Carrier of catalyst in conducting typed honeycomb ceramics and its preparation method

A catalyst carrier, honeycomb ceramic technology, applied in catalyst carrier, chemical instrument and method, physical/chemical process catalyst, etc., can solve the problems of polluting the environment, not completely solved, taking a long time to start, etc., to achieve good electrical conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

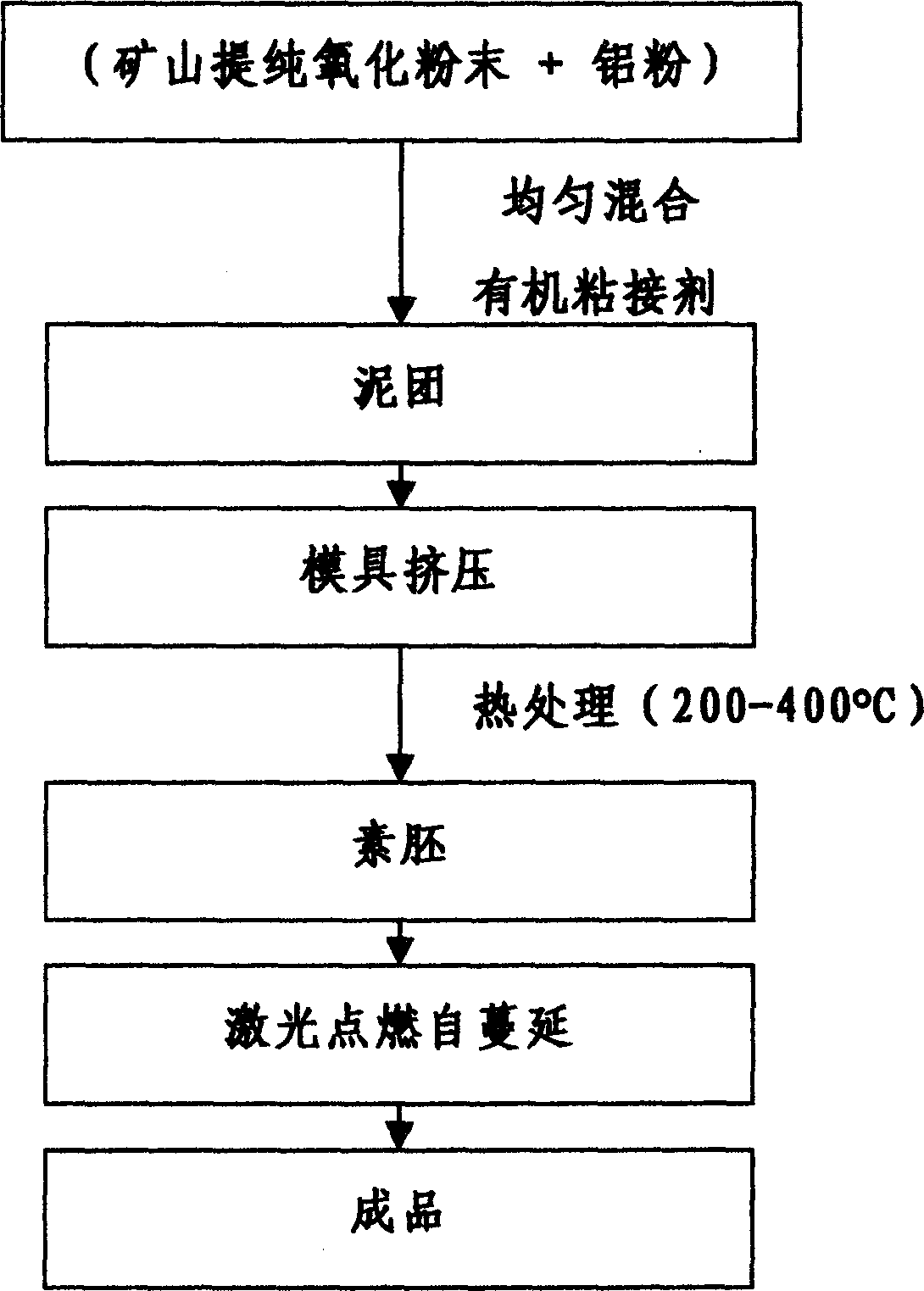

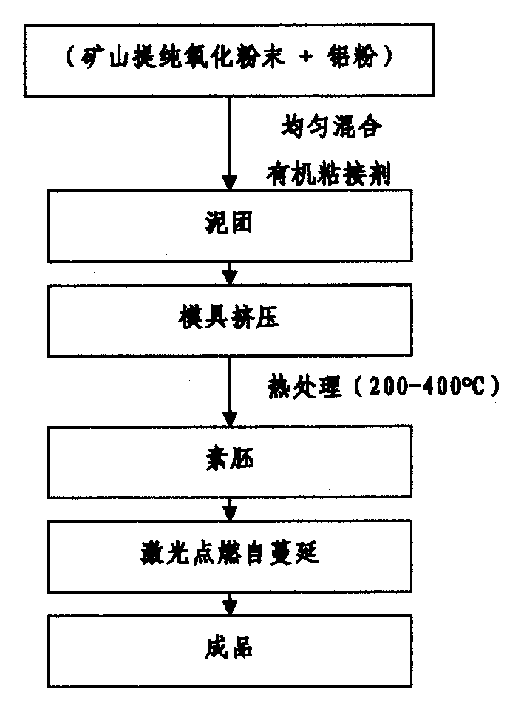

Method used

Image

Examples

Embodiment 1

[0023] Titanium dioxide (TiO2) purified from mines 2 ), the boron trioxide powder (B 2 o 3 ), common industrial pure aluminum powder (Al) is raw material, and the purity of three kinds of powders is all 98%, and particle size is all>200 orders, and above three kinds of powders are pressed Al:TiO 2 :B 2 o 3 =37.6%: 33.3%: 29.1% weight percentage is evenly mixed, and 2% gum arabic is added to form a dough, and the honeycomb ceramic carrier pottery embryo is formed by extrusion technology. Heat treatment at 200°C for 0.5-2 hours, and then use electric spark or laser beam to ignite self-propagating high-temperature synthesis to obtain the finished product. The product performance analysis table is as follows:

[0024] main chemical ratio

Embodiment 2

[0026] main chemical ratio

Embodiment 3

[0028] main chemical ratio

[0029] main chemical ratio

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com