Electrochemical element separation membrane including low-resistance coating layer, and method for manufacturing same

An electrochemical and diaphragm technology, applied in the field of diaphragms for electrochemical devices, can solve problems such as cycle life deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

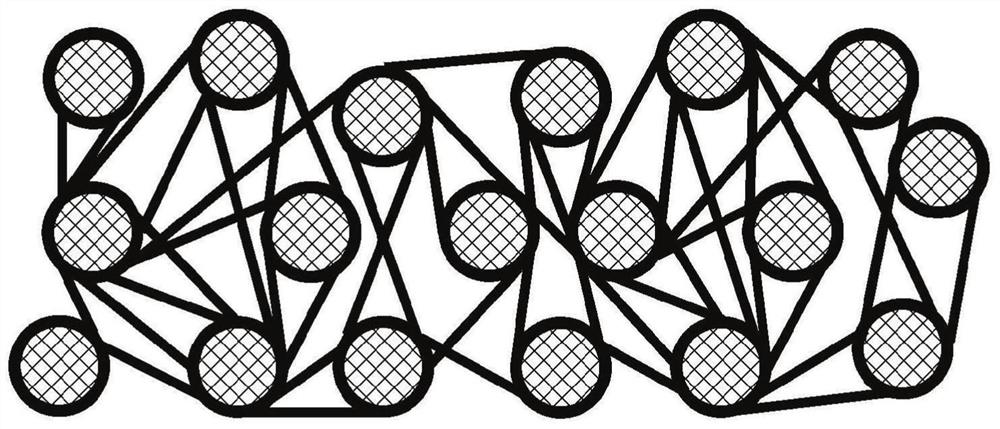

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

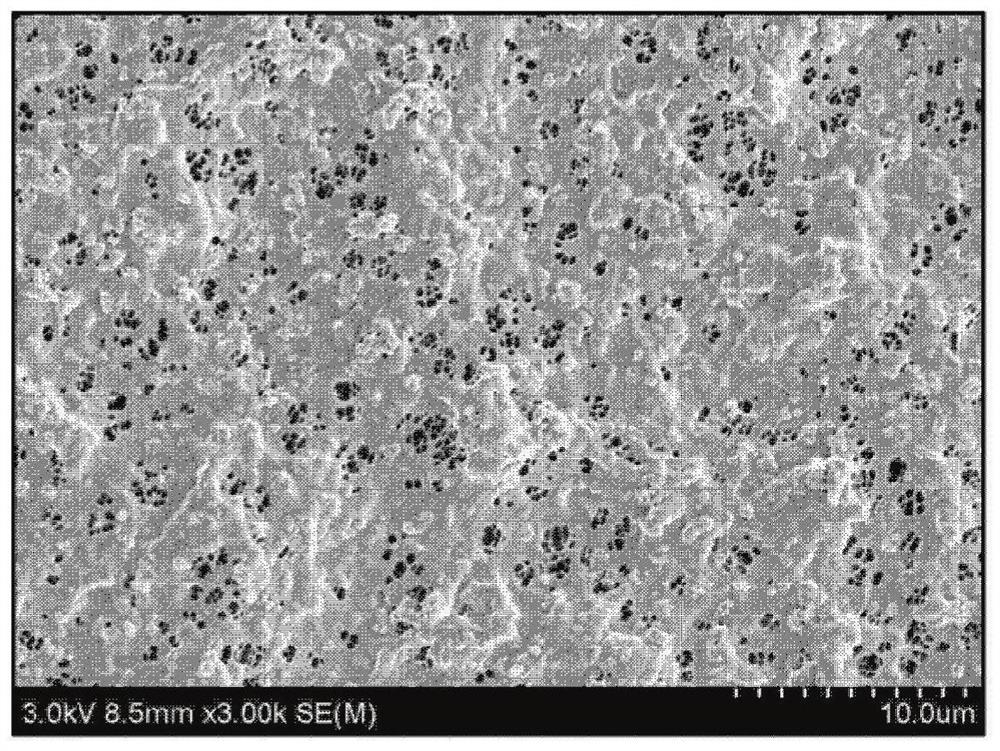

[0106] [Example 1: Manufacture of separator]

[0107] Example 1

[0108] First, 35 g of PVdF-HFP (Solvay Solef 21510, T m 132°C, weight average molecular weight 300,000, HFP substitution degree 15 mol%) was dissolved in 400g of NMP, and 65g of Al was introduced into it 2 o 3 (Japanese Light Metal Co., LS235, D50 500 nm) and dispersed by ball milling to prepare a slurry.

[0109] Next, the slurry was sequentially applied to a porous substrate made of polyethylene (ND9 from Shanghai Energy Co., thickness 9 μm, air transmission time 180 seconds) by microgravure coating method / 100cc, resistance 0.79Ω, porosity 37%) on both surfaces, and then, sequentially dipped in a primary coagulation bath and a secondary coagulation bath to solidify the slurry. The coagulation solution contained in the primary coagulation bath contained NMP as a solvent and water as a non-solvent mixed in a weight ratio of 5:95, and the coagulation solution was controlled at a temperature of 15° C., and t...

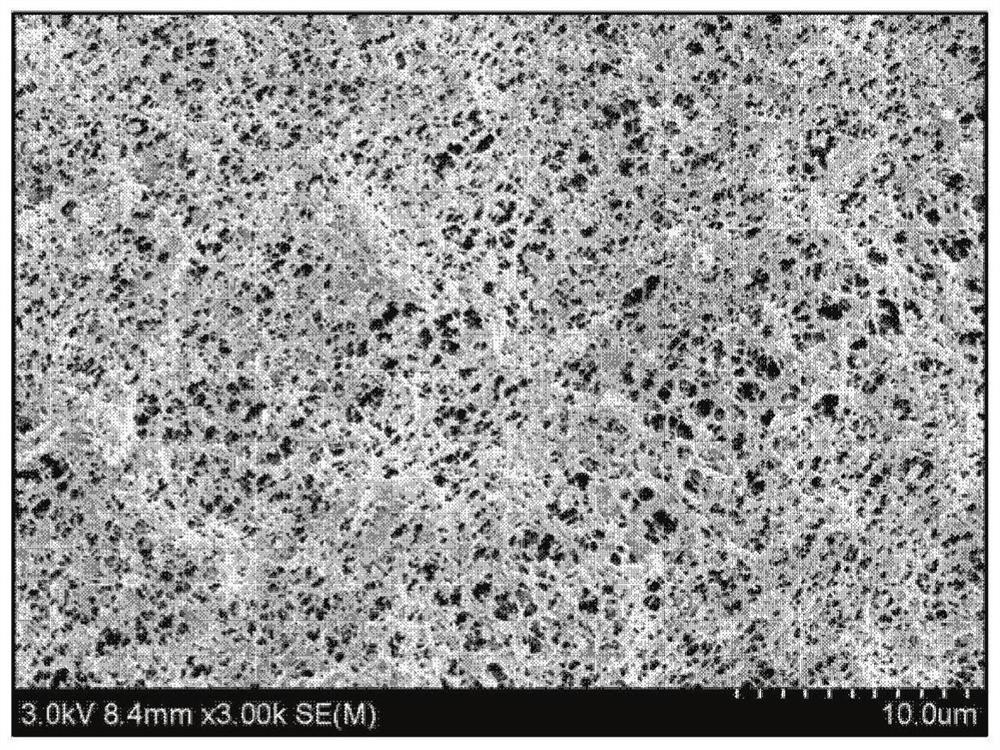

Embodiment 2

[0111] A separator was obtained in the same manner as in Example 1 except that the respective amounts of the binder resin and the inorganic particles were 50 g.

[0112] The produced separator had a thickness of 17 μm, an air transmission time of 222 seconds / 100 cc, and an electric resistance of 1.10Ω. A high peel force of 111 gf / 25mm was measured.

Embodiment 3

[0114] In addition to the binder resin for Kynar 2500(T m 127° C., weight average molecular weight 230,000, HFP substitution degree 18 mol %), a separator was obtained in the same manner as in Example 1. The produced separator had a thickness of 17 μm, an air transmission time of 217 seconds / 100 cc, and an electric resistance of 1.08Ω. A high peel force of 108 gf / 25mm was measured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com