Patents

Literature

176results about How to "Avoid Inaccurate Positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

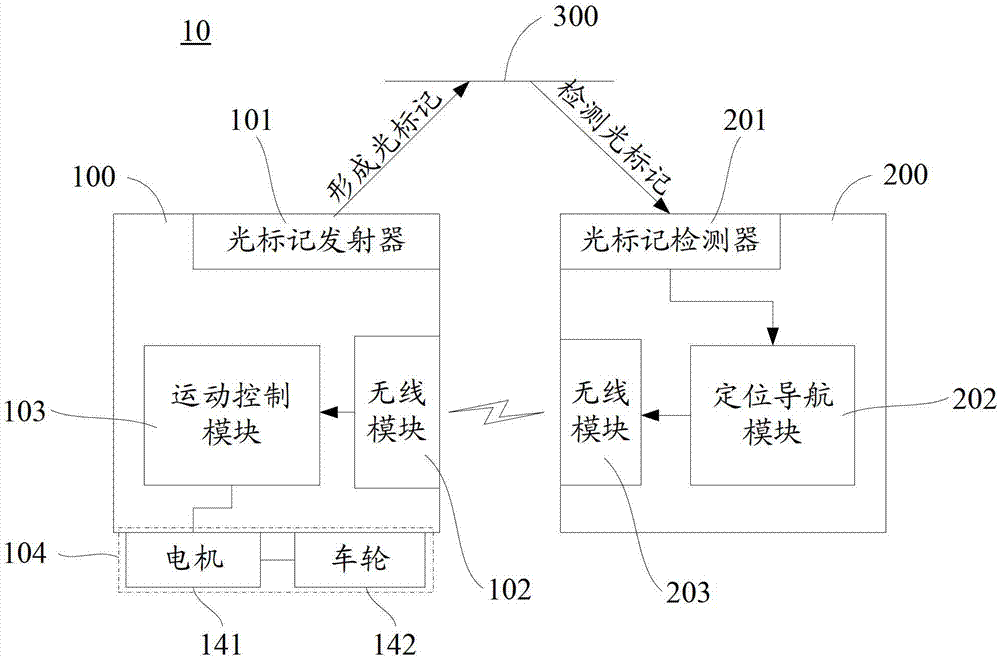

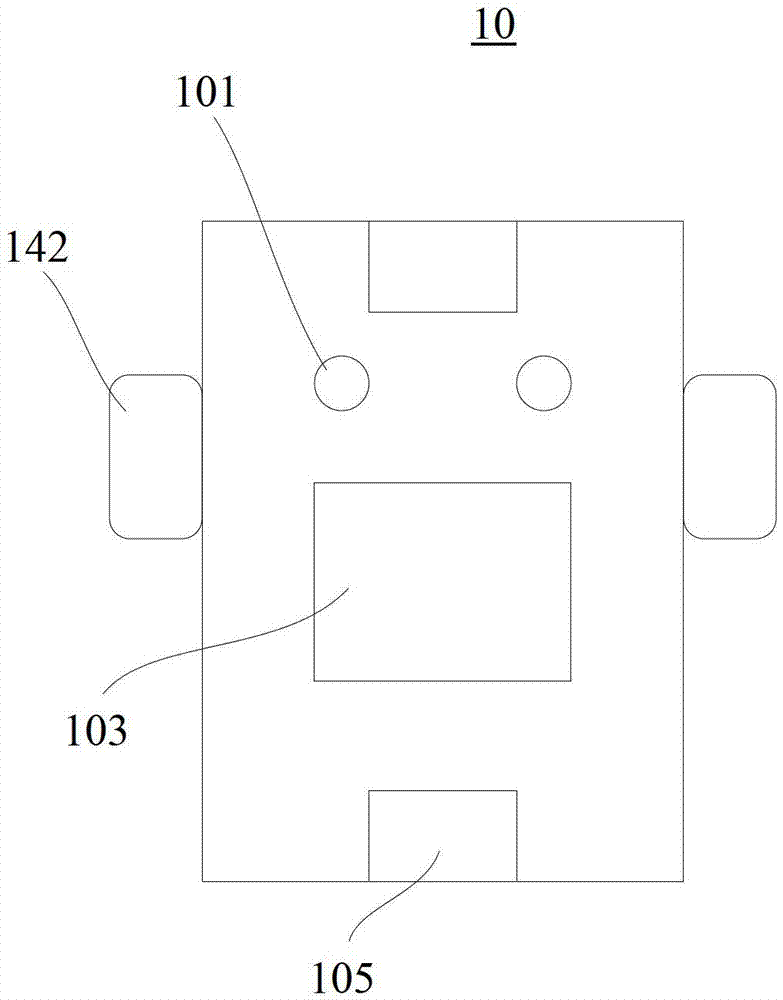

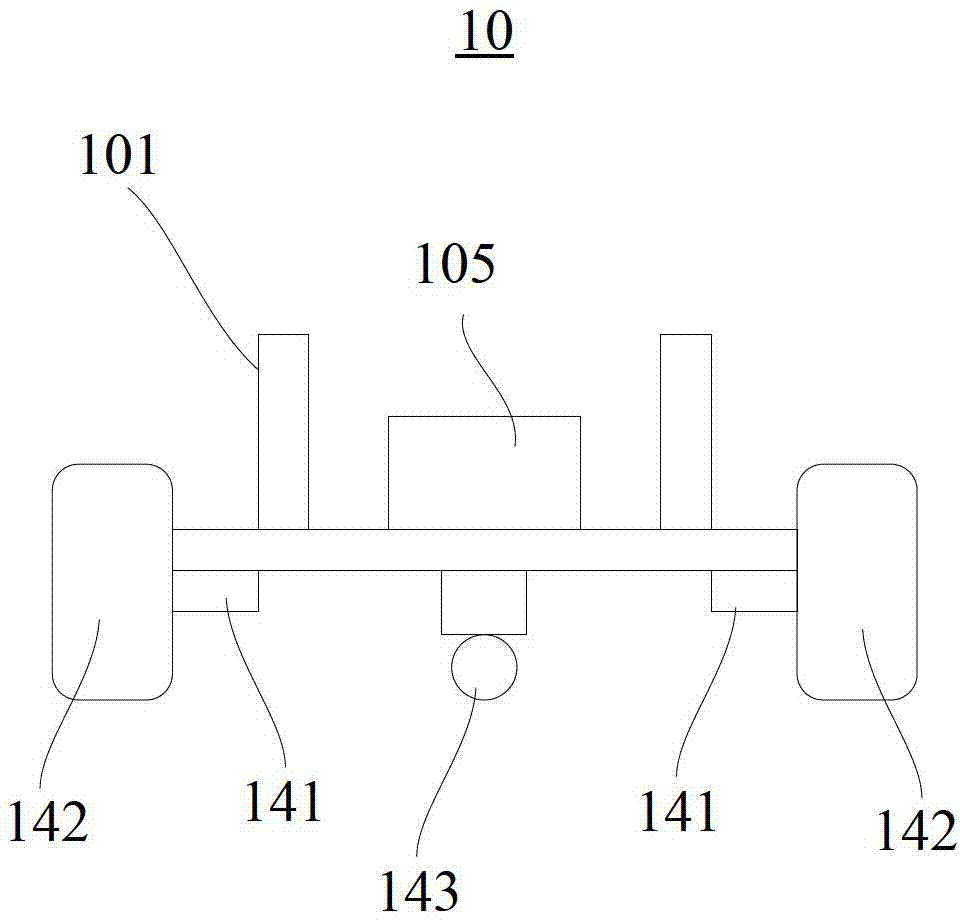

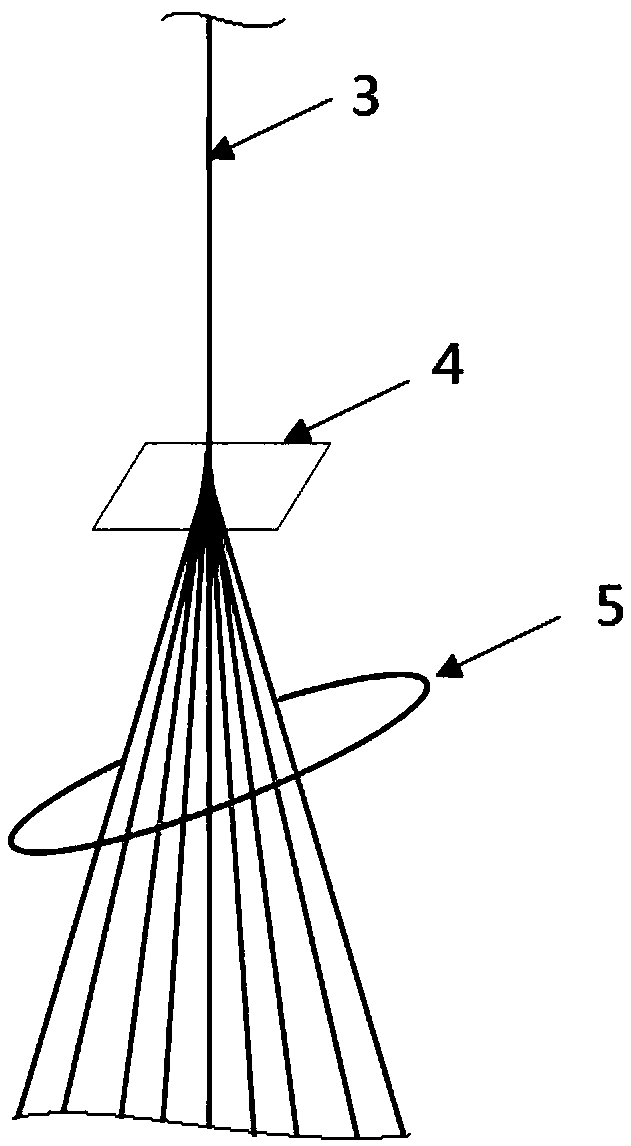

Positioning and navigation system and method of indoor robot

ActiveCN102818568ALow costSolve the fragileNavigation instrumentsPosition/course control in two dimensionsRoute planningMovement control

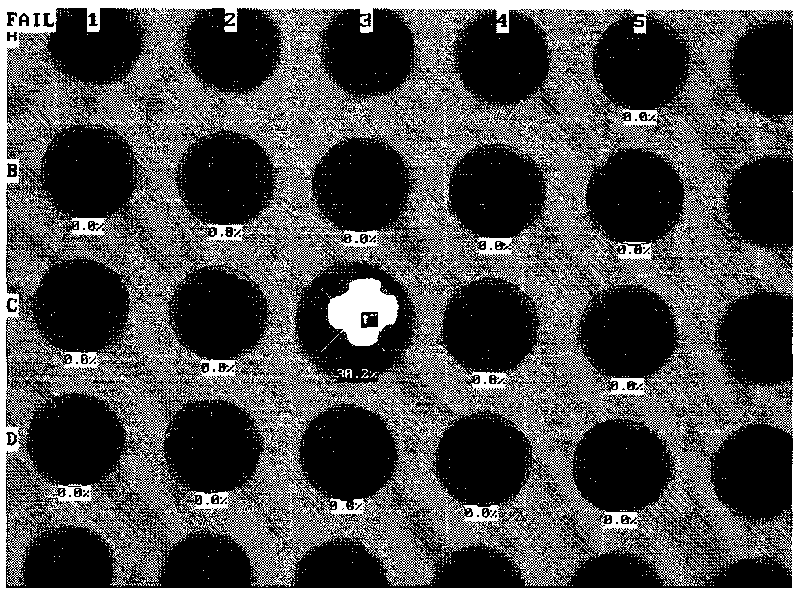

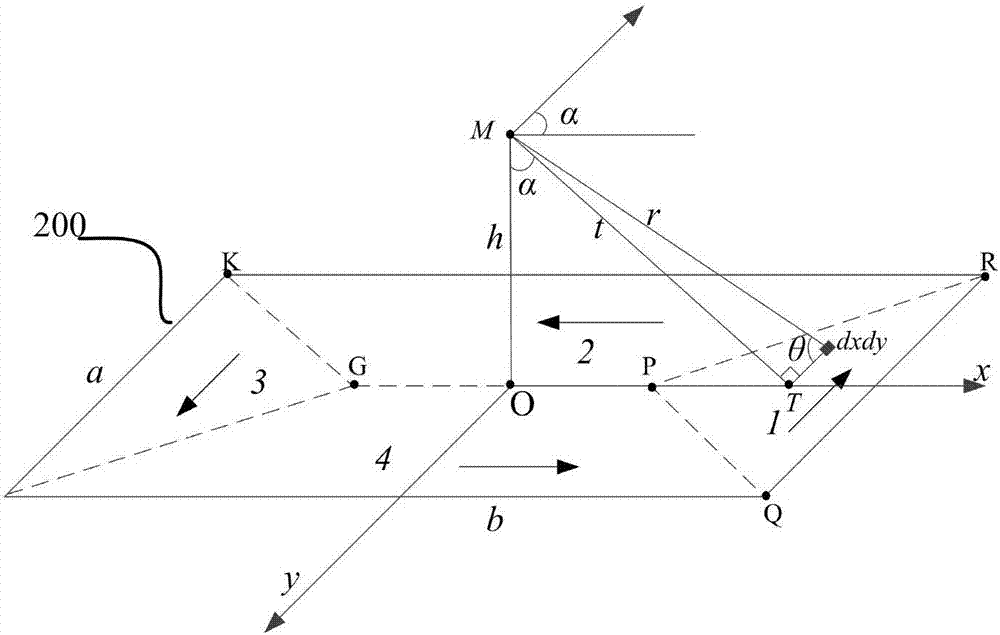

The invention discloses a positioning and navigation system of an indoor robot, comprising an optical label transmitter, a wireless module, a motion control module, a motion mechanism, an optical label detector, a positioning navigation module and a wireless module, wherein the optical label transmitter is used for forming an optical label on the fixed surface, and the position of the optical label in the fixed surface corresponds to the position of the robot in the motion area in a one-to-one manner; the wireless module is used for receiving navigation signals; the motion control module is used for generating corresponding drive control signals according to the received navigation signals; the motion mechanism is used for operating and driving the robot to move according to the drive control signals; the optical label detector is used for detecting the optical label and determining a coordinate of the optical label; the positioning navigation module is used for positioning the position of the robot in the motion area according to the coordinate of the optical label, and generating navigation signals according to a target position and the position planning and the corrected moving path of the robot; and the wireless module is used for sending the navigation signals. The invention also discloses a method applying the system. The method and the system are accurate in positioning, flexible in route planning and lower in cost.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

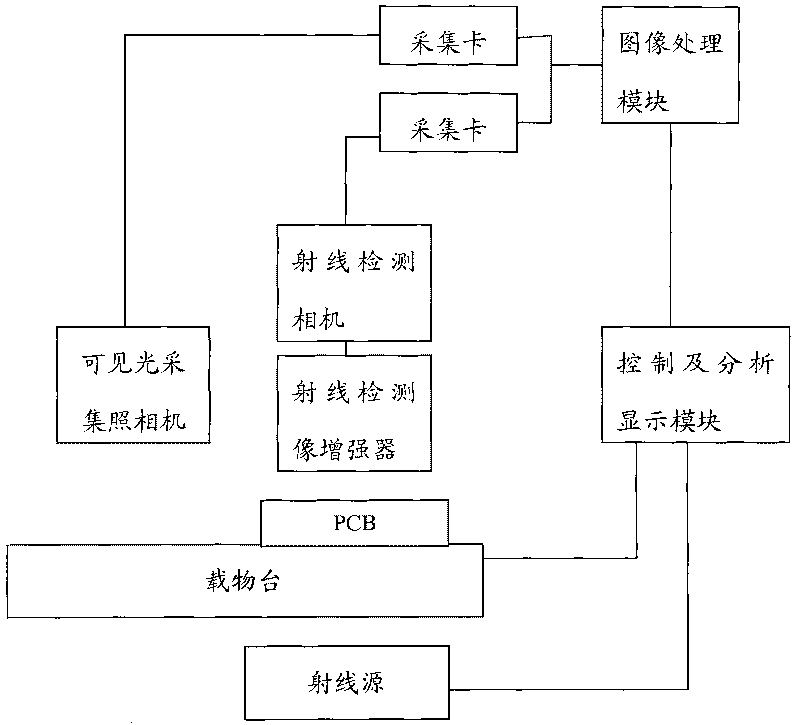

Automatic detection system and detection method of high resolution printed circuit board

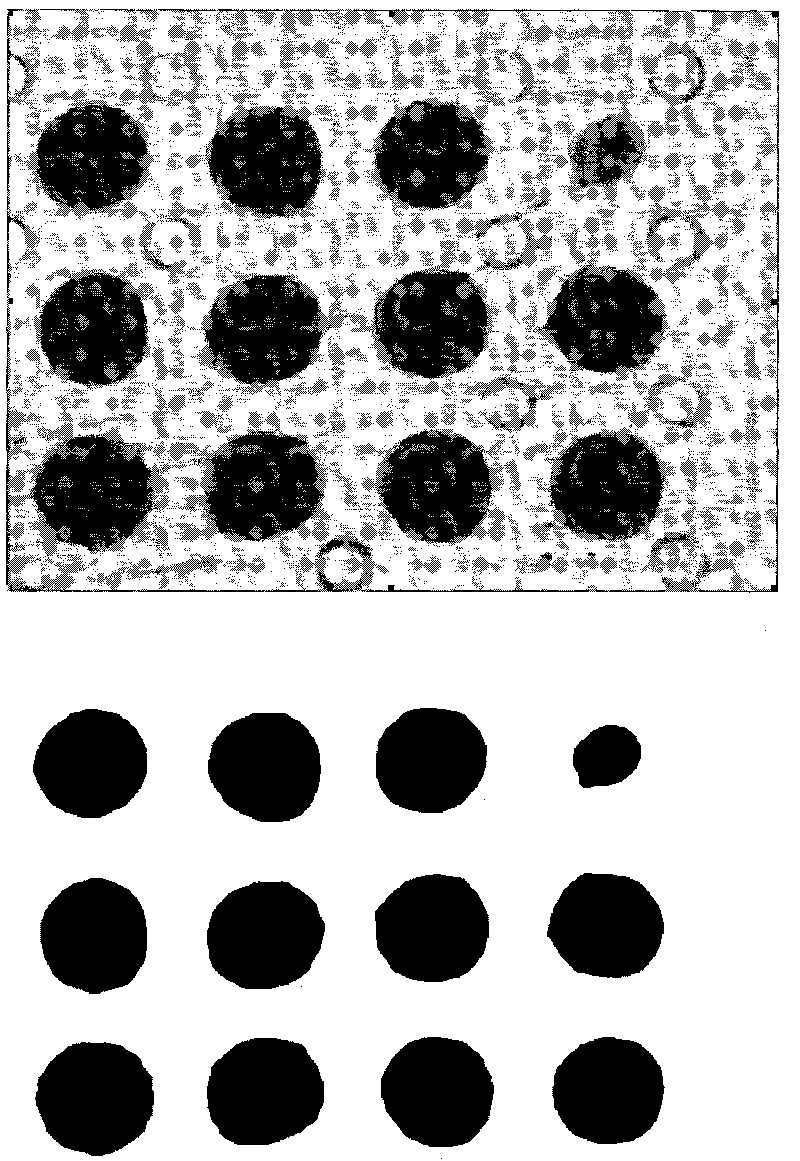

InactiveCN101706458AReduce blurReduce volumeMaterial analysis by optical meansMaterial analysis by transmitting radiationPrinted circuit boardHigh resolution

Owner:ZHONGBEI UNIV

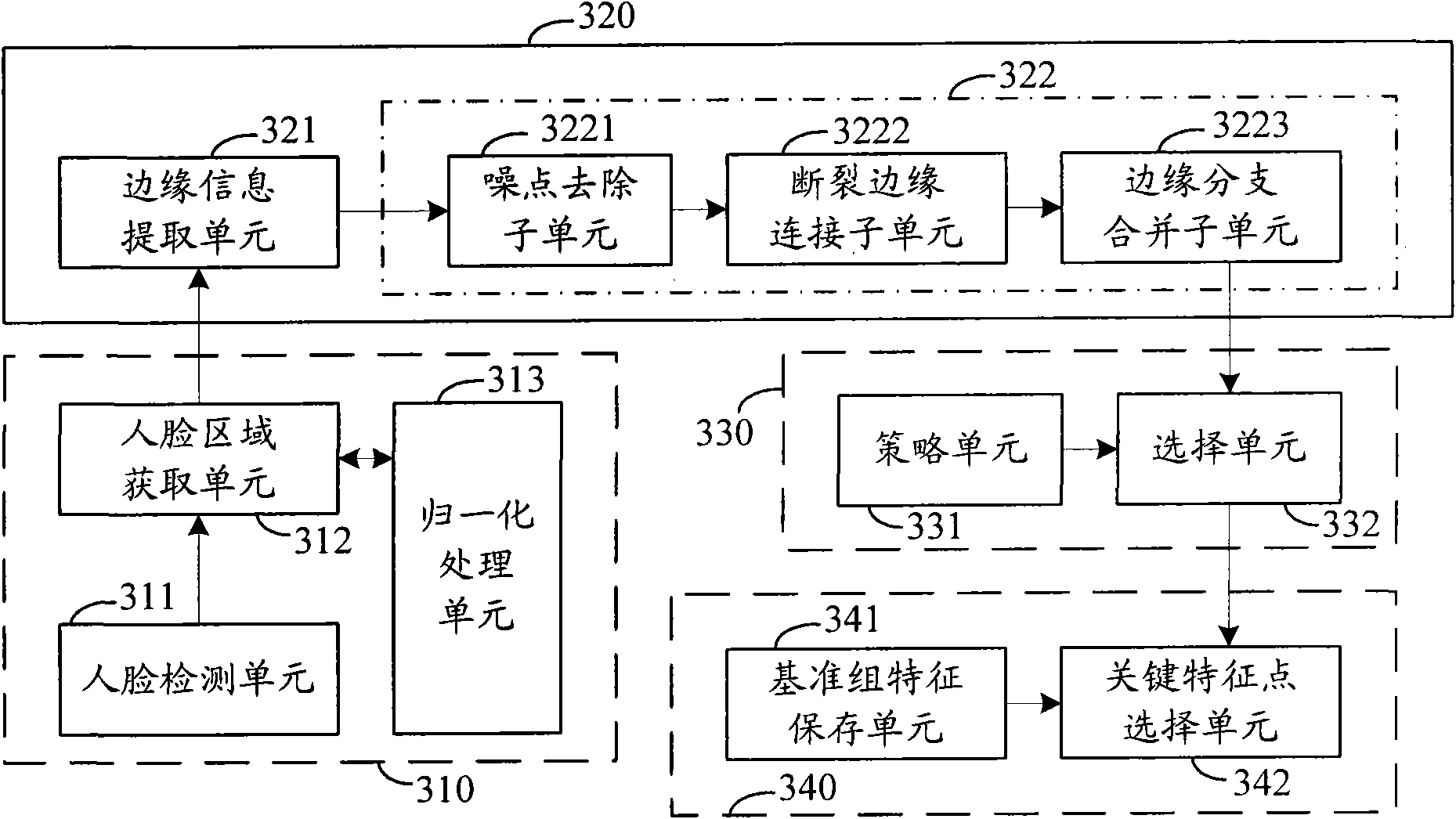

Method and device for positioning key feature point

InactiveCN101877055ARapid positioningAchieve accurate positioningCharacter and pattern recognitionPattern recognitionComputer vision

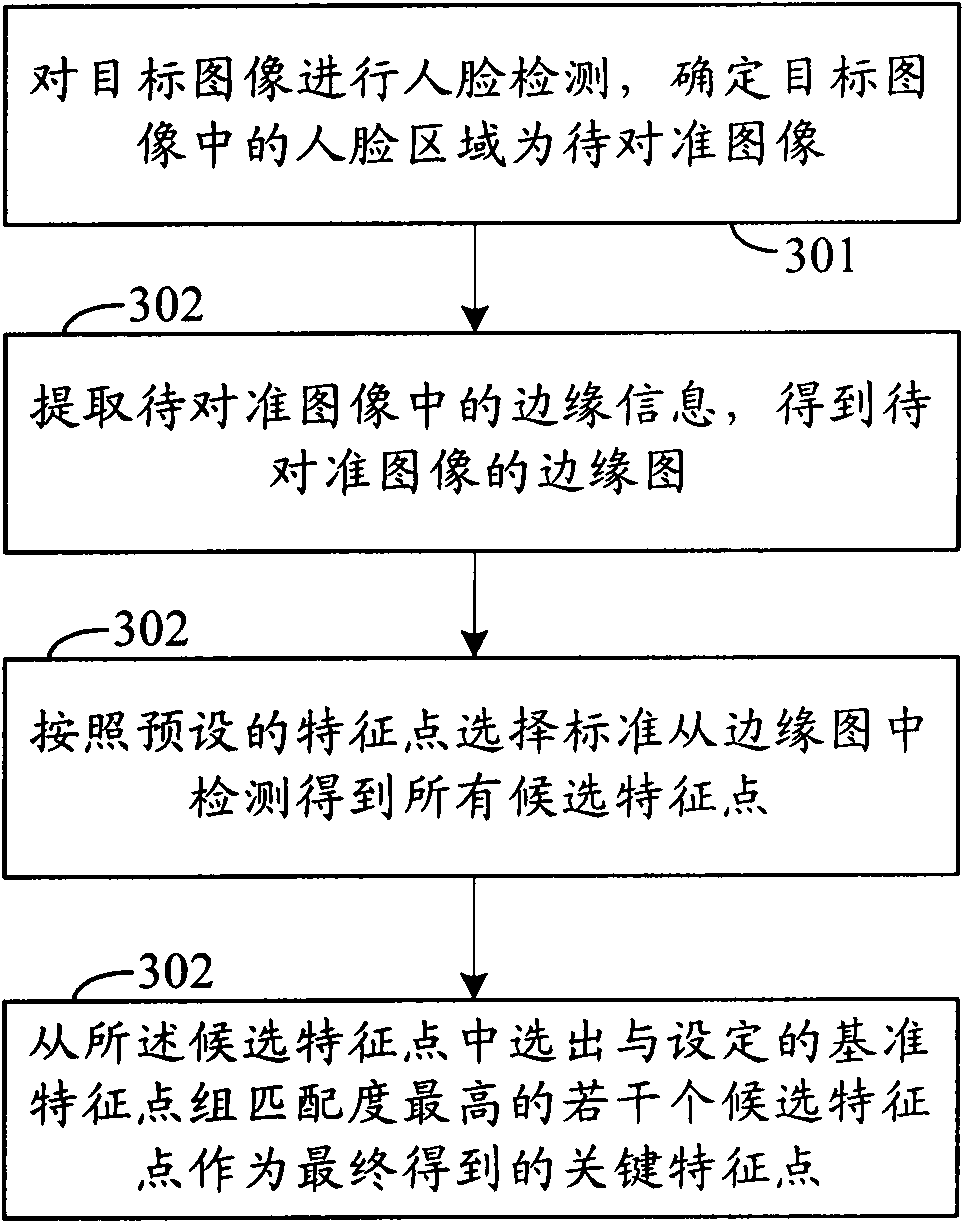

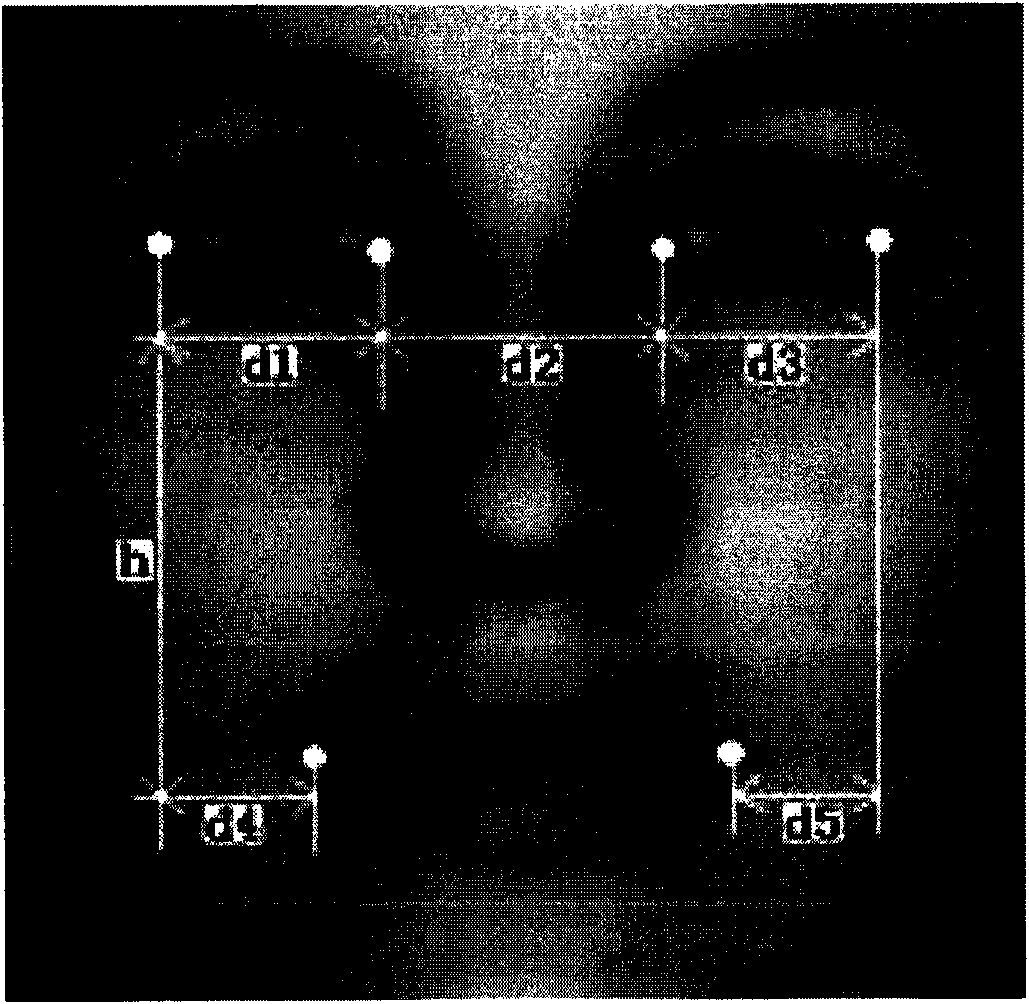

The invention discloses a method for positioning a key feature point, which comprises the following steps: detecting a face in a target image and determining the face area in the target image as an image to be aligned; extracting the edge information in the image to be aligned to obtain an edge graph of the image to be aligned; detecting all candidate feature points from the edge graph according to a pre-set feature point selecting standard; and selecting a plurality of candidate feature points with the highest match degree with a set reference feature point from the candidate feature points to serve as the finally obtained key feature points. The invention further discloses a device for positioning the key feature point, which comprises an image to be aligned determining module, an edge graph acquiring module, a candidate point determining module and a key feature point determining module. The method and device of the embodiment of the invention can accurately position the key feature point in the face area, and the algorithm of the scheme has the advantages of simplicity, small calculation amount and fast implementation.

Owner:VIMICRO CORP

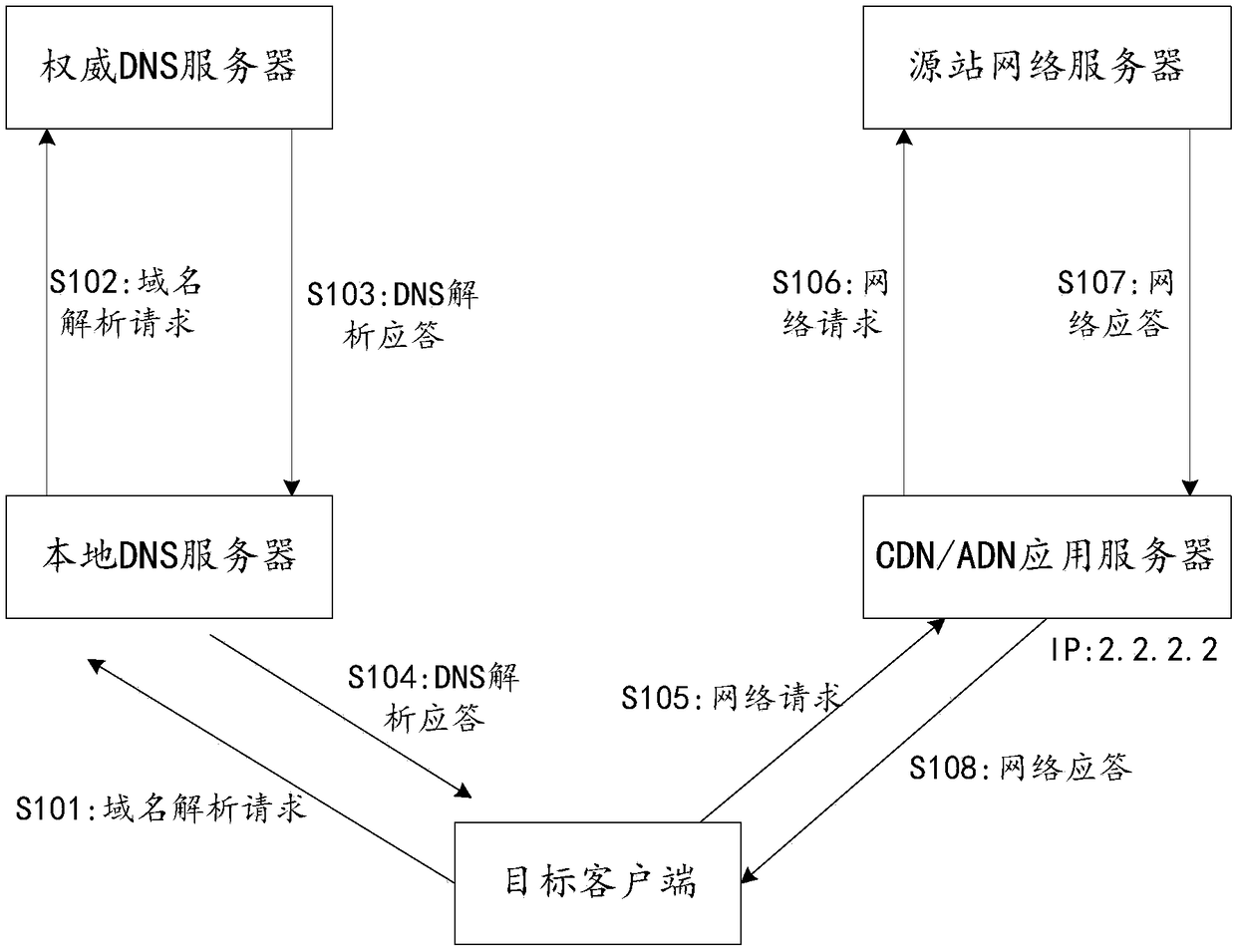

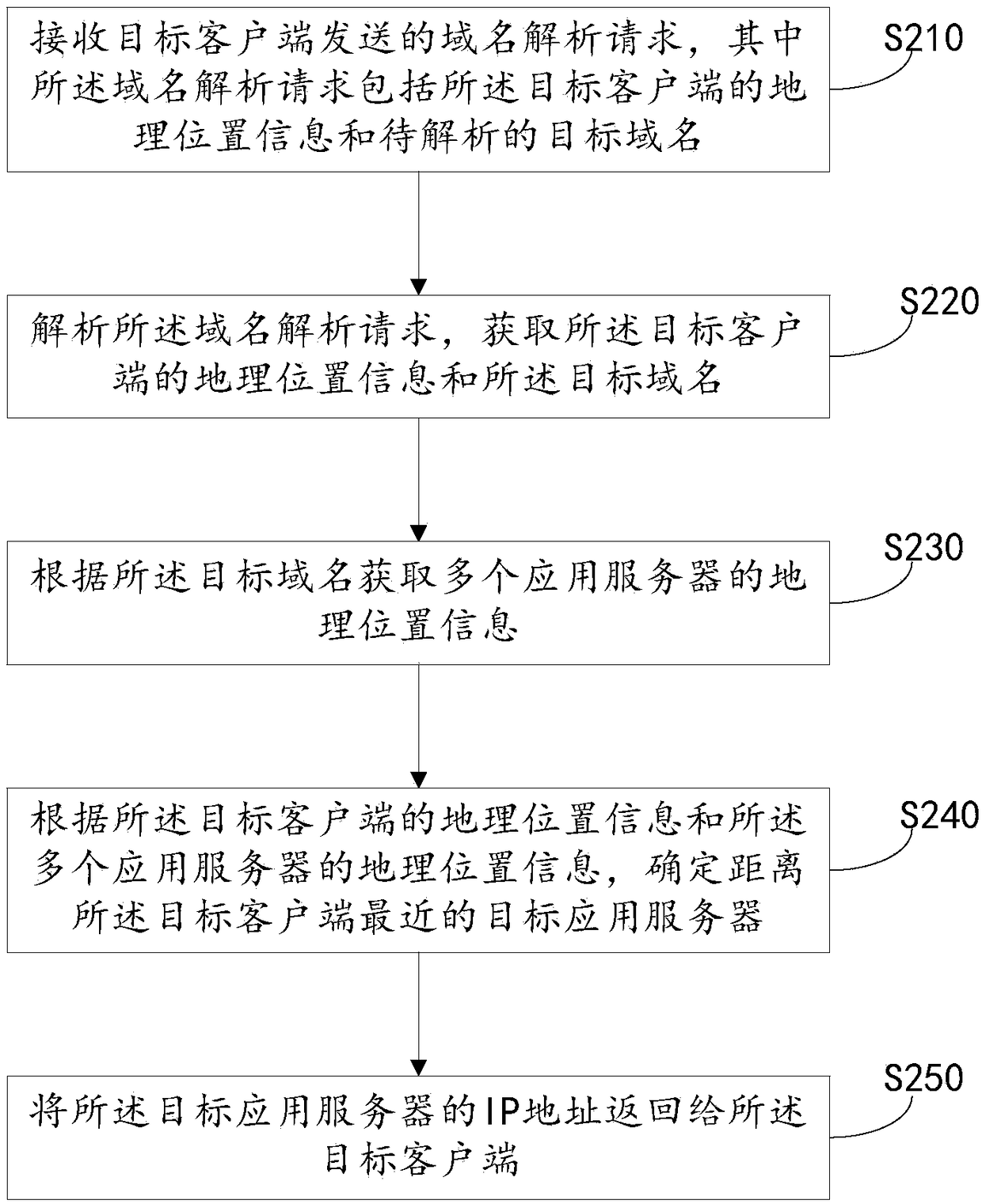

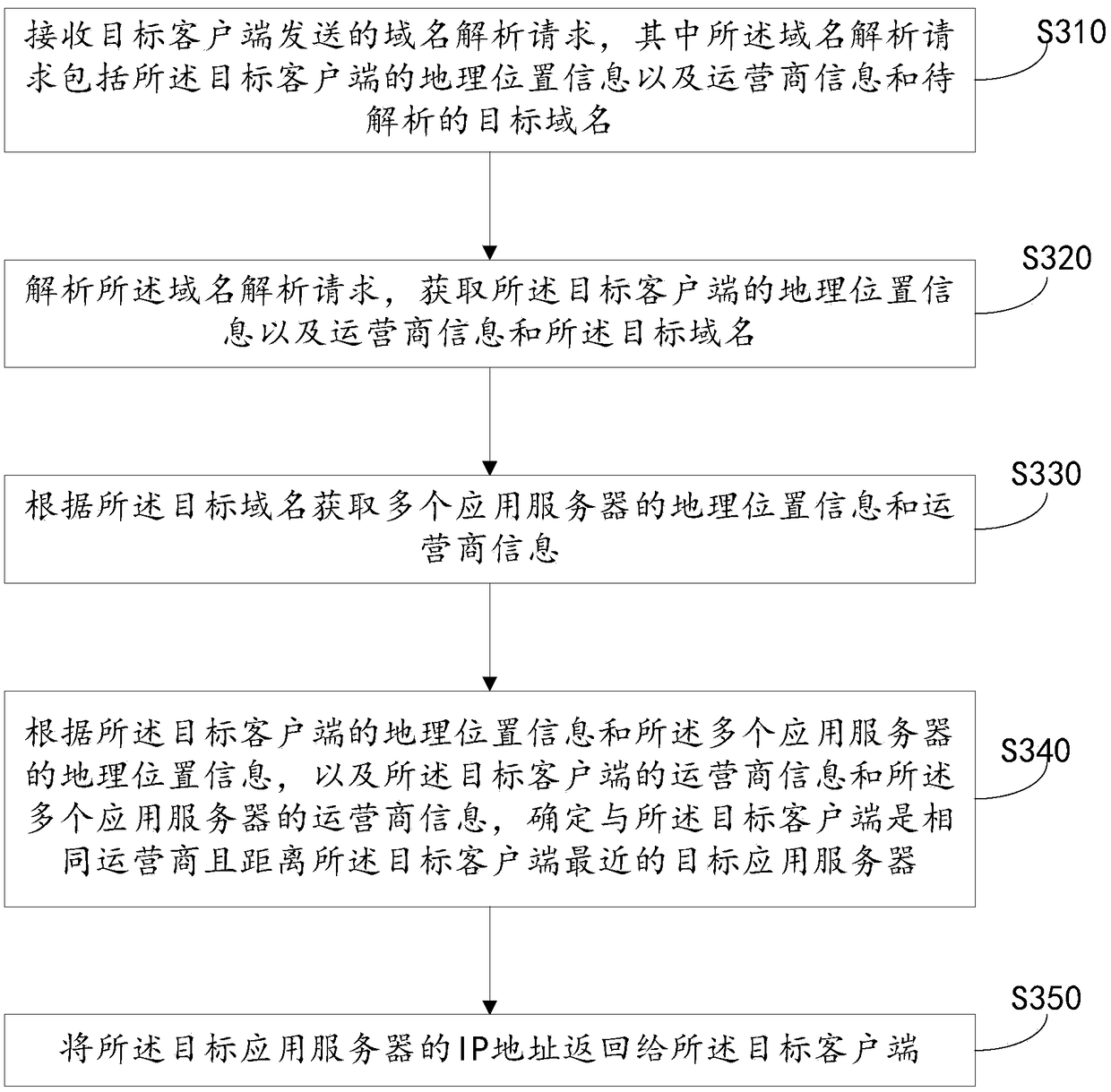

Domain name resolution method, device, computer readable storage medium and electronic device

ActiveCN109040343AHigh positioning accuracyAvoid Inaccurate PositioningTransmissionGeographic siteDomain name

The present disclosure relates to a domain name resolution method, a device, a computer readable storage medium and an electronic device. The domain name resolution method provided by the disclosed embodiment is applied to an authoritative domain name server. The method comprises the following steps: receiving a domain name resolution request sent by a target client, wherein the domain name resolution request comprises geographic position information of the target client and a target domain name to be resolved; analyzing the domain name resolution request to obtain the geographic position information of the target client and the target domain name; acquiring geographic location information of a plurality of application servers according to the target domain name; determining a target application server closest to the target client according to the geographic location information of the target client and the geographic location information of the plurality of application servers; returning an IP address of the target application server to the target client. The domain name resolution method provided by the disclosed embodiment can improve the positioning accuracy of the target client.

Owner:CLOUDMINDS BEIJING TECH CO LTD

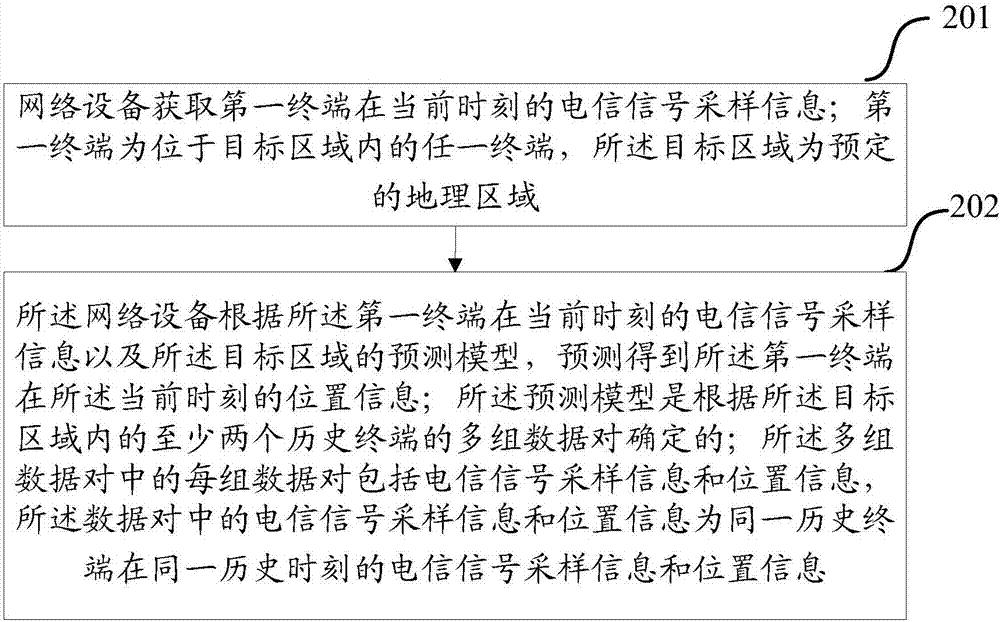

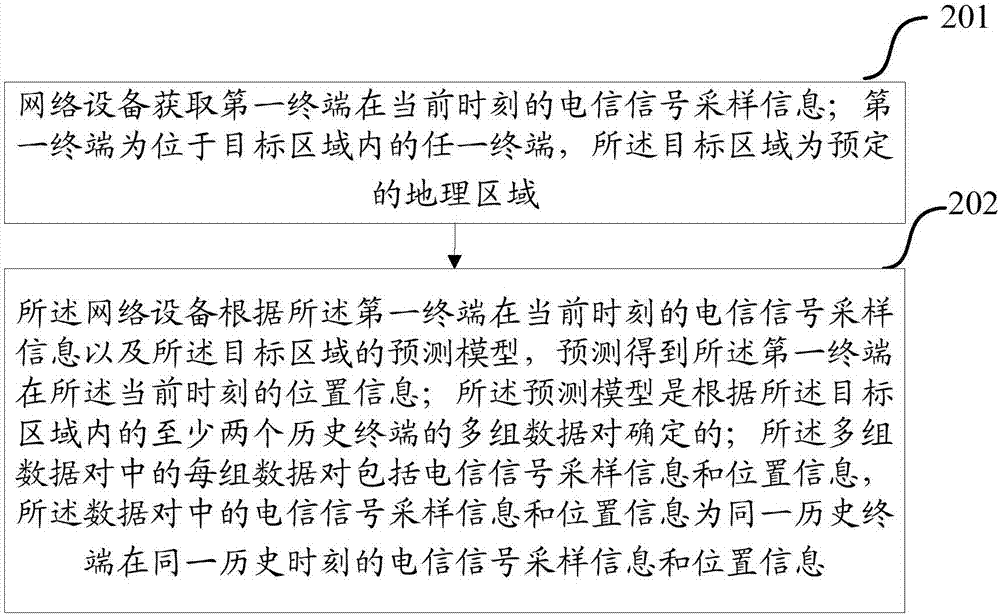

Terminal positioning method and network equipment

ActiveCN107333232AImprove accuracyReflect the relationshipPosition fixationMachine learningTelecommunicationsGeographic area

Embodiments of the invention disclose a terminal positioning method and network equipment. The terminal positioning method comprises the following steps that the network equipment obtains telecommunication signal sampling information of a first terminal at the current moment, wherein the first terminal is any terminal in a target area, and the target area is a predetermined geographic area; and the network equipment predicts to obtain location information of the first terminal at the current moment according to the telecommunication signal sampling information of the first terminal at the current moment and a prediction model of the target area. In the embodiments of the invention, the prediction model is obtained by training of mass data in the target area, the fault-tolerant capability and the error correcting capability are stronger, and the relation between the telecommunication signal sampling information and the location information of the terminal can be accurately reflected, so that the positioning can be carried out according to the prediction model and the telecommunication signal sampling information of the terminal, the accuracy of terminal positioning is effectively improved, the positioning error is reduced, and the practical value is greater.

Owner:HUAWEI TECH CO LTD

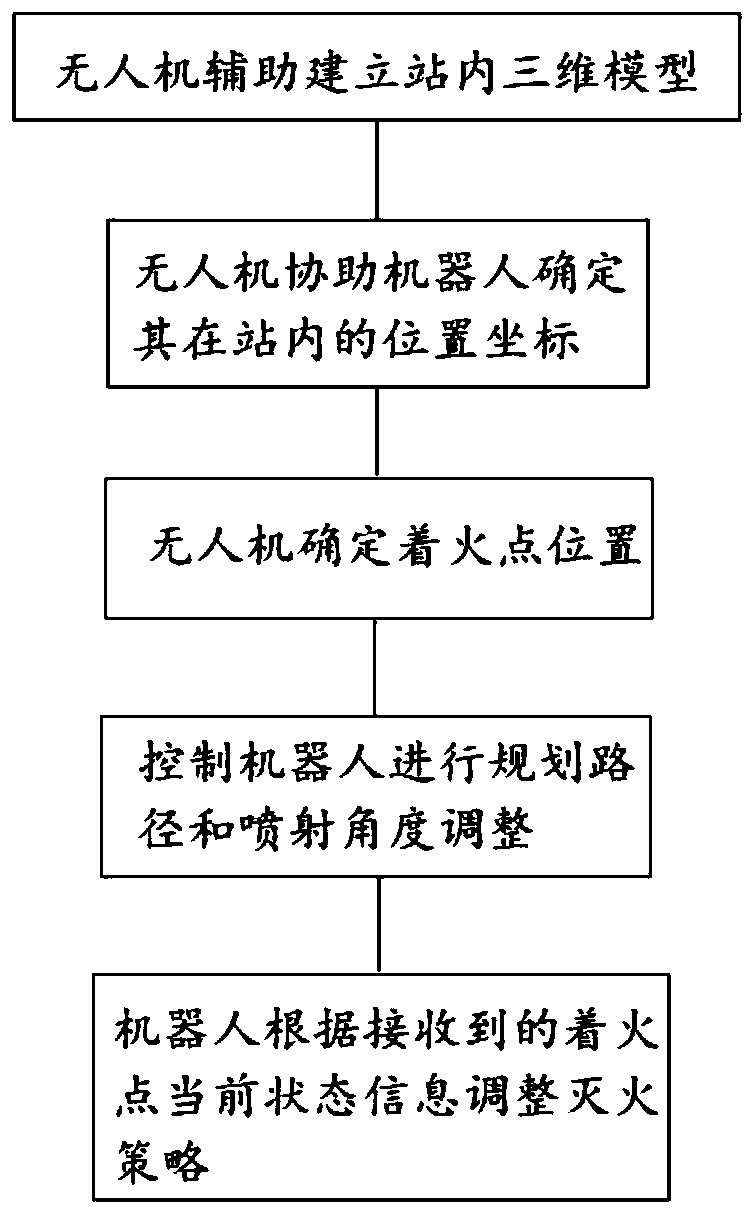

Panoramic monitoring and linking control method and system for fire-fighting robot of transformer substation

InactiveCN110898353APrecise positioningEliminate distractionsImage enhancementImage analysisControl engineeringRobot position

The invention discloses a panoramic monitoring and linking control method and system for a fire-fighting robot of a transformer substation. The panoramic monitoring and linking control method comprises the following steps: acquiring image information of different perspectives of equipment in the station through an unmanned aerial vehicle, and assisting the fire-fighting robot of the transformer substation to establish an in-station three-dimensional model; in a fire-fighting robot operation process, acquiring image information in the transformer substation in real time through the unmanned aerial vehicle, and assisting the robot to determine position coordinates, in the station, of the robot; acquiring ignition equipment image information through the unmanned aerial vehicle, and determining an ignition point position; controlling the robot to perform path planning and spray angle regulating according to the robot position and the ignition point position; in a robot operation process, acquiring ignition point position image in real time through the unmanned aerial vehicle, determining current state information of an ignition point, and transmitting the current state information to the robot, and regulating a fire-extinguishing strategy according to the received current state information of the ignition point through the robot. The panoramic monitoring and linking control methodhas the beneficial effects that: the unmanned aerial vehicle and robot equipment share data and operate in a linked mode, so that more clear field information can be obtained, more correct judgment isfavorably made, and operation effect is improved.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

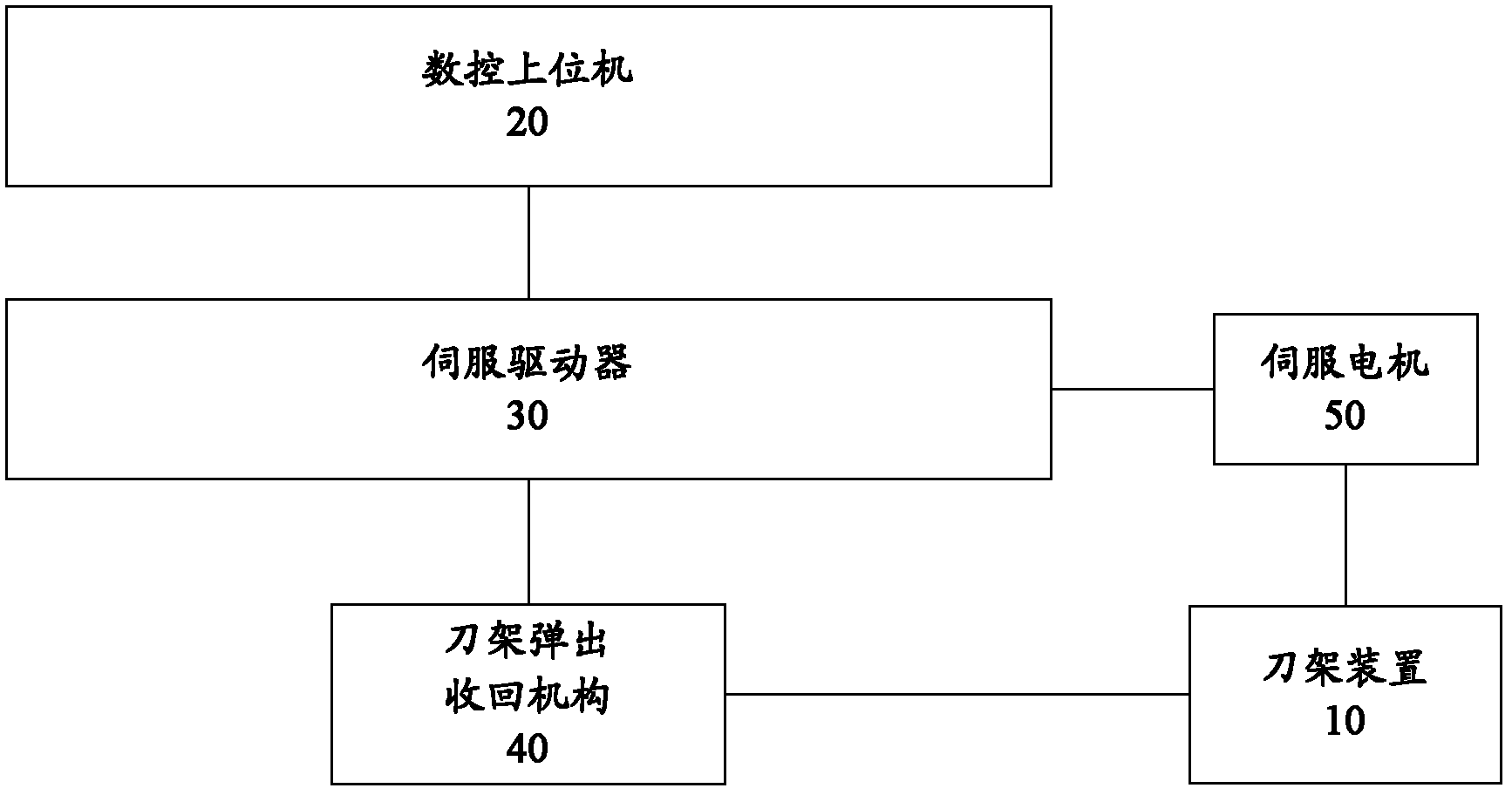

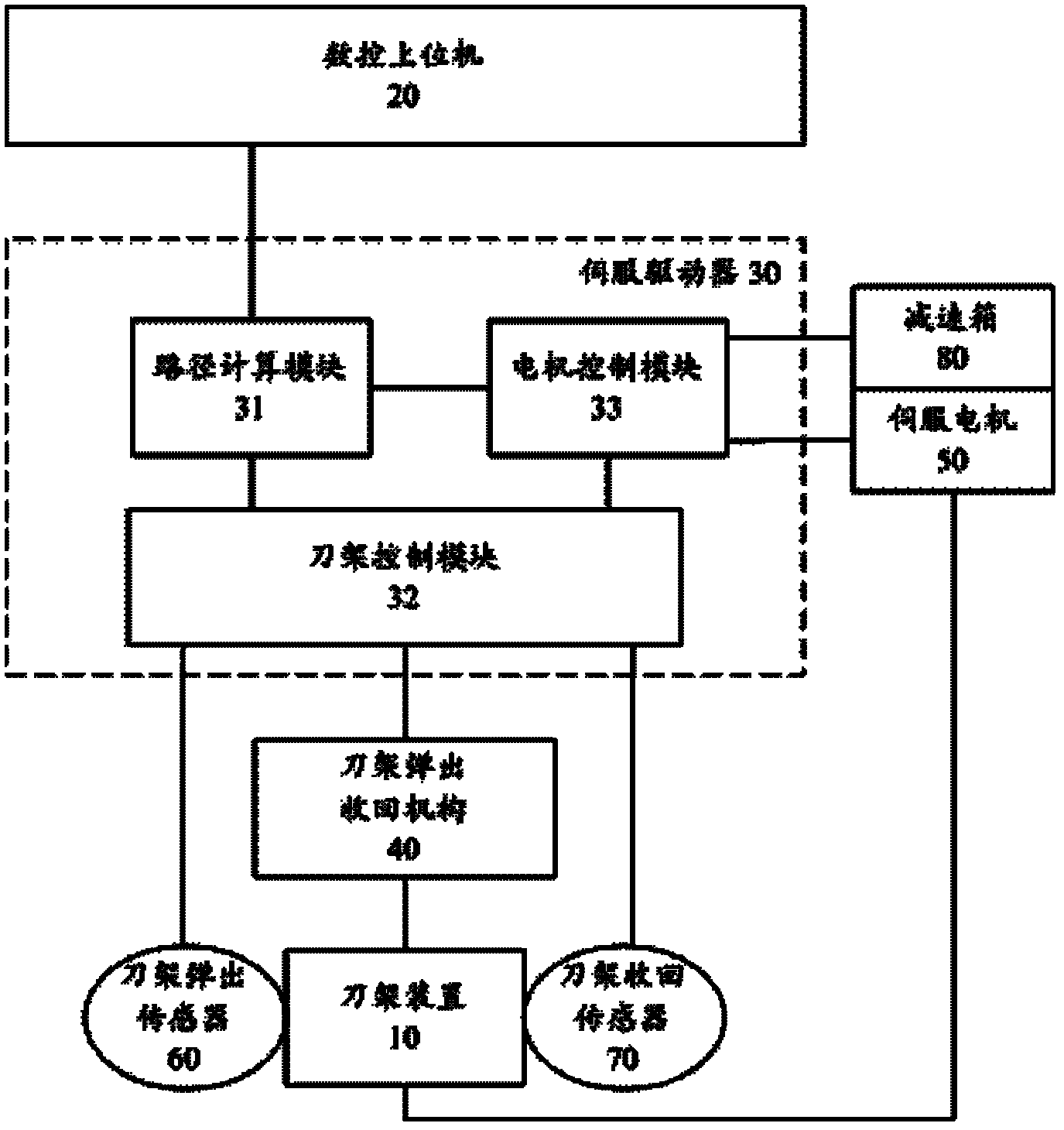

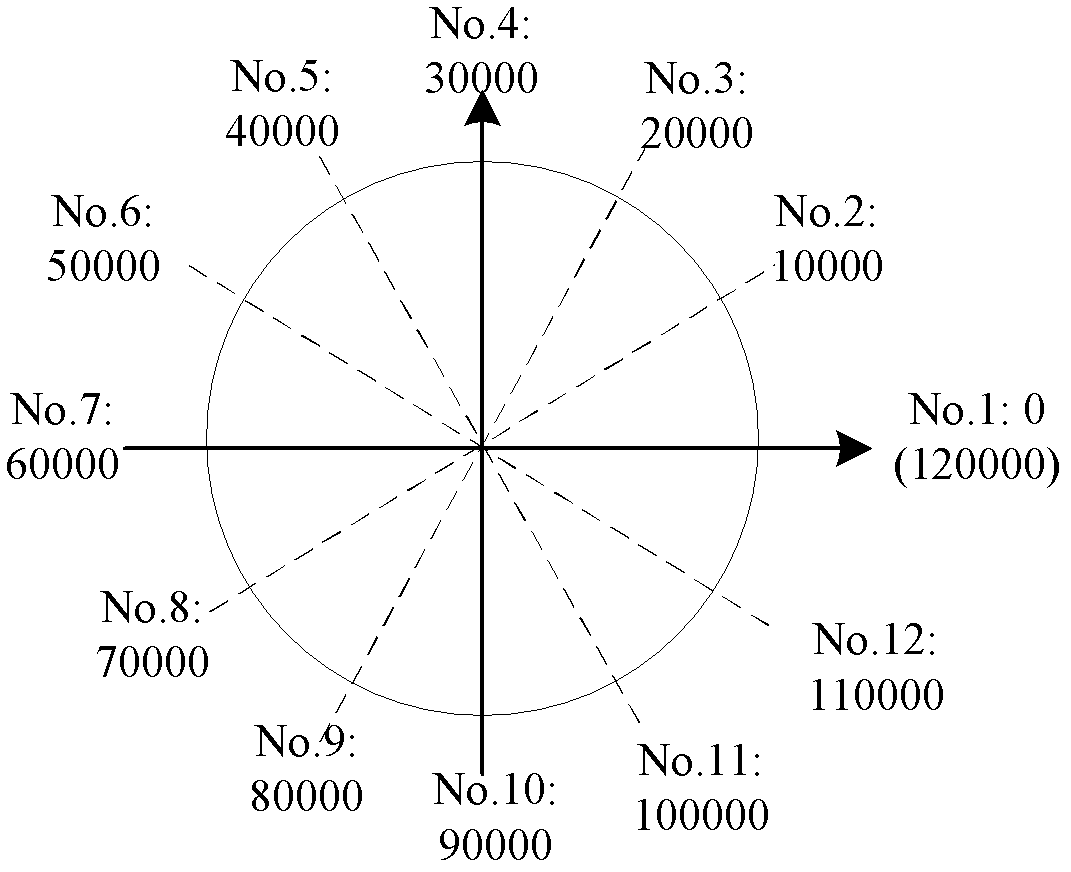

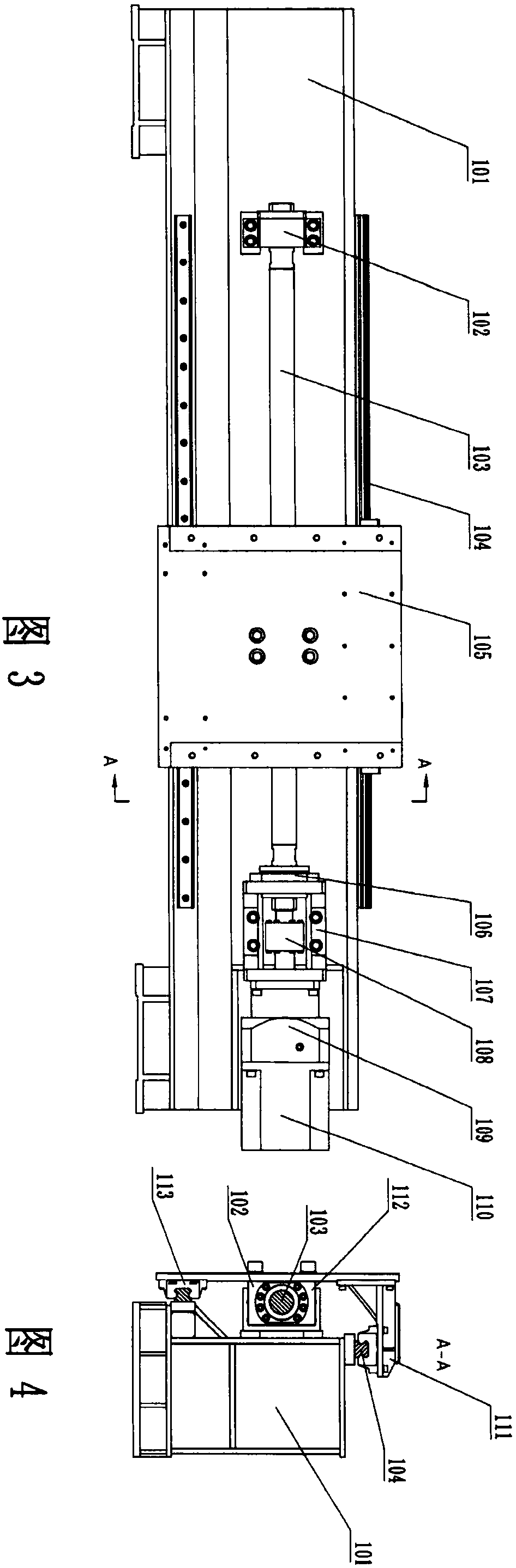

Servo drive system and servo drive method for numerically controlled tool rest

InactiveCN102621926AReduce interfaceReduce the amount of programmingNumerical controlEngineeringMotor control

The invention relates to a servo drive system and a servo drive method for a numerically controlled tool rest. The system comprises a numerically controlled upper computer, a servo driver, a tool rest popup and withdrawal mechanism, a servo motor and a tool rest device. The numerically controlled upper computer sends out tool changing orders including a target position of an appointed tool rest. The servo driver receives the tool changing orders, calculates the rotation direction and distance of the tool rest according to the current position and the target position of the tool rest, controls the tool rest popup and withdrawal mechanism to pop up the tool rest and generate motor control signals to the servo motor so as to control the tool rest to rotate to the target position, and controls the tool rest popup and withdrawal mechanism to withdraw the tool rest. The servo driver of the servo drive system directly receives the tool changing orders to generate internal position orders instead of receiving the pulse-form orders generated by the numerically controlled upper computer, so that inaccuracy in positioning caused by loss of pulse orders can be avoided. Further, programming quantity of the numerically controlled upper computer is reduced, and a tool rest controller is omitted.

Owner:SUZHOU INOVANCE TECH CO LTD +1

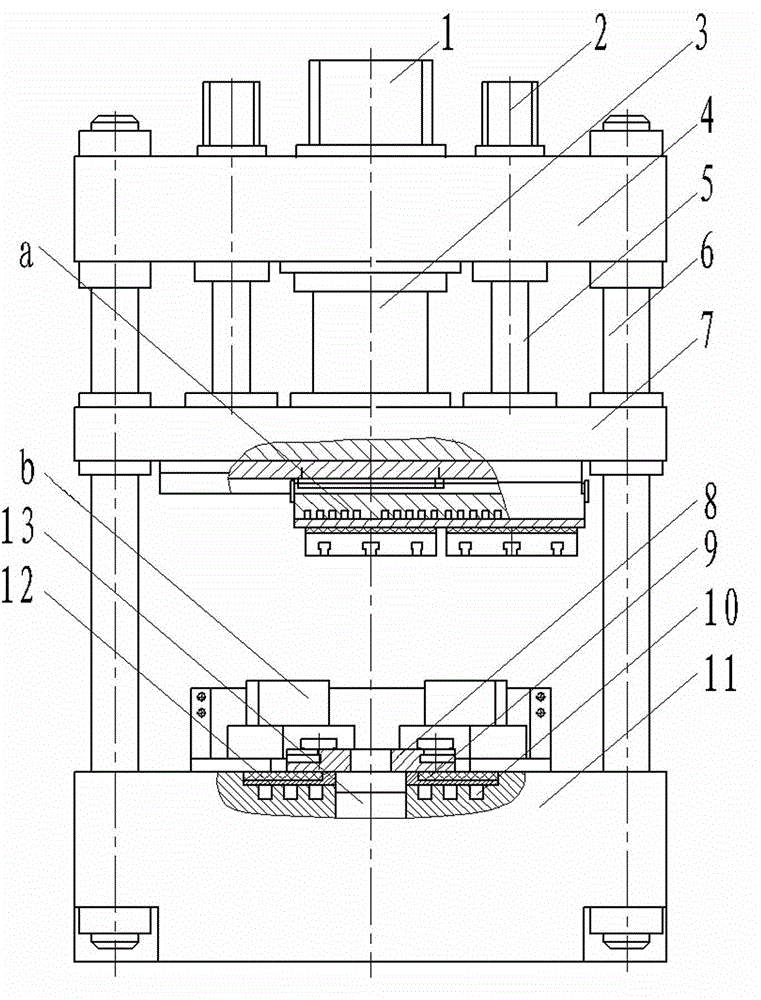

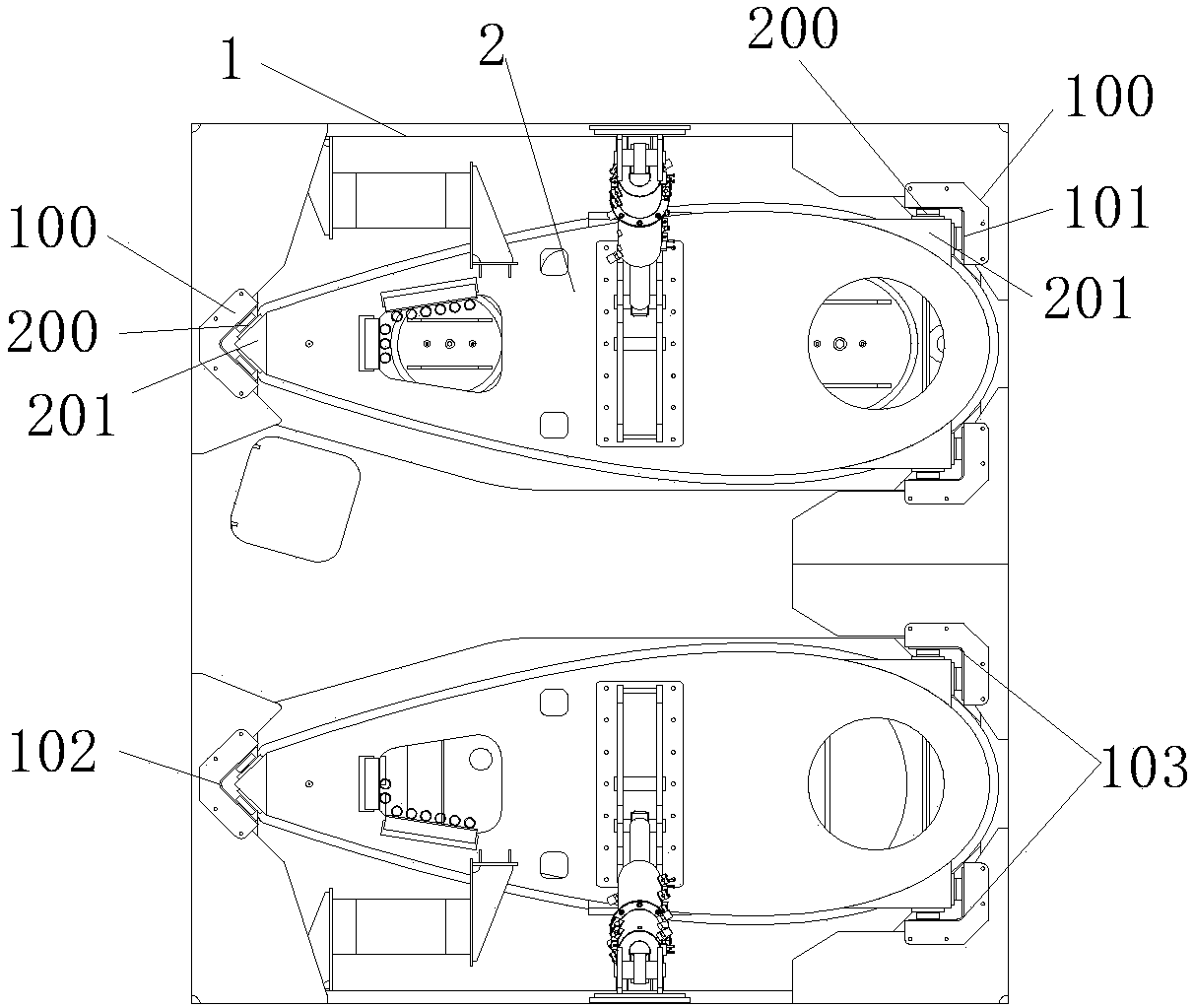

Compound plastic forming equipment, die transposition mechanism thereof and positioning method for die transposition mechanism

ActiveCN104647038AAvoid leaningHigh precision productsShaping toolsExtrusion diesEngineeringMechanical engineering

The invention relates to compound plastic forming equipment, a die transposition mechanism thereof and a positioning method for the die transposition mechanism. The compound plastic forming equipment comprises the die transposition mechanism; the die transposition mechanism comprises a fixed part and a movable part which is in director motion relative to the fixed part; a positioning device used for enabling the fixed part and the movable part to be positioned along the direction of the director motion is arranged between the fixed part and the movable part, and a locking device used for enabling the fixed part and the movable part to be in force fit along the jacking direction of a die is also arranged between the fixed part and the movable part; the movable part can be positioned on the fixed part along the direction of the director motion through the positioning device, so the positioning accuracy in the direction of the director motion is improved; the movable part and the fixed part can be in force fit along the jacking direction of the die through the locking device, so the die can be prevented from inclining during die assembly, and while the product accuracy is improved, the phenomenon that positioning is inaccurate due to the fact that the die inclines during the die assembly under the condition that the die is only positioned by the positioning device can be avoided, and the manufacturing accuracy and the product quality can be helped to increase.

Owner:江苏宗颐新材料科技有限公司

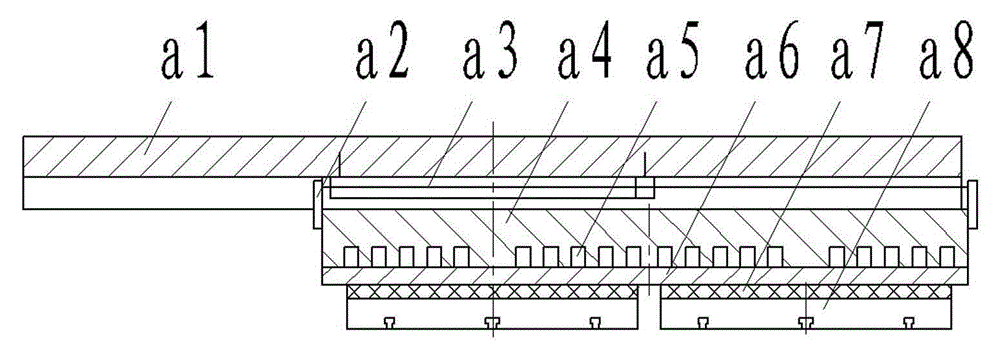

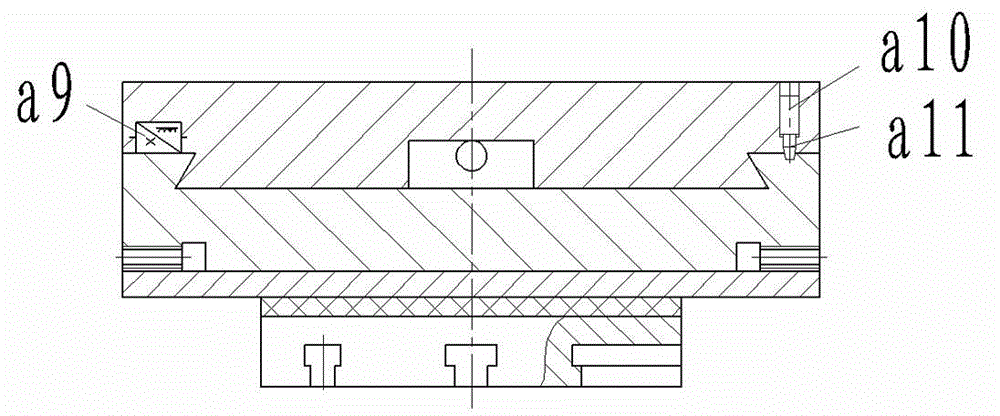

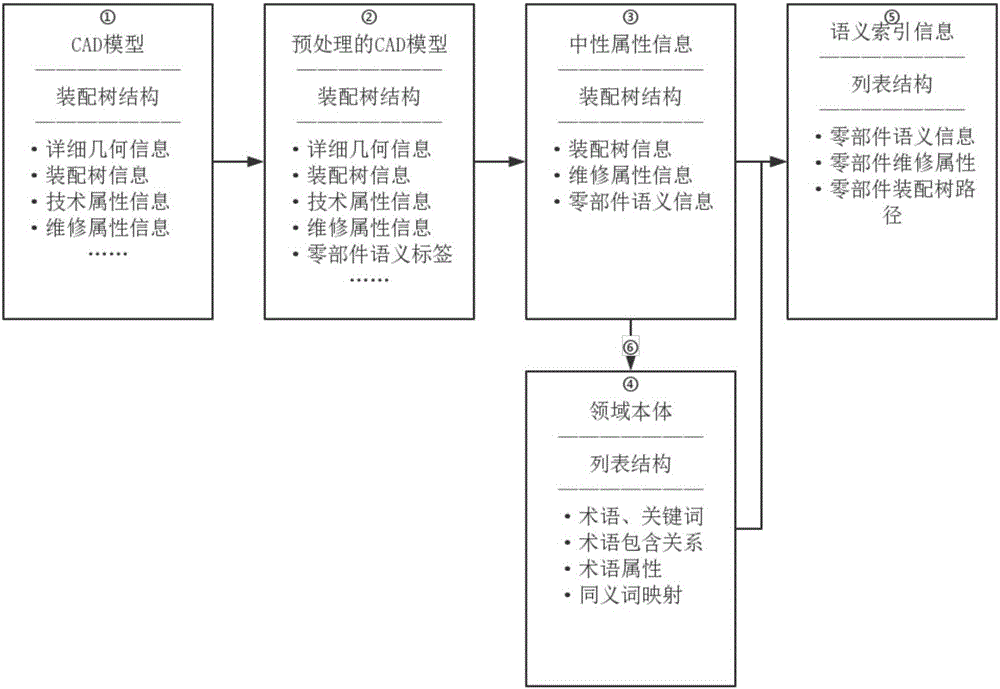

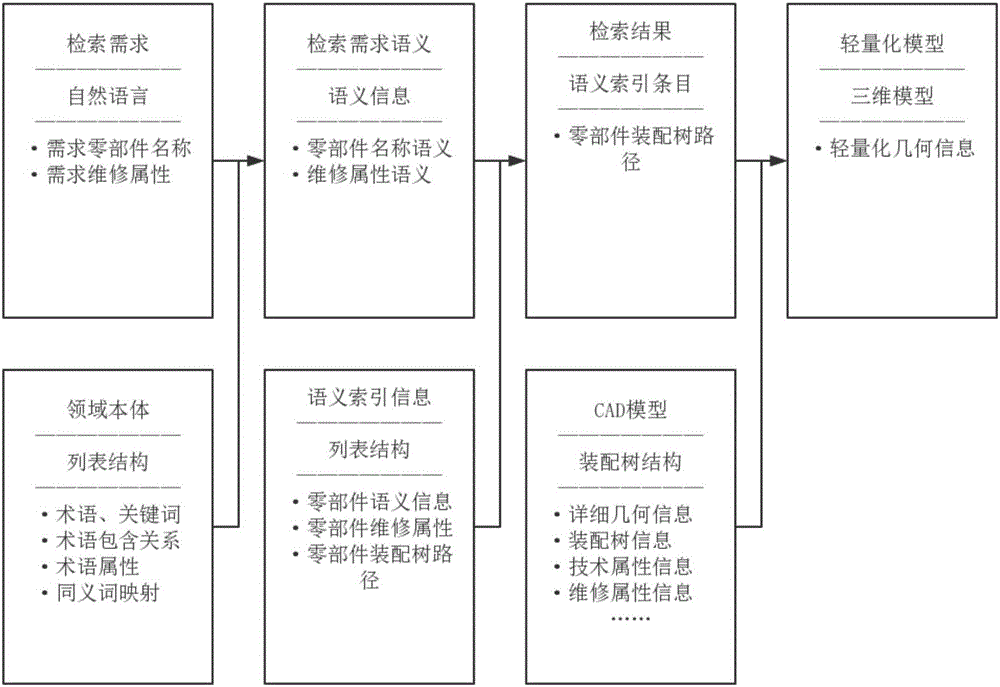

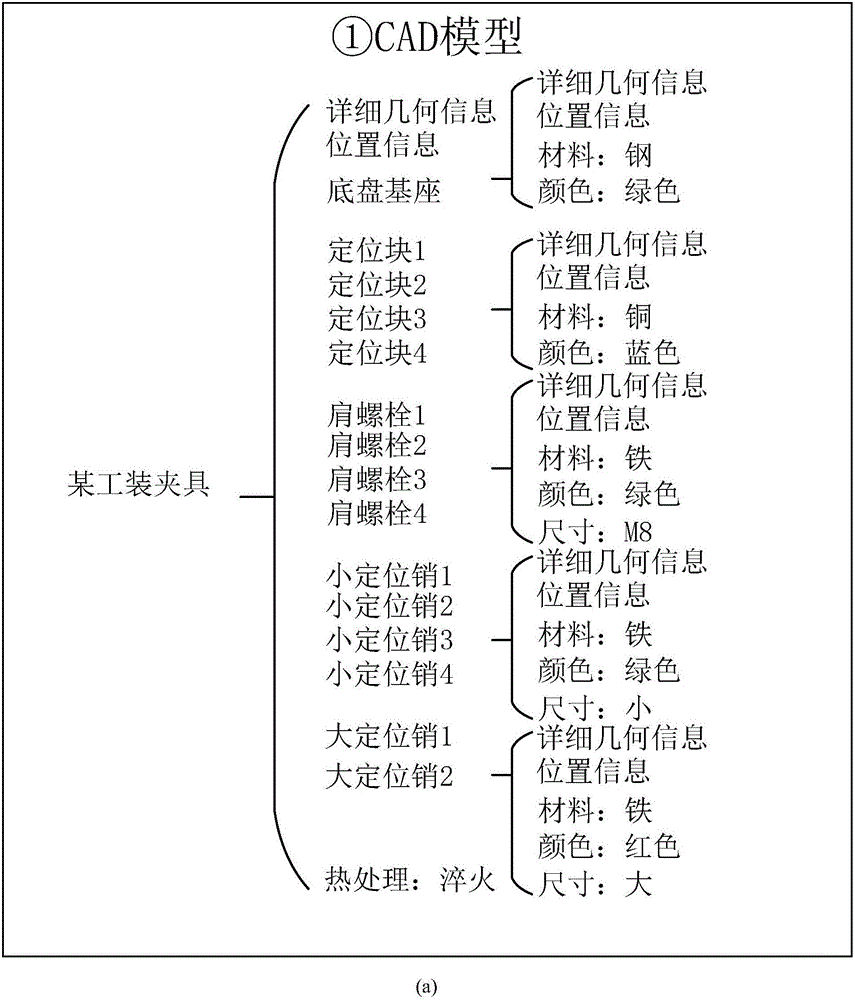

Quick positioning and display method for key components in maintenance geometry model based on ontology

ActiveCN106649988AAvoid Inaccurate PositioningAvoid duplication of workDesign optimisation/simulationSpecial data processing applicationsData miningAnnotation

The invention provides a quick positioning and a display method for key components in maintenance geometry model based on ontology. Firstly, a product CAD model is used as the information source, and some preprocessing is carried out to obtain and store the product assembly tree information and attribute information of each component. Simultaneously a corresponding ontology list is established as the terminology standard and reasoning standard. According to the established ontology, the attribute information contained in the CAD model is semantically labeled and corresponding to the assembly tree structure, and the annotation result is recorded into the semantic index information. Finally, the annotated semantic index information is retrieved by applying ontology and ontology reasoning method to obtain the assembly tree location of the target component. The 3D model of CAD is transformed into a lightweight model, and the corresponding relationship between the lightweight model and the original model is established through the assembly tree information. The lightweight model of transformation is applied to quick positioning and display. The quick positioning and the display method for key components in maintenance geometry model based on ontology provide a method of quick positioning of key components in to be maintained in the lightweight model of maintenance for digital maintenance.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

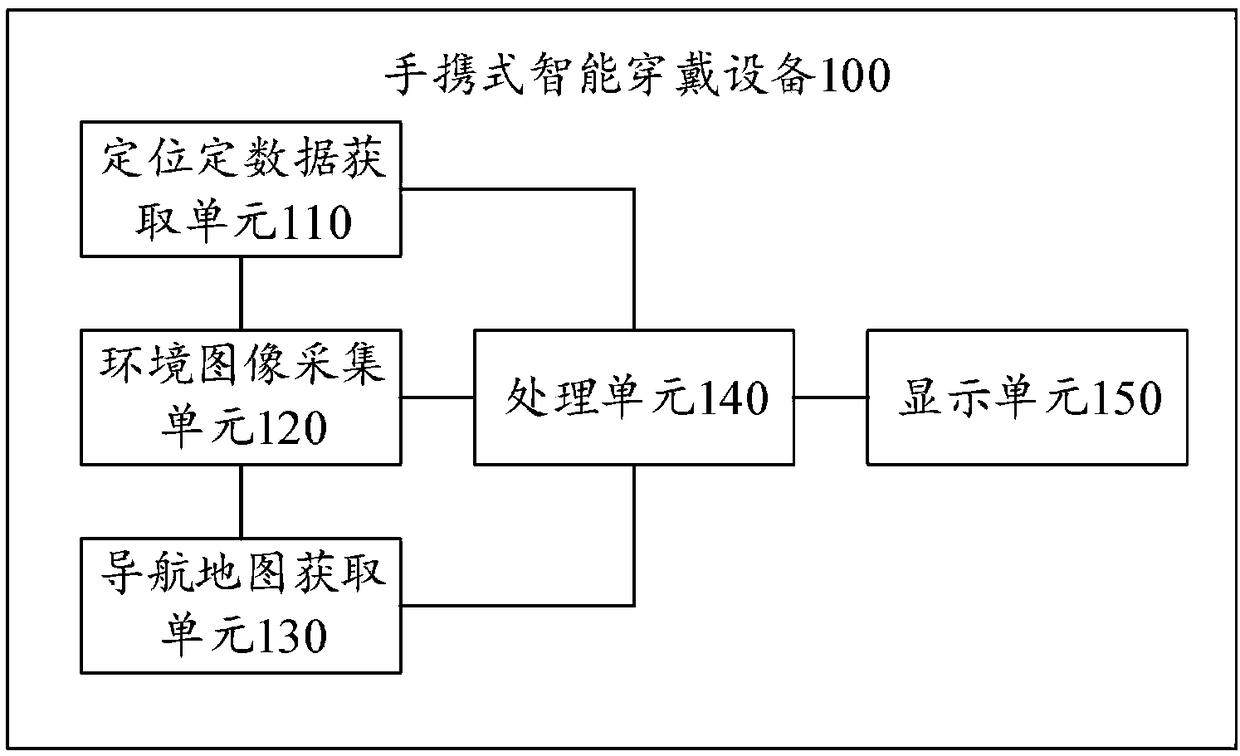

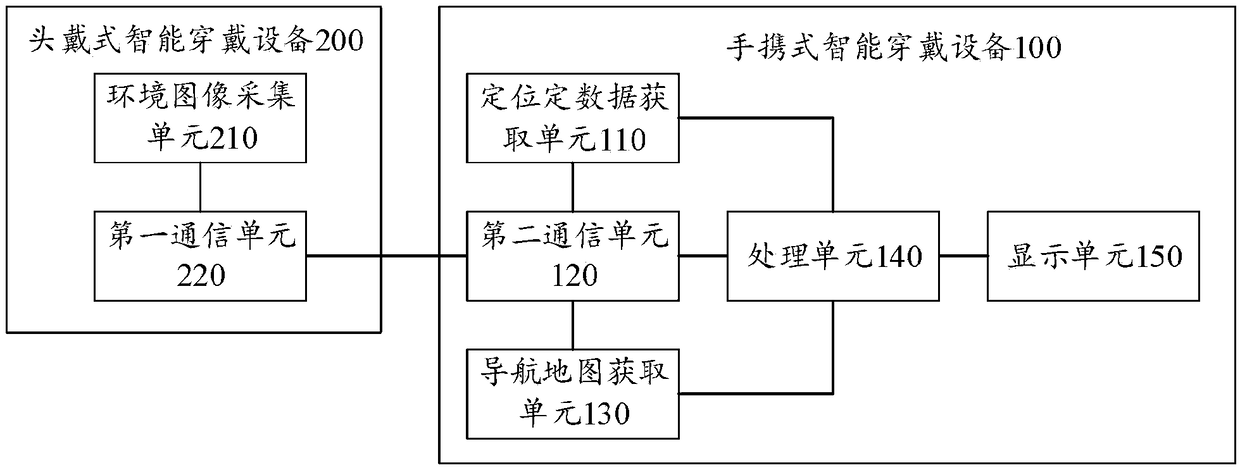

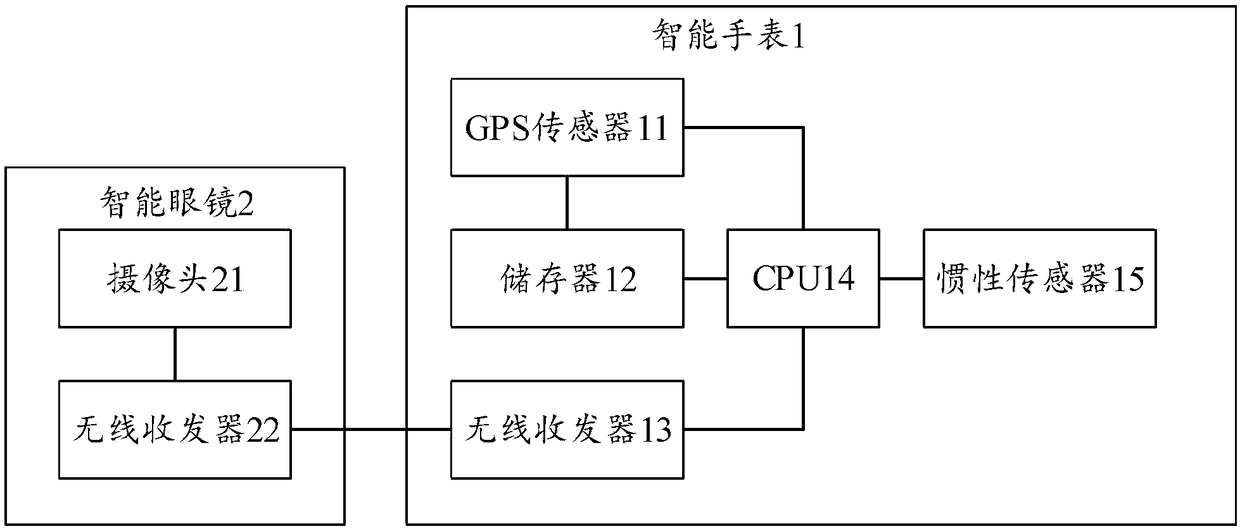

Location method and system, and handheld intelligent wearing device

InactiveCN108957505AAvoid Inaccurate PositioningThe positioning result is accurateSatellite radio beaconingComputer graphics (images)Computer vision

The present invention provides a location method and system, and a handheld intelligent wearing device. The method comprises the steps of: obtaining GPS location data and motion state data of a handheld location device, and obtaining environment image data and a navigation map, wherein the GPS location data, the motion state data and the environment image data comprise time stamps; matching the environment image data corresponding to the current moment with the navigation map to obtain a first position of a user at the current moment; and according to the first position, performing fusion operation of the GPS location data and the motion state data to determine the orientation location information corresponding to the current moment. The location method and system, and the handheld intelligent wearing device can improve the location accuracy through combination operation of the environment image data.

Owner:PHICOMM (SHANGHAI) CO LTD

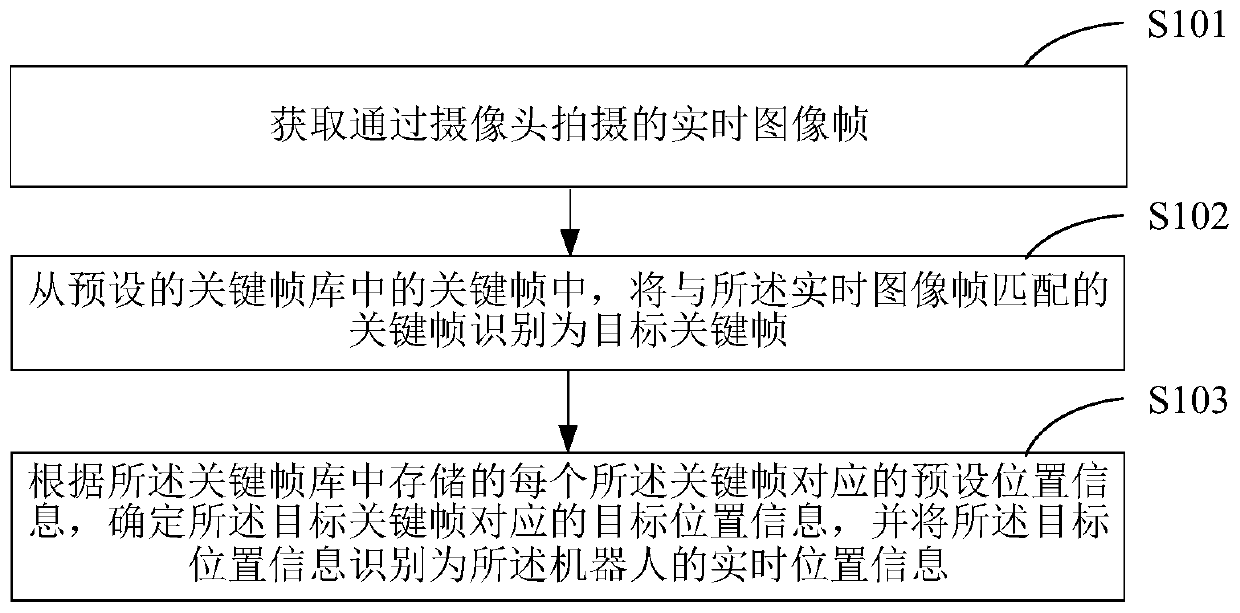

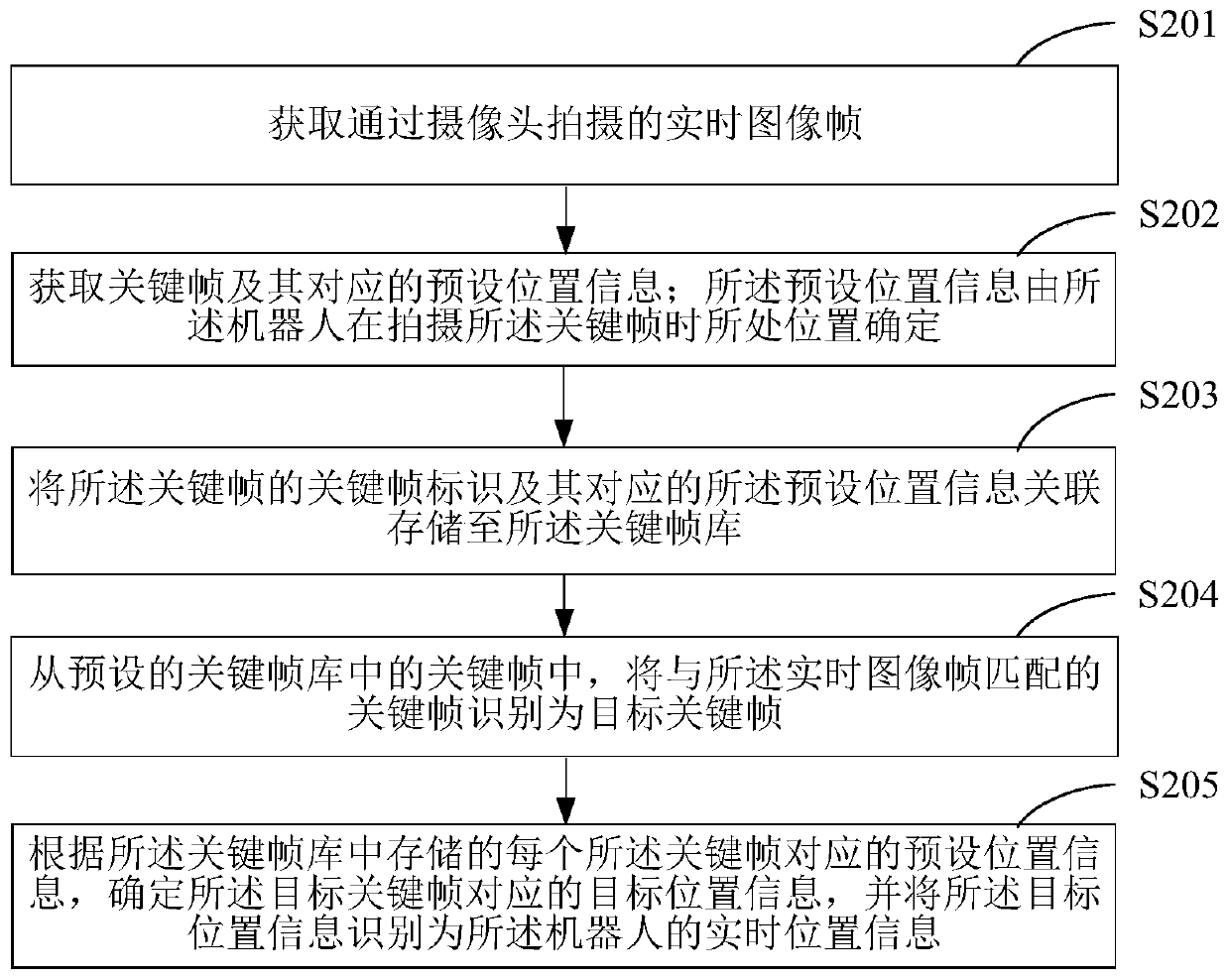

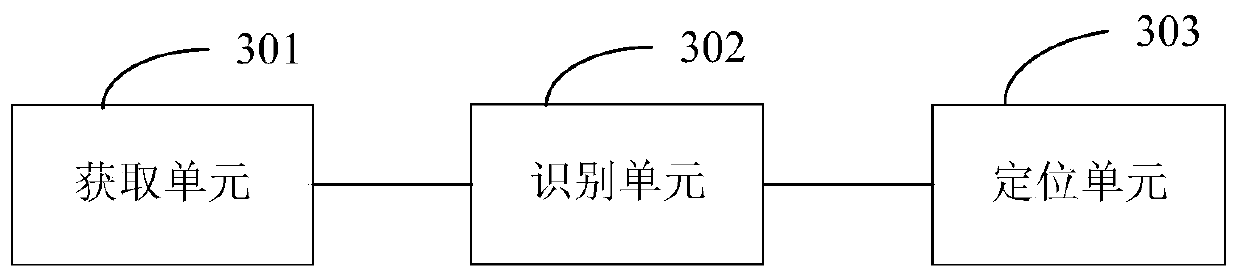

Laser radar re-positioning method and robot

ActiveCN110561416AHigh precisionImprove reliabilityProgramme-controlled manipulatorRadarNo reference

The invention is applicable to the technical field of computer application, and provides a laser radar re-positioning method and a robot. The laser radar re-positioning method comprises the steps of comparing real-time image frames shot in real time with key frames in a preset key frame library, determining target key frames matched with the real-time image frames, and then determining real-time position information corresponding to the target key frames according to the corresponding relationship between position information preset in the key frame library and the key frames. By means of thelaser radar re-positioning method and the robot, the situation that positioning is inaccurate since reference substances are lacked when the position is determined through synchronous positioning andmapping, and the positioning accuracy and reliability of the robot are improved.

Owner:SHENZHEN SILVER STAR INTELLIGENT TECH CO LTD

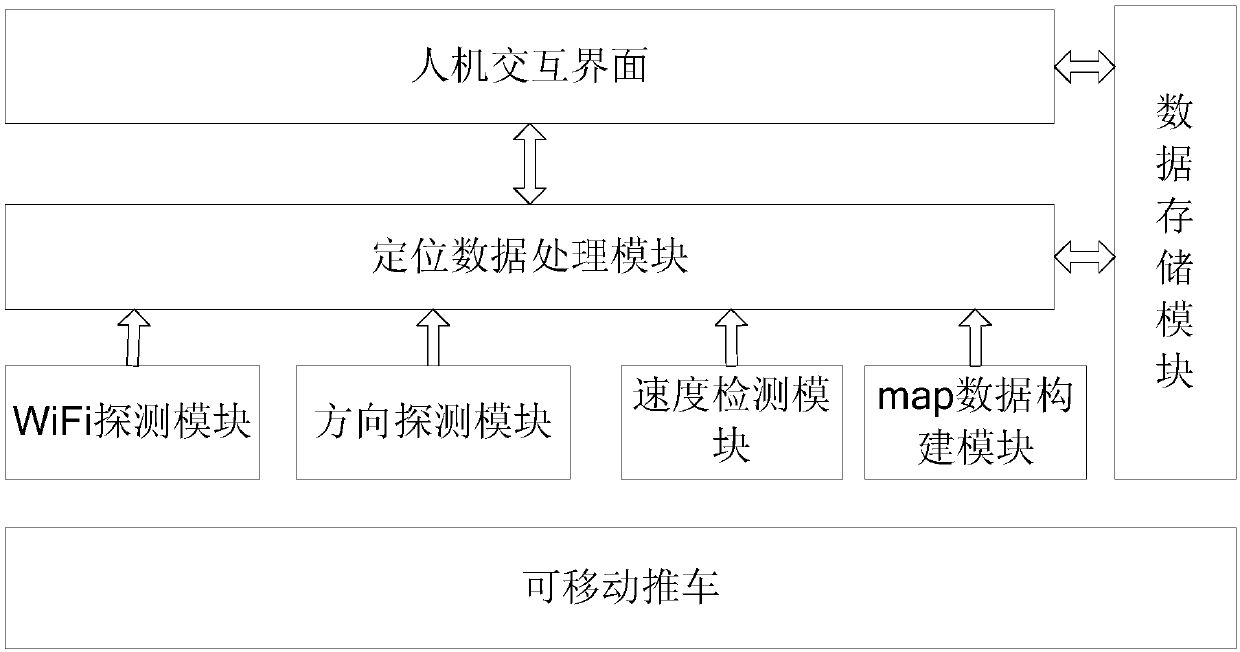

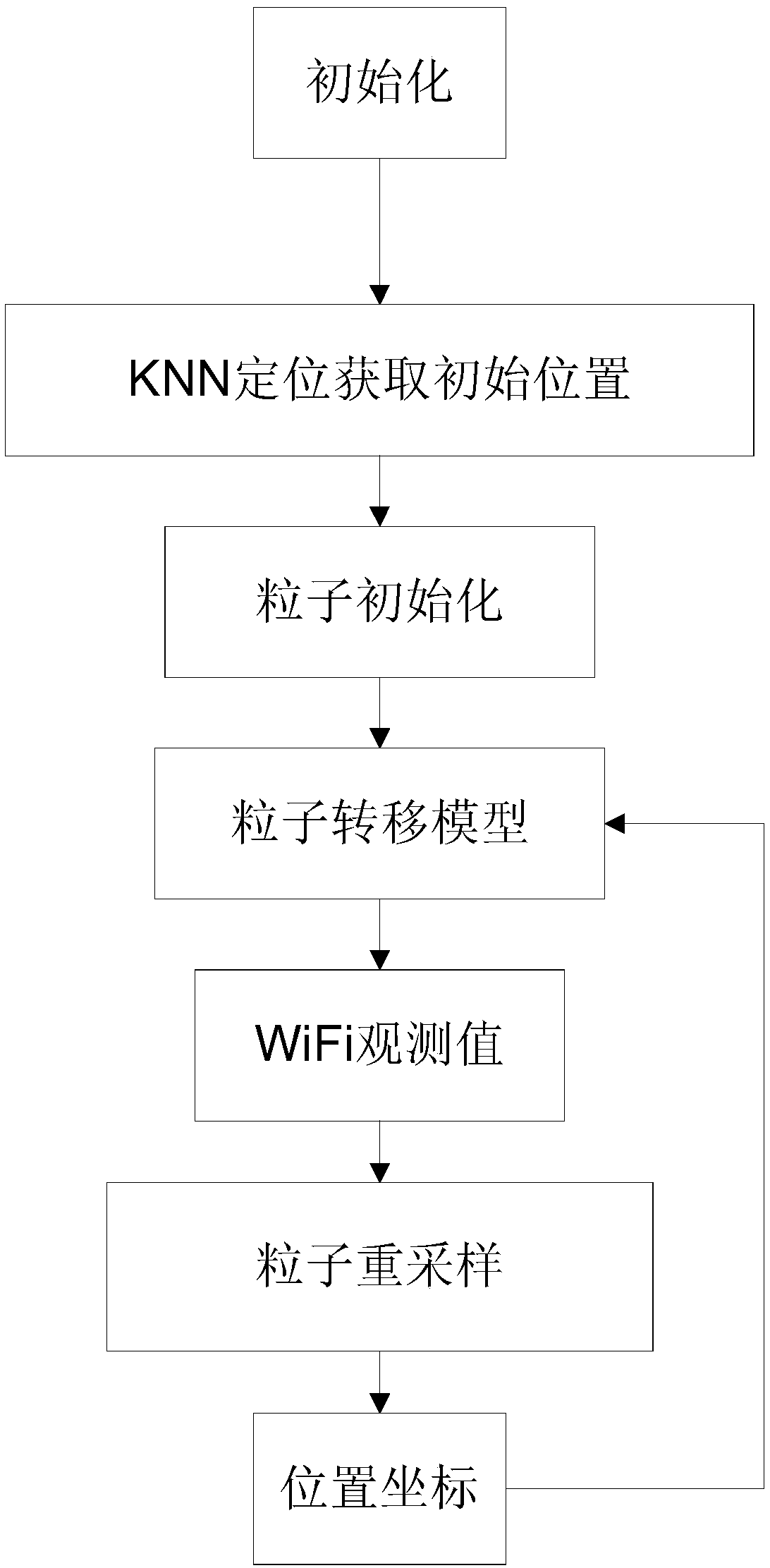

Indoor positioning navigation trolley system based on WiFi, and positioning method thereof

ActiveCN107063251AReduce direct dependenceAvoid Inaccurate PositioningNavigational calculation instrumentsReal Time KinematicInteraction interface

The invention discloses an indoor positioning navigation trolley system based on WiFi, and a positioning method thereof. The indoor positioning navigation trolley system comprises a movable trolley, a human-computer interaction interface, a speed detection module, a direction detection module, a WiFi detection module, a positioning data processing module, a map data construction module and a data storage module. The positioning method comprises that when a pedestrian pushes the movable trolley to walk in a room, the speed detection module and the direction detection module acquire the real-time movement information of the movable trolley; and the relative position of the movable trolley is continuously acquired in an iterated manner according to the movement information while online position prediction is performed by using a particle filter technology, and finally the real-time position of the movable trolley is calculated. According to the present invention, with the indoor positioning navigation trolley system and the positioning method, the indoor dynamic positioning navigation precision can be effectively improved, and the system and the method are suitable for the positioning service for the large-area and complex-environment indoor mobile device.

Owner:SOUTH CHINA UNIV OF TECH

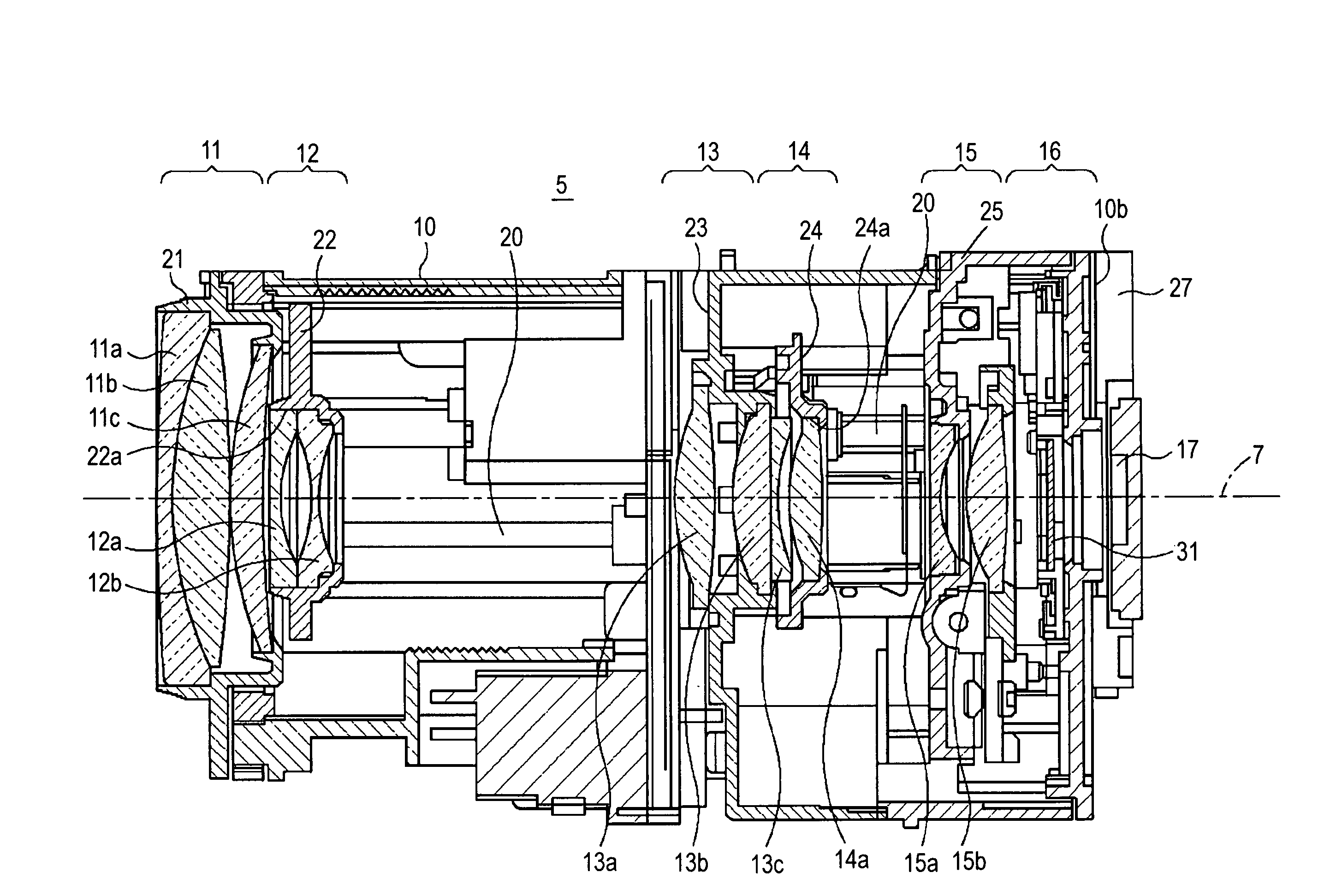

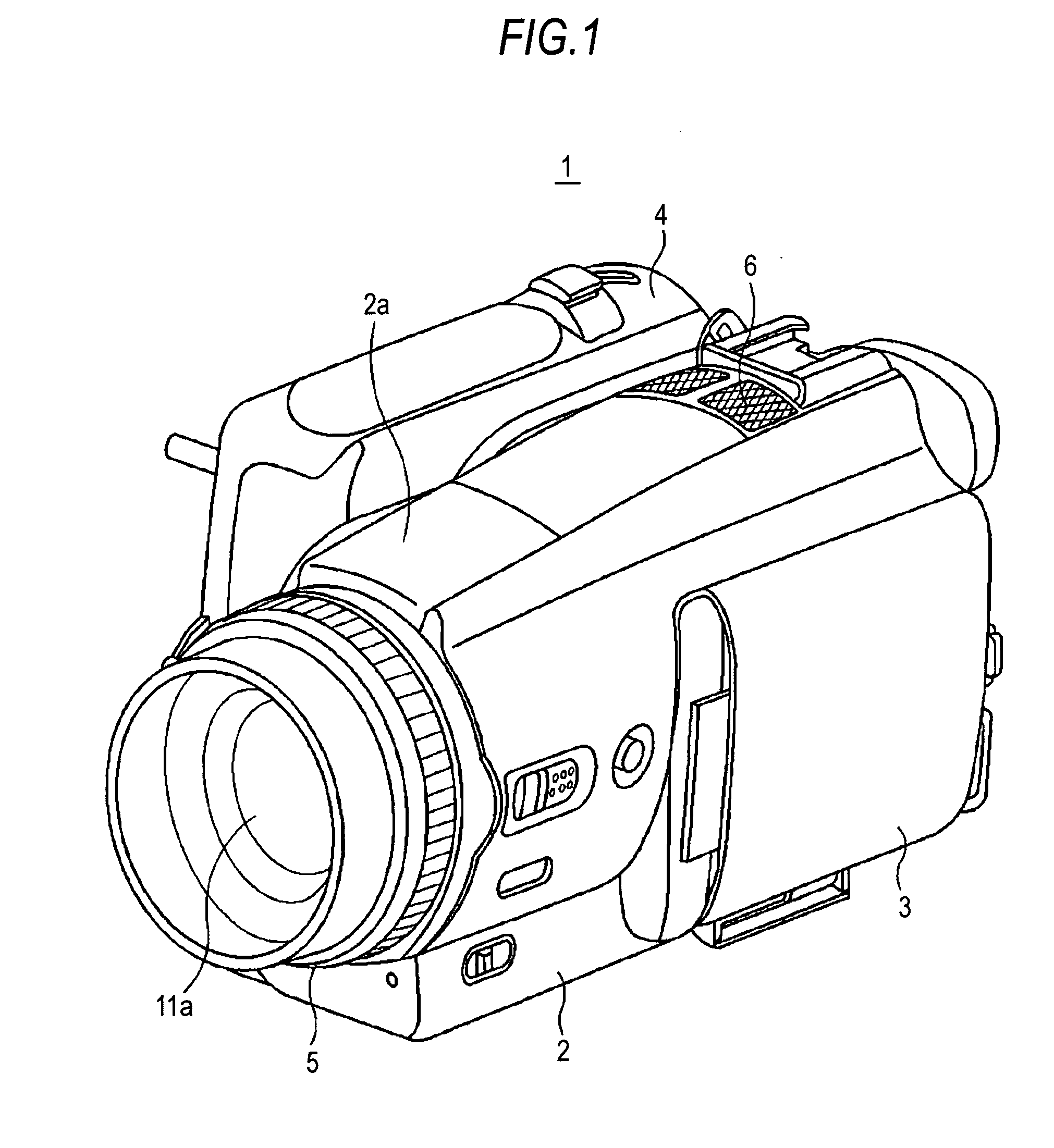

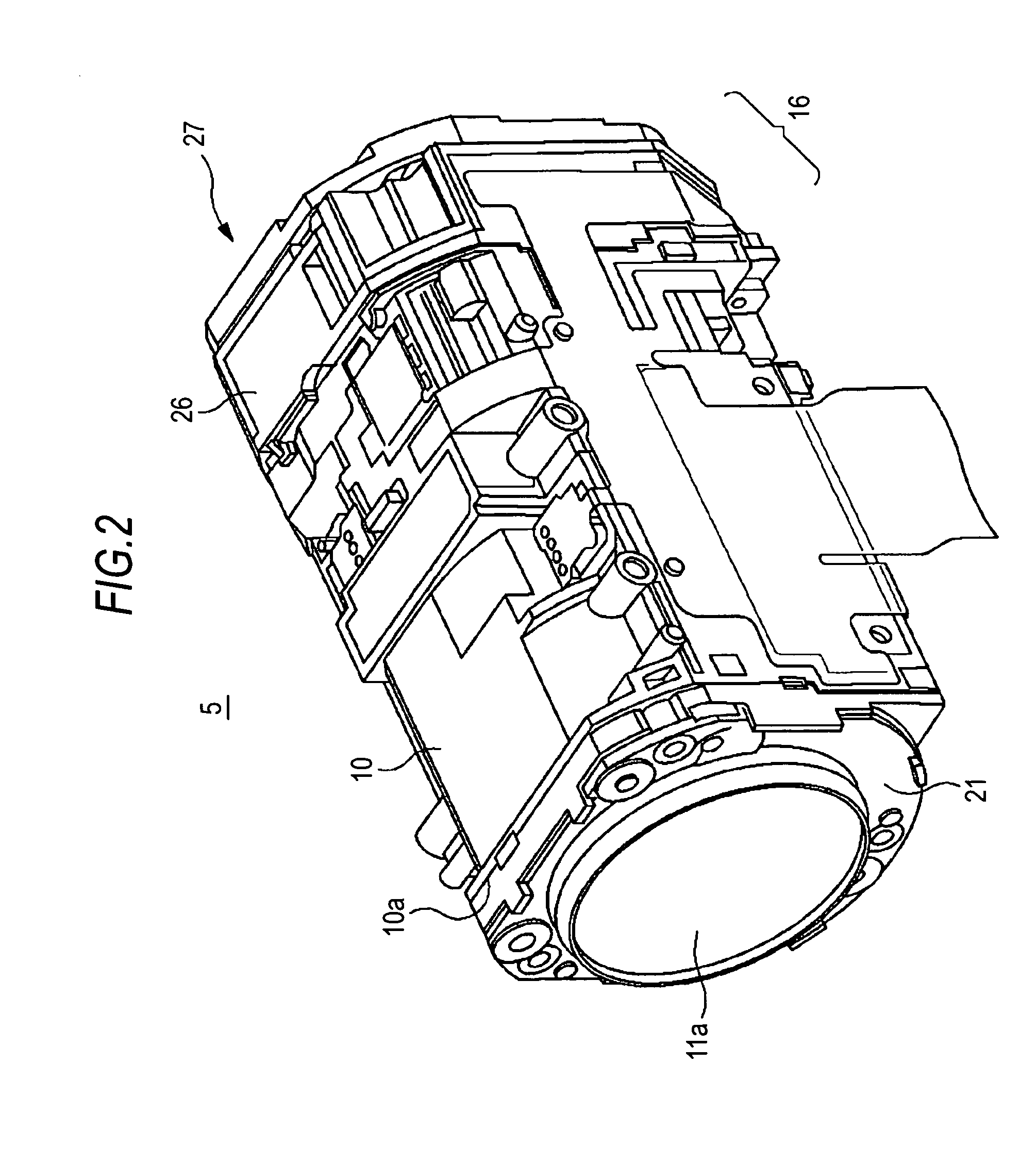

Switching mechanism for optical component, lens barrel, and imaging device

InactiveUS20100165173A1Precise positioningAvoid Inaccurate PositioningTelevision system detailsColor television detailsOptical axisEngineering

A switching mechanism for optical component includes: an optical component; a holder member holding the optical component; a drive mechanism having a drive motor that drives the optical component held by the holder member to rotate on a plane orthogonal to an optical axis from an optical axis position at which the optical component is on the optical axis to an evacuation position at which the optical component is off the optical axis; and a restriction member restricting a rotation of the holder member, by which at least a rotation of the optical component held by the holder member is restricted at the optical axis position. The drive mechanism includes the drive motor, a worm attached to a rotation shaft of the drive motor, and a worm wheel meshed with the worm and provided to the holder member.

Owner:SONY CORP

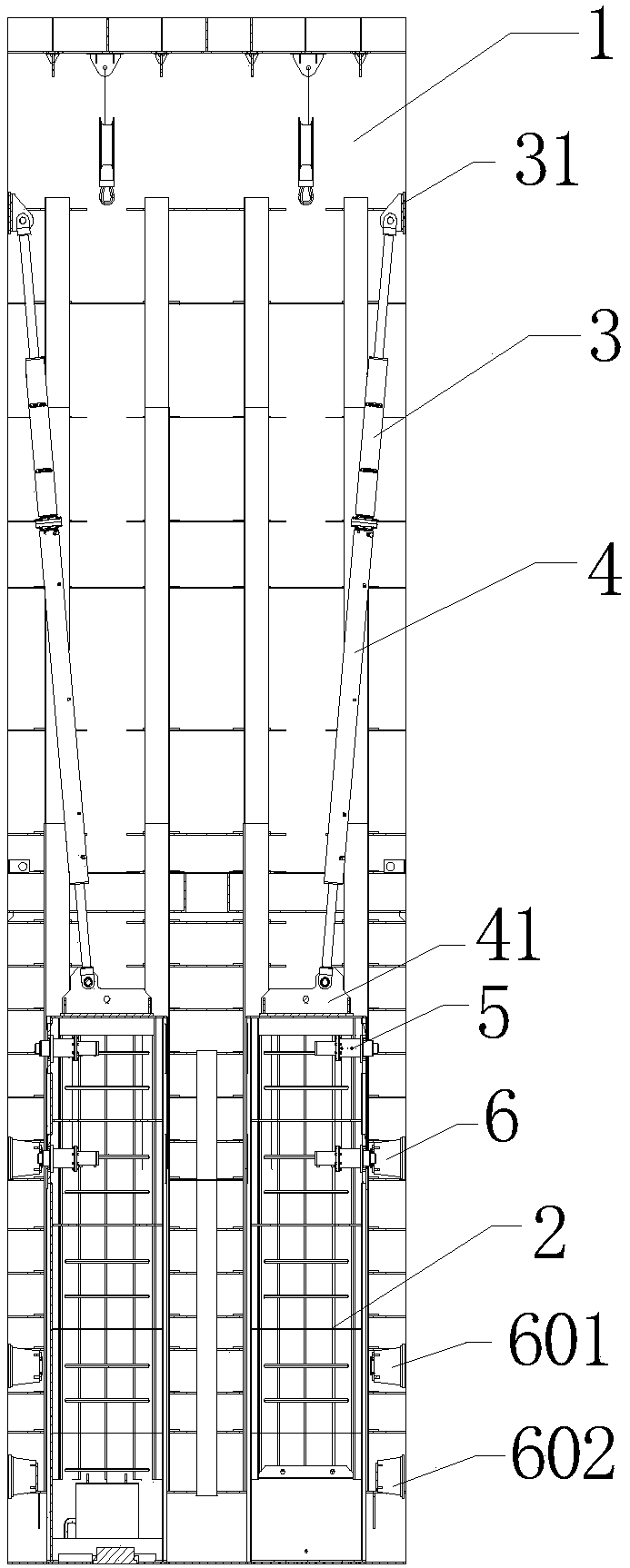

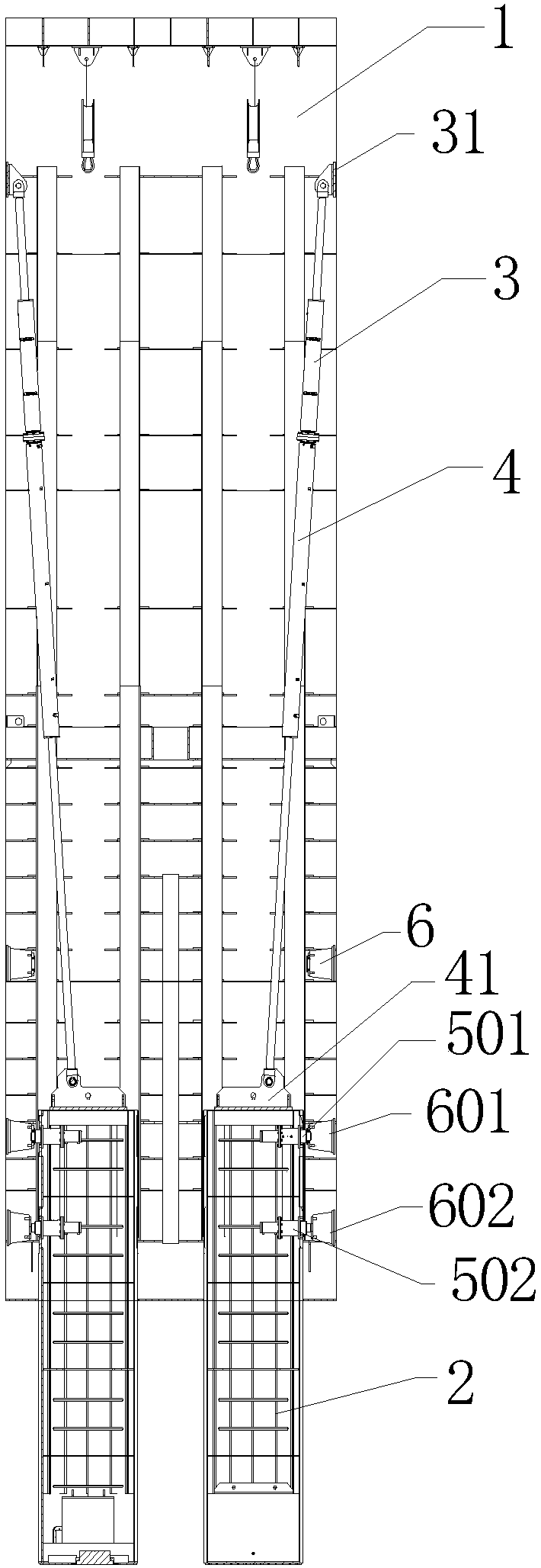

Lifting fin plate stabilizing system

The invention discloses a lifting fin plate stabilizing system. The system comprises a vertical well and fin plates located in the vertical well; hydraulic locking pins are arranged in the middles ofthe fin plates; grooves are formed in the tops of piston push rods of the hydraulic locking pins, and infrared emitting devices provided with power sources are embedded in the grooves; locking pin bases are arranged on the wall of the vertical well, limiting grooves are formed in the front ends of the locking pin bases, and the piston push rods can stretch into the limiting grooves for jacking; signal line through holes communicated with the outside of the locking pin bases are formed in the bottoms of the limiting grooves; infrared receiving devices are arranged in the through holes, the hydraulic locking pins are connected with a petroleum supply station, the petroleum supply station, the infrared emitting devices and the infrared receiving devices are connected with a control device through a communication line, pressure sensors are arranged in the limiting grooves and connected with the control device, the petroleum supply station comprises a hydraulic locking pin control system, and the hydraulic locking pin control system is connected with the hydraulic locking pins.

Owner:SHANGHAI FUXUN IND CO LTD

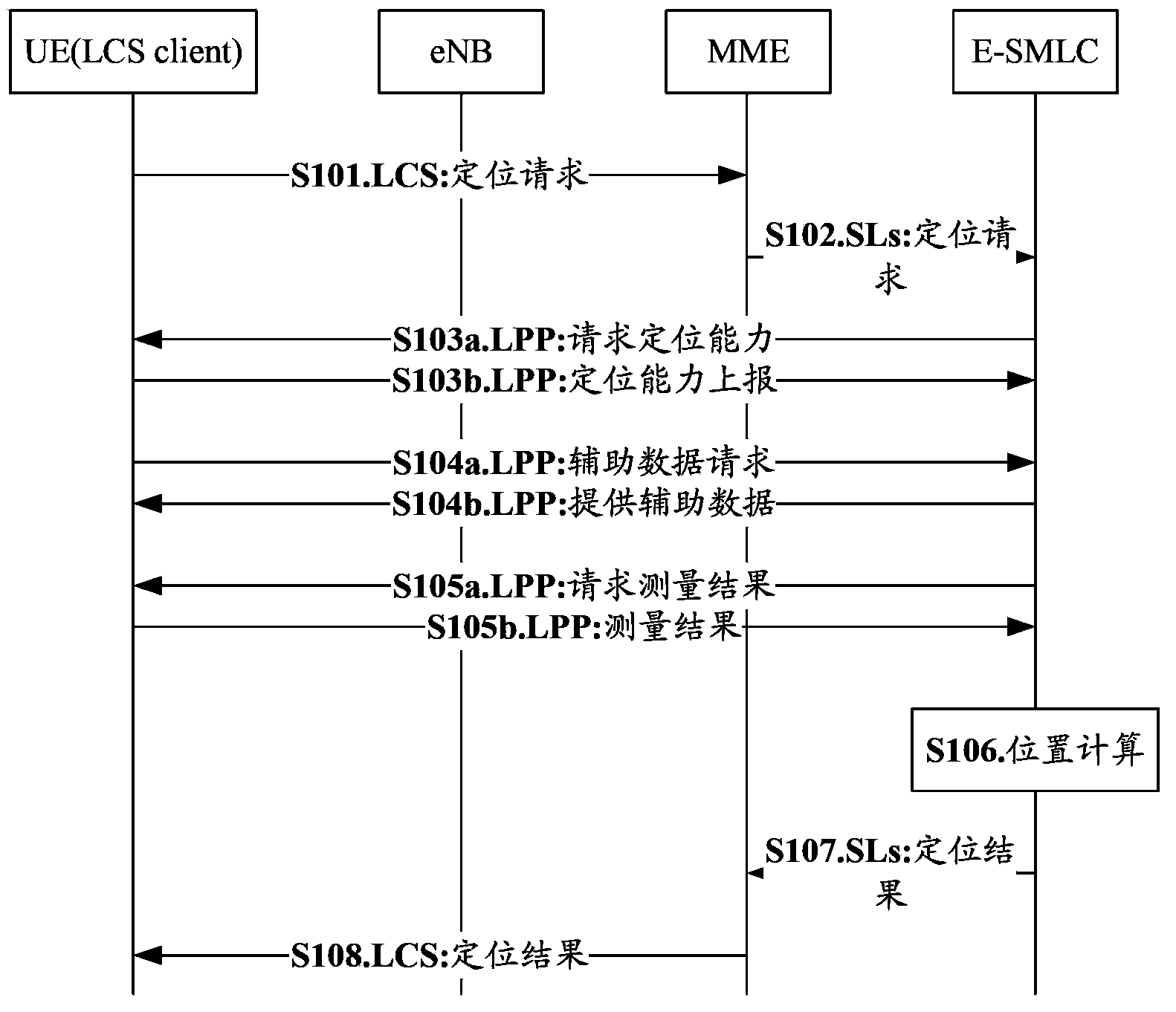

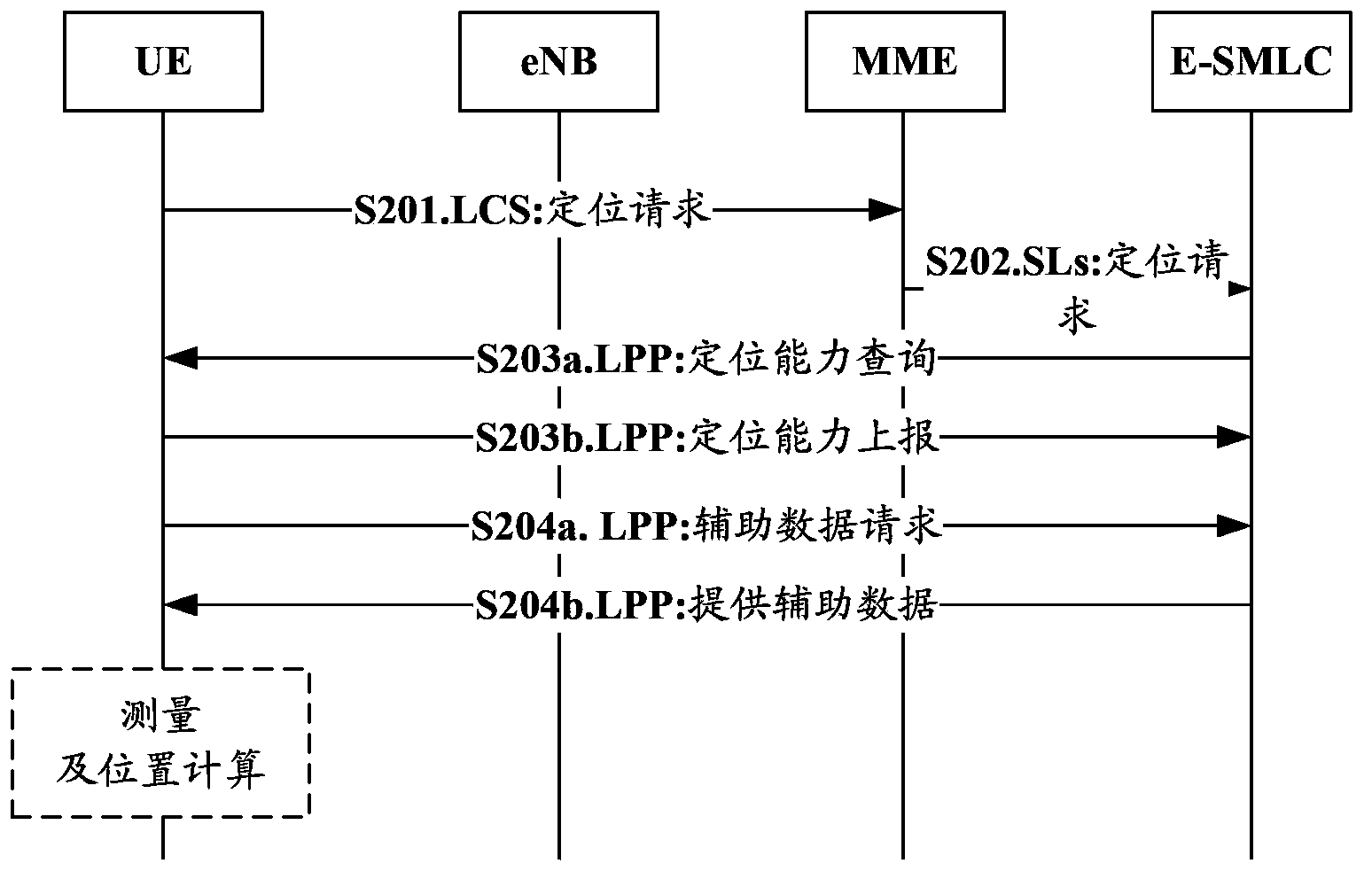

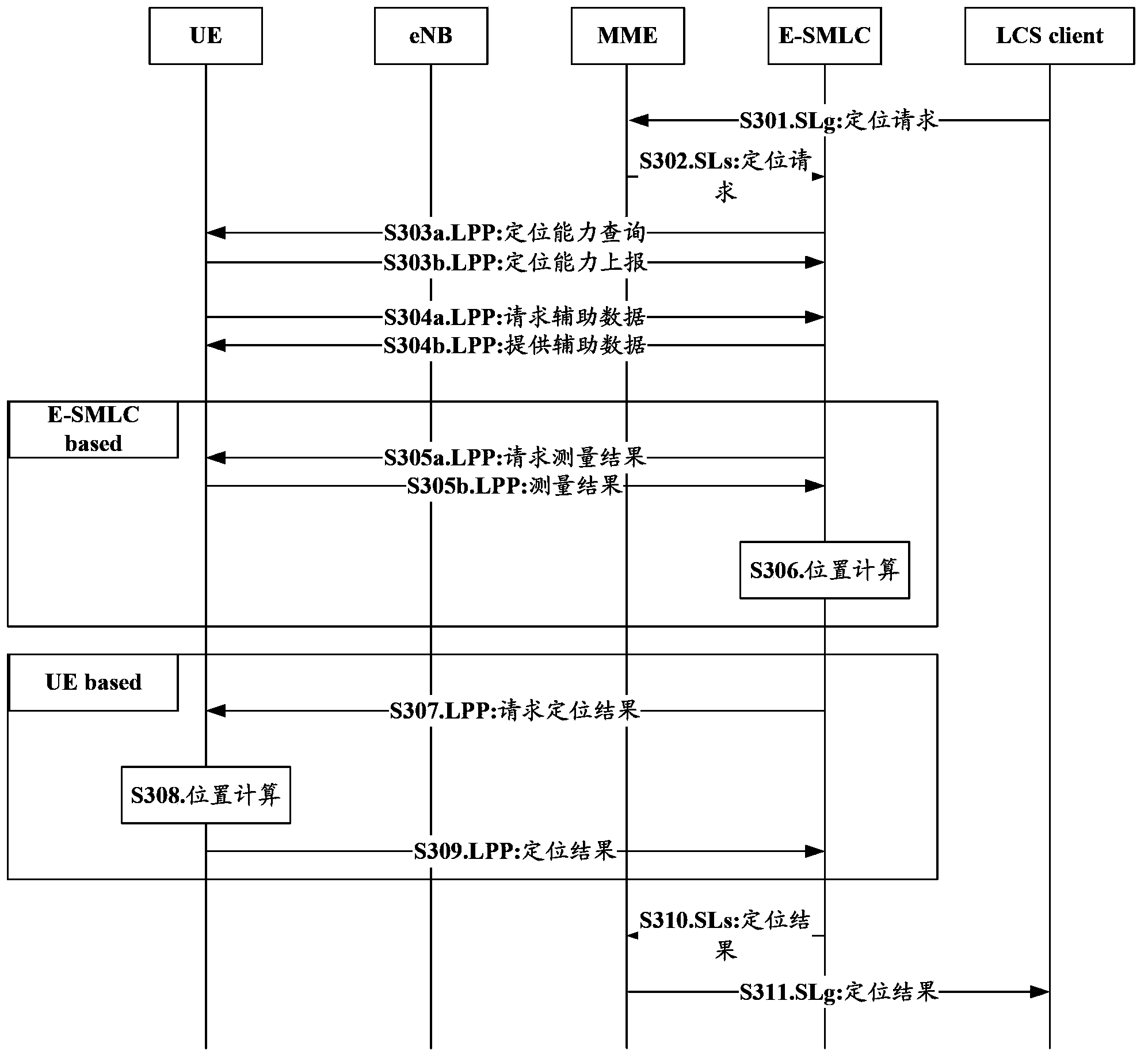

Terminal positioning method, terminal and positioning server

InactiveCN104301994AImprove accuracyAvoid Inaccurate PositioningSatellite radio beaconingWireless communicationComputer terminalPseudolite

The present invention relates to communication technology. Disclosed are a terminal positioning method, terminal and positioning server. When determining, according to the serving cell information of a terminal, that the terminal can be positioned via a pseudolite, a positioning server transmits auxiliary data of the pseudolite to the terminal. The auxiliary data of the pseudolite in the terminal can be timely updated to avoid inaccurate positioning of the terminal due to inaccurate auxiliary data of the pseudolite, thus improving terminal positioning accuracy.

Owner:CHINA ACAD OF TELECOMM TECH

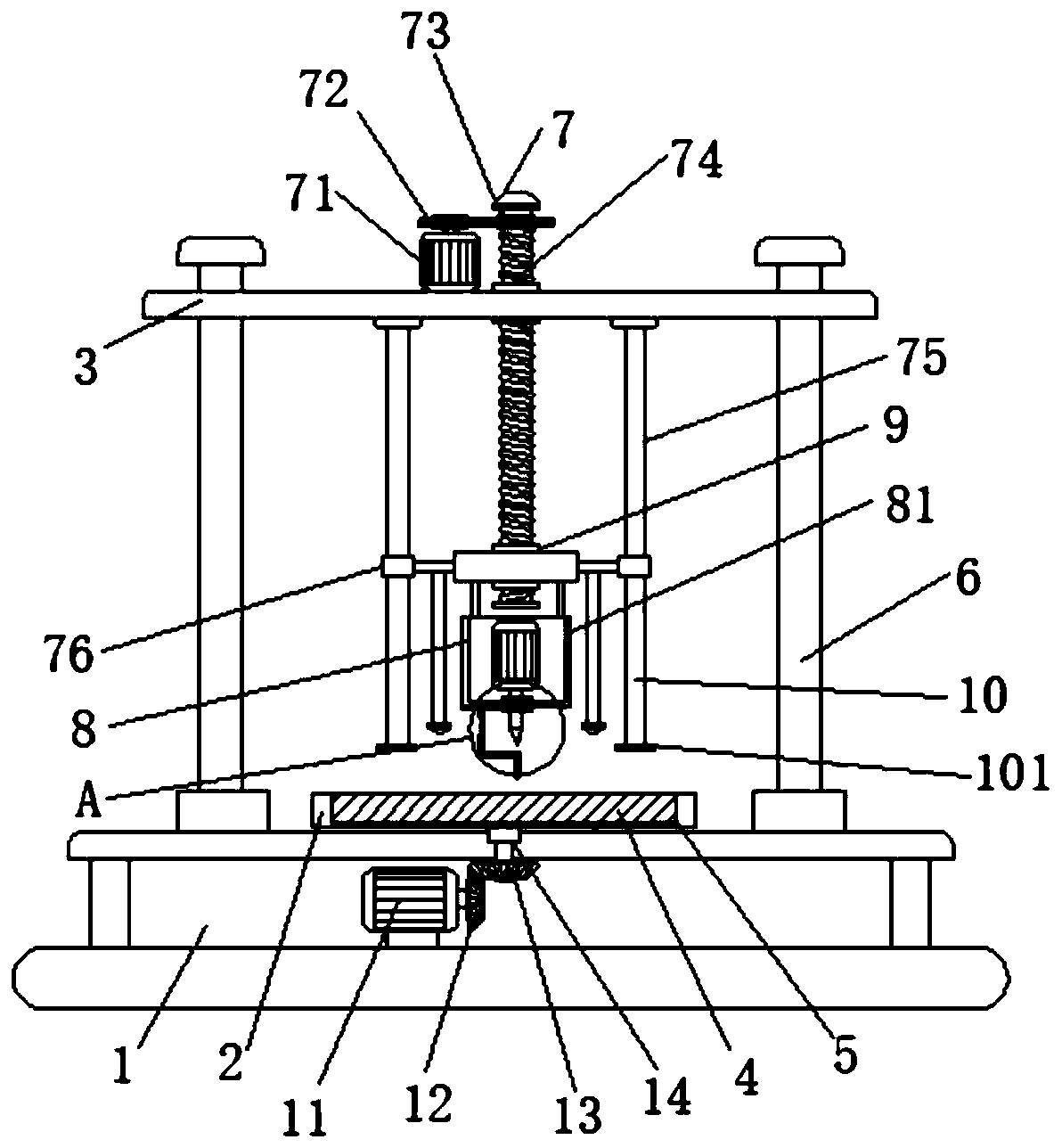

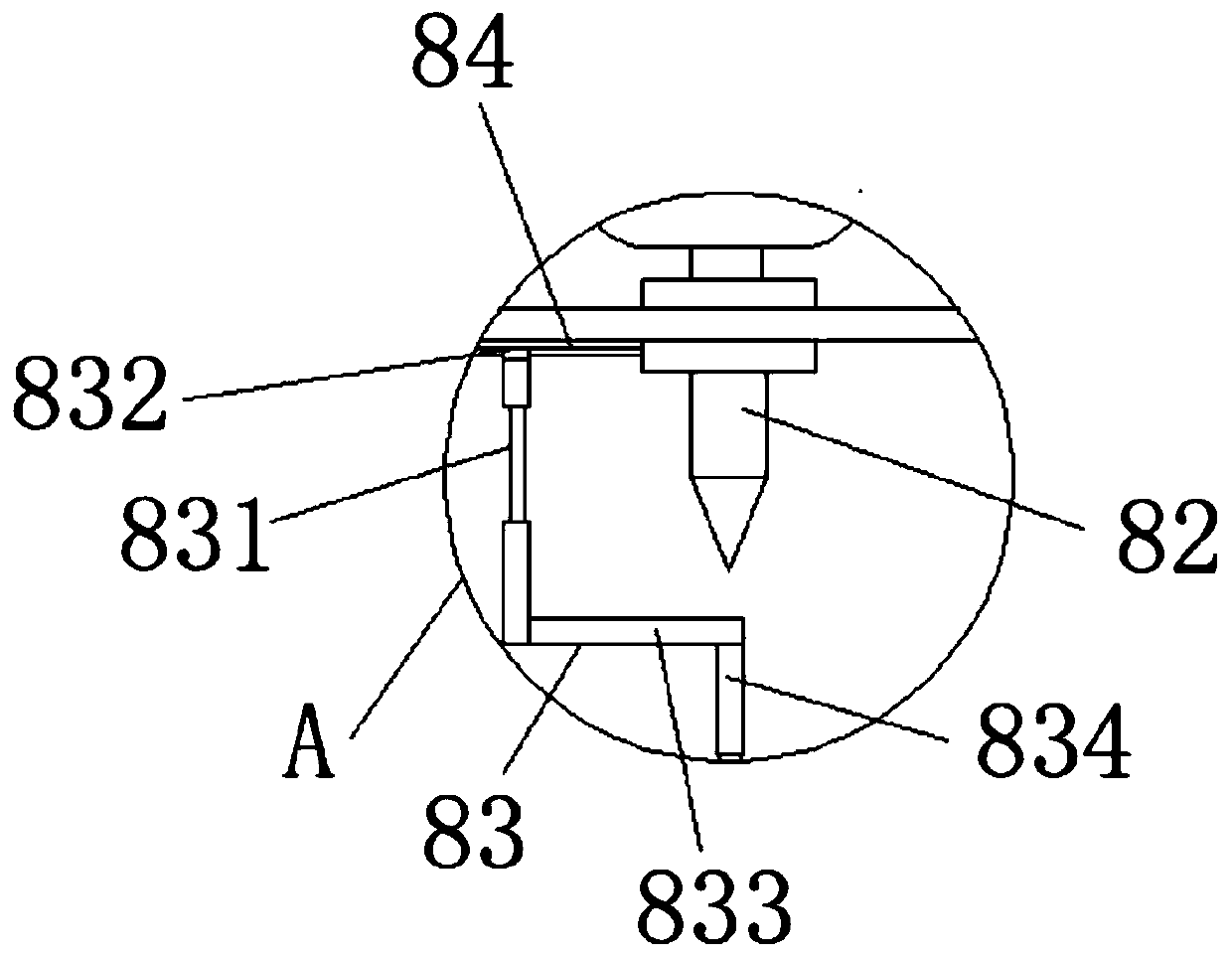

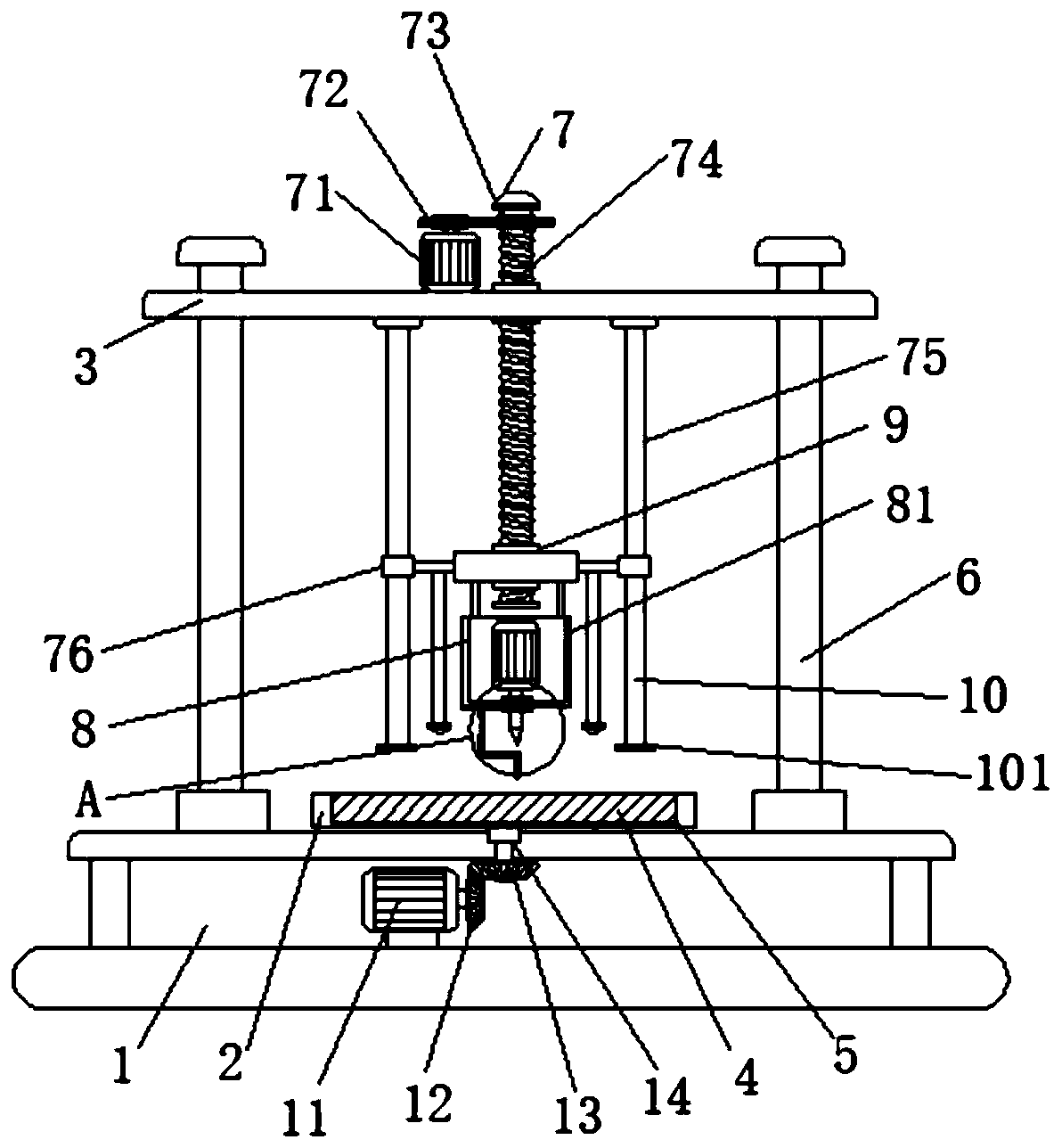

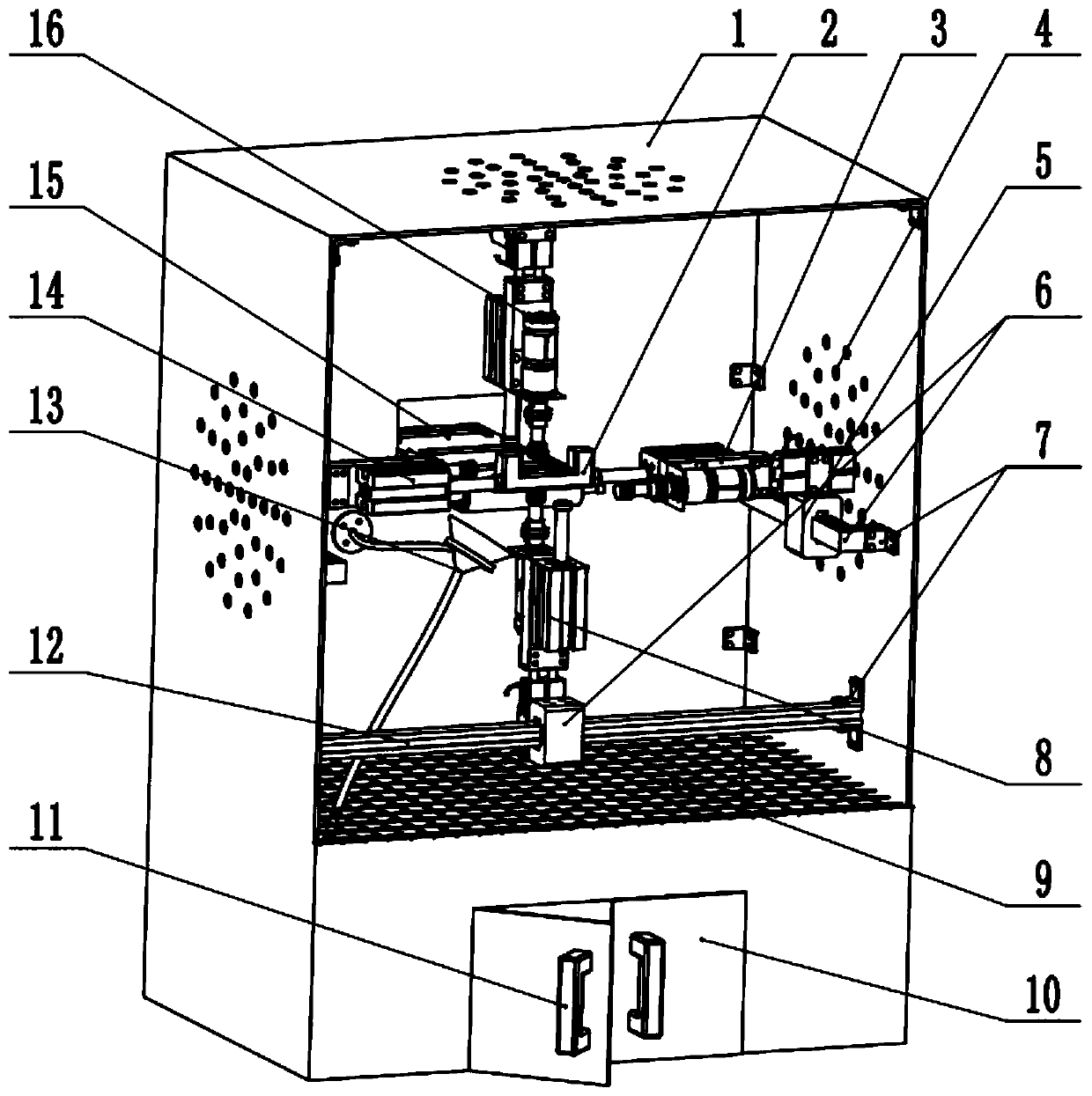

Intelligent automation household plate material punching device

InactiveCN109702815AAvoid Inaccurate PositioningImprove efficiency and accuracyStationary drilling machinesEngineeringAutomation

The invention discloses an intelligent automation household plate material punching device. The intelligent automation household plate material punching device comprises a base plate and a punching mechanism, wherein the base plate is placed on a horizontal plane, a placing base plate and an installation plate are parallelly arranged above the base plate in sequence, the placing base plate is usedfor placing a household plate material and is provided with a placing groove, the household plate material is embedded and fixed inside the placing groove, the two sides of the placing groove are provided with supporting columns, one ends of the supporting columns are fixedly connected to the base plate, the other ends of the supporting columns extend upwards in the direction perpendicular to thebase plate, the supporting columns are connected with the installation plate, the installation plate is provided with a lifting device, the lifting device is used for ascending and descending of thepunching mechanism and comprises a first motor, a driving gear and a driven gear, the driving gear is connected with the output end of the first motor and is in transmission connection with the drivengear, the driven gear is connected with a screw rod, the screw rod runs through the installation plate in a threaded manner and extends below the installation plate, and the bottom end of the screw rod is connected with an installation frame.

Owner:安徽吉露科技有限公司

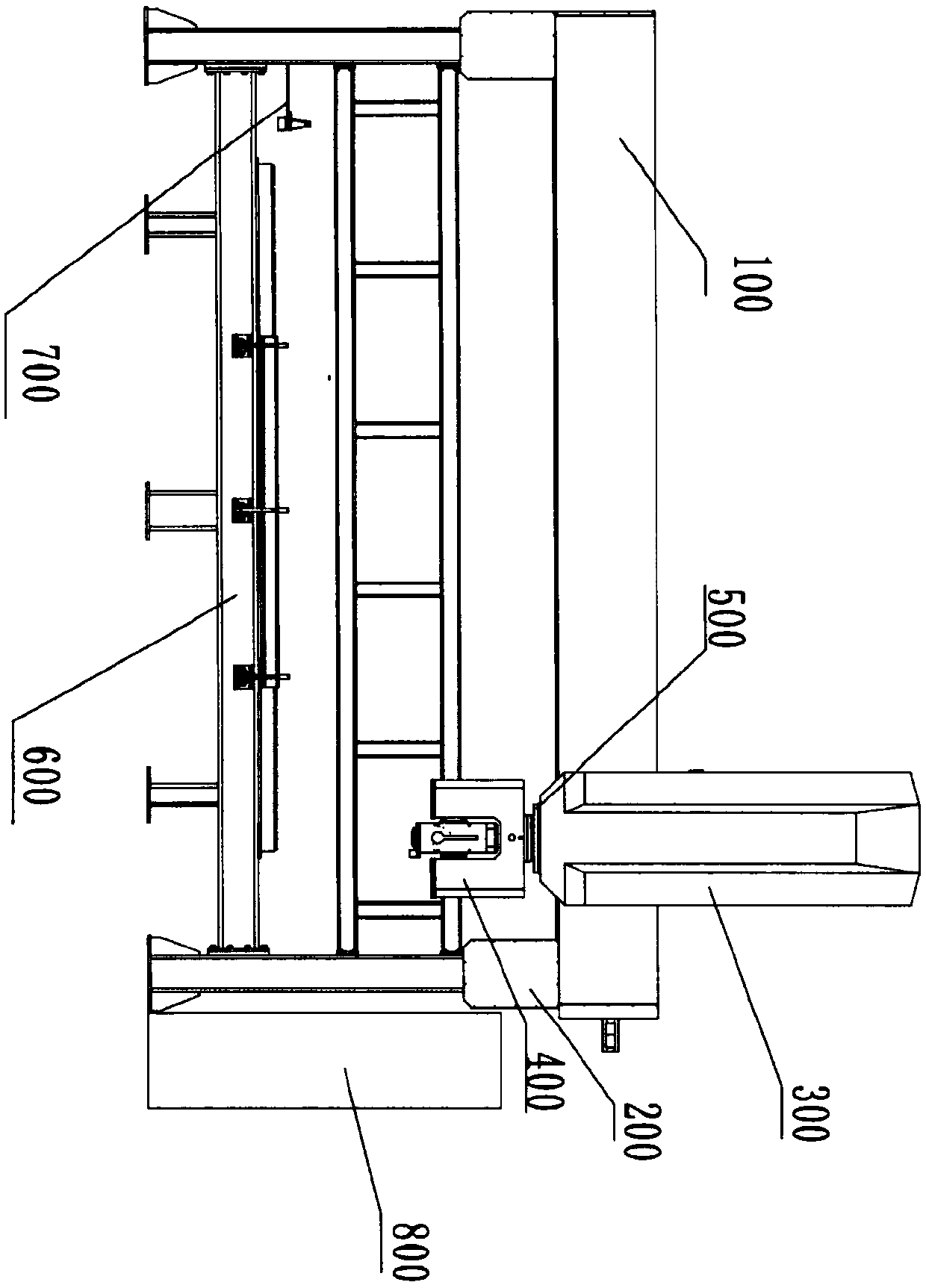

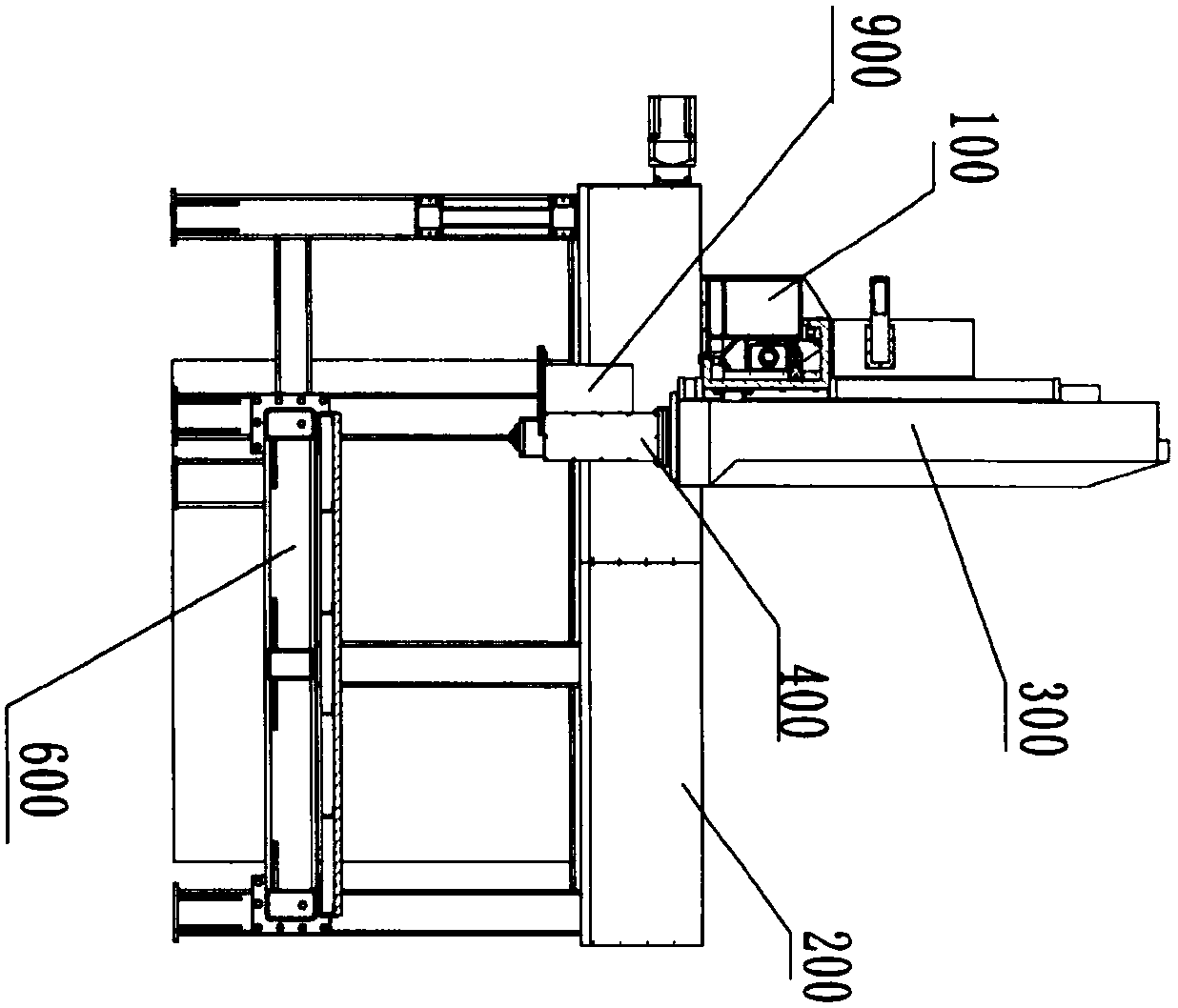

Five-axis machining center and stone machining method thereof

InactiveCN107310057AAutomatic replacementRealize processingModel makingStone-like material working toolsSurface finishEngraving

The invention discloses a five-axis machining center and a stone machining method thereof. The five-axis machining center is of a five-axis-linked structure which is composed of an axis X, axes Y, an axis Z, an axis C and an axis B. A framework body is of a gantry type structure. The axes Y are arranged in a bilateral symmetry mode and longitudinally arranged on a Y-axis base. The axis X is transversely arranged on a cross beam, and the cross beam is connected to a pair of Y-axis sliding tables in a crossing mode. The perpendicularly-arranged axis Z is connected with an X-axis sliding table through a Z-axis sliding table. The lower end face of a Z-axis body is connected with the axis C. An output disk of the axis C is connected with a U-shaped end in the axis B, and the U-shaped end is connected with a spindle motor through a connecting flange. A workbench assembly is arranged between two overhead walls. A tool magazine assembly is arranged on the inner side face of one overhead wall, and an electrical control cabinet is arranged on the outer side of the other overhead wall. According to the five-axis machining center and the stone machining method thereof, cutting of special-shaped plates and engraving of stereoscopic stone can be completed automatically through five-axis linkage, clamping is easier, positioning is accurate, the machining cost is low, the working efficiency is high, the surface smoothness of workpieces is high, the machining precision is improved, and the quality of all products is effectively guaranteed.

Owner:LAIZHOU FULIN MACHINERY

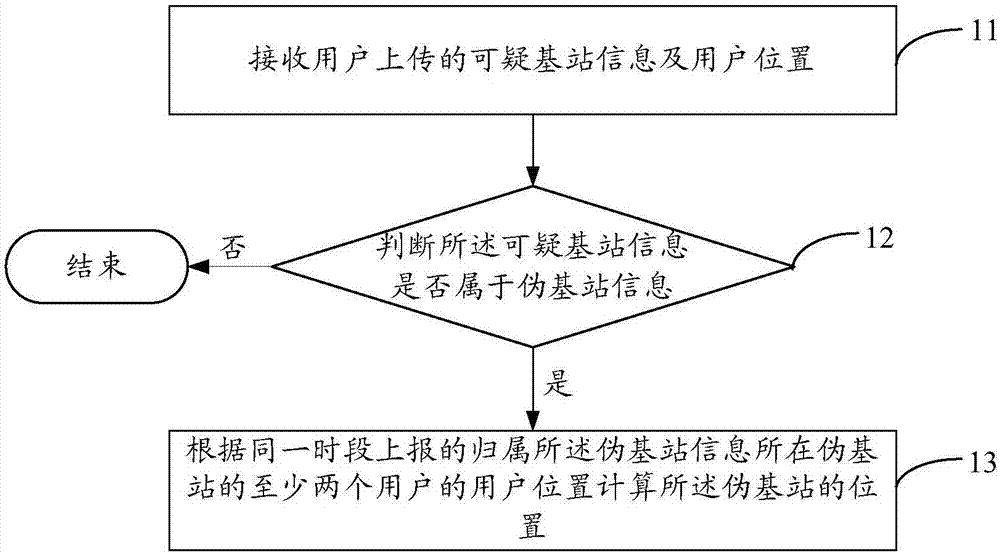

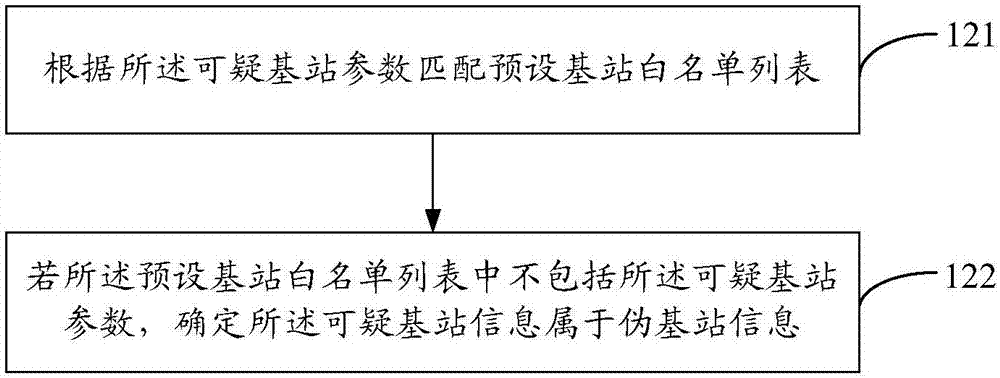

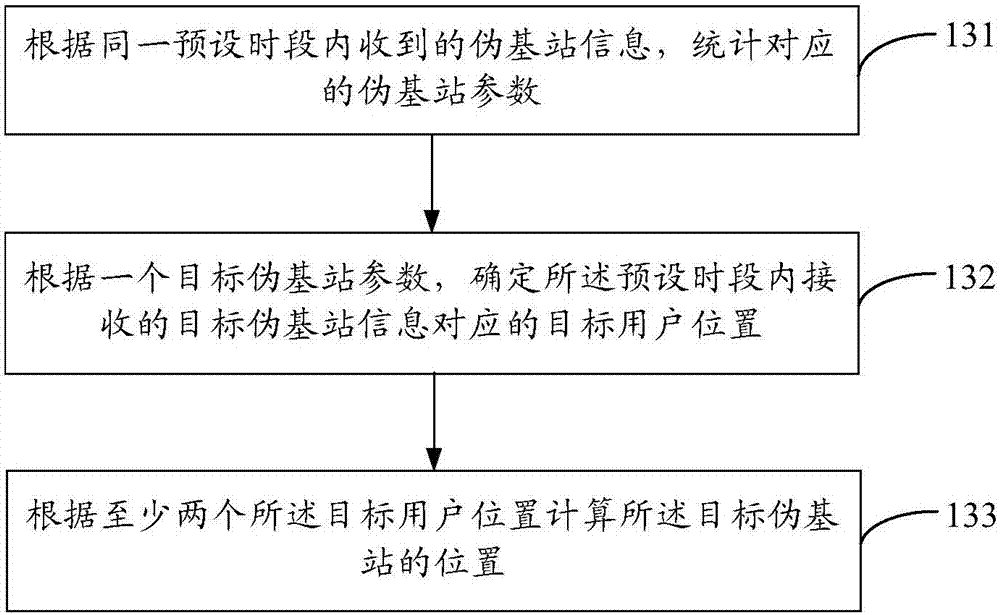

Pseudo base station location method and device

InactiveCN106998532APrecise positioningAccurate methodLocation information based serviceSecurity arrangementUser equipment

The invention provides a pseudo base station location method and device. The method comprises the steps that suspicious base station information and the user location, which are uploaded by a user, are received; whether the suspicious base station information belongs to pseudo base station information is determined; and if so, according to the user location of at least two users of a pseudo base station to which the pseudo base station information belongs, the location of the pseudo base station is calculated, wherein the user location is reported at the same time. According to the pseudo base station location method provided by the invention, the pseudo base station can be accurately located; accurate information is provided for the relevant law enforcement agencies to clean up the pseudo base station; and the pseudo base station is prevented from sending deceptive or interfering information to user equipment.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

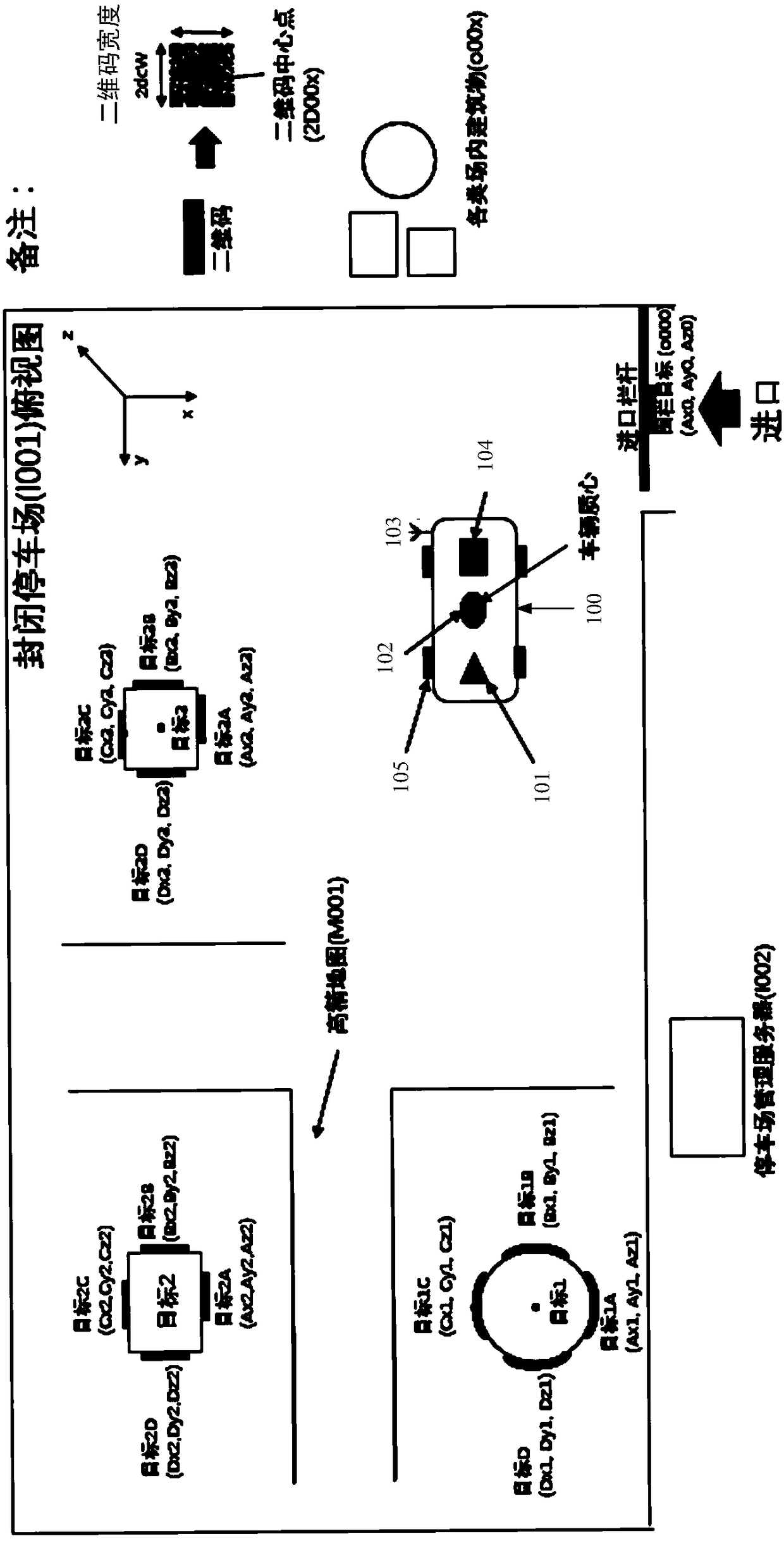

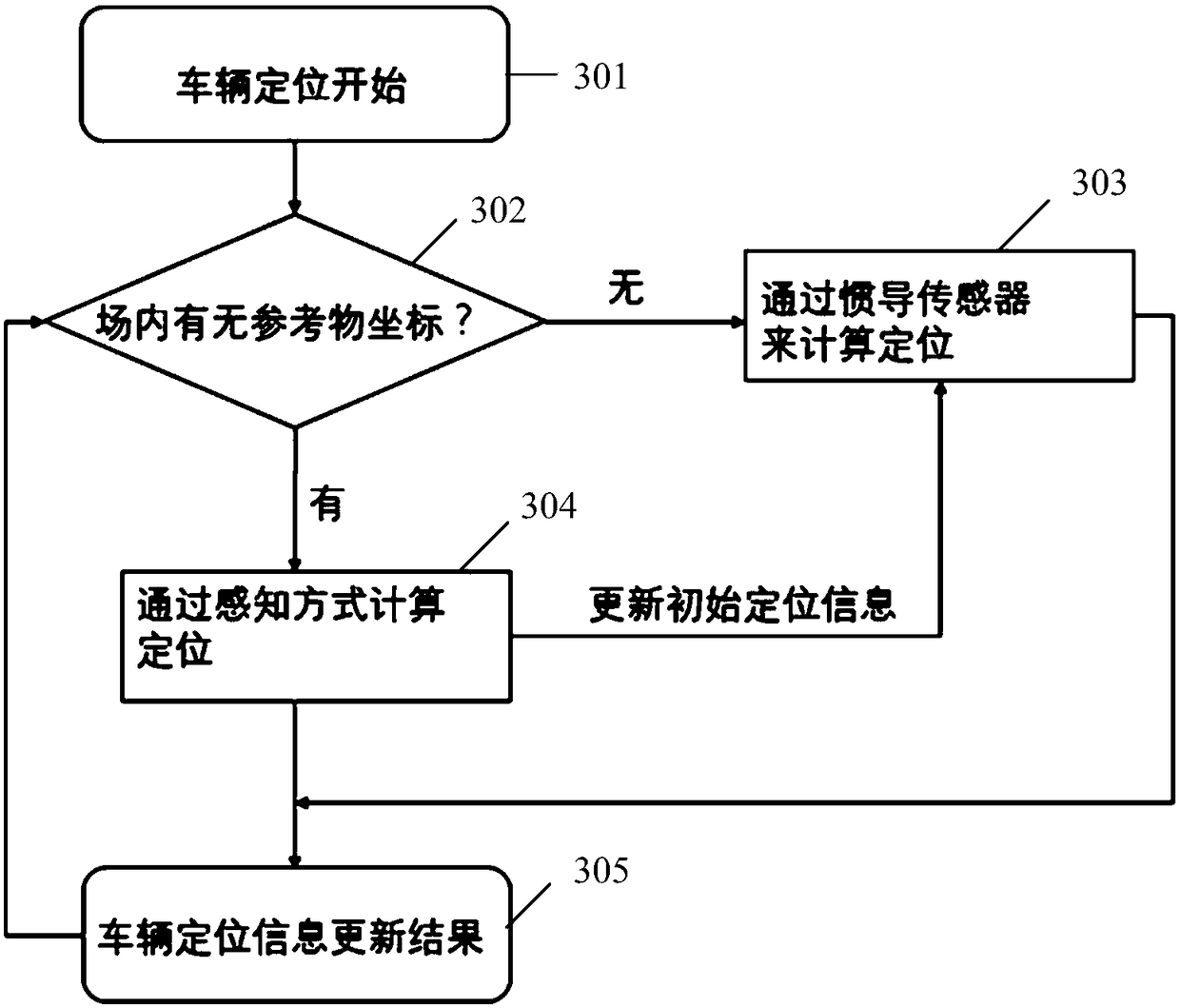

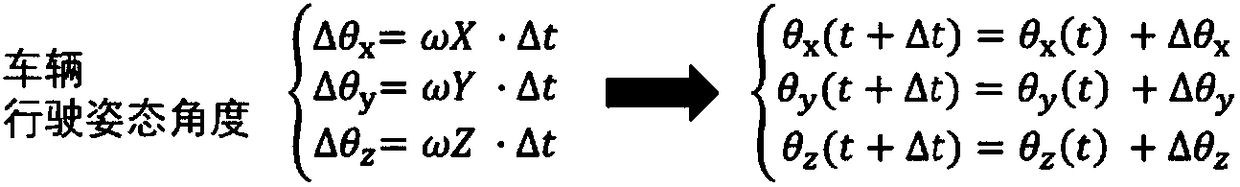

Method for positioning vehicle in enclosed area

InactiveCN109029418ASupporting requirements are lowAvoid Inaccurate PositioningNavigation by speed/acceleration measurementsPattern perceptionNo reference

A method of positioning vehicles in an enclosed area, comprising the following steps: a. determining whether a reference object coordinate exists in the enclosed area, and if the reference object coordinate exists in the closed area, executing the step b; if no reference object coordinate exists in the closed area, executing the step c; b. calculating vehicle positioning information by an inertialnavigation sensor of a vehicle inertial navigation system; c. respectively calculating vehicle positioning information using a perception sensor and the inertial navigation sensor, wherein the perception sensor periodically corrects positioning errors of the inertial navigation system according to the reference object coordinate; and d, updating the positioning information of the vehicle.

Owner:WM SMART MOBILITY (SHANGHAI) CO LTD

Automatic polishing workroom suitable for combined cabinet handles

PendingCN110181367ASwipe does not generatePrevent fallingGrinding drivesGrinding machinesEngineeringMachining

The invention discloses an automatic polishing workroom suitable for combined cabinet handles, and belongs to the field of machining equipment. The automatic polishing workroom consists of a workroomseparation plate, a first machining device, a slide mechanism, a guide mechanism, a bottom machining device, a dustproof net, a dust collecting room door sheet, a dust collecting room door sheet handle, a bottom slide rail, a dust sucking device, a second machining device, a loading device, a top machining device and a top slide rail; the first machining device and the second machining device aremounted on two sides of the workroom separation plate; the bottom machining device and the top machining device are mounted at the bottom and the top of the workroom separation plate; the loading device is mounted behind the workroom separation plate; and the dust sucking device is mounted on the inclined lower side of a polishing piece. The automatic polishing workroom has the following beneficial effects: during polishing of handles, the first machining device, the second machining device, the top machining device and the bottom machining device can synchronously polish multiple surfaces ofthe handles through cooperation between respective guide mechanisms and double-shaft double-rod cylinders, so that both manpower and time are saved.

Owner:孙浩翔

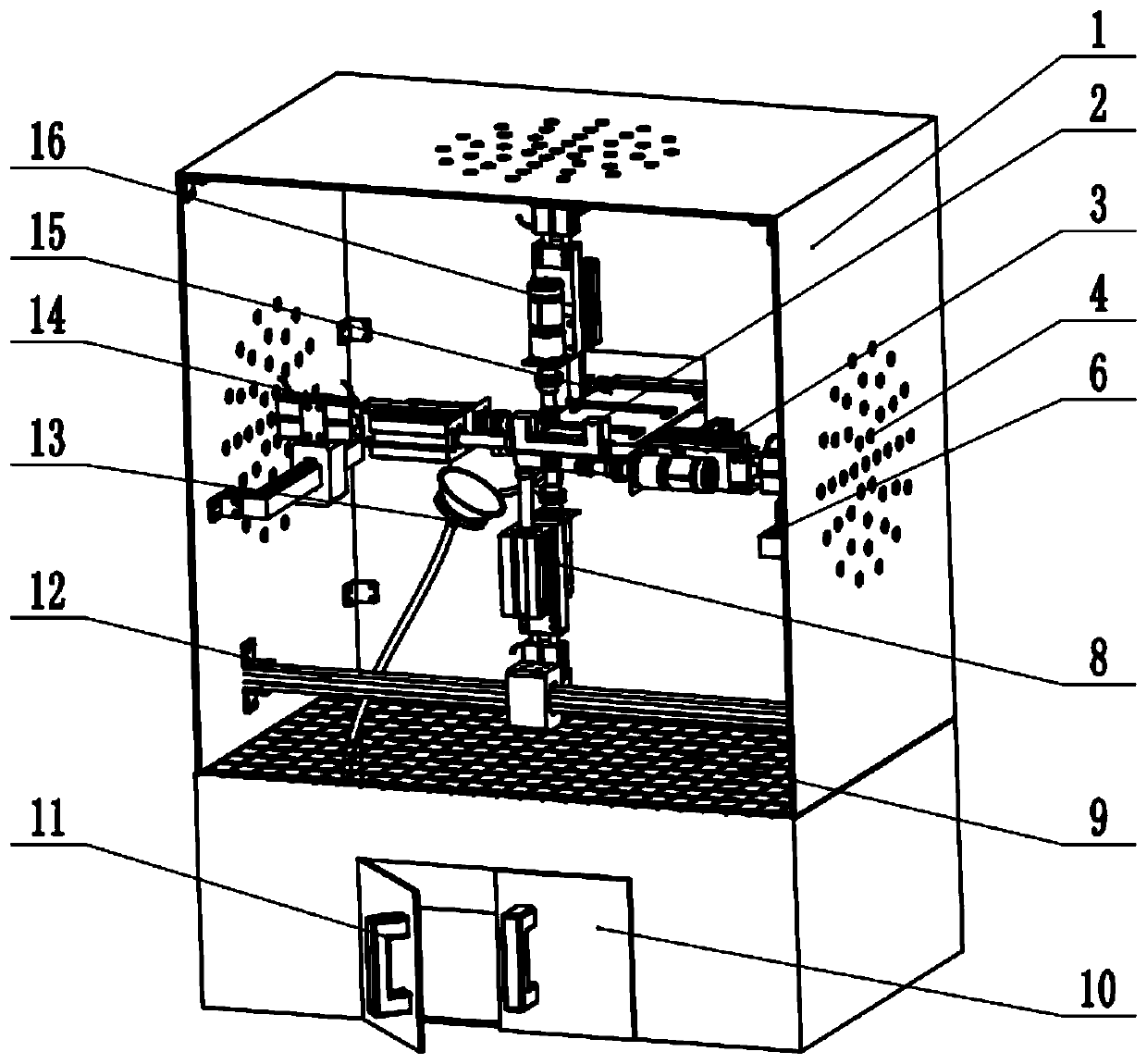

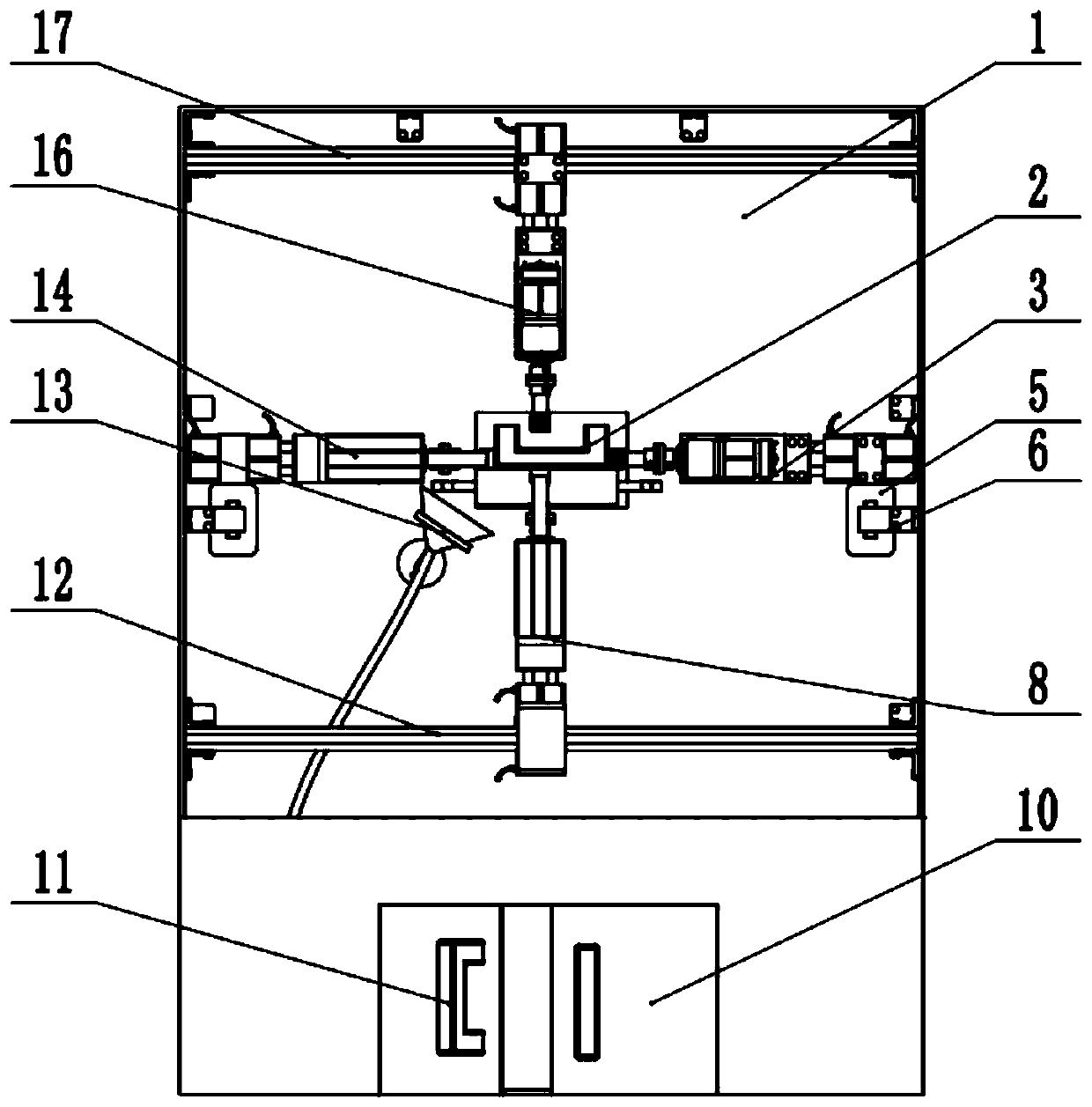

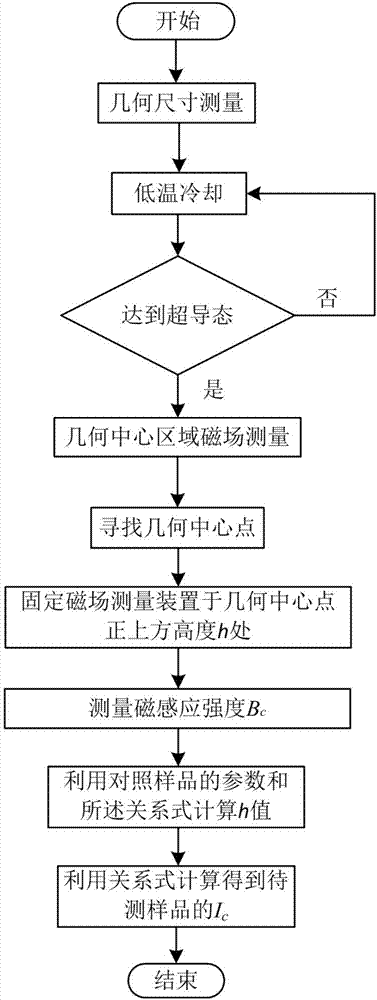

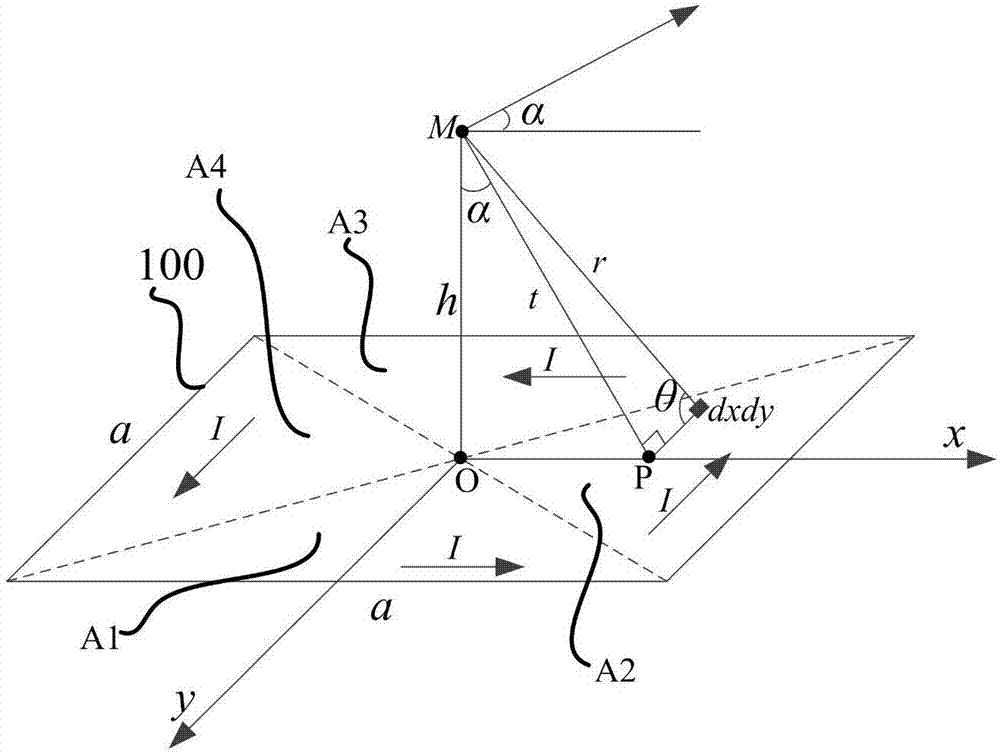

Method for quickly measuring average critical current of superconducting film

ActiveCN107144802AAvoid Inaccurate PositioningEasy to operateSuperconductive properties measurementsMeasurement deviceCritical current

A method for quickly measuring average critical current of a superconducting film comprises the steps of measuring the geometric dimension of a to-be-measured superconducting film sample; cooling the to-be-measured sample to a superconducting state and performing excitation; scanning and measuring a magnetic induction strength B at a geometric center area of the to-be-measured sample by means of a magnetic field measurement device; determining the coordinate of a geometric center point of the to-be-measured sample by means of a maximal value of B; fixing a magnetic field measuring device at a position right above or right below the geometric center point at a distance h for measuring a magnetic induction intensity B which is generated by the to-be-measured sample at the magnetic field measuring device fixing part; performing all above steps on a superconducting film with known average critical current Ic for obtaining the Bc value of the comparing sample; and according to a relationship among Bc, h, Ic and the geometric dimension of the superconducting film, obtaining value of the h based on the geometric dimension of the comparing sample through measurement, Bc value and the known Ic value, and introducing the value of h, the geometric dimension of the to-be-measured sample and the Bc value into the relationship, thereby obtaining the Ic value of the to-be-measured sample.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

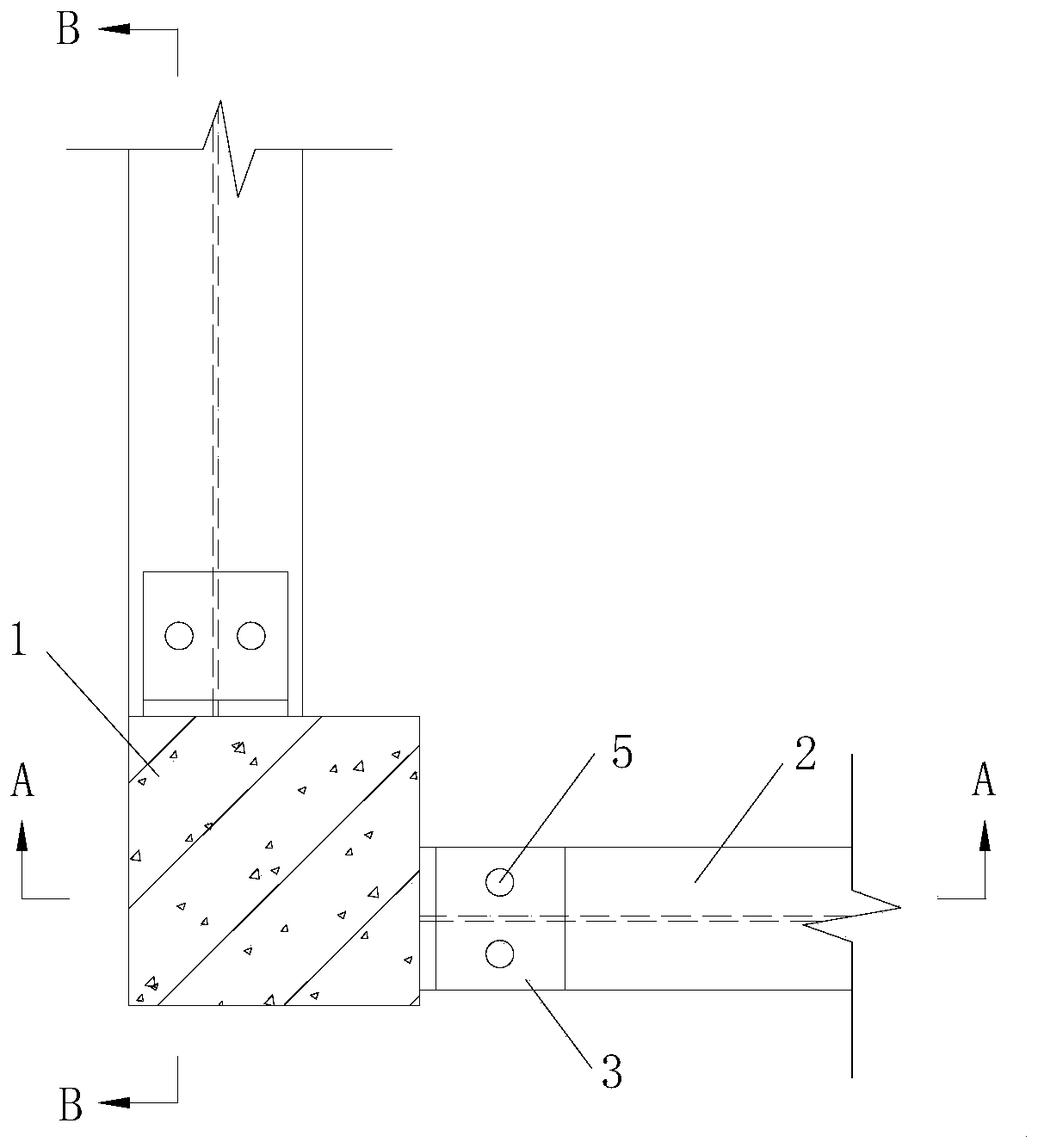

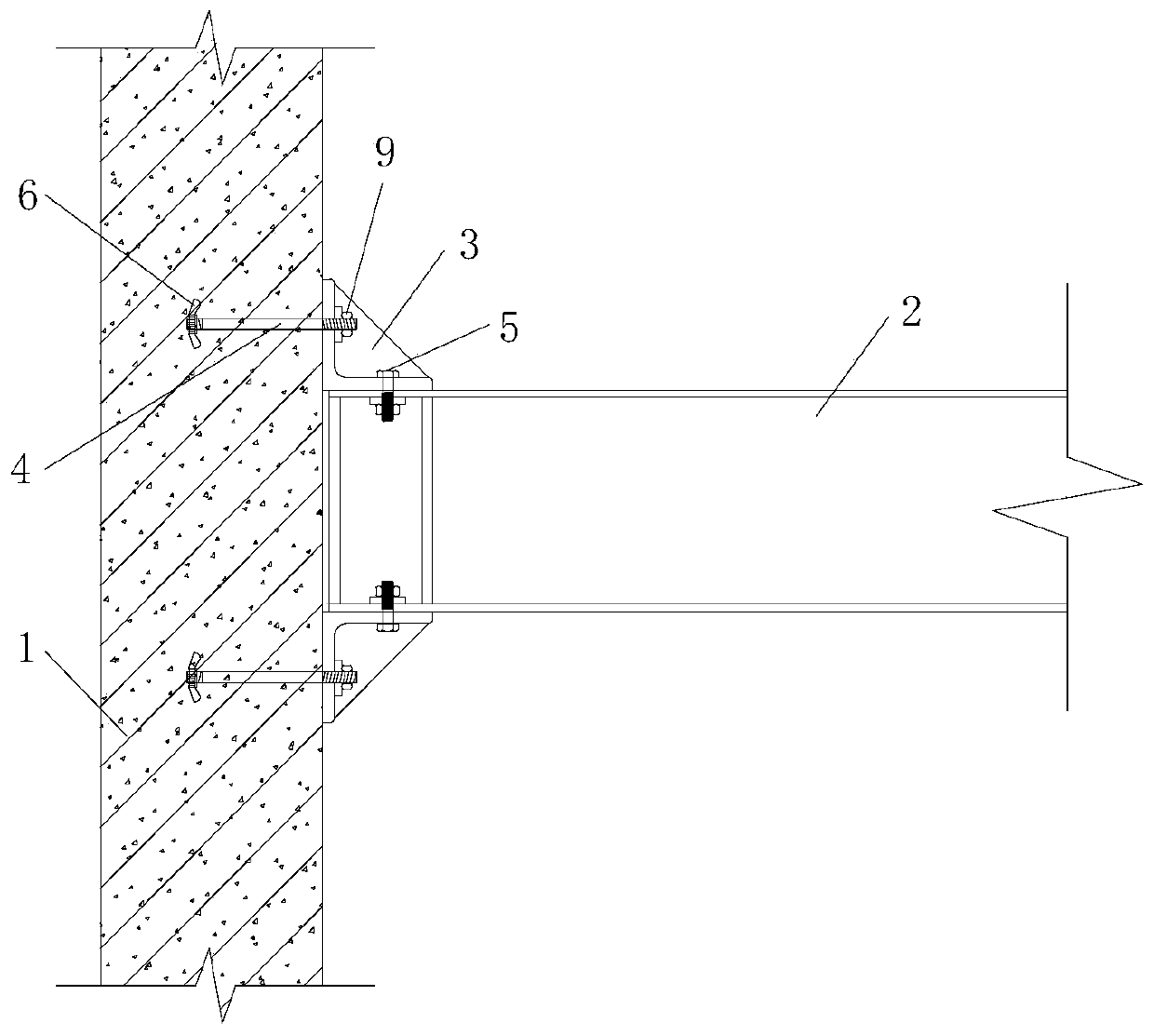

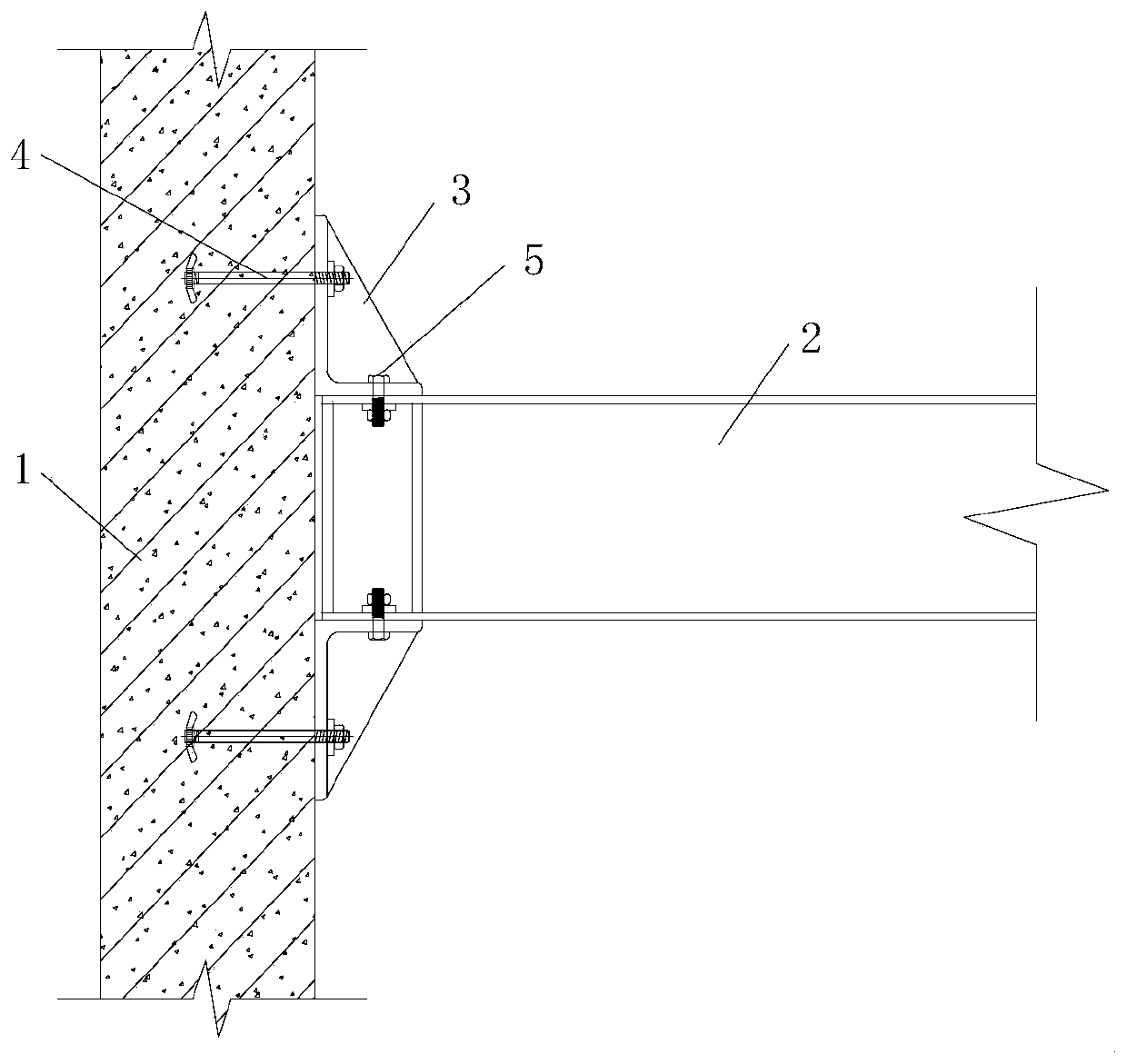

Dry construction connecting structure of duct corners and girder for building with fabricated frame structure

PendingCN109914616AAvoid displacementGuaranteed aestheticsProtective buildings/sheltersShock proofingRebarUltimate tensile strength

The invention discloses a dry construction connecting structure of duct corners and a girder for a building with a fabricated frame structure. The structure comprises prefabricated columns and the steel girder; the steel girder is connected with the prefabricated columns by means of the duct corners which are respectively arranged at the upper side and lower side of the end of the steel girder; split bolts are pre-buried in the prefabricated columns; one ends of the split bolts are arranged in the prefabricated columns, and the other ends of the split bolts extend outside the prefabricated columns and pass through a first connecting plate; the split bolts are positioned in the prefabricated columns and are connected with longitudinal steel bars in the prefabricated columns in a welding way. According to the connecting structure provided by the invention, the split bolts and the longitudinal steel bars form a whole, so that the ultimate bearing capacity and anti-seismic property of theframe structure are improved; furthermore, the pre-buried split bolts are prevented from shifting in a construction process of the prefabricated columns, so that the construction accuracy is guaranteed. The connecting structure is simple in structure and convenient for construction, and greatly improves the construction quality and shortens the construction period under the premise of guaranteeingthe construction structuring strength of the frame structure.

Owner:中民筑友房屋科技集团有限公司

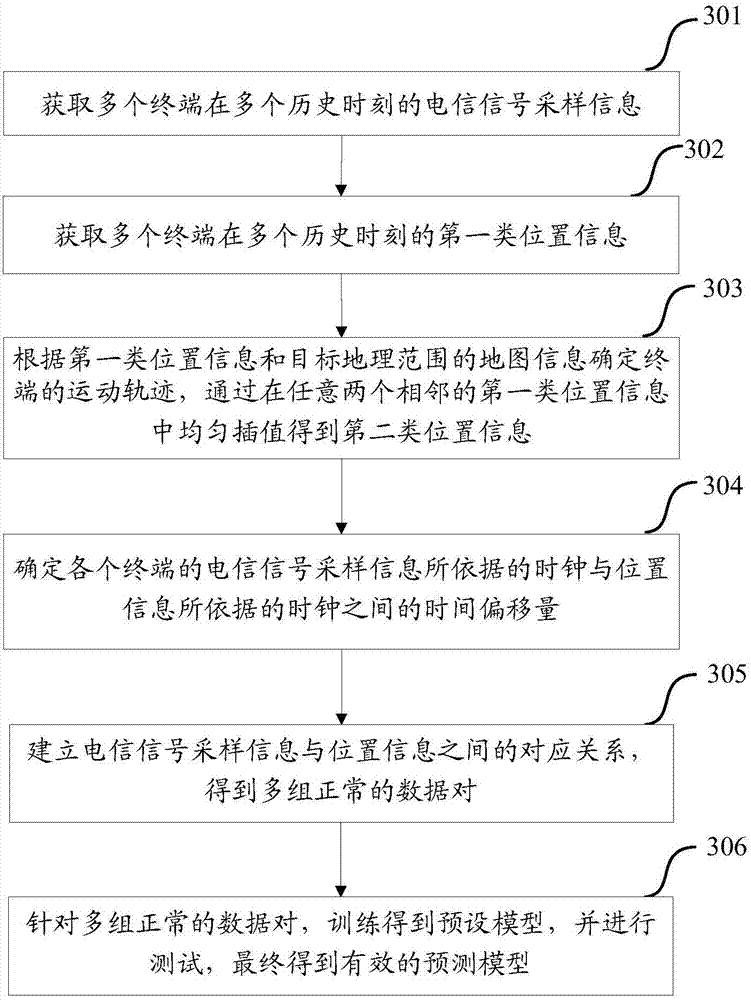

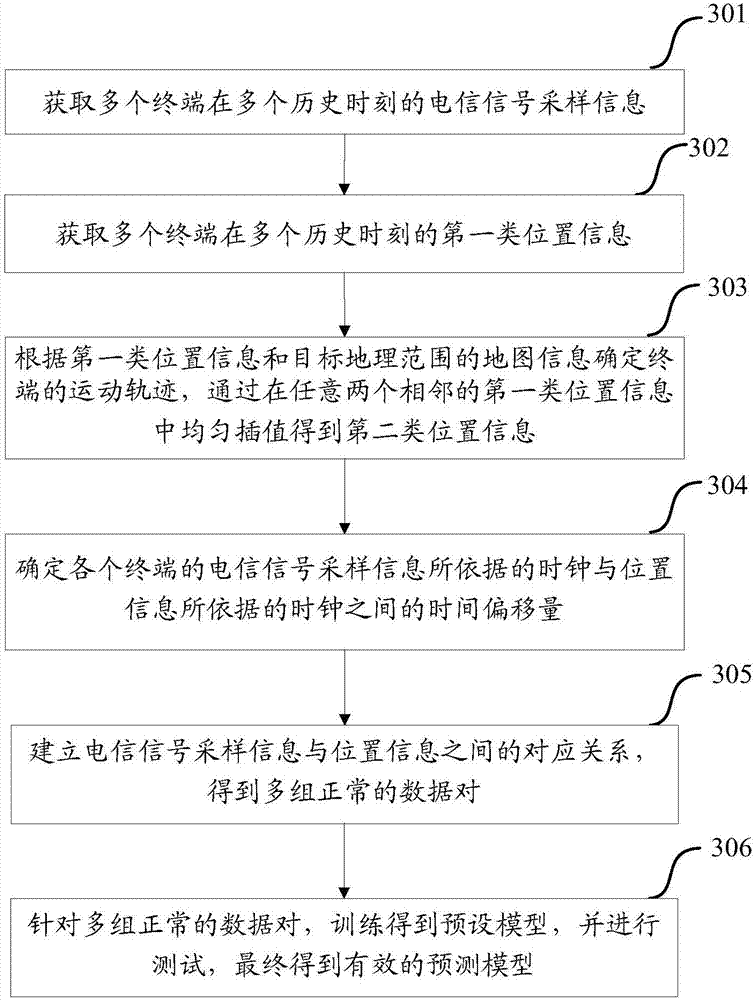

Terminal positioning method and network equipment

ActiveCN107466103AImprove accuracyReflect the relationshipPosition fixationMachine learningReal-time computing

The embodiment of the invention discloses a method and equipment for acquiring position information. Aiming at a first historical terminal, network equipment acquires telecommunication signal sampling information of the first historical terminal at a plurality of first historical moments and position information of the first historical terminal at a plurality of second historical moments; and the network equipment obtains a plurality of groups of data pairs of the first historical terminal according to the telecommunication signal sampling information of the first historical terminal at the plurality of first historical moments and the position information of the first historical terminal at the plurality of second historical moments, wherein each group of data pair in the plurality of data pairs comprises the telecommunication signal sampling information and the position information. In the embodiment of the invention, the relationship between the telecommunication signal sampling information and the position information of the terminal can be relatively accurately reflected.

Owner:HUAWEI TECH CO LTD

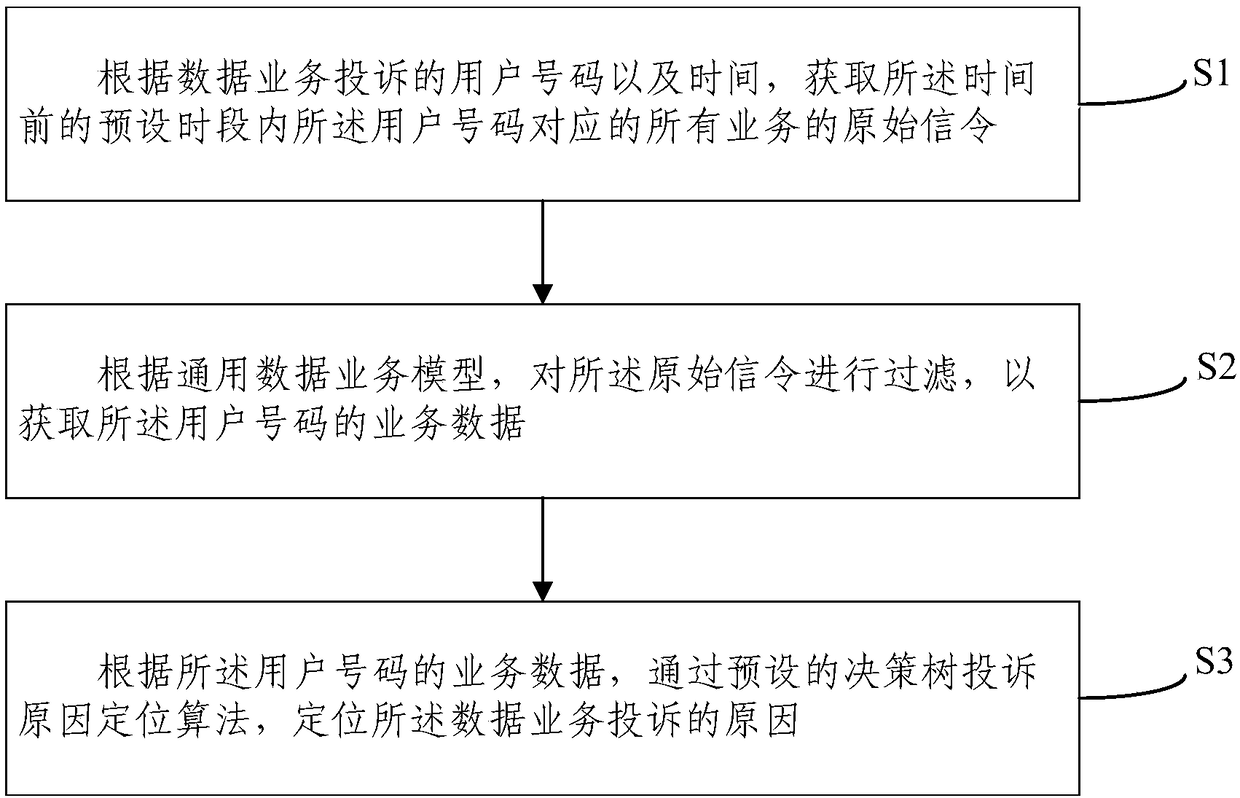

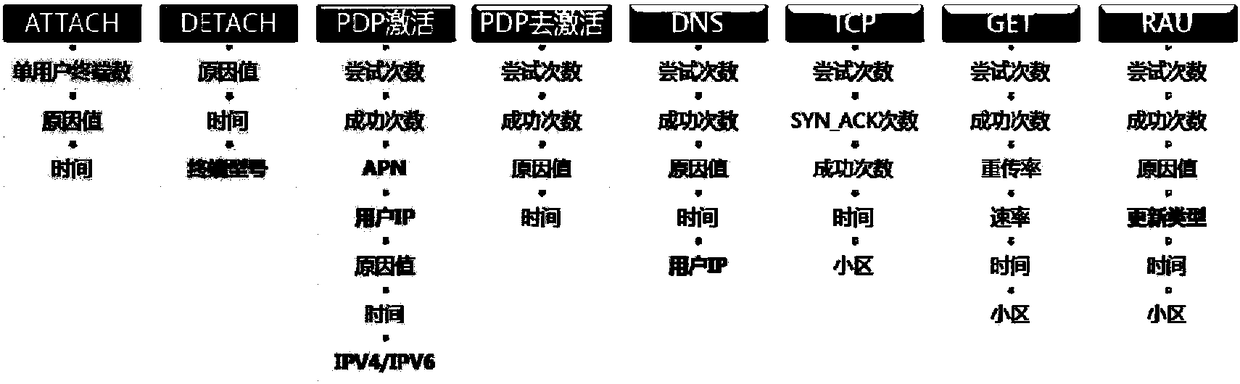

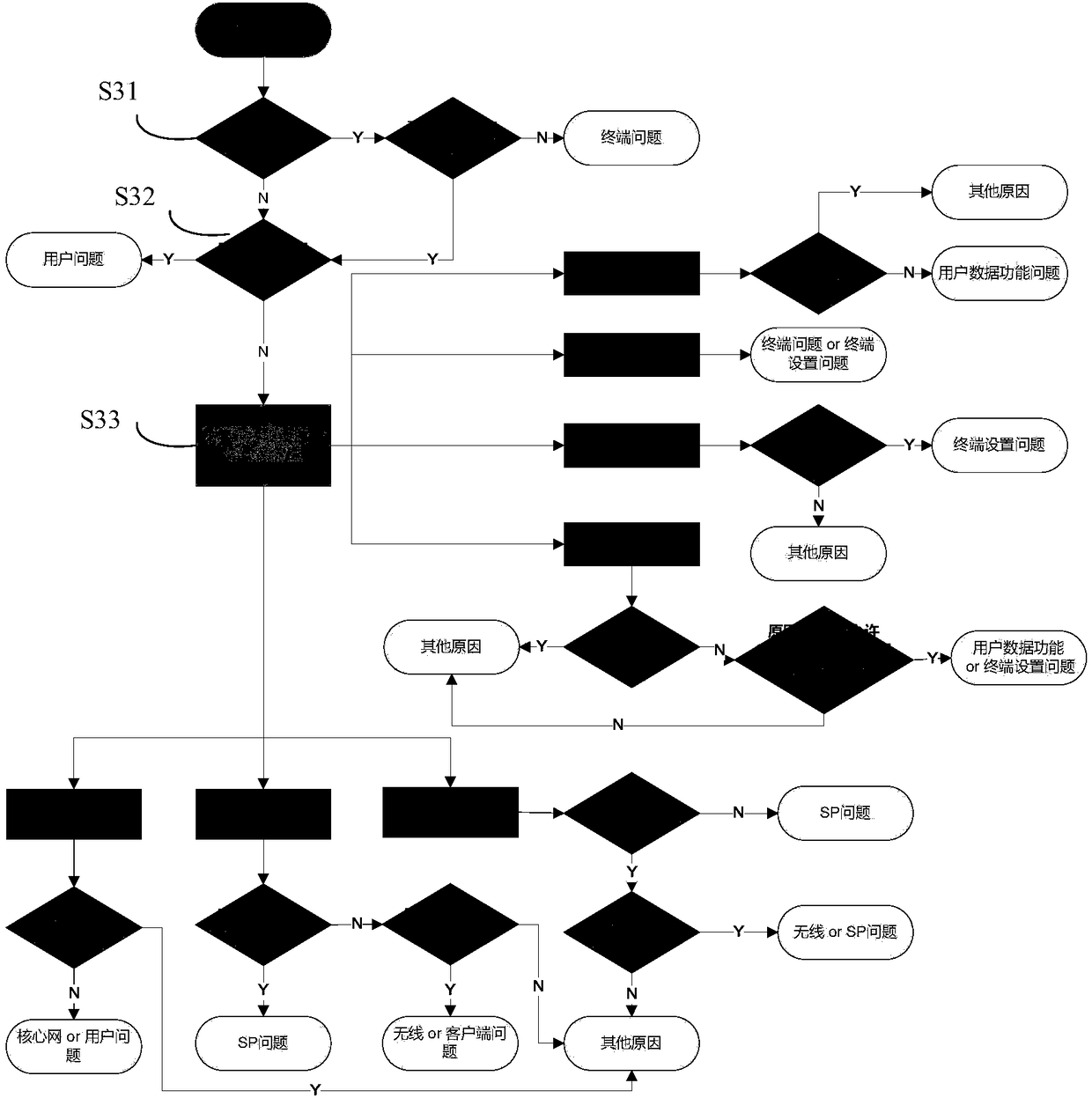

Method and device for locating cause of data service complaint

The embodiment of the invention discloses a method and device for locating the cause of a data service complaint. The method comprises the steps of according to the user number and time of the data service complaint, obtaining original signaling of all services corresponding to the user number within a preset time period prior to the time; filtering the original signaling according to a universalservice model so as to obtain service data of the user number; and locating the cause of the data service complaint through a preset decision-making tree complaint cause locating algorithm according to the service data of the user number. The device is used for implementing the method. The method provided by the embodiment of the invention for locating the cause of the data service complaint can quickly and accurately locate the cause of the data service complaint.

Owner:CHINA MOBILE GRP GUANGDONG CO LTD +1

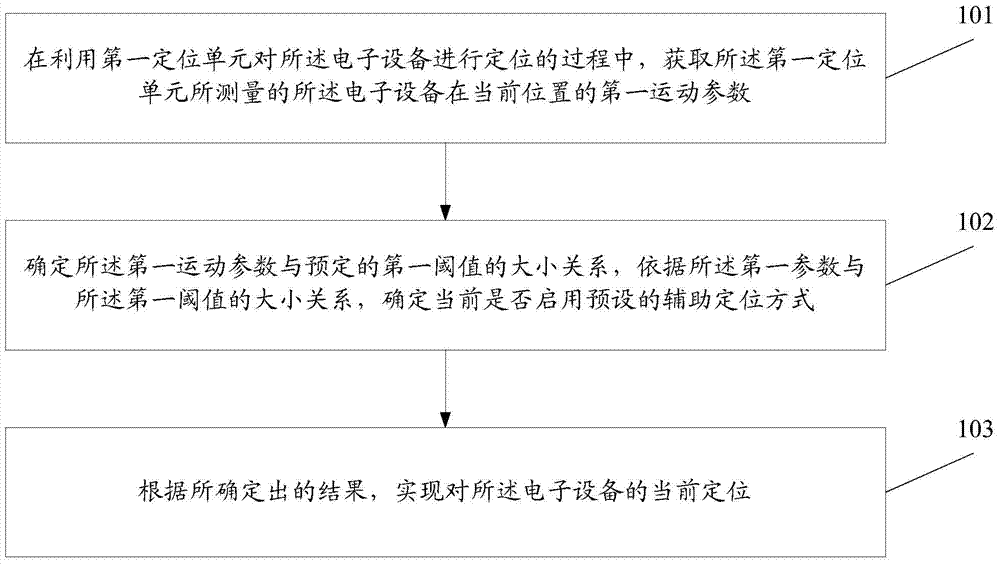

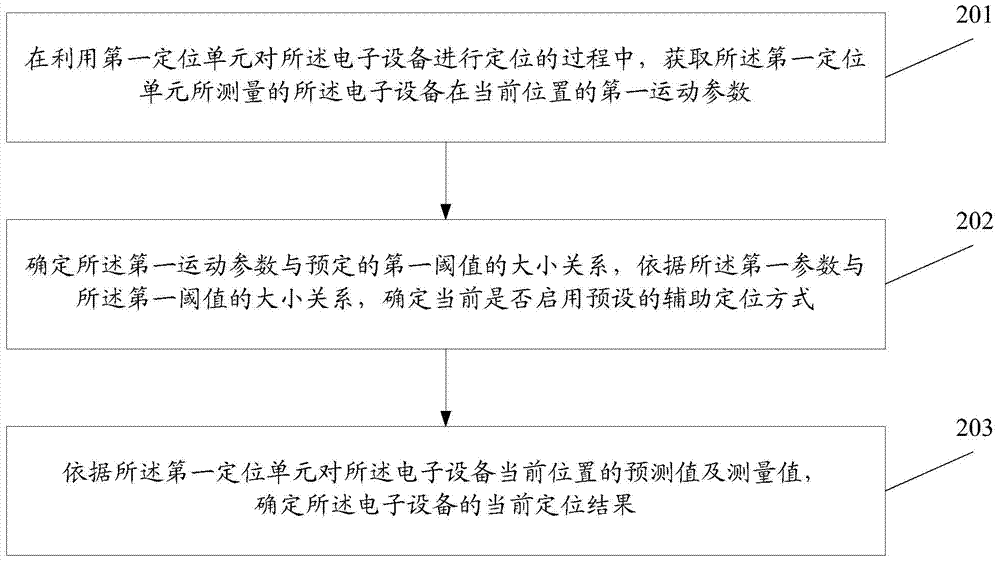

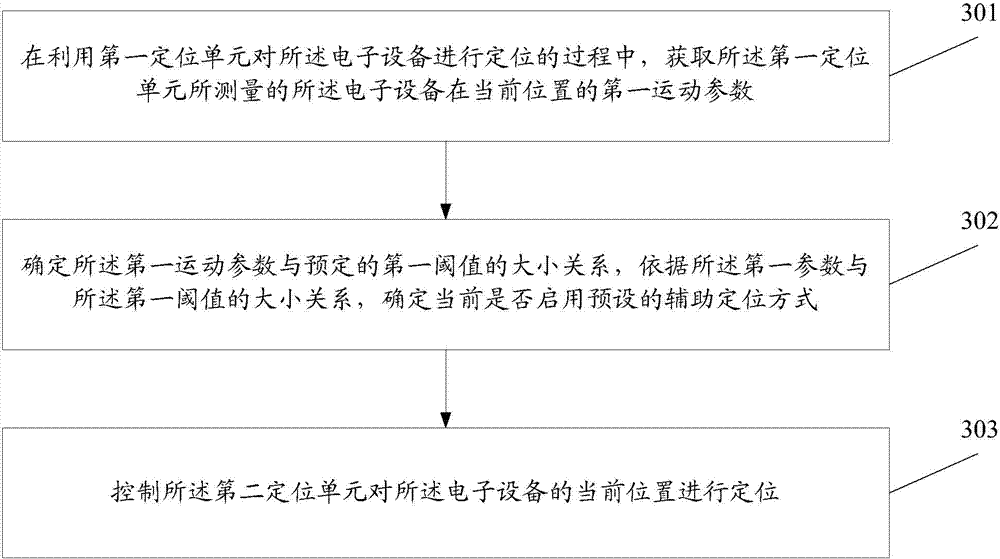

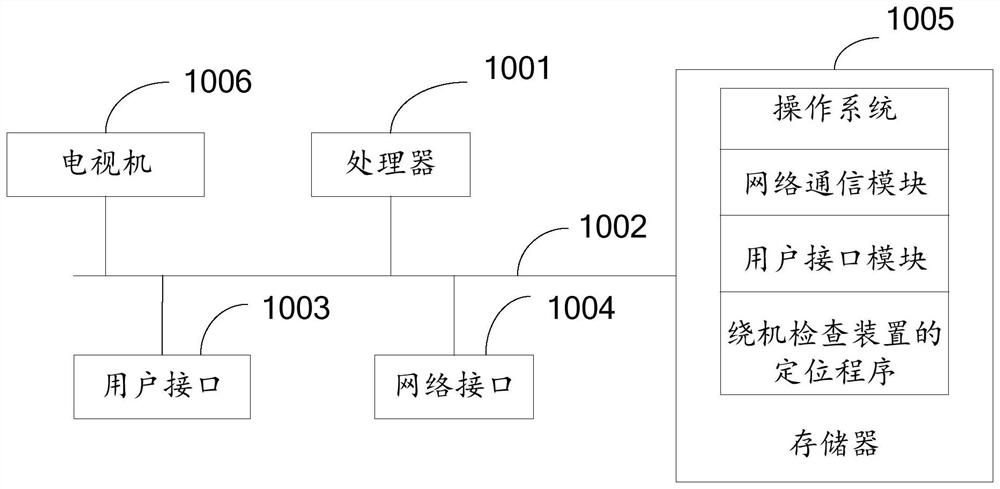

Information processing method and electronic equipment

ActiveCN103926602AAvoid Inaccurate PositioningReduce positioning errorsSatellite radio beaconingInformation processingMotion parameter

The invention provides an information processing method. The method is suitable for electronic equipment, and the electronic equipment comprises a first location unit capable of locating the electronic equipment. The method comprises the steps of obtaining a first motion parameter of the electronic equipment measured by the first location unit at the current position in the process of locating the electronic equipment through the first location unit; determining the relationship between the first motion parameter and a predetermined first threshold value; according to the relationship between the first motion parameter and the first threshold value, determining whether to start a preset auxiliary location mode at present; and according to the determined result, achieving current location of the electronic equipment. Meanwhile, the invention provides the electronic equipment. Through the information processing method and the electronic equipment, the location errors can be reduced, and the location accuracy can be improved.

Owner:LENOVO (BEIJING) CO LTD

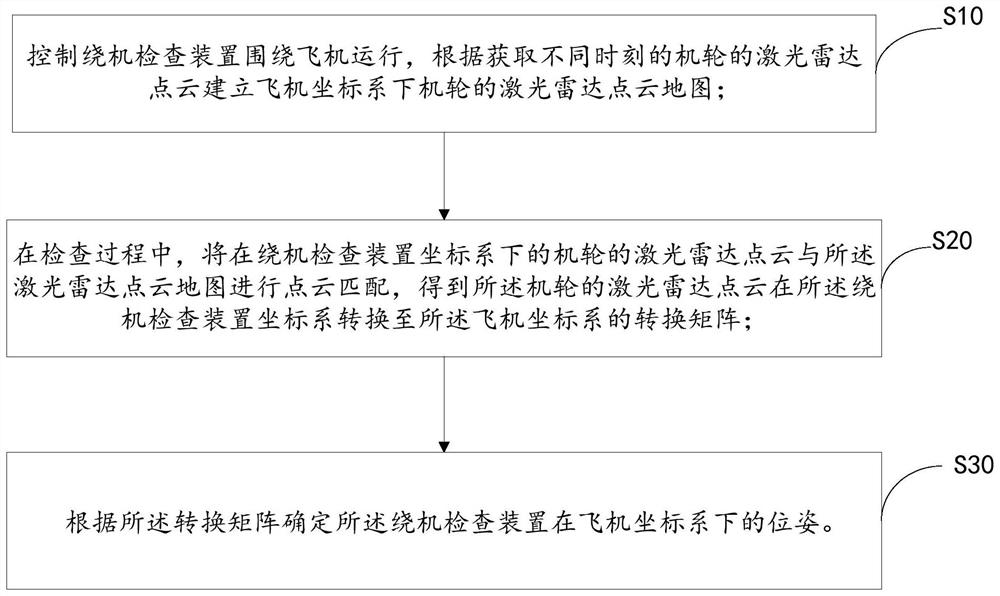

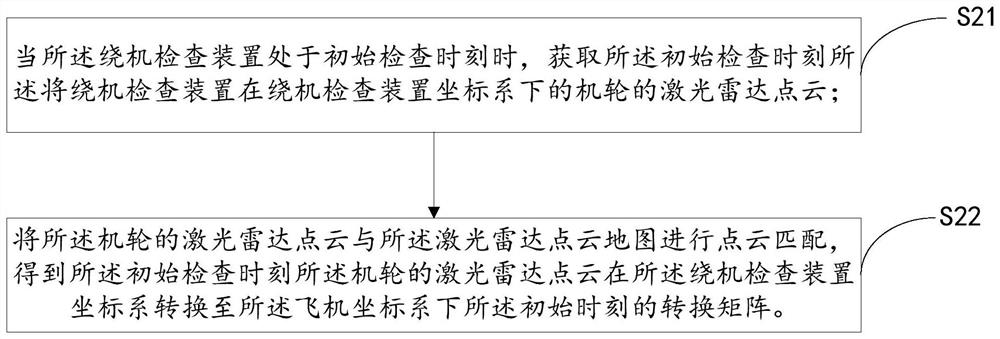

Aircraft winding inspection device and positioning method thereof, and storage medium

ActiveCN111812669AAvoid Inaccurate PositioningHigh precisionElectromagnetic wave reradiationManufacturing computing systemsPoint cloudRadar

The invention discloses an aircraft winding inspection device and a positioning method thereof, and a readable storage medium. The method comprises the steps: controlling the aircraft winding inspection device to operate around an aircraft, and establishing a laser radar point cloud map of an aircraft wheel under an aircraft coordinate system according to the acquired laser radar point clouds of the aircraft wheel at different moments; in the inspection process, carrying out point cloud matching on the laser radar point cloud of the airplane wheel under the coordinate system of the airplane winding inspection device and the laser radar point cloud map to obtain a conversion matrix of converting the laser radar point cloud of the airplane wheel from the coordinate system of the airplane winding inspection device to the coordinate system of the airplane; and determining the pose of the aircraft winding inspection device under the aircraft coordinate system according to the conversion matrix. The problem that in the prior art, it is inaccurate to determine the pose information of the aircraft winding inspection device through a GPS positioning method is solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

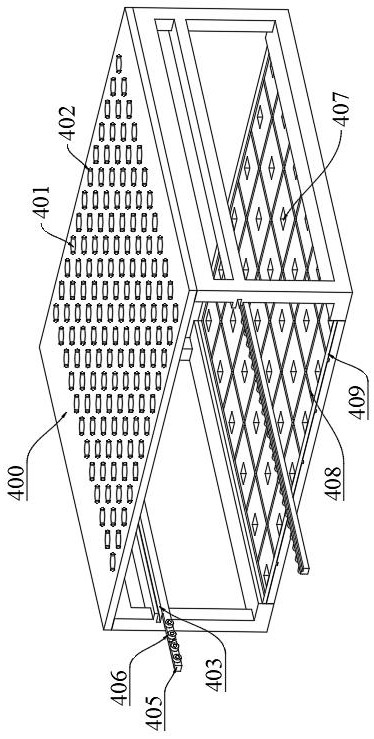

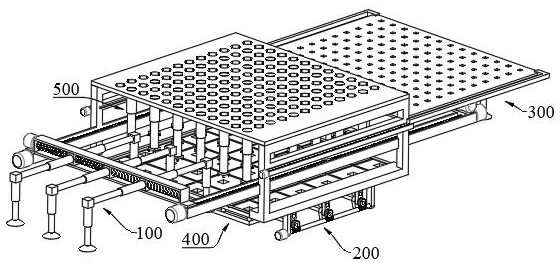

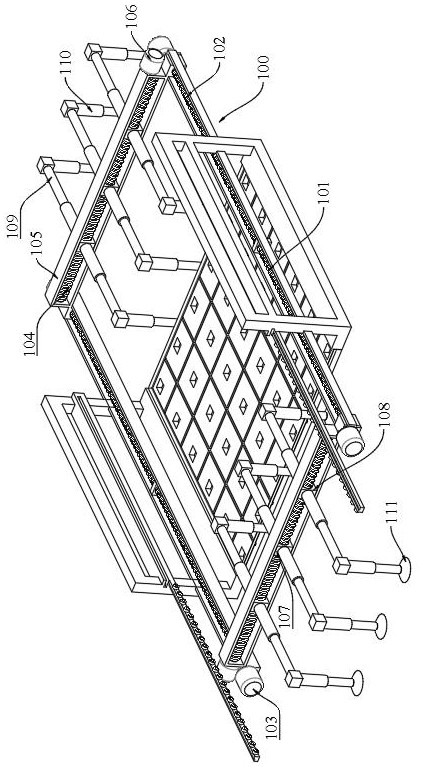

Printed circuit board copper embedding device and printed circuit board processing method

ActiveCN113630969AFirmly connectedAvoid damage phenomenonCircuit thermal detailsMultilayer circuit manufactureProcess engineeringTransfer mechanism

The invention provides a printed circuit board copper embedding device and a printed circuit board processing method. The device comprises a transfer mechanism, a jacking mechanism, a bearing mechanism, a supporting frame and a clamping mechanism. The supporting frame is used for bearing a printed circuit board. The transfer mechanism comprises two sets of transfer assemblies which are symmetrically arranged and used for transferring the printed circuit board, and the jacking mechanism is arranged below the supporting frame and used for jacking the printed circuit board to a preset height. The bearing mechanism is fixed to the supporting frame and used for loading the copper block to the position below the clamping mechanism. The clamping mechanism comprises a plurality of clamping assemblies and is used for clamping copper blocks into square holes of the printed circuit board. The printed circuit board processing method comprises the following steps: manufacturing a circuit board; manufacturing a copper block; clamping the copper block into the square hole of the circuit board; injecting resin; flattening the circuit board; performing press fit; performing electroplating; drilling holes; and performing copper deposition. The printed circuit board copper embedding device is simple in structure, adapts to the requirements of different printed circuit board sizes, can avoid inaccurate positioning, is convenient to clamp, shortens the production time, and improves the production efficiency.

Owner:四川英创力电子科技股份有限公司

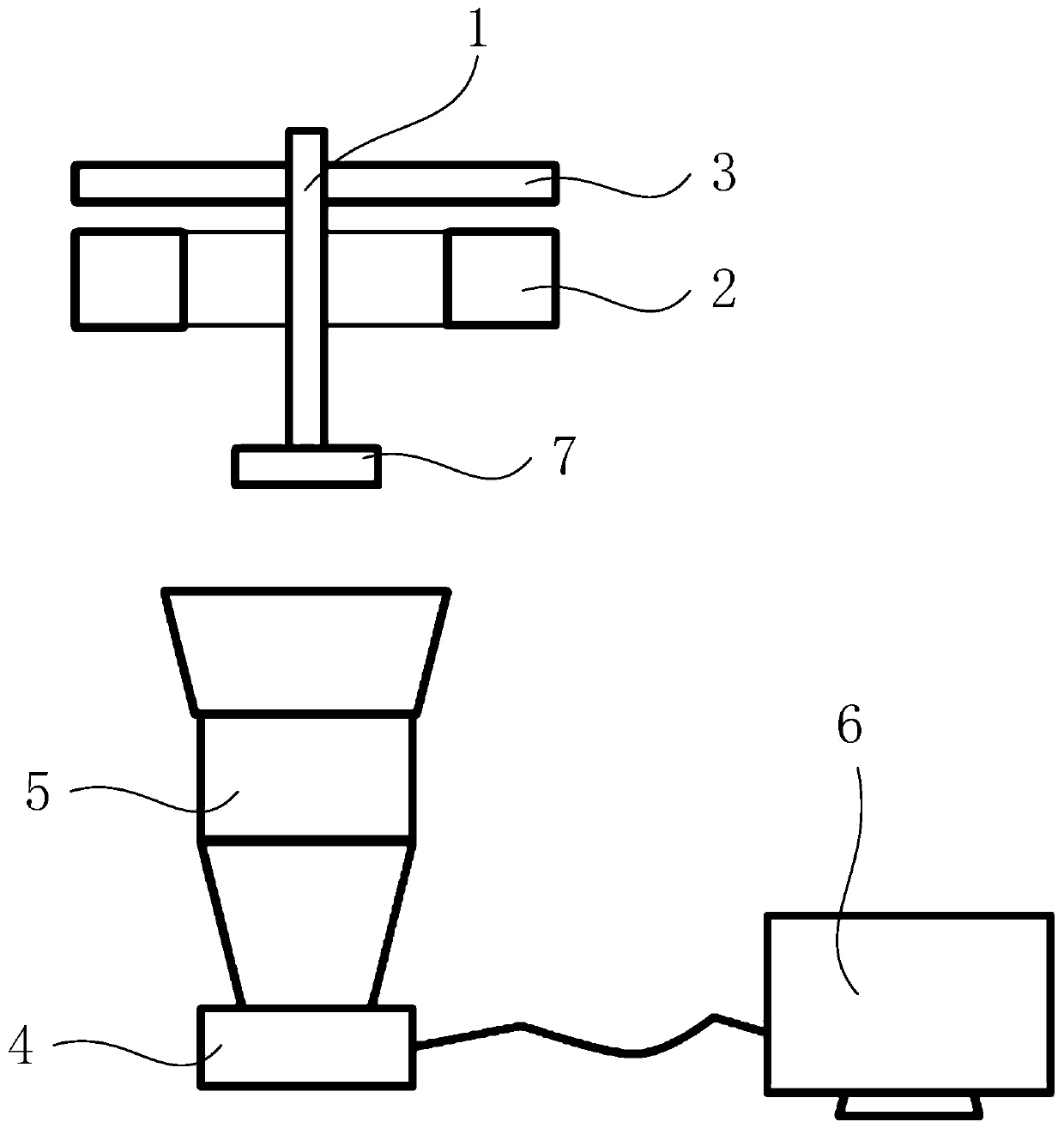

Backlight imaging device

PendingCN111578842APrevent movementRealize the effect of backlight imagingUsing optical meansConveyor partsMedicineEngineering

The invention relates to the technical field of chip detection, in particular to a backlight imaging device. The backlight imaging device comprises a manipulator, a light source assembly, a reflectorand an image acquisition device. The manipulator can pick up a chip to be detected and move the chip to a detection position. The image acquisition device is positioned below the detection position and is used for acquiring an image of the chip. The reflector is located above the chip and is fixedly connected with the manipulator. The light source assembly is located between the chip and the reflector, light emitted by the light source assembly irradiates towards the reflector, and the light emitted by the light source assembly cannot directly irradiate the plate face of the side, facing the camera, of the chip. After light rays irradiate the reflector, the light rays are reflected back through the reflector, the reflected light rays vertically and downwards irradiate into the image acquisition device below the reflector, part of the reflected light rays are shielded by the chip, imaging of the chip on the image acquisition device is black, and therefore the backlight imaging effect isachieved.

Owner:BEIJING CITY UNIVERSITY

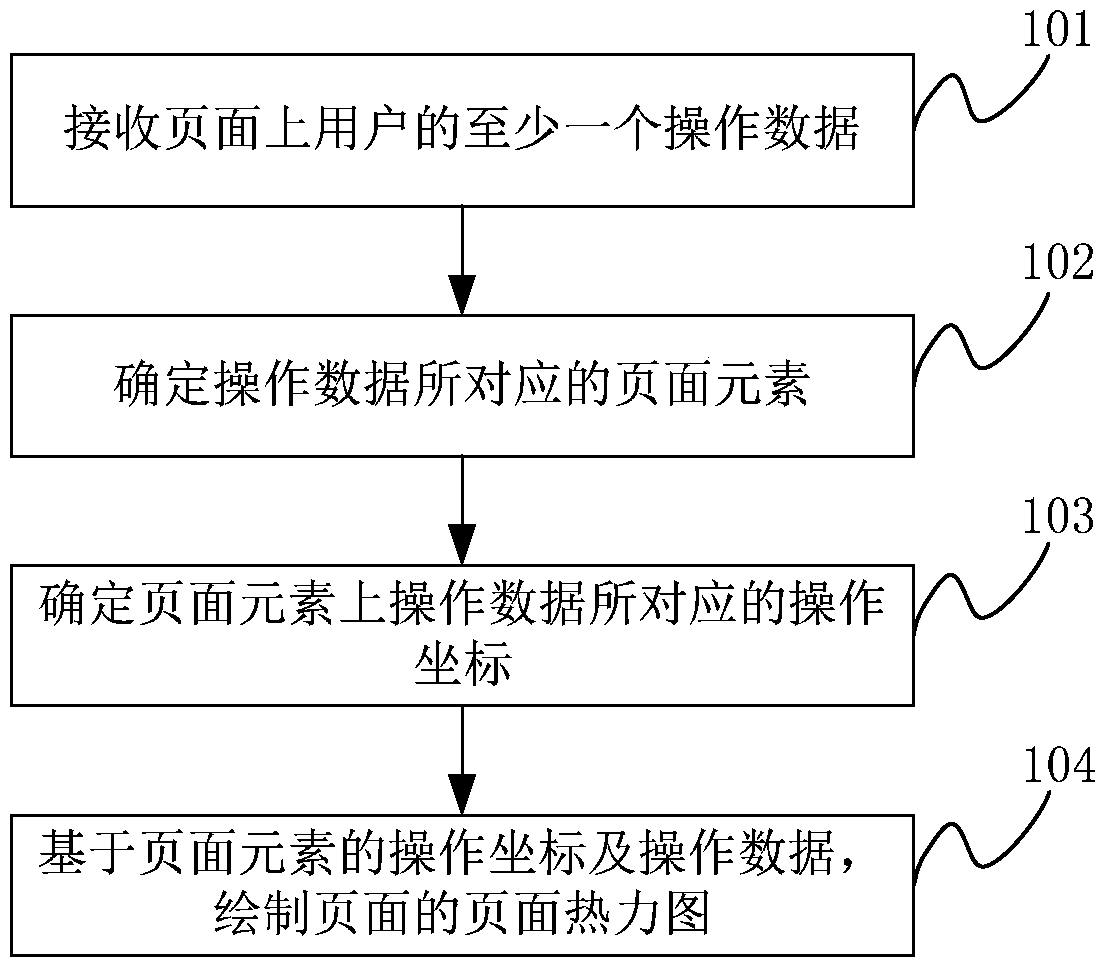

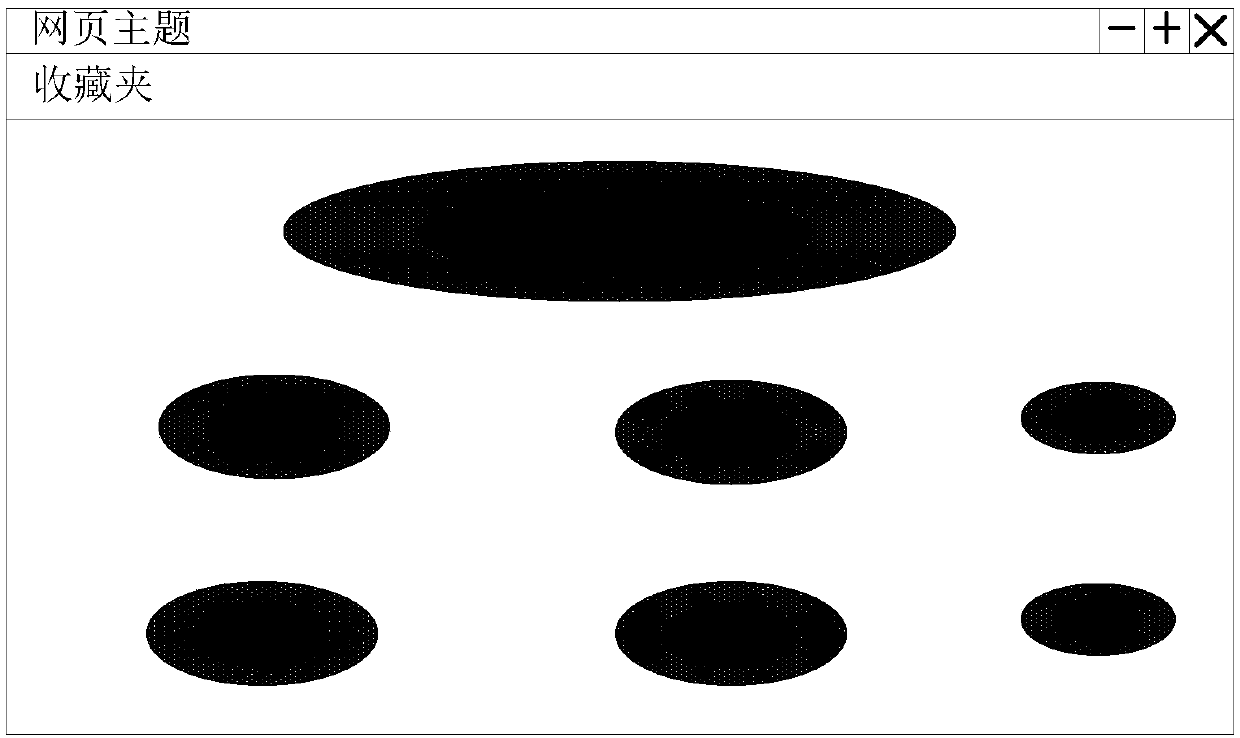

Page operation thermodynamic diagram drawing method and device, storage medium and processor

ActiveCN109857964AAvoid inaccurate positioningImprove accuracy2D-image generationWebsite content managementComputer scienceThermodynamic diagrams

Owner:BEIJING GRIDSUM TECH CO LTD

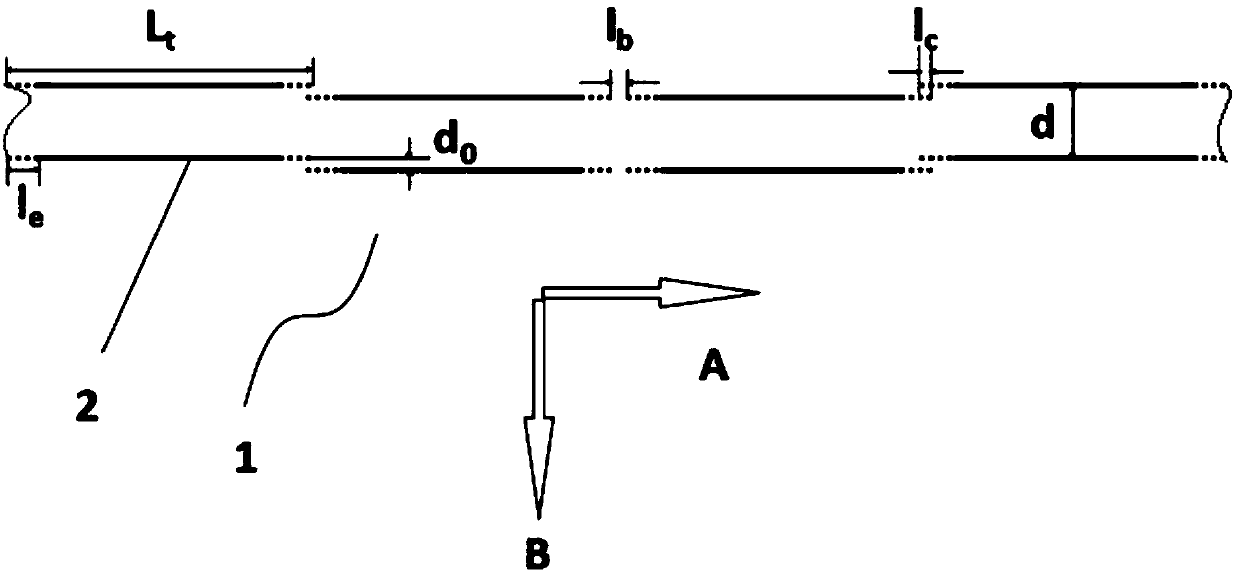

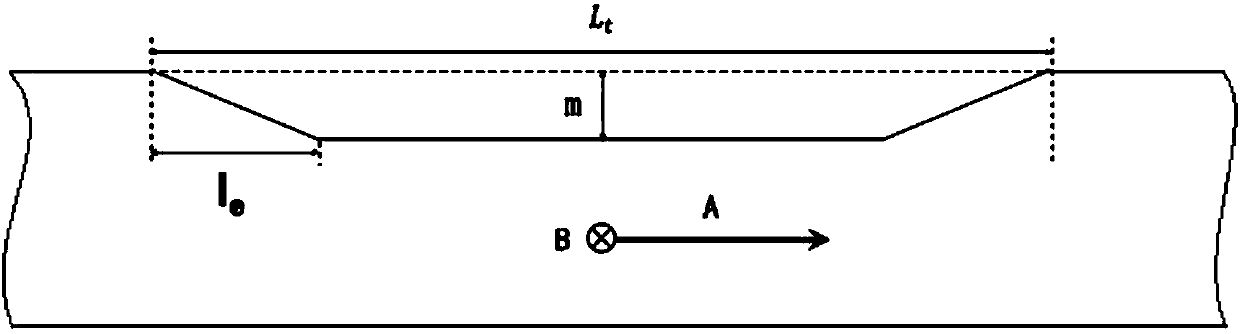

Heat-resistant magnetic domain refined-type oriented silicon steel and manufacturing method thereof

ActiveCN110323044ADomain refinementReduce iron lossInorganic material magnetismTransformers/inductances detailsLaser beamsSilicon

The invention discloses a heat-resistant magnetic domain refined-type oriented silicon steel. A plurality of parallel grooves formed in a nicking mode are formed in a single-face surface or a double-face surface of the heat-resistant magnetic domain refined-type oriented silicon steel, wherein each groove extends in the width direction of the heat-resistant magnetic domain refined-type oriented silicon steel, and the parallel grooves are evenly distributed in the rolling direction of the heat-resistant magnetic domain refined-type oriented silicon steel. Each groove extending in the width direction of the heat-resistant magnetic domain refined-type oriented silicon steel is formed by splicing a plurality of sub-grooves extending in the width direction of the heat-resistant magnetic domainrefined-type oriented silicon steel. The invention further discloses a manufacturing method of the heat-resistant magnetic domain refined-type oriented silicon steel. The method comprises the steps: forming the grooves in the single-face surface or the double-face surface of the heat-resistant magnetic domain refined-type oriented silicon steel in a laser nicking mode, and dividing a laser beam ofthe laser nicking into a plurality of sub-beams by an optical splitter, wherein the sub-beams form the sub-grooves spliced into the same groove.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com