Printed circuit board copper embedding device and printed circuit board processing method

A technology of printed circuit boards and circuit boards, which is applied in the direction of circuit heating devices, printed circuit manufacturing, printed circuits, etc., can solve problems affecting production efficiency, printed circuit board damage, and product quality, and achieve the goal of reducing clamping time, avoiding inaccurate positioning, and convenient and fast clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0054] The specific implementation is described as follows:

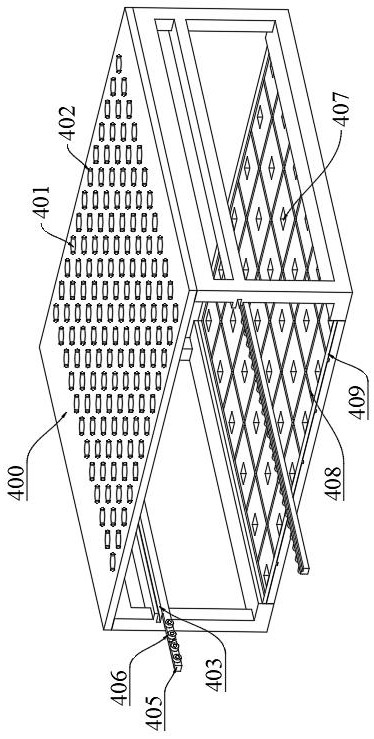

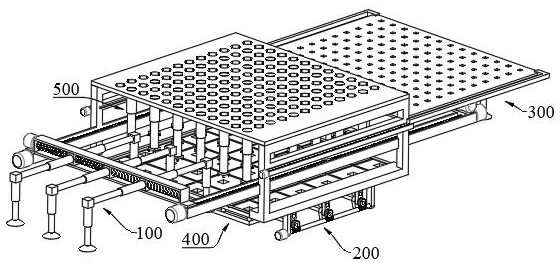

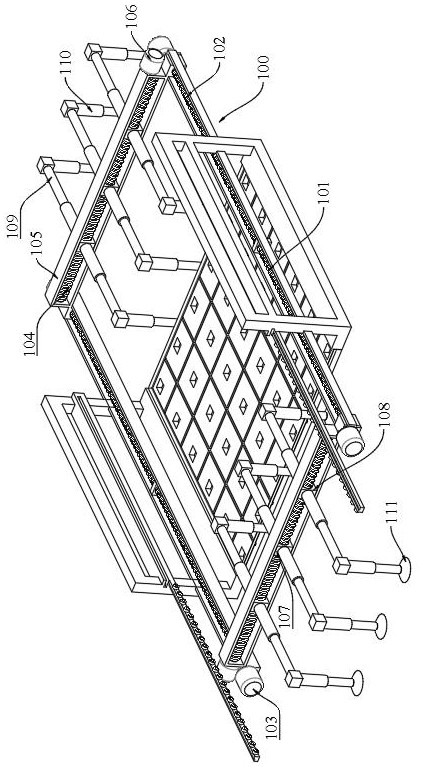

[0055] Wherein the method for using the printed circuit board embedded copper block device used in step 3 is to select different limit strips 409 according to the size of the printed circuit board, and connect the four limit strips 409 end to end to make one limit strip The second locking pin 411 on the 409 cooperates with the second locking groove 412 of another adjacent limiting bar 409 to form a limiting area, and the combined limiting bar 409 is placed on the bottom of the support frame 400, so that The boss 410 cooperates with the mounting groove 408; the first telescopic rod 109 is started to adjust the distance between the second telescopic rods 110 on both sides of the second screw mandrel 104, and the second motor 106 is started to drive the second screw mandrel 104 to rotate. The two sections of thread of the second screw mandrel 104 rotate in the opposite direction, so that the connecting blocks 108 can m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com