Online-maintenance up-flow anaerobic reactor

An anaerobic reactor and upflow technology, applied in anaerobic digestion treatment, chemical instruments and methods, biological water/sewage treatment, etc. Insufficient water separation effect and other problems, to achieve the effect of reducing the risk of scaling, increasing the volume, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

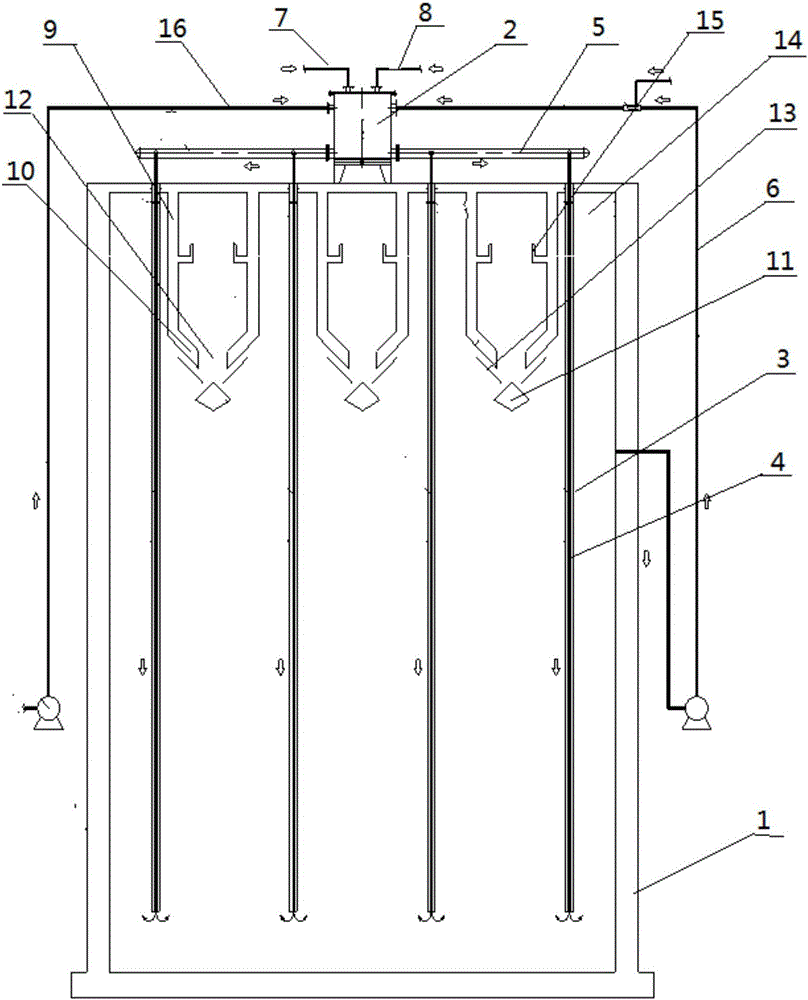

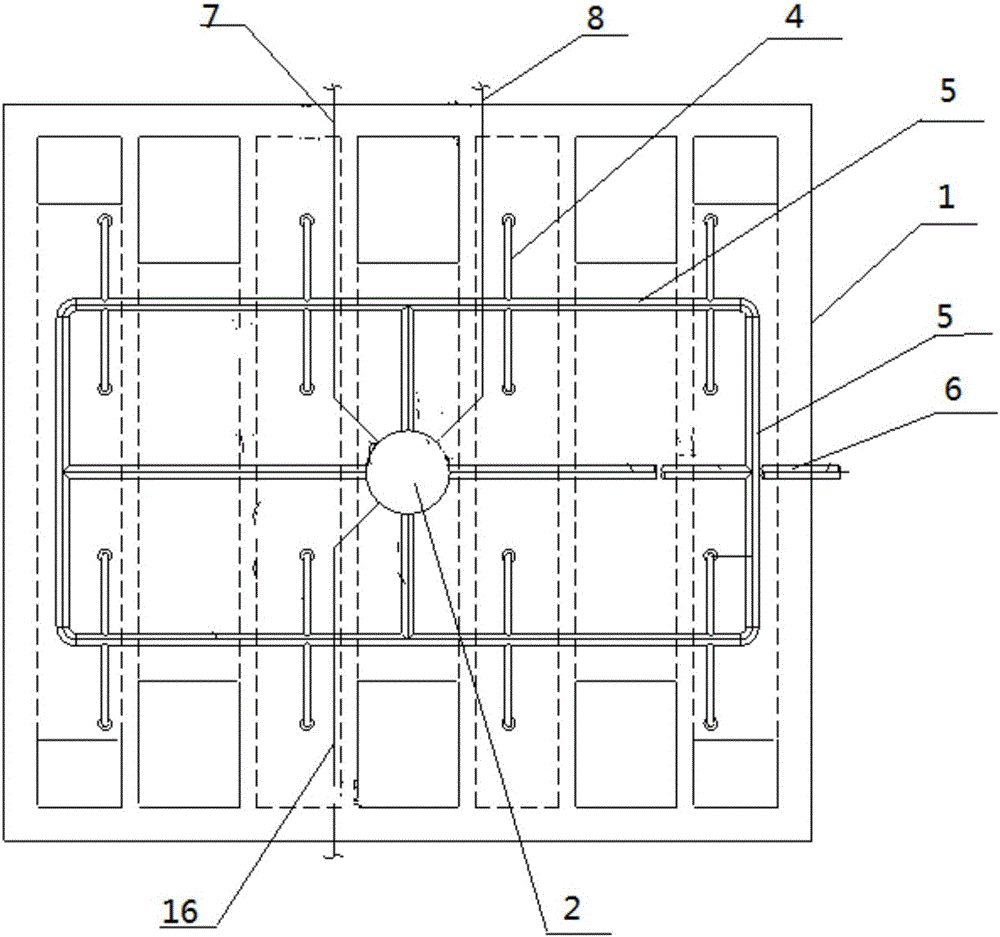

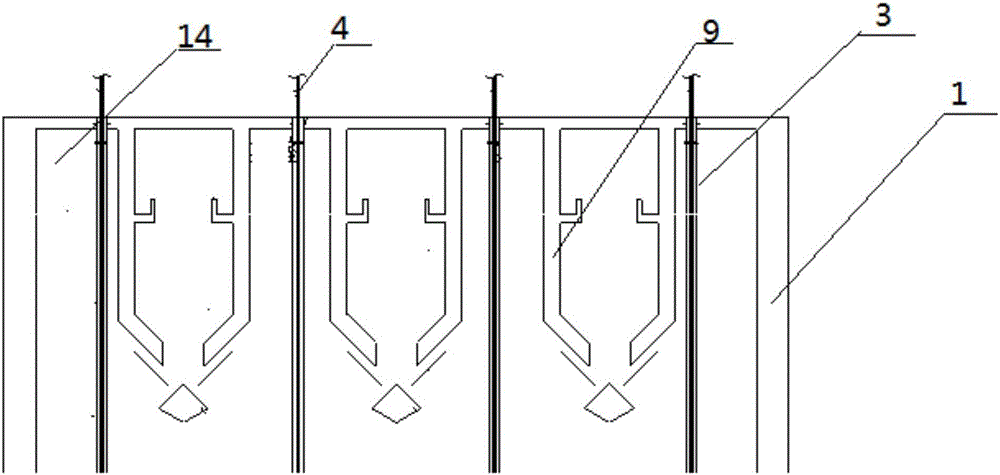

[0035] Such as Figures 1 to 4As shown, an upflow anaerobic reactor that can be maintained online includes a reactor body 1. Specifically, the bottom of the reactor body 1 is a bottom sludge reaction zone, and the middle is a flocculent sludge reactor zone. The upper part is a three-phase separation area. The reactor body 1 is equipped with a three-phase separation unit and a water distribution unit. The water distribution unit includes a pressure water distributor 2 and a plurality of water distribution pipes extending to the lower part of the reactor body 1. The water distribution pipeline includes a casing 3 and a detachable water distribution branch pipe 4 sleeved in the casing 3 , and the water distribution branch pipe 4 communicates with the pressure water distributor 2 . The casing 3 is fixedly connected in the reactor body 1, such as flanged with the embedded waterproof wing ring on the top of the tank, and the water distribution branch pipe 4 is a rigid or flexible pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com