Nanometer silver line circuit spray printing system and technology

A nano-silver wire and circuit technology, applied in printing, typewriters, etc., can solve the problems of difficulty in maintenance work, waste of ink, difficulty in using time and difficulty in nozzle smoothness, etc., and achieve the effect of convenient maintenance and simplification of the nozzle structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

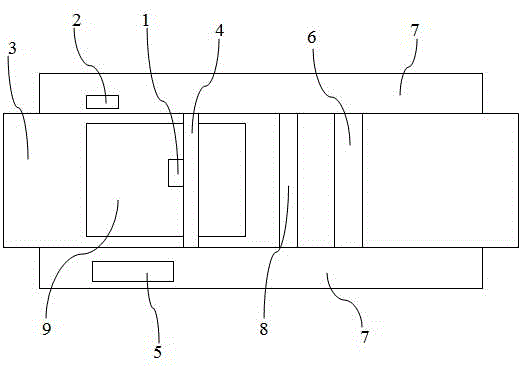

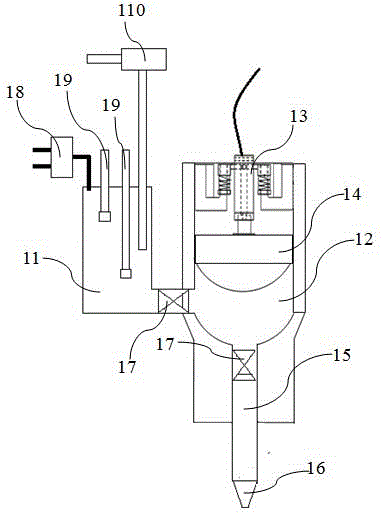

[0019] like figure 1 As shown, the nano silver wire circuit printing system and process include a control processing system, a nozzle (1), a camera (2) for collecting marked images, a conveying device (3) for conveying substrates, and a moving device for controlling the movement of the nozzle (1). Positioning device (4), driving device (5) for driving transmission device (3) and shifting device (4), sintering device (6) for sintering nano-silver wire ink, and base (7) carrying the above-mentioned various devices. The nozzle (1) is fixed on the shifting device (4), and the shifting device (4) can adopt an XYZ three-axis movement mechanism to ensure that the nozzle (1) fixed on it can be moved within the entire range of the printing position (9). Horizontal, vertical and up-and-down movements, on the one hand, ensure that the nozzle (1) can move to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com