Method for preparing nitrided ferrovanadium

A technology of ferrovanadium nitride and iron powder, which is applied in the field of metallurgy, can solve the problems of large vanadium slag, vanadium loss, high energy consumption and high cost, and achieve the effects of high vanadium utilization rate, resource saving and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

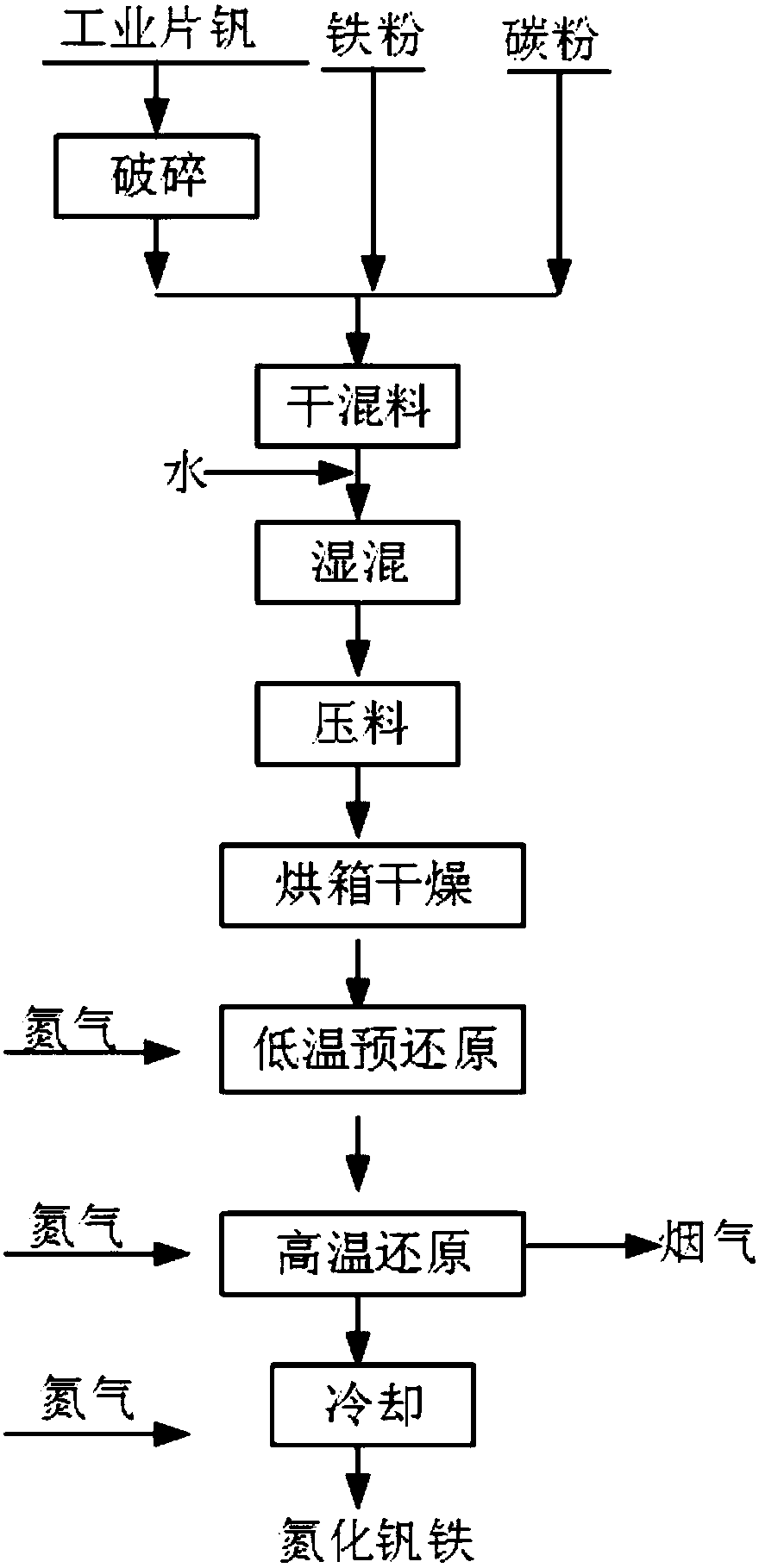

[0037] The method for preparing ferrovanadium nitride of the present embodiment comprises the following steps:

[0038] Step 1, place V 2 O 5 The powder, iron powder and carbon powder were all dried at 100~105℃ for 1h, and then the V 2 O 5 Sieve powder, iron powder and carbon powder to 200 mesh;

[0039] Step 2, place the dry V 2 O 5 Powder, iron powder and carbon powder are mixed evenly, V 2 O 5 The mass ratio of powder to toner is 1:0.38, V 2 O 5 The mass ratio of powder to iron powder is 1:0.45, then 4% water by mass is added to the mixture for wet mixing, and then the wet mixture is pressed on a powder press with a pressing pressure of 8 MPa, and then pressed The samples were dried in a drying oven, the drying temperature was 100-105 °C, and the drying time was 4 hours to obtain the samples;

[0040] Step 3, put the sample into a tubular heating furnace, and heat it up to 650 °C at a rate of 10 °C / min for pre-reduction. During pre-reduction, the nitrogen flow rat...

Embodiment 2

[0045] The method for preparing ferrovanadium nitride of the present embodiment comprises the following steps:

[0046] Step 1, place V 2 O 5 The powder, iron powder and carbon powder were all dried at 100~105℃ for 1.5h, and then the V 2 O 5 Sieve powder, iron powder and carbon powder to 180 mesh;

[0047] Step 2, place the dry V 2 O 5 Powder, iron powder and carbon powder are mixed evenly, V 2 O 5 The mass ratio of powder to toner is 1:0.30, V 2 O 5 The mass ratio of powder to iron powder is 1:0.50, then 2% by mass of water is added to the mixture for wet mixing, and then the wet mixture is pressed on a powder press with a pressing pressure of 8.5 MPa, and then the pressing The good samples are dried in a drying oven, the drying temperature is 100-105 °C, and the drying time is 2 hours to obtain the samples;

[0048] Step 3, put the sample into the tubular heating furnace, and heat it up to 650 °C at a rate of 10 °C / min for pre-reduction. During pre-reduction, the n...

Embodiment 3

[0053] The method for preparing ferrovanadium nitride of the present embodiment comprises the following steps:

[0054] Step 1, place V 2 O 5 The powder, iron powder and carbon powder were all dried at 100-105 ℃ for 2 hours, and then the V 2 O 5 Sieve powder, iron powder and carbon powder to 200 mesh;

[0055] Step 2, place the dry V 2 O 5 Powder, iron powder and carbon powder are mixed evenly, V 2 O 5 The mass ratio of powder to toner is 1:0.37, V 2 O 5 The mass ratio of powder to iron powder is 1:0.4, and then 3% of water by mass is added to the mixture for wet mixing, and then the wet mixture is pressed on a powder press with a pressing pressure of 9MPa, and then pressed The samples were dried in a drying oven, the drying temperature was 100-105 °C, and the drying time was 3 hours to obtain the samples;

[0056] Step 3, put the sample into a tubular heating furnace, and heat it up to 660 °C at a rate of 10 °C / min for pre-reduction. During pre-reduction, the nitrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com