A kind of micro-nano fiber tissue engineering scaffold and preparation method thereof

A technology of fibrous tissue and micron fibers, which is applied in the direction of using microorganisms, medical science, prostheses, etc., to achieve strong process controllability, high degree of bionics, and favorable adhesion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

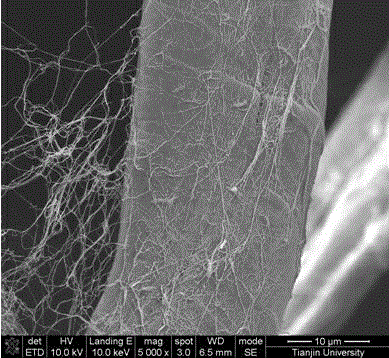

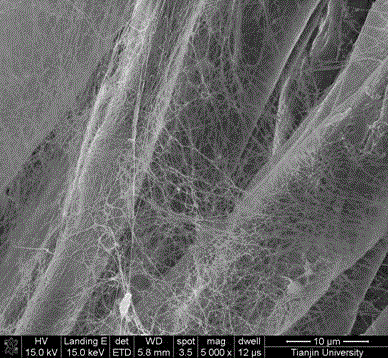

Image

Examples

Embodiment 1

[0022] As an embodiment of the micro-nanofibrous tissue engineering scaffold of the present invention, it includes micron fibers, bacterial cellulose nanofibers, micropores and bacterial cellulose nanopores; the diameter of the micron fibers is 5 microns, and the bacterial cellulose The diameter of the nanofiber is 10 nanometers; the diameter of the micropore is 100 micrometers, and the diameter of the bacterial cellulose nanopore is 10 nanometers.

[0023] A preparation method for preparing micro-nanofibrous tissue engineering scaffolds using cellulose as microfiber scaffolds, cutting the cellulose microfiber scaffolds into square pieces with a size of 20×20×0.5 mm, and preparing Acetobacter xylinum culture medium, that is, using deionized Water is the solvent, and the mass fractions of each solute are: 2.5% glucose, 0.75% yeast powder, 1.0% peptone, 1.0% Na2HPO4, stir in a beaker at room temperature until the solute is completely dissolved, and adjust the pH of the medium to ...

Embodiment 2

[0026] As an embodiment of the micro-nanofibrous tissue engineering scaffold of the present invention, the difference from Embodiment 1 is that in this embodiment, the diameter of the micron fibers is 500 microns, and the diameter of the bacterial cellulose nanofibers is 100 microns. nanometer; the diameter of the micrometer pore is 500 microns, and the diameter of the bacterial cellulose nanopore is 100 nanometers.

[0027] A method for preparing micro-nanofibrous tissue engineering scaffolds using gelatin as a microfiber scaffold, cutting the gelatin microfiber scaffold into square pieces with a size of 20×20×2mm, and preparing Acetobacter xylinum culture medium (that is, using deionized water as a solvent , the mass fractions of each solute are: 2.5% glucose, 0.75% yeast powder, 1.0% peptone, 1.0% Na2HPO4), stir in a beaker at room temperature until the solute is completely dissolved, adjust the pH of the medium to 5 by adding acetic acid dropwise; Put the plain microfiber ...

Embodiment 3

[0030] As an embodiment of the micro-nanofibrous tissue engineering scaffold of the present invention, the difference from Embodiment 1 is that in this embodiment, the diameter of the micron fibers is 250 microns, and the diameter of the bacterial cellulose nanofibers is 50 microns. nanometer; the diameter of the micrometer pore is 300 microns, and the diameter of the bacterial cellulose nanopore is 60 nanometers.

[0031] Step 1 in the preparation method of micro-nanofibrous tissue engineering scaffold: prepare bacterial fermentation medium: use deionized water as solvent, and the mass fractions of each solute are: glucose 2.5%, yeast powder 0.75%, peptone 1.0%, Na2HPO41 .0%, stir in a beaker at room temperature until the solute is completely dissolved, and adjust the pH of the medium to 4.5 by adding acetic acid dropwise.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com