Method for preparing collagen/bioglass/hyaluronic acid tissue repairing materials

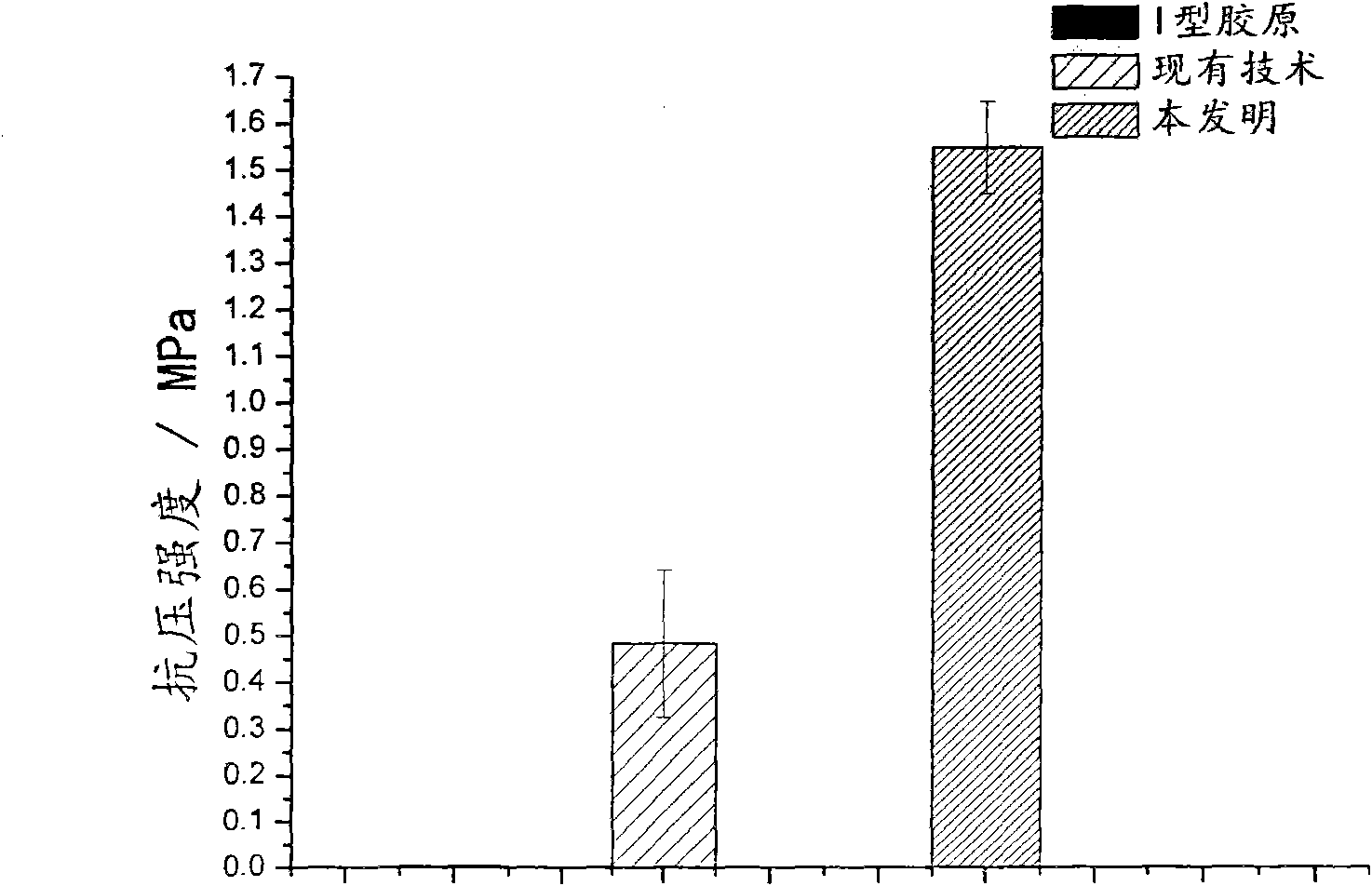

A bio-glass, hyaluronic acid technology, applied in medical science, prosthesis and other directions, can solve the problems of low mechanical properties and anti-degradation performance, and achieve the effects of improving mechanical strength, increasing mechanical strength, and enhancing aggregation state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Compounding of type I collagen and bioactive glass:

[0045] In the state of stirring the type I collagen solution, add CaO-P in the ratio of type I collagen to bioactive glass mass ratio of 0.33:1 2 o 5 -SiO 2 Department of bioglass, then stirred for 2 hours to obtain a mixture of the two, in which CaO-P 2 o 5 -SiO 2 The bioactive glass is prepared by the sol-gel method;

[0046] (2) Static layering:

[0047] Put the mixture of type I collagen and biological glass at 4°C for 3 days, and obtain the white flocculent precipitate of the mixture;

[0048] (3) Suction filtration:

[0049] First filter the white flocculent precipitate in step (2), until the volume of the precipitate is reduced to 1 / 4 of the original volume, that is, a viscous liquid with interlaced distribution of collagen fibers is formed, and then the viscous Stir the thick liquid until uniform;

[0050] (4) Adjust the pH value:

[0051] Add biological buffer agent 2-(N-morpholine)ethanesulfonic...

Embodiment 2

[0062] (1) Compounding of type I collagen and bioactive glass:

[0063] In the state of stirring the type I collagen solution, add Na 2 O-CaO-P 2 o 5 -SiO 2 Department of biological glass, then stirred for 2 hours to obtain a mixture of the two, in which Na 2 O-CaO-P 2 o 5 -SiO 2 The bioactive glass is prepared by melting method;

[0064] (2) Static layering:

[0065] Put the mixture of type I collagen and biological glass at 0°C for 1 day, and obtain the white flocculent precipitate of the mixture;

[0066] (3) Suction filtration:

[0067] First filter the white flocculent precipitate in step (2) until the volume of the precipitate is reduced to 1 / 2 of the original volume, that is, a viscous liquid with interlaced distribution of collagen fibers is formed, and then the viscous Stir the thick liquid until uniform;

[0068] (4) Adjust the pH value:

[0069] Add the biological buffer Tris hydrochloride to the above homogeneous viscous liquid to adjust the pH to 9;

...

Embodiment 3

[0079] (1) Compounding of type I collagen and bioactive glass:

[0080] In the state of stirring the type I collagen solution, add CaO-P at a mass ratio of type I collagen to bioactive glass of 1:1 2 o 5 -SiO 2 Department of bioglass, then stirred for 3 hours to obtain a mixture of the two, in which CaO-P 2 o 5 -SiO 2 The bioactive glass is prepared by the sol-gel method;

[0081] (2) Static layering:

[0082] Put the mixture of type I collagen and biological glass at 1°C for 3 days, and obtain the white flocculent precipitate of the mixture;

[0083] (3) Suction filtration:

[0084] First filter the white flocculent precipitate in step (2), until the volume of the precipitate is reduced to 1 / 4 of the original volume, that is, a viscous liquid with interlaced distribution of collagen fibers is formed, and then the viscous Stir the thick liquid until uniform;

[0085] (4) Adjust the pH value:

[0086] Add biological buffer agent 2-(N-morpholine)ethanesulfonic acid to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

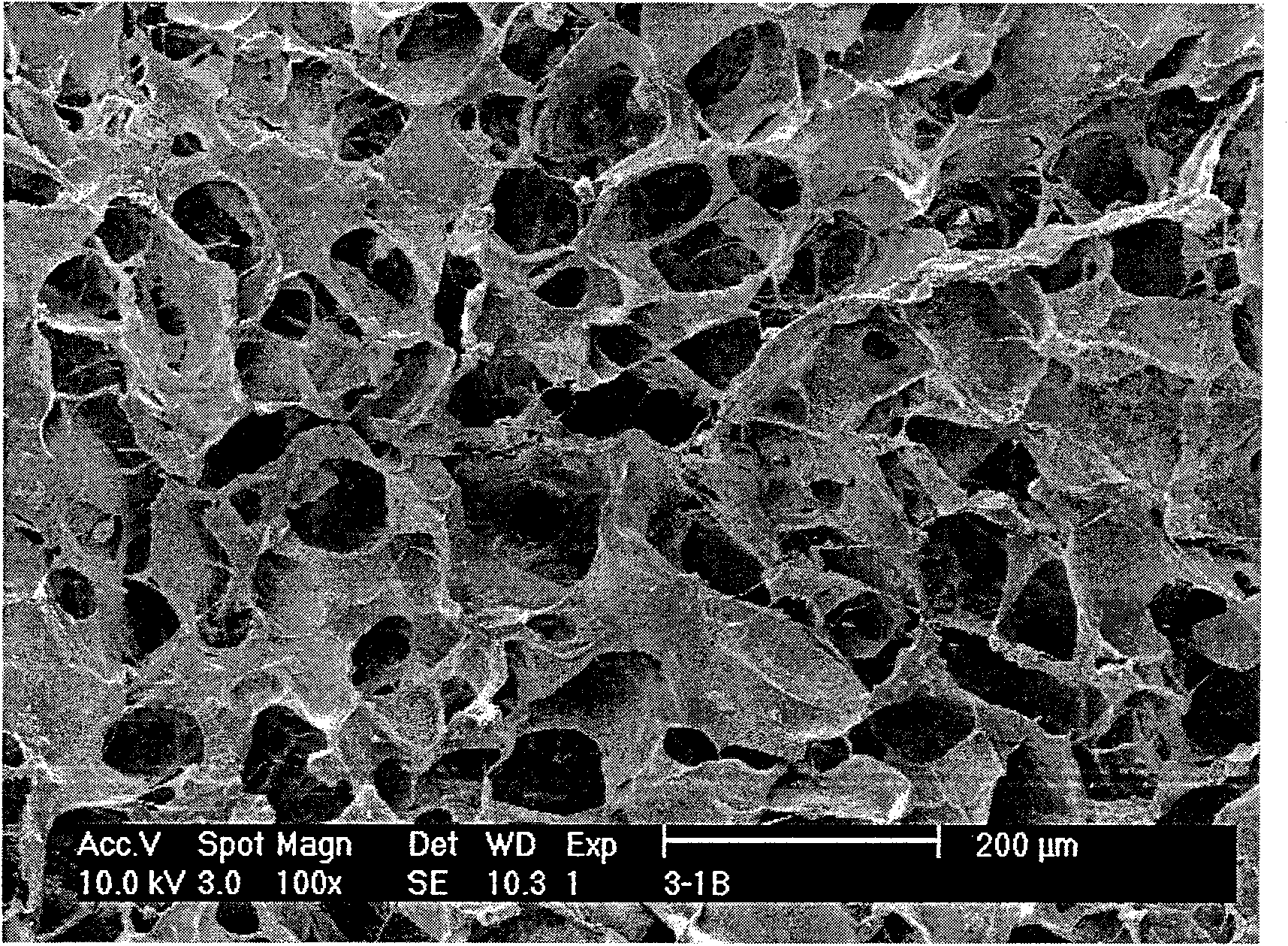

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com