHUN SINOBIOMATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com