Automatic detection system and detection method of high resolution printed circuit board

A printed circuit board, automatic detection technology, applied in measurement devices, analysis materials, material analysis using radiation, etc., can solve the problems of inability to test, high cost, limited test coverage, achieve accurate defect identification, reduce Clarity, hardware for simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

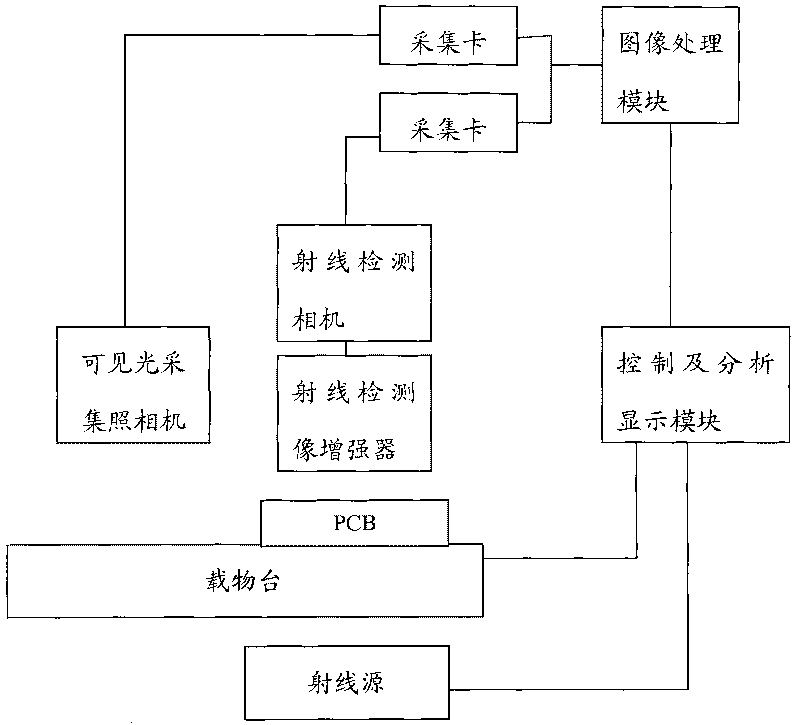

[0032] Such as figure 1 As shown, the detection system is composed of a ray source, a stage, a visible light collection camera, a ray detection camera, a ray detection image intensifier and an acquisition card, an image processing module, and a control and analysis display module. The sources are respectively connected to the control and analysis display modules through connecting lines. The stage is set with two initial positions, which are respectively the visible light shooting position and the radiation detection position. The position is provided with a radiation detection camera and a radiation detection image intensifier, and the radiation detection camera takes images in the radiation detection image intensifier; the visible light acquisition camera and the radiation detection camera are respectively connected through an acquisition card and an image processing module, and the image The processing module is connected to the control and analysis display module through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com