A biological patch for repairing tissue damage

A biological patch, tissue damage technology, applied in the field of medical devices, can solve the problems of complicated preparation, high price, etc., and achieve the effects of a good growth environment, a simple and easy method, and good tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Culture and purification of Schwann cells

[0031] One-day-old SD rats were taken from newborns, killed and disinfected with alcohol, and the bilateral sciatic nerves were taken, placed on an ice-bath operating table to remove the epineurium and adhesion tissue, after the collagenase / trypsin mixed digestion was complete, the supernatant was discarded and the complete medium Resuspend the cells and inoculate them into culture dishes coated with PDL. Replace with complete medium containing cytarabine (10μM) for 24 hours and culture for 48 hours, then replace with complete medium containing HRG (50ng / ml) and Forsklin (2μM) to continue culturing, change the medium every 3 days until the cells are confluent . After the cells are fused, trypsinize and centrifuge to obtain the cell pellet, resuspend the cells with 1ml Thy1.1 complete medium (1:1000), incubate on ice for 2 hours; centrifuge to discard the supernatant, and use a mixture of DMEM and complement (3:1) Resuspe...

Embodiment 2

[0039] The preparation of embodiment 2 biological patch

[0040] (1) Preparation of elastic stamp

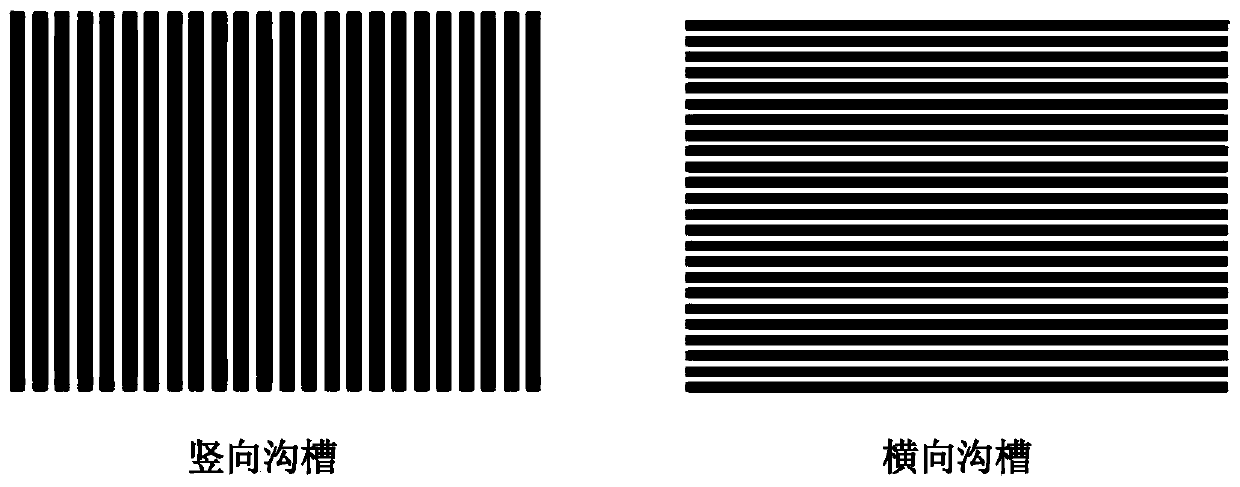

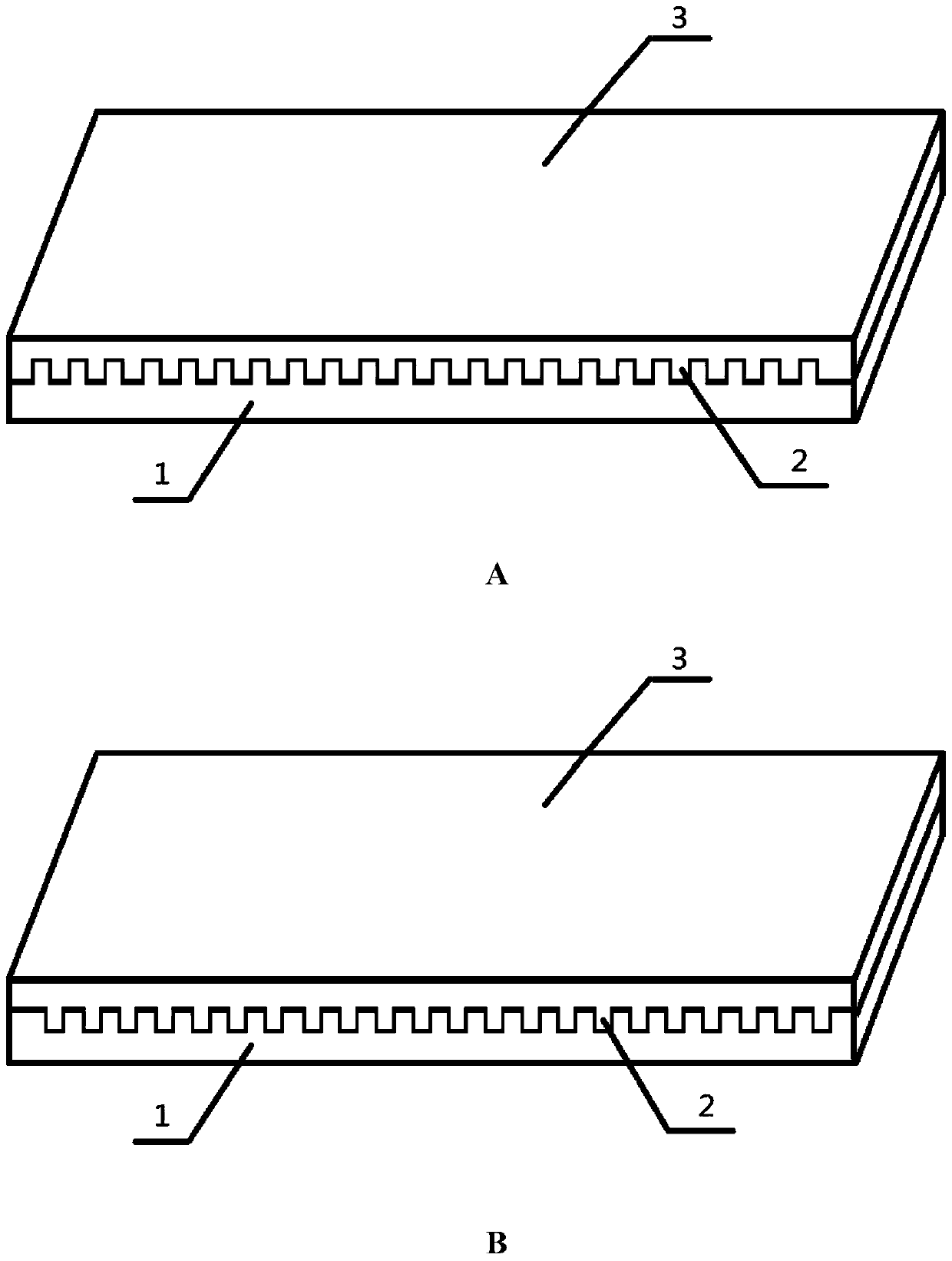

[0041] The elastic stamp used in the present invention is polydimethylsiloxane (polydimethylsiloxane, PDMS), and its preparation method is to mix the PDMS liquid prepared at room temperature and the cross-linking agent in a ratio of 10:1, and then cast it to the On the silicon wafer-based master template with horizontal or vertical groove-shaped micro-pattern distribution obtained by mask exposure, such as figure 1 shown. Then put it into a vacuum drying oven to vacuum out air bubbles, dry and cure, and finally peel off after curing to obtain a planar PDMS elastic stamp.

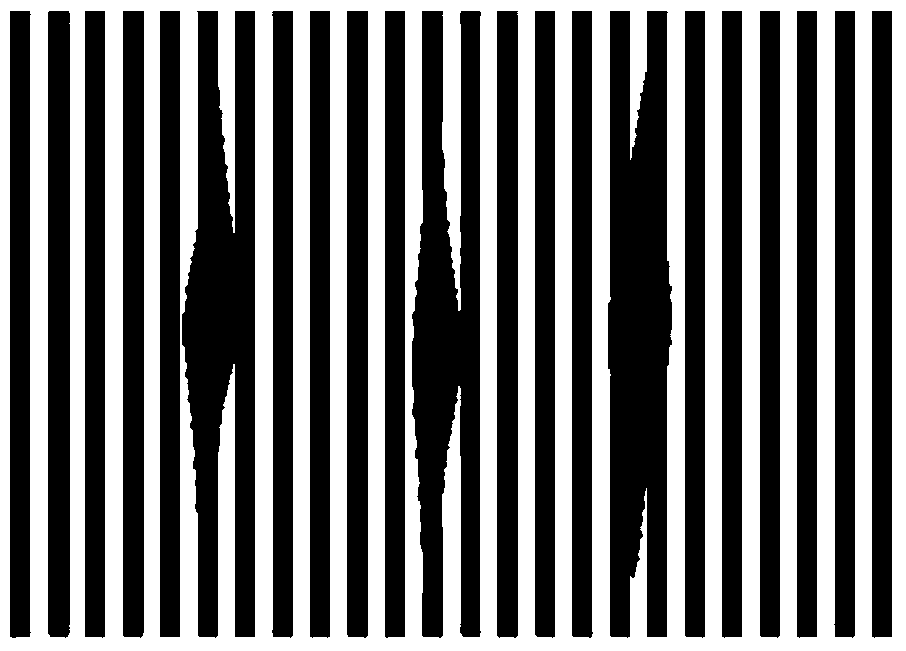

[0042] (2) Preparation of micropatterned chitosan base layer

[0043] First dissolve chitosan with acetic acid to prepare a solution with a certain concentration (1%, 2% and 5%), then add the solution dropwise on PDMS, place at -60°C-90°C, freeze for 2-4 hours, and After freezing, the chitosan ice body is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com