Patents

Literature

53results about How to "Supporting requirements are low" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

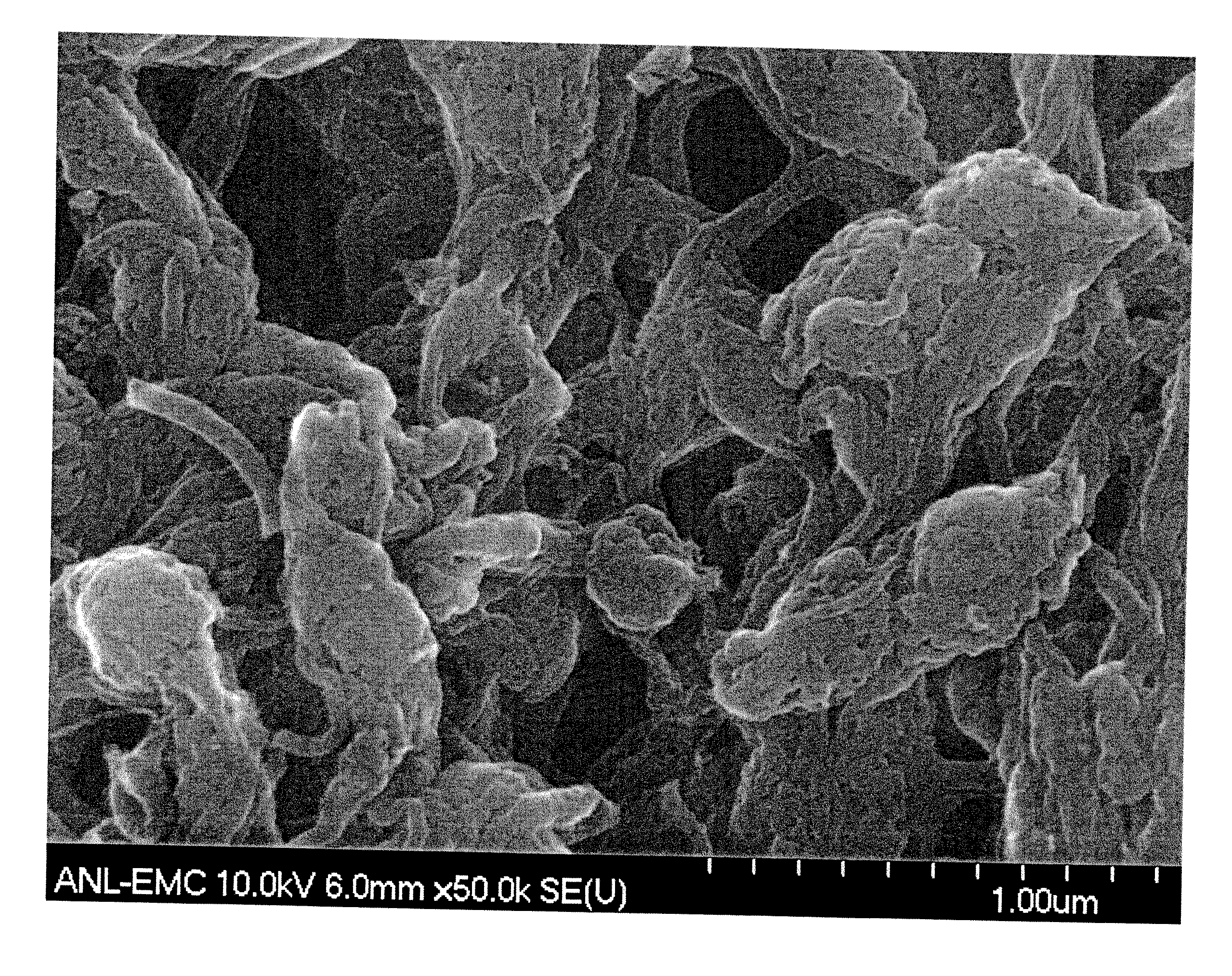

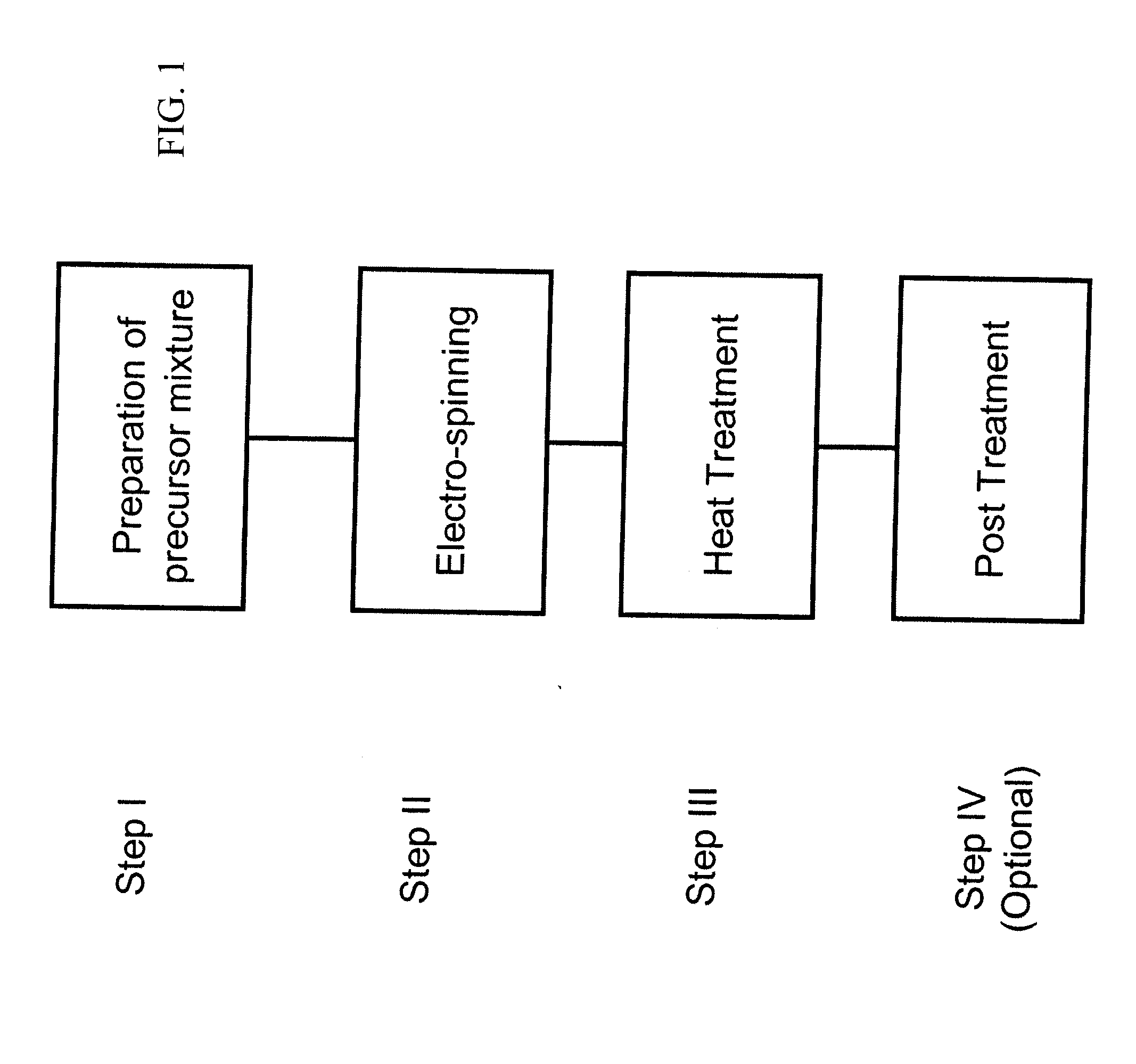

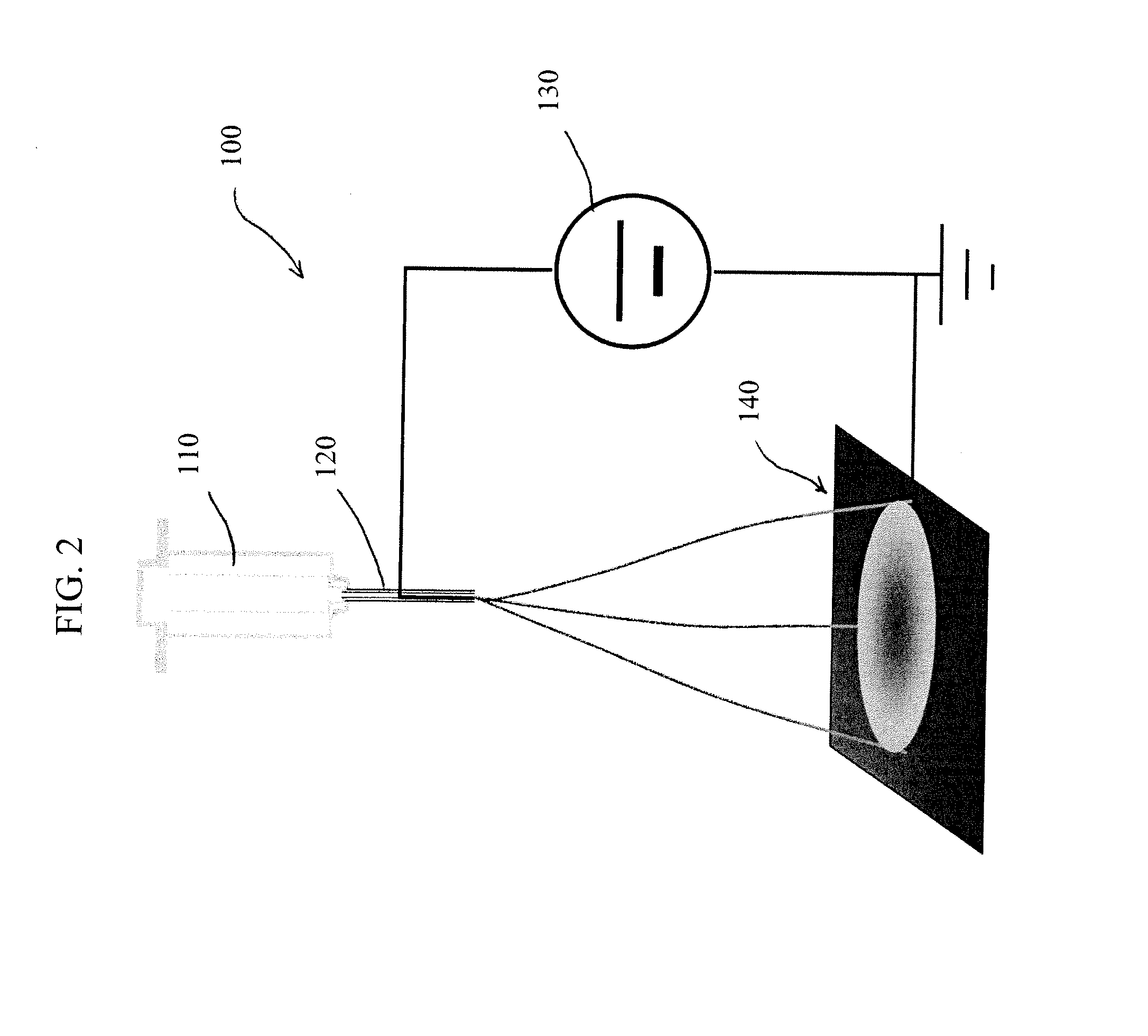

Nanofibrous electrocatalysts

ActiveUS20140093790A1Promoting mass transportImproves thermalMaterial nanotechnologyFuel and secondary cellsNanofiberMetal

A nanofibrous catalyst and method of manufacture. A precursor solution of a transition metal based material is formed into a plurality of interconnected nanofibers by electro-spinning the precursor solution with the nanofibers converted to a catalytically active material by a heat treatment. Selected subsequent treatments can enhance catalytic activity.

Owner:UCHICAGO ARGONNE LLC

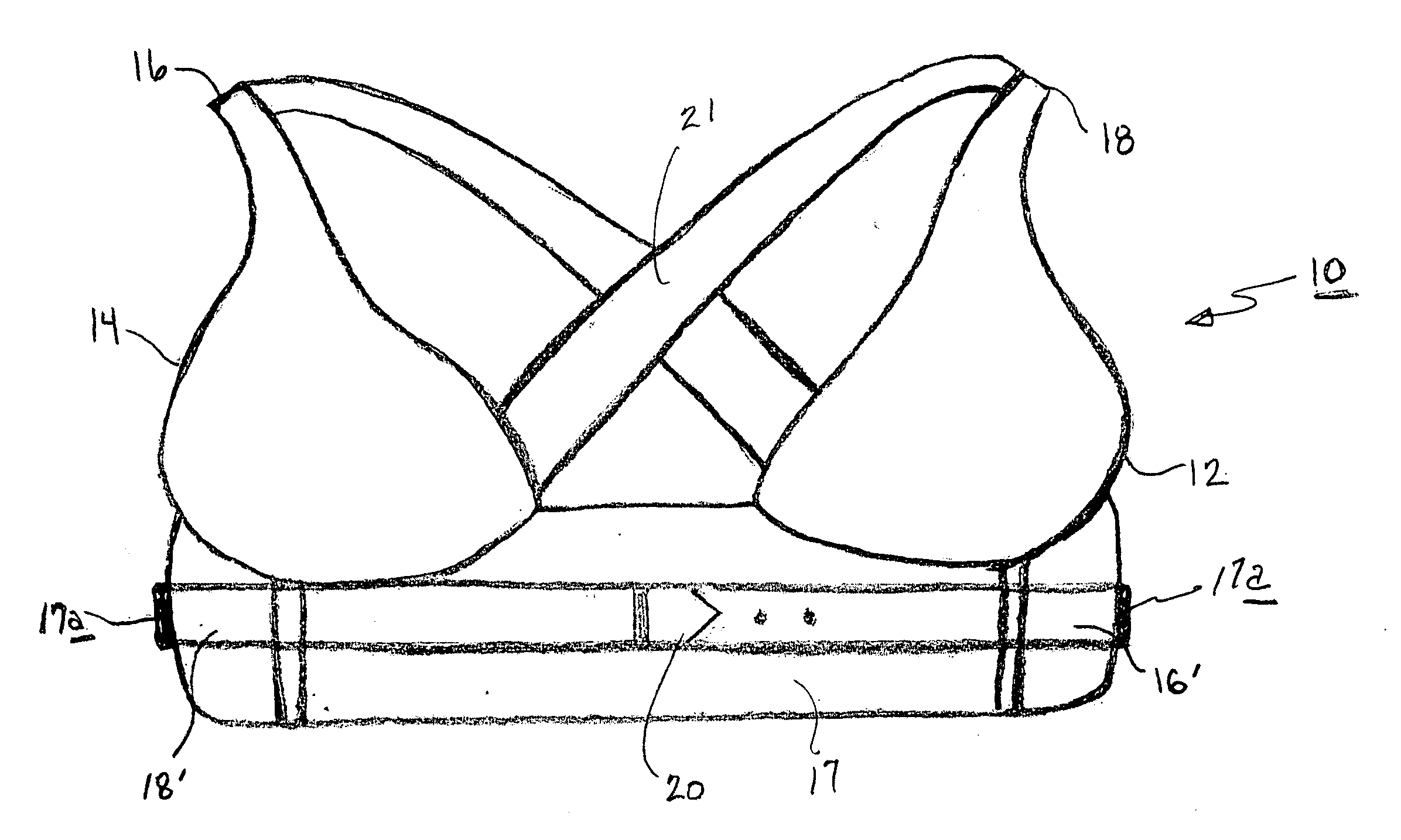

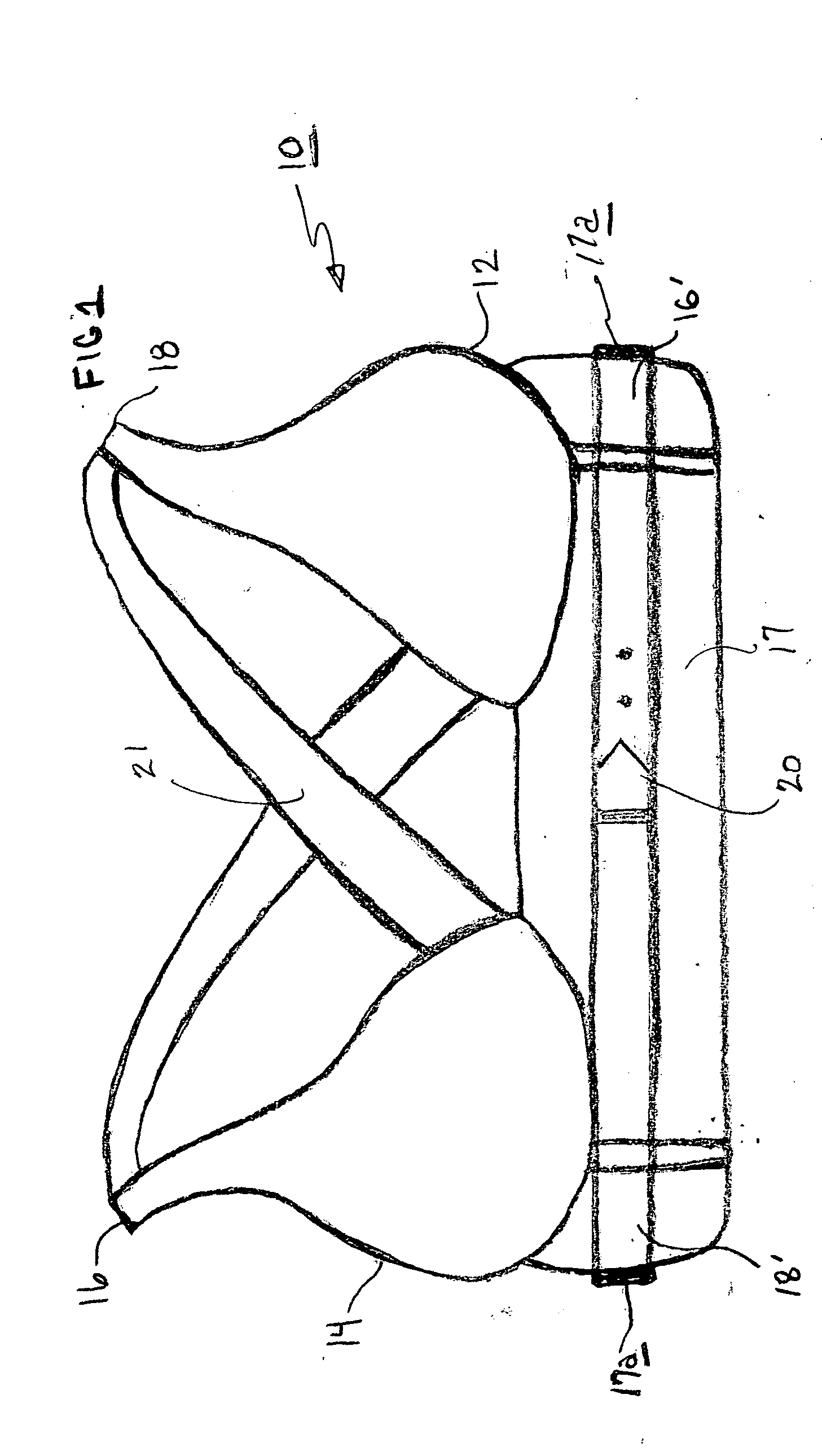

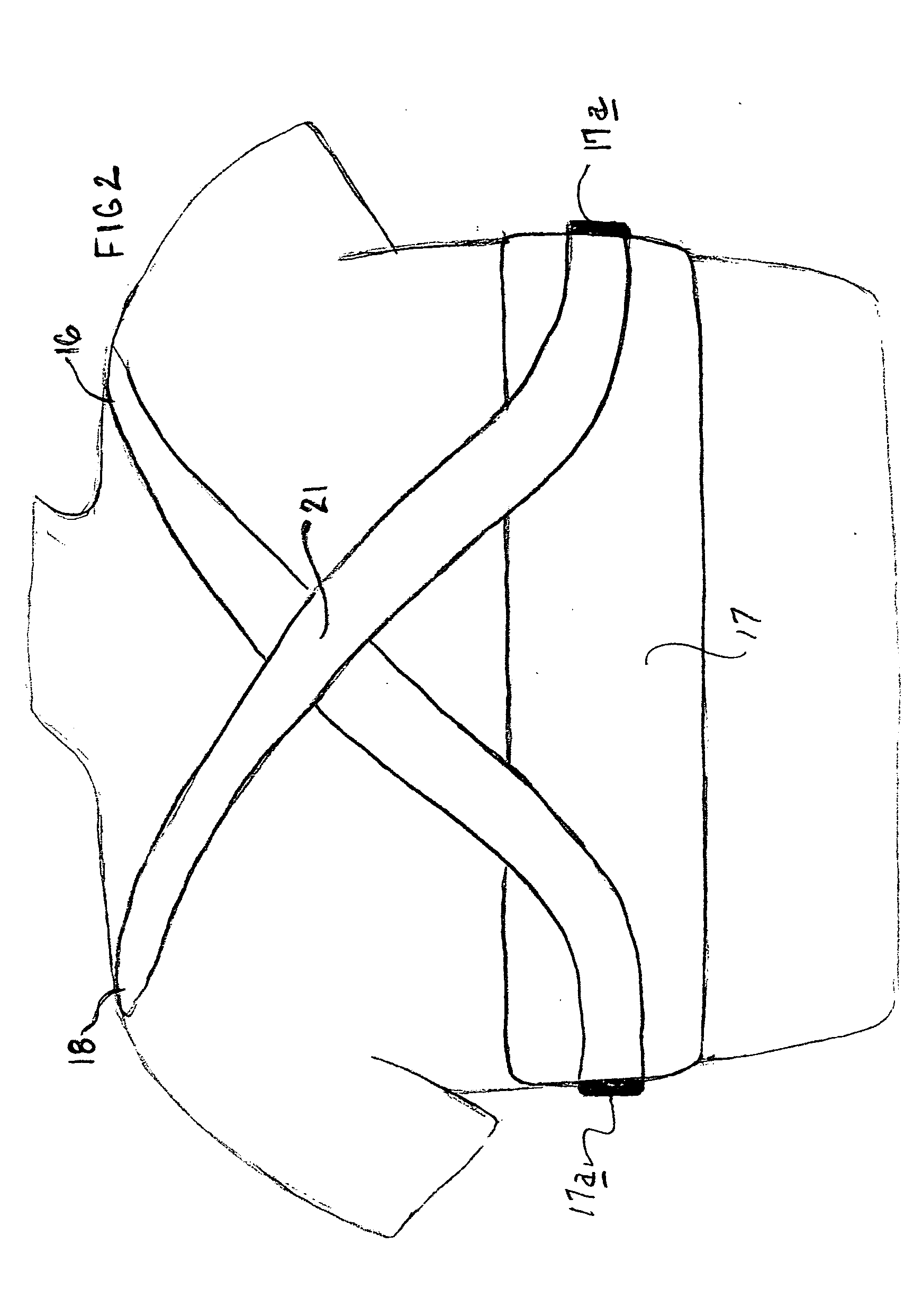

Support brassiere

InactiveUS20060089083A1Provide supportSupporting requirements are lowBrassieresBiomedical engineering

Owner:TONSOR DAWN

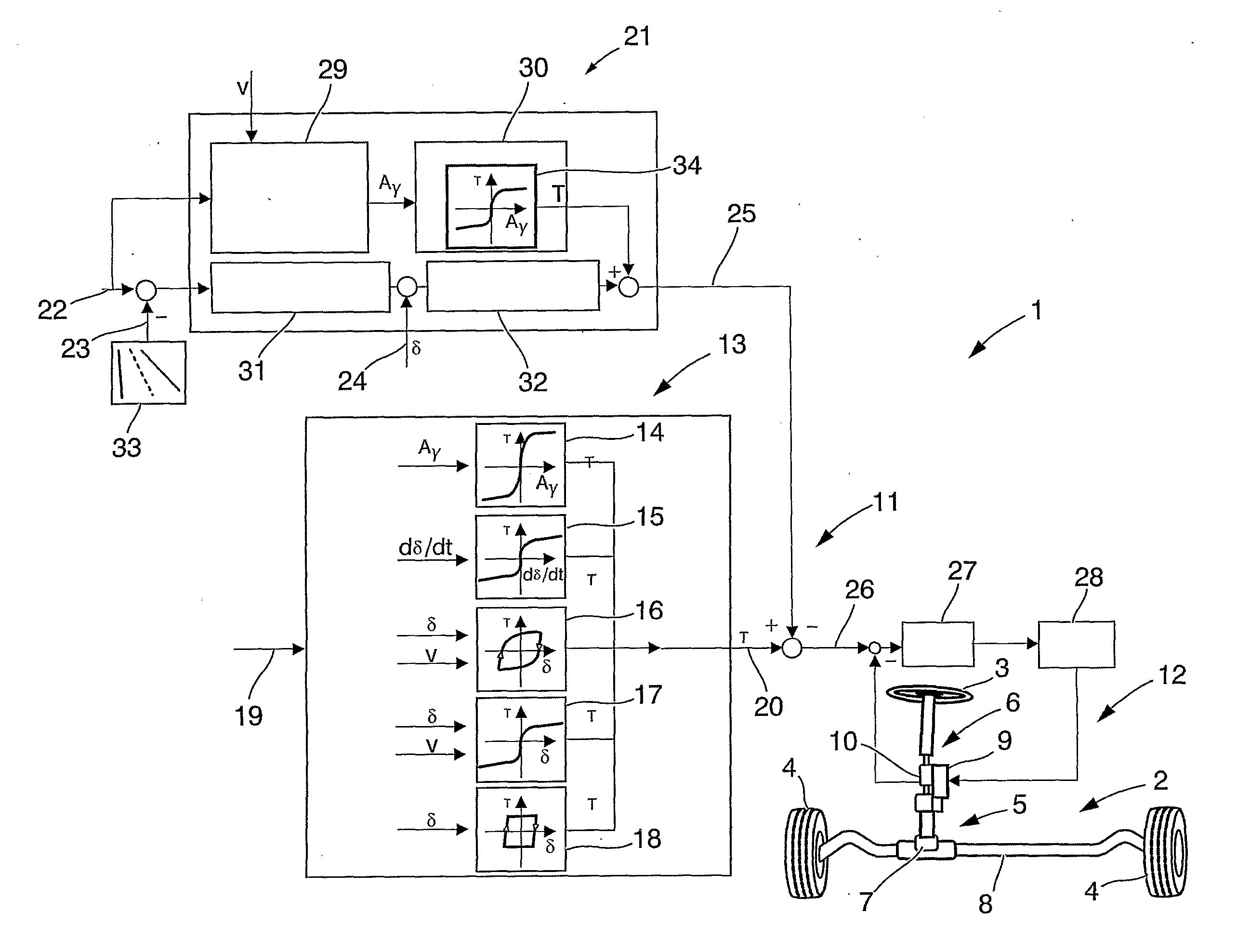

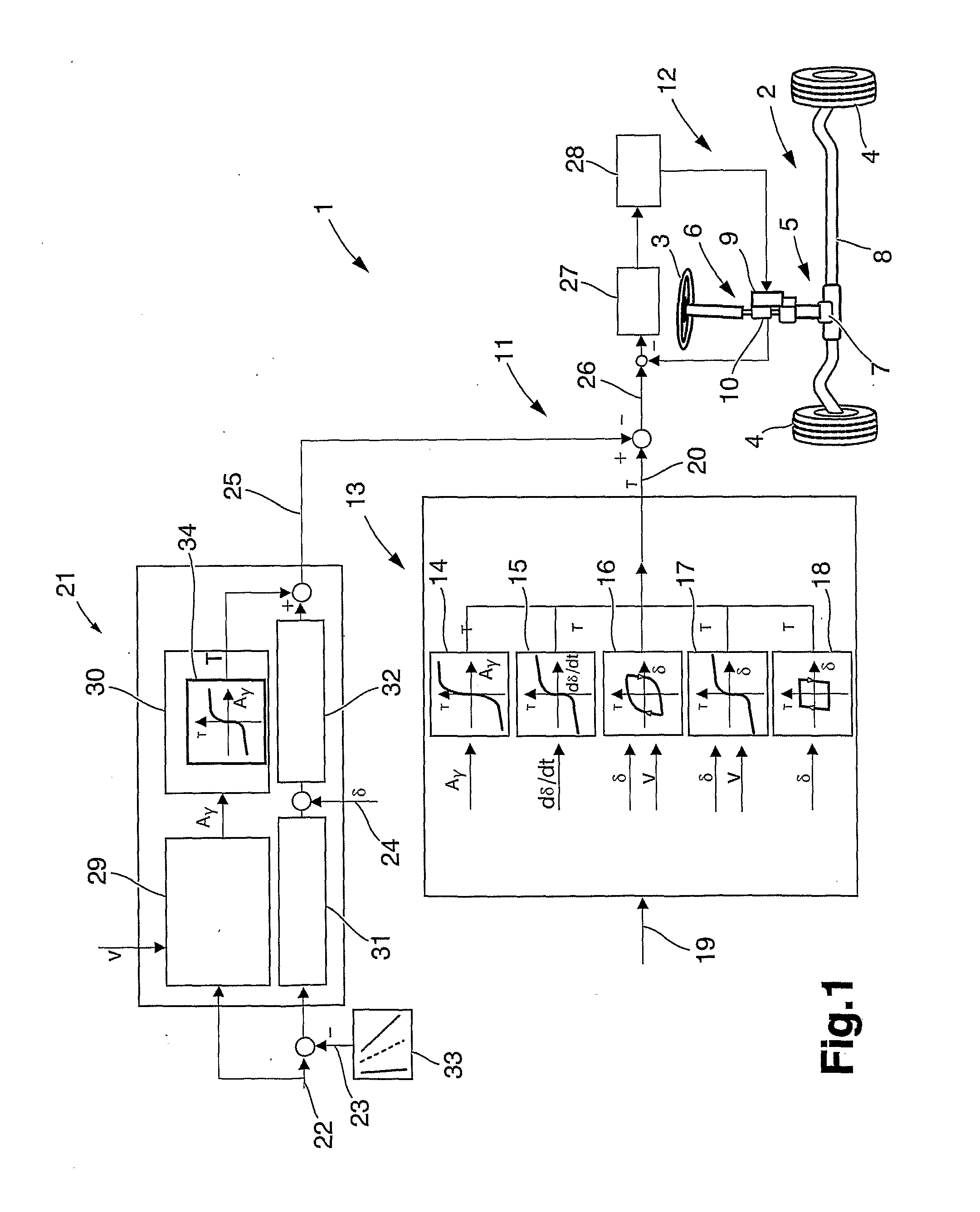

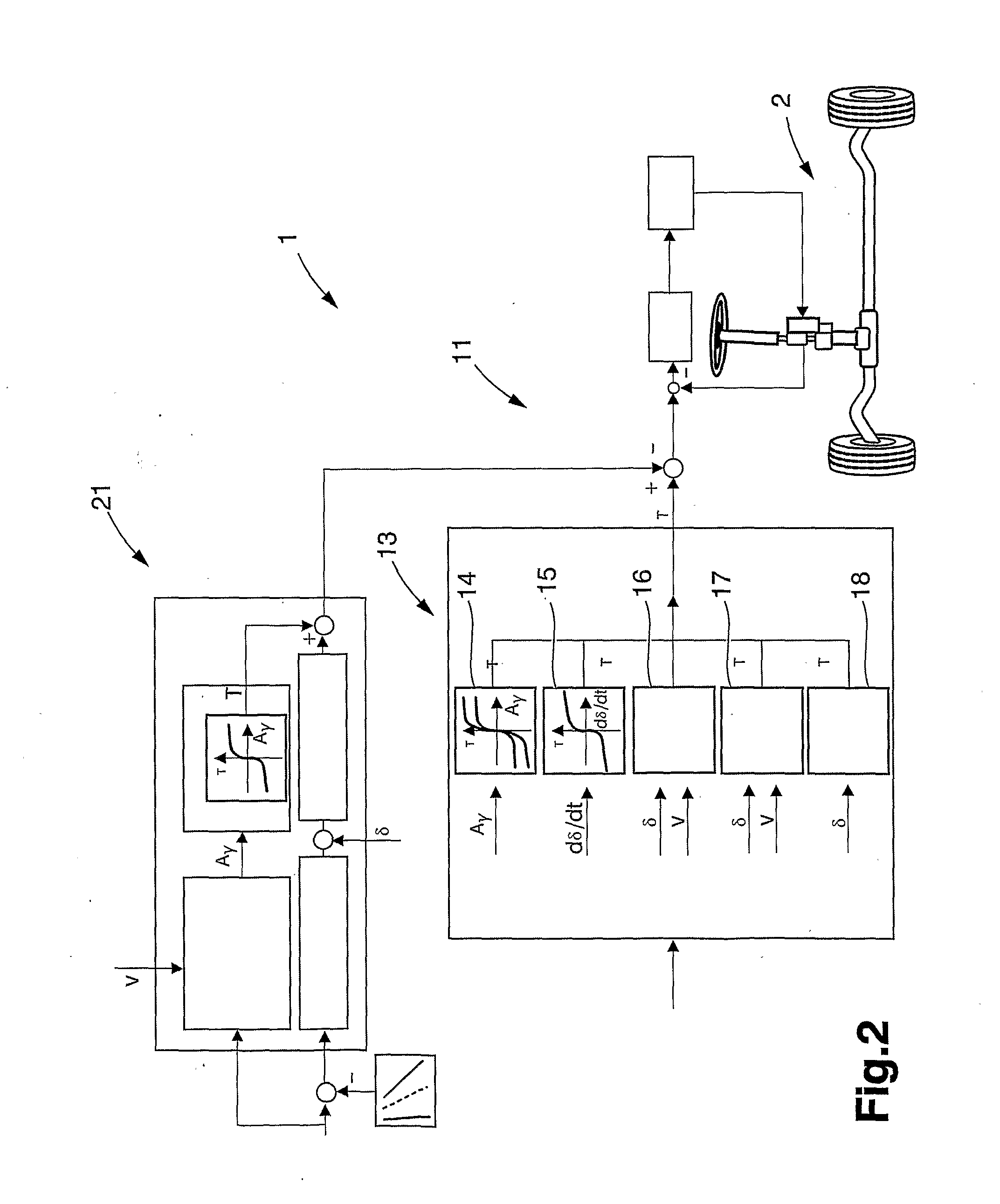

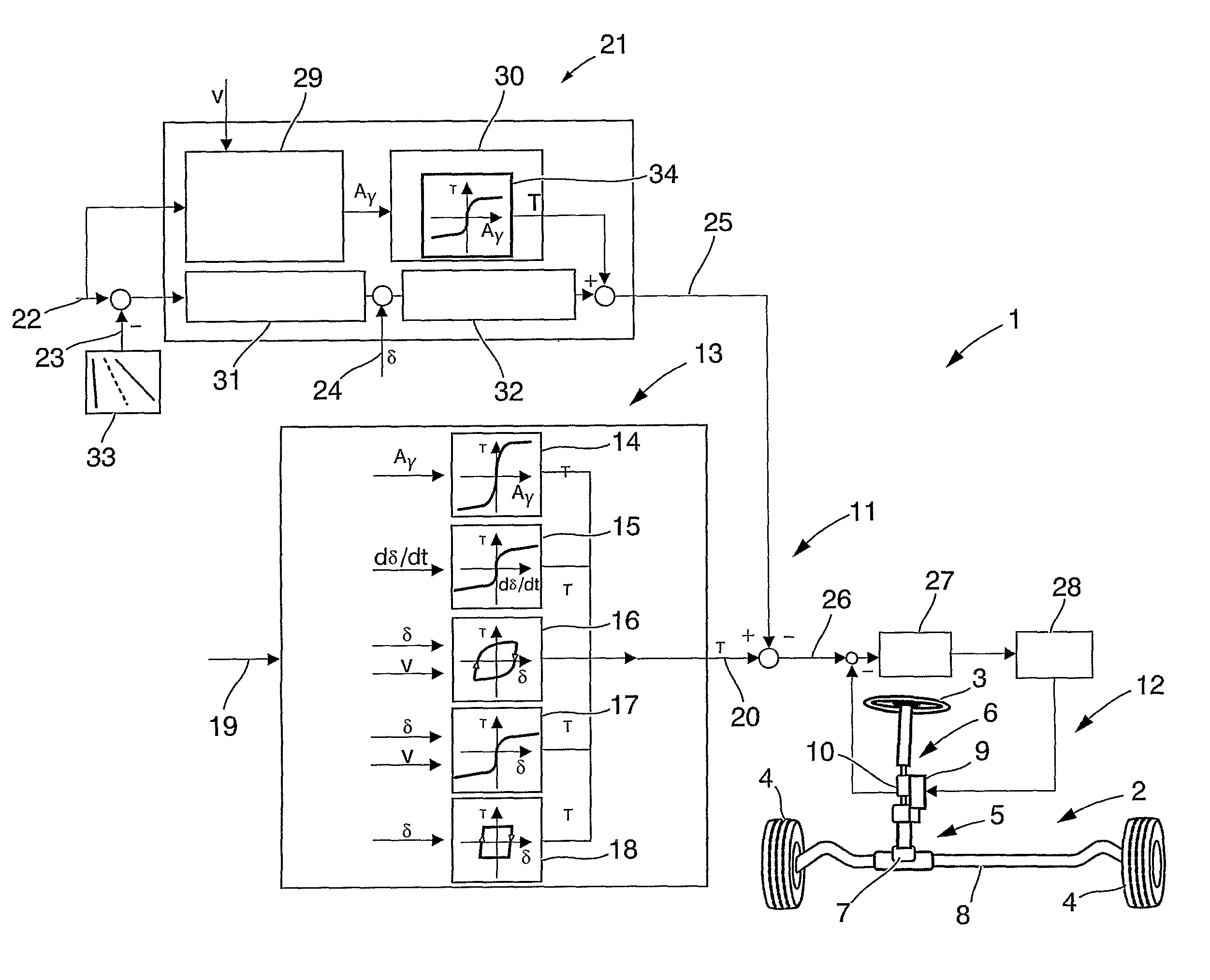

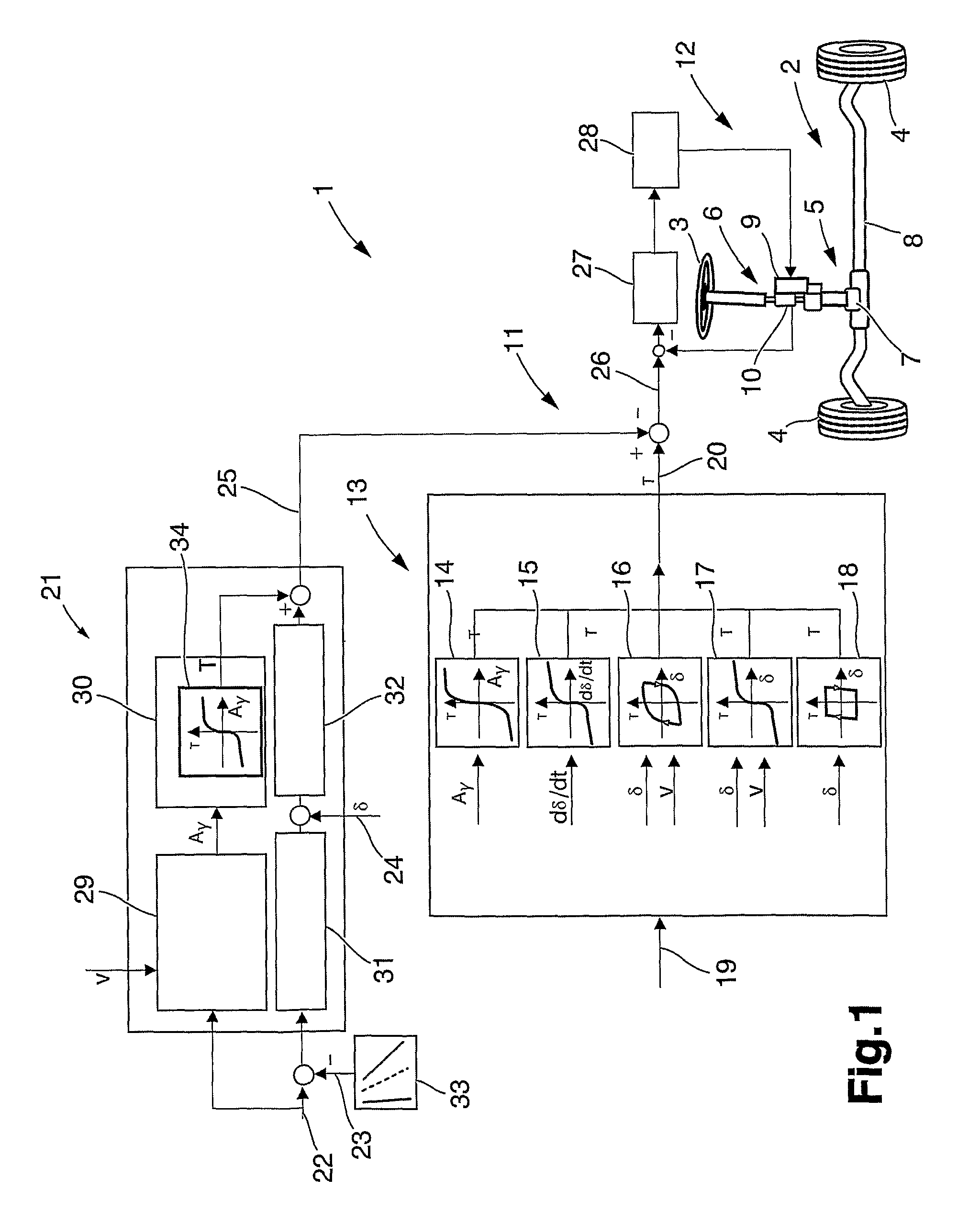

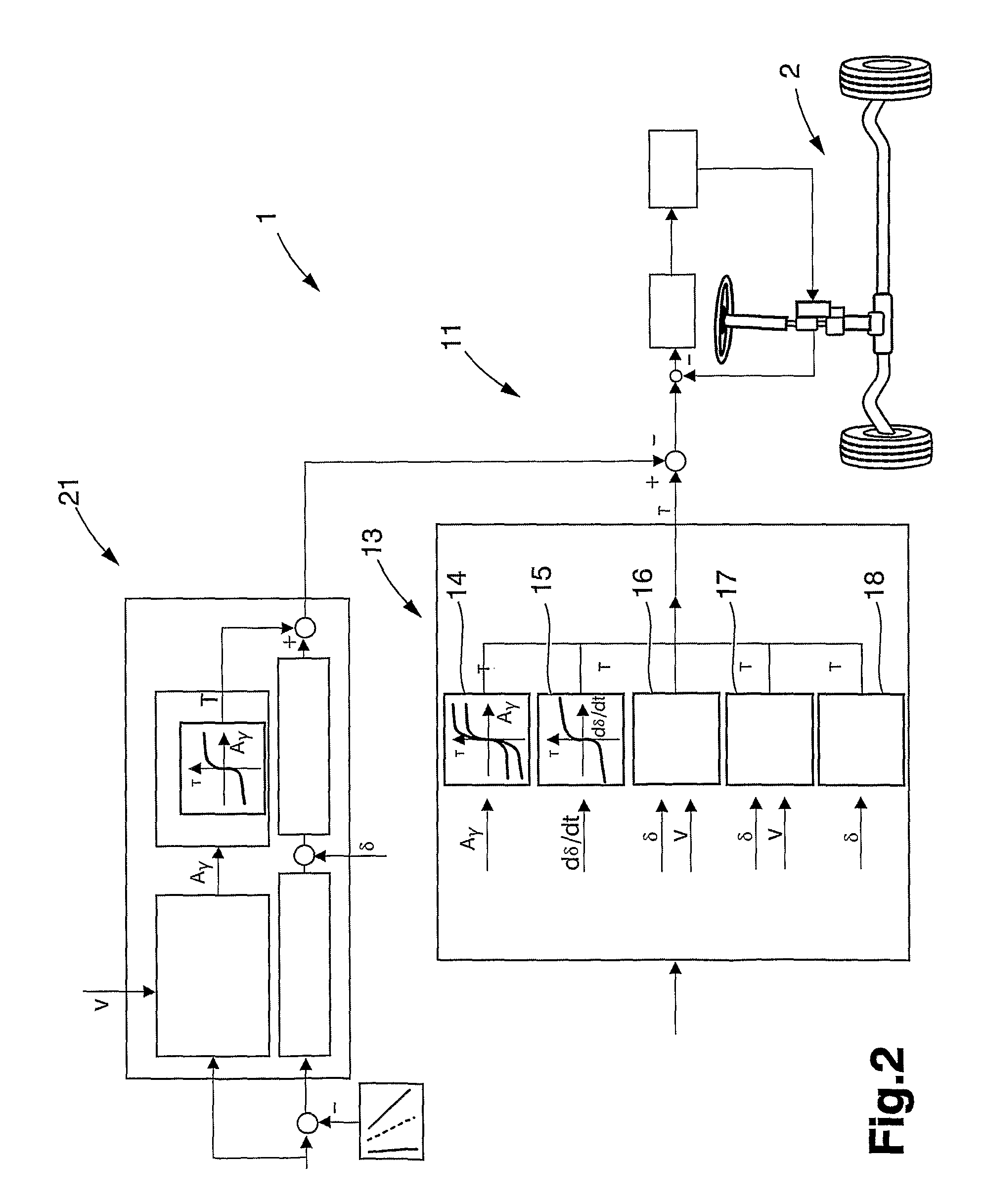

Method and a system for assisting a driver of a vehicle during operation

ActiveUS20120265403A1Improve securityReduce impactVehicle fittingsSteering initiationsEngineeringVehicle driving

A method for assisting a driver of a vehicle during operation in order to avoid an undesired situation based on a current driving scenario includes predicting if a first guiding force to a vehicle steering device is desired in order to avoid the undesired situation and, if the first guiding force is desired, predicting a total guiding force comprising the first guiding force, which would be applied to the steering device for avoiding the undesired situation, comparing the predicted total guiding force with a limit value, and if the predicted total guiding force exceeds the limit value, in advance, deciding whether to apply the predicted total guiding force to the steering device for avoiding the undesired situation or not.

Owner:VOLVO LASTVAGNAR AB

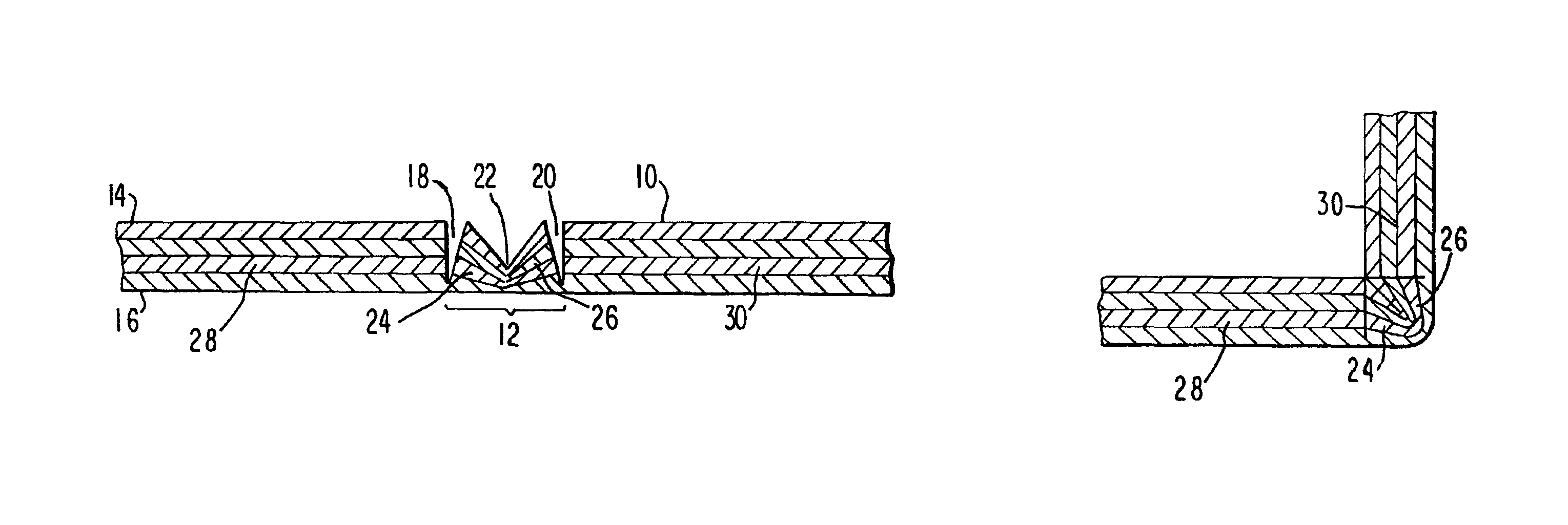

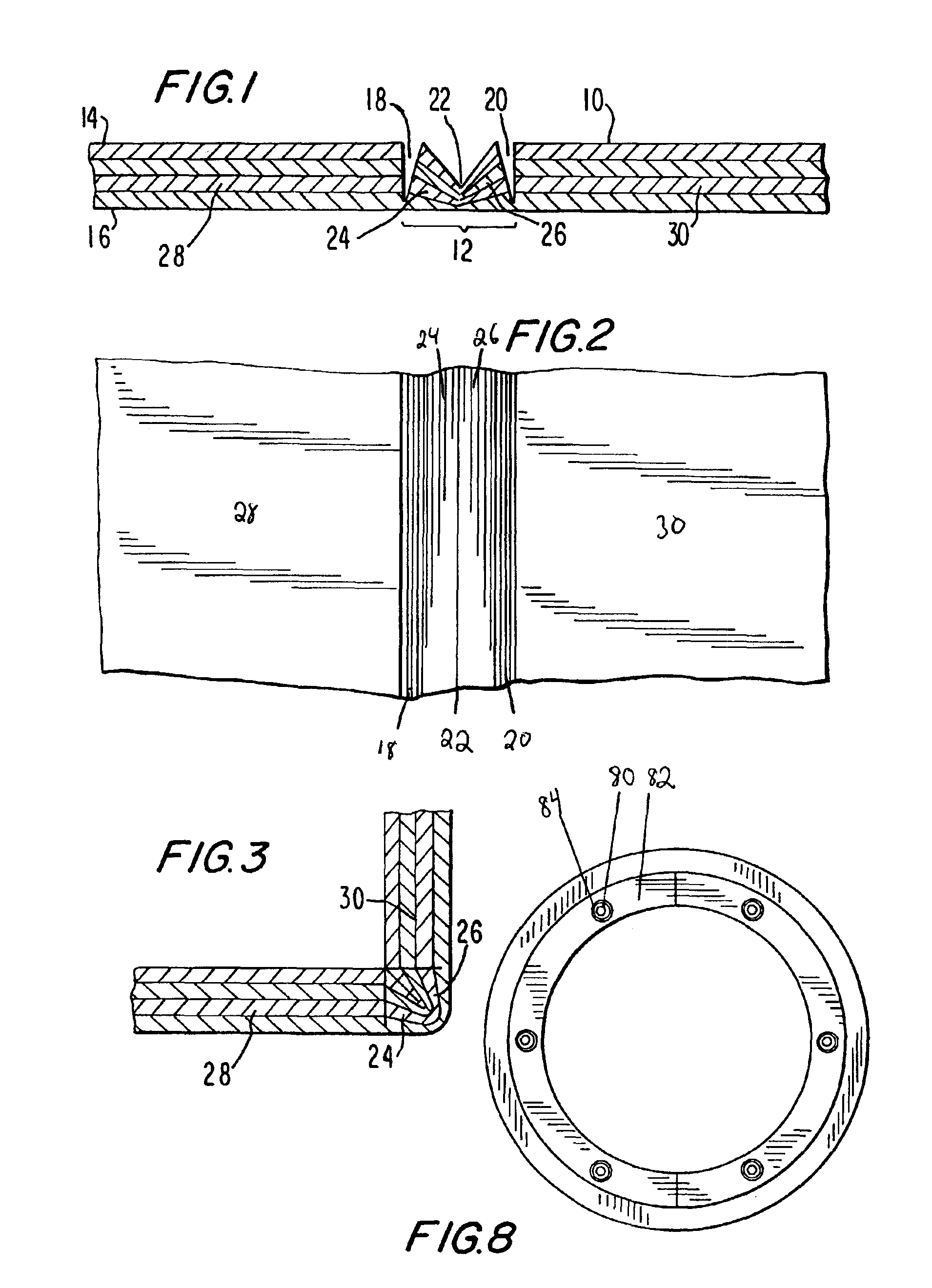

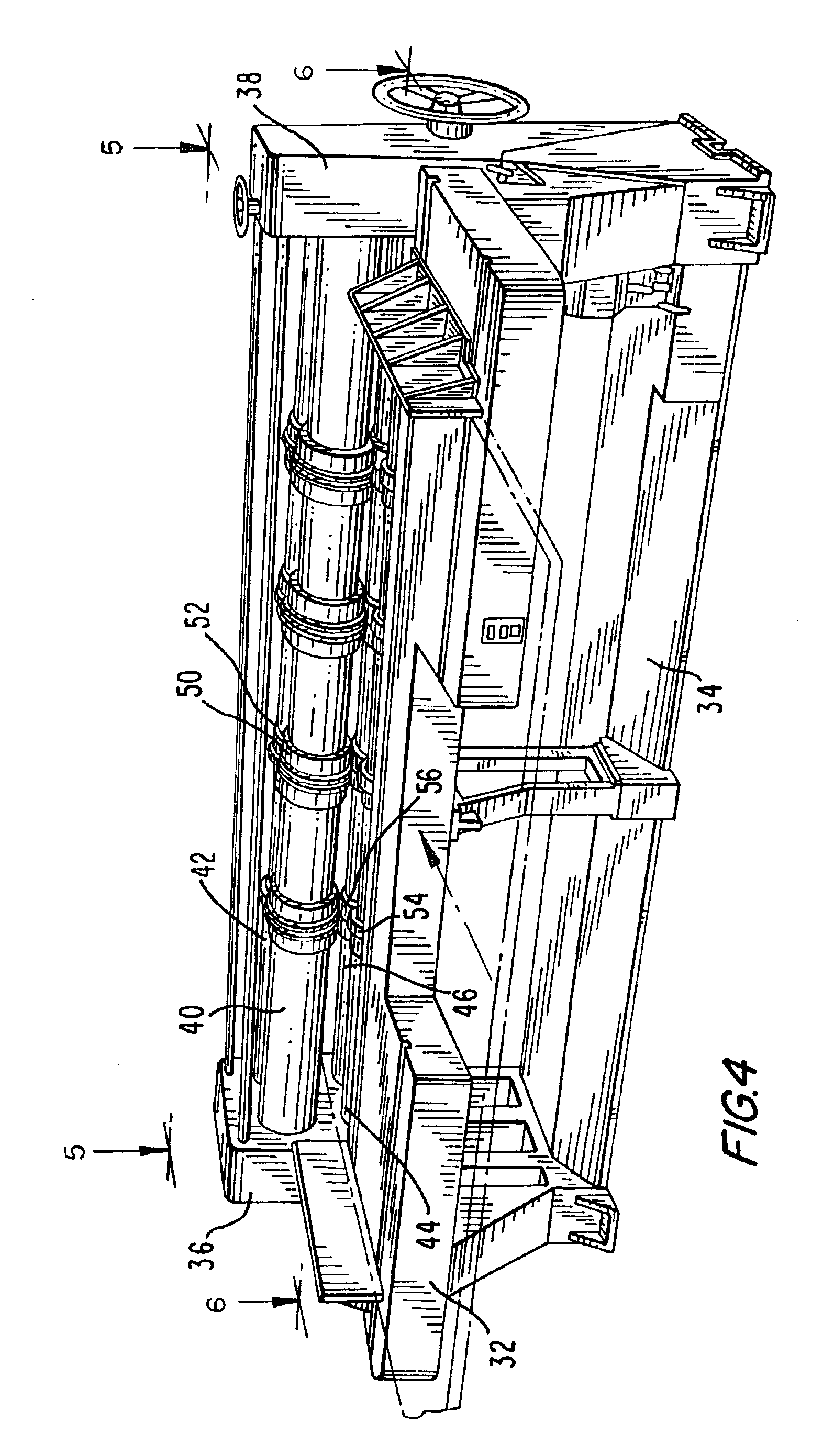

Bendable corrugated paperboard

InactiveUS6902103B2Increase speedReduce the amount requiredMechanical working/deformationPaper/cardboardPaperboardEngineering

This invention provides a paperboard with an improved score line, the method for making the improved score line, and the apparatus for imparting the improved score line. The score line makes the process of folding a flat paperboard into a corner an easier and more consistent process. The score is a V-shaped groove fashioned from a bar score line flanked by two parallel slit cut lines. The method for creating the score line includes utilizing different scoring hubs for bar scoring and slit scoring the paperboard. The apparatus for creating the bar score is a four shaft slitter-scorer having multiple shafts in series, wherein each shaft has at least one hub for slit scoring, bar scoring or supporting the paperboard.

Owner:INT PAPER CO

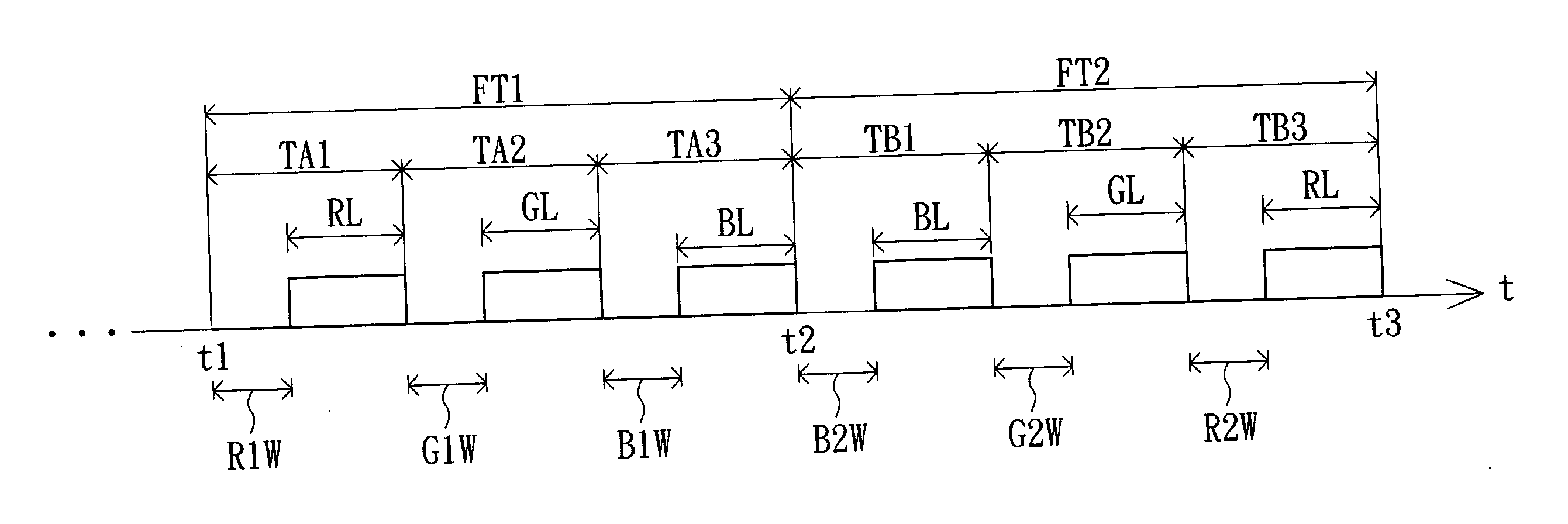

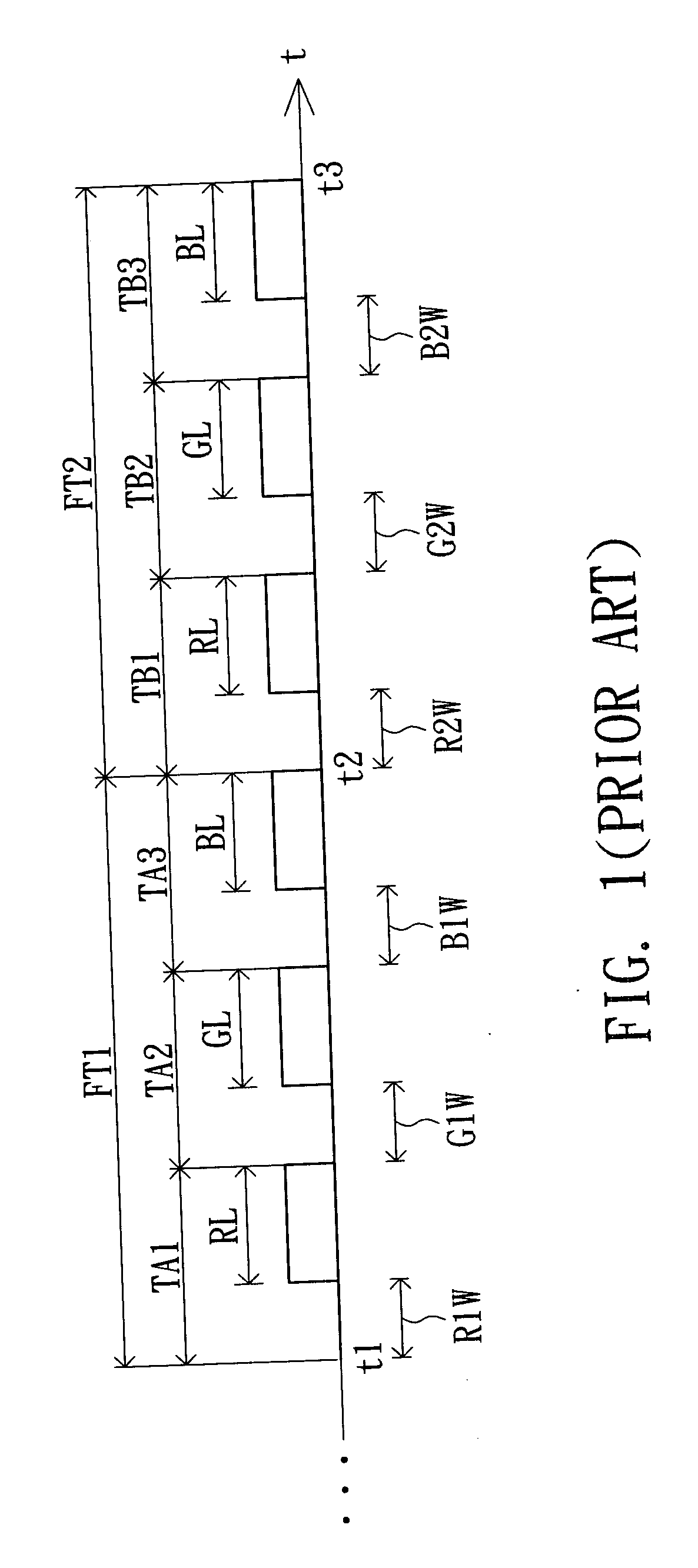

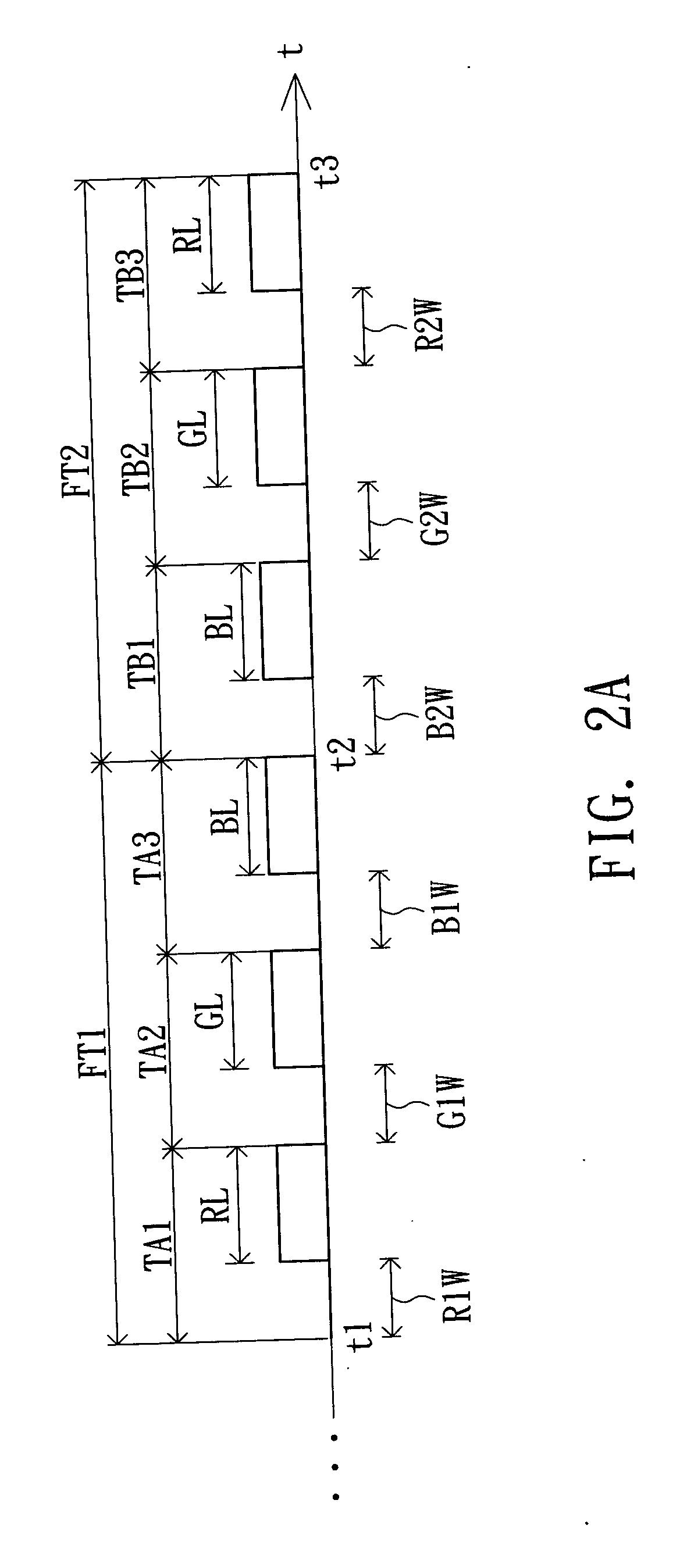

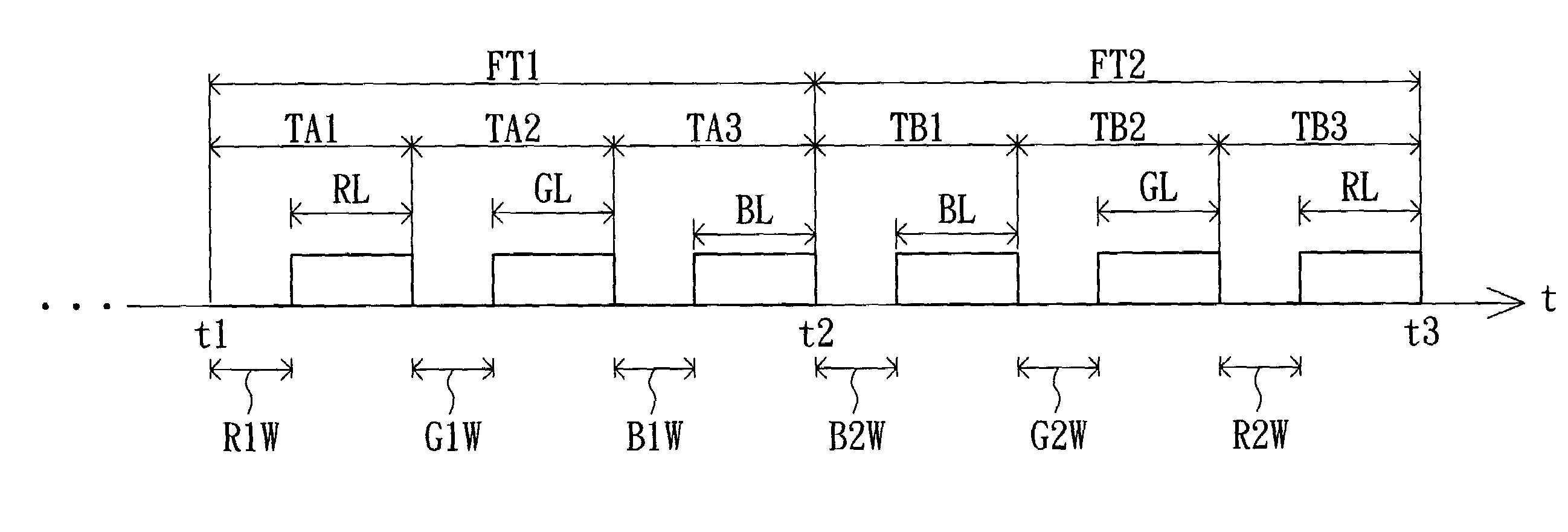

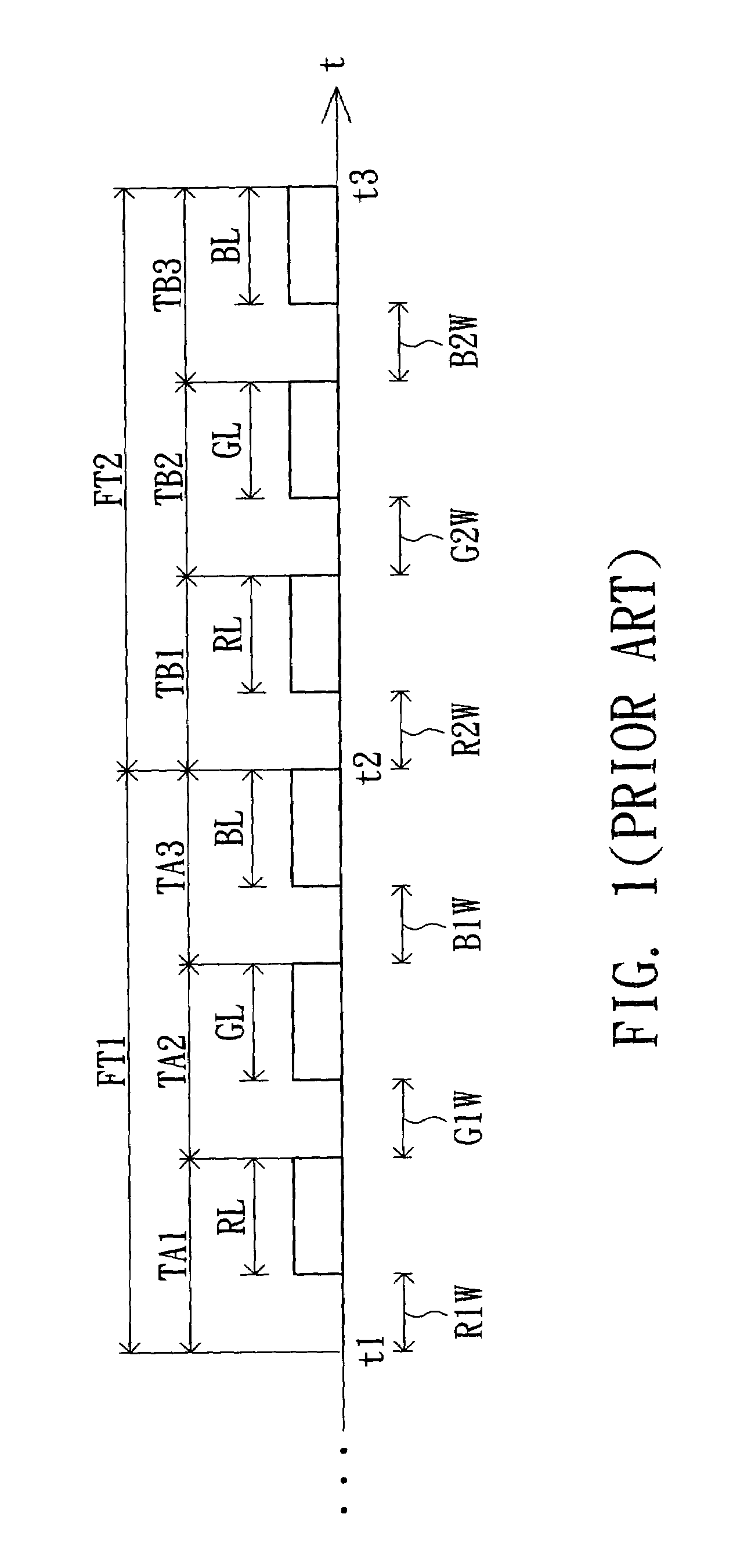

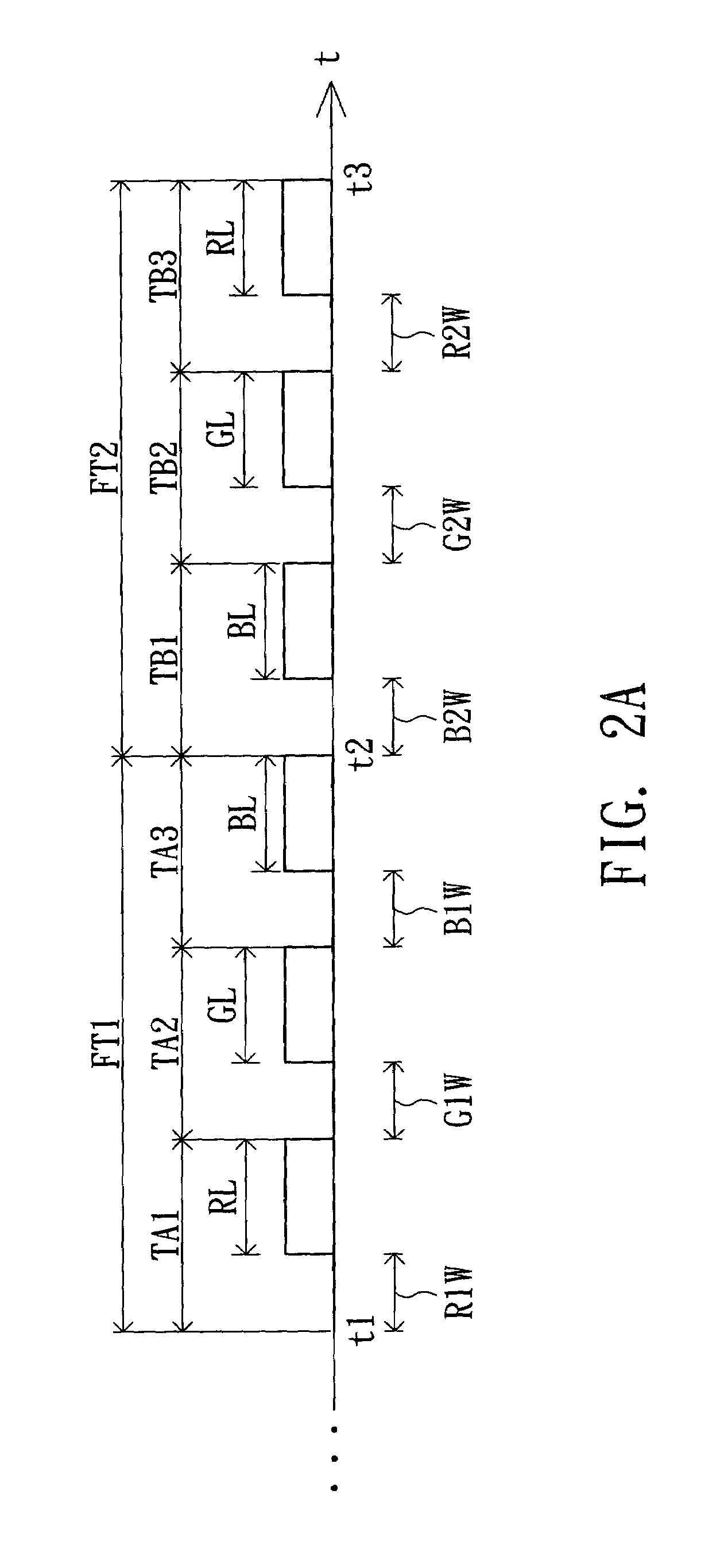

Color-sequential display method

InactiveUS20060028424A1Reduce power consumptionLow power mode supportCathode-ray tube indicatorsInput/output processes for data processingDisplay deviceColor data

A display method for driving a color-sequential display of an electronic device is provided. When the electronic device is not at low power mode, a first image is displayed first by using a second color data and a first color data of the first image sequentially to drive the display. Next, a second image is displayed by using a second color data and a third color data of the second image sequentially to drive the display. When the electronic device is at low power mode, the respective luminance of the first and the second images are obtained. Then, the respective luminance of the first image and the second image are sequentially used to drive the display.

Owner:HIMAX TECH LTD

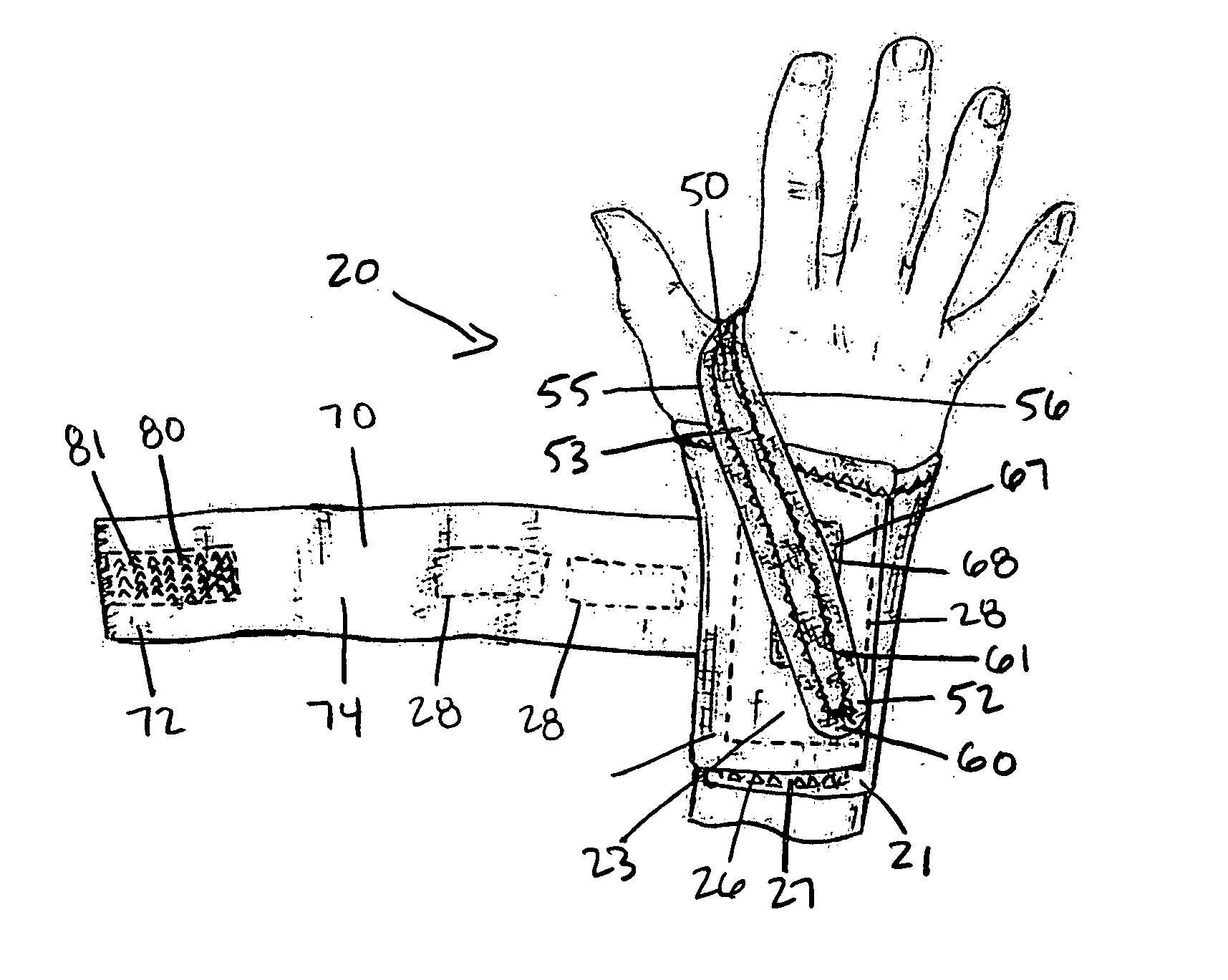

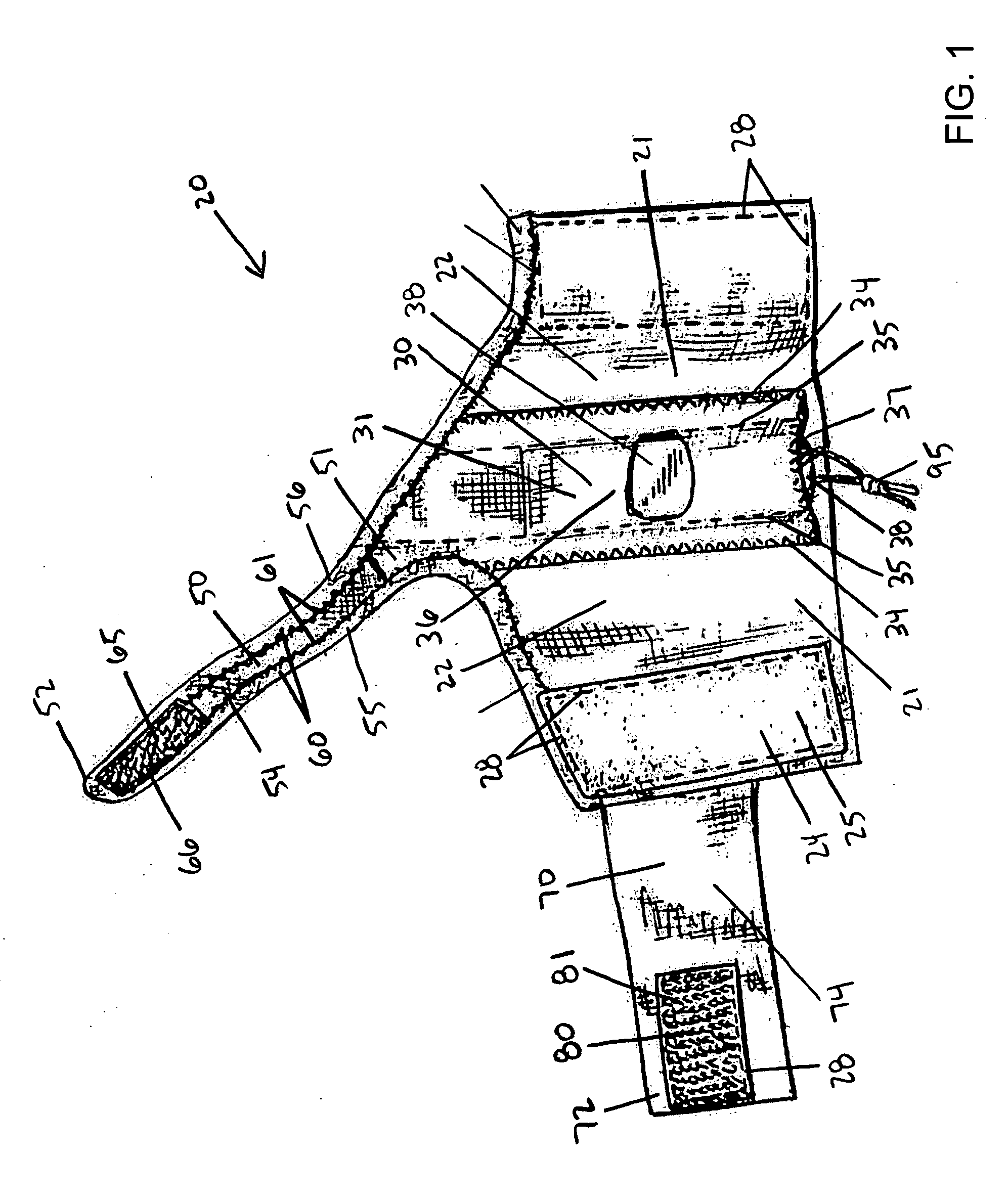

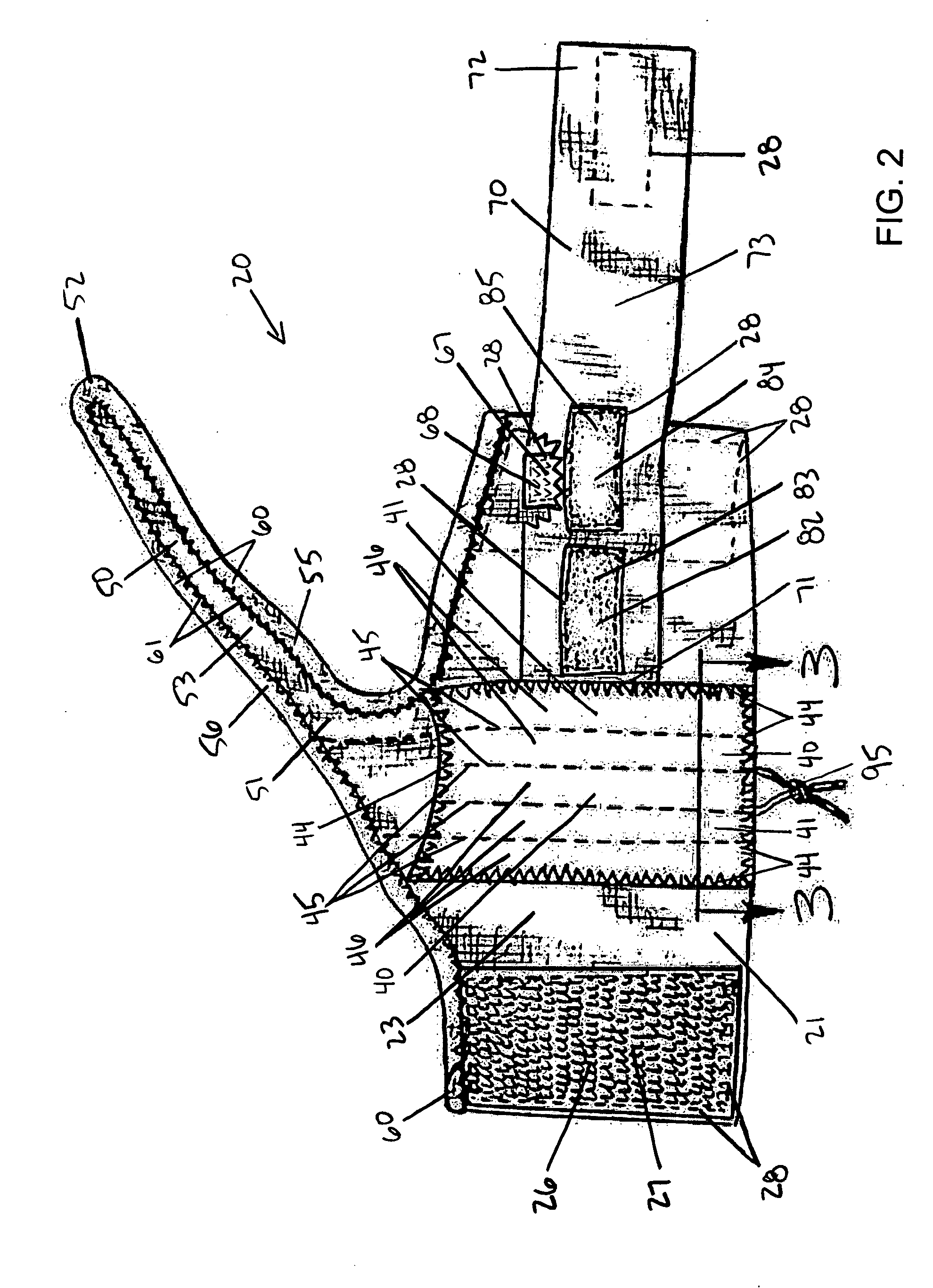

Wrist brace with adjustable support

InactiveUS20050240140A1High degreeLow degreeFeet bandagesNon-surgical orthopedic devicesSupport beltWrist support

An wrist brace that can be configured to provide adjustable support to the wrist of a person. The wrist brace includes a splint pocket adapted to receive a removable splint. The splint can be inserted in the splint pocket to form a wrist brace that provides complete or nearly complete immobilization. The splint can be removed from the splint pocket to form a wrist brace providing flexible support without complete immobilization. The wrist brace includes an elastic support strap that can be secured in a first position under a relatively high degree of tension, or in a second position under a relatively low degree of tension, thereby allowing adjustment of the degree of compression and support provided by the elastic support strap.

Owner:MUELLER SPORTS MEDICINE

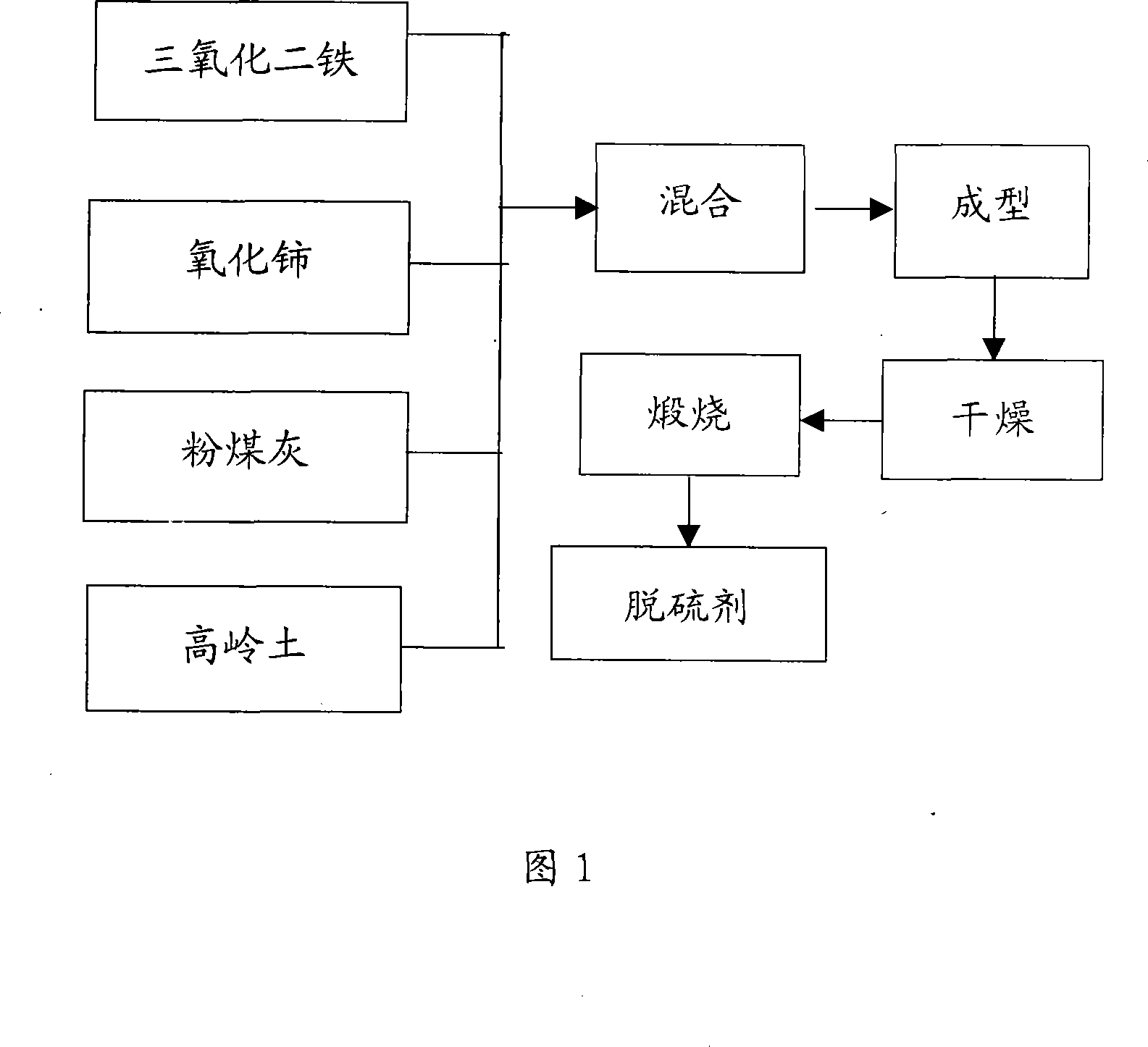

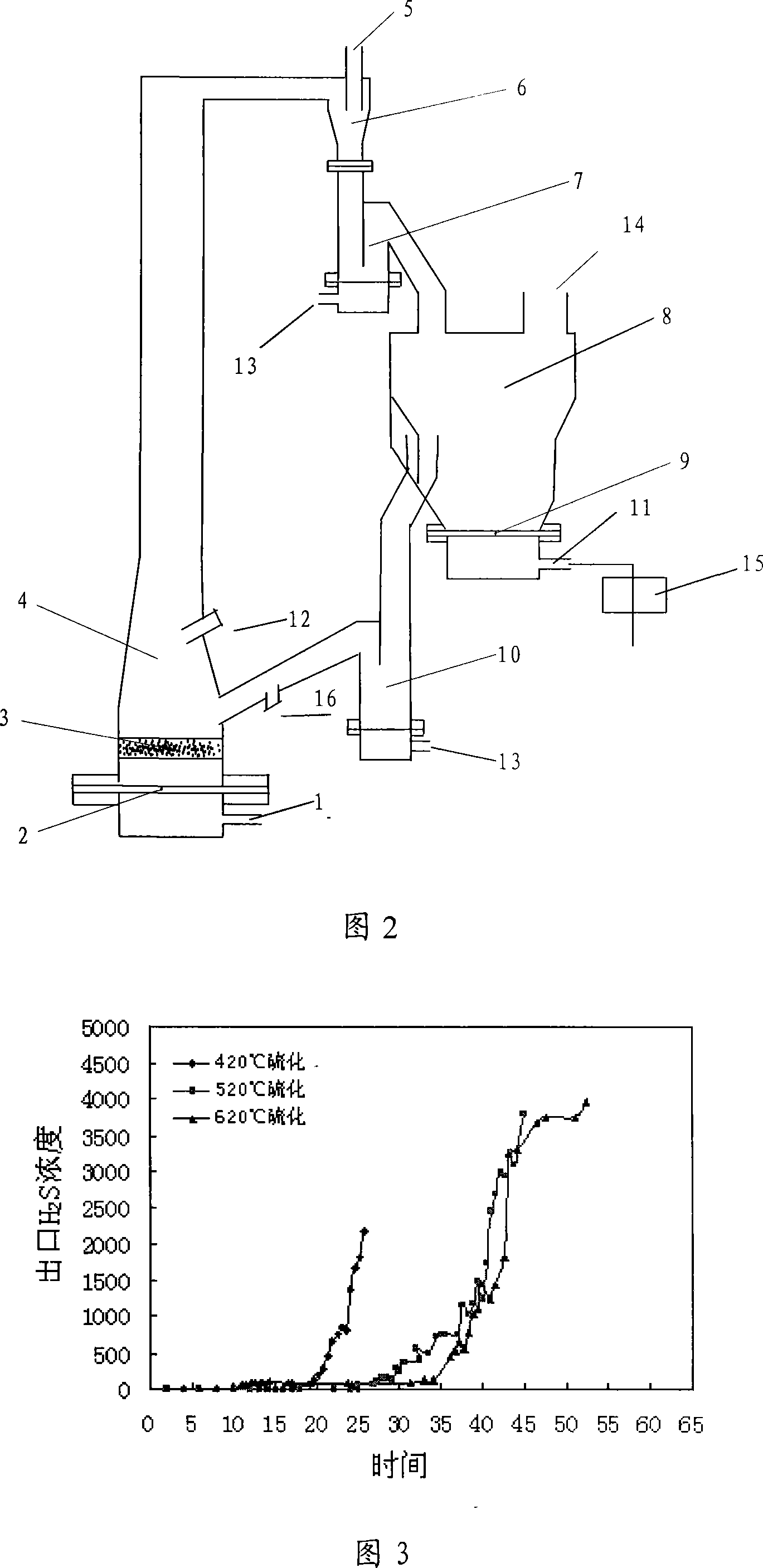

High-temperature coal gas desulfurizer using coal ash as carrier and desulfurization device thereof

InactiveCN101235324ASimple manufacturing processLow costCombustible gas purificationVulcanizationSulfur

The invention aims at solving the problem such as low desulphurization activity of desulfurizer, low mechanical strength, poor regeneration property and higher cost and the like, which discloses a high temperature desulfurizer which uses coal ash as carrier and a desulfurization device , the method comprises utilizing mechanical mixing method to mix multicomponent metal oxide, coal ash and adhesive of the activity component through machine, then extruding into strip shape by utilizing a self-made desulfurizer, drying formed desulfurizer under the temperature of 100-200 DEG C, and calcining under the temperature of 600-1000 DEG C, desulfurizer which is calcined is directly used to desulfurize coal gas under the high temperature. High-temperature desulfuration of hot coal gas adopts a circulating fluidized bed to achieve continuous desulfurization and regeneration, and desulfurizer can effectively remove H2S in high-temperature coal gas under the temperature scope which is 400-750 DEG C. Desulfurizer after being vulcanized can be regenerated in a fluid bed regenerating device. The high temperature desulfurizer has the advantages of simple preparation technique, simple equipment and low cost, which has higher vulcanization activity and sulfur capacity, excellent desulfurizing capacity and higher mechanical strength, and opens up a new approach which utilizes ash from power plant to be carrier to prepare high-temperature coal gas desulfurizer.

Owner:SHENYANG INST OF AERONAUTICAL ENG

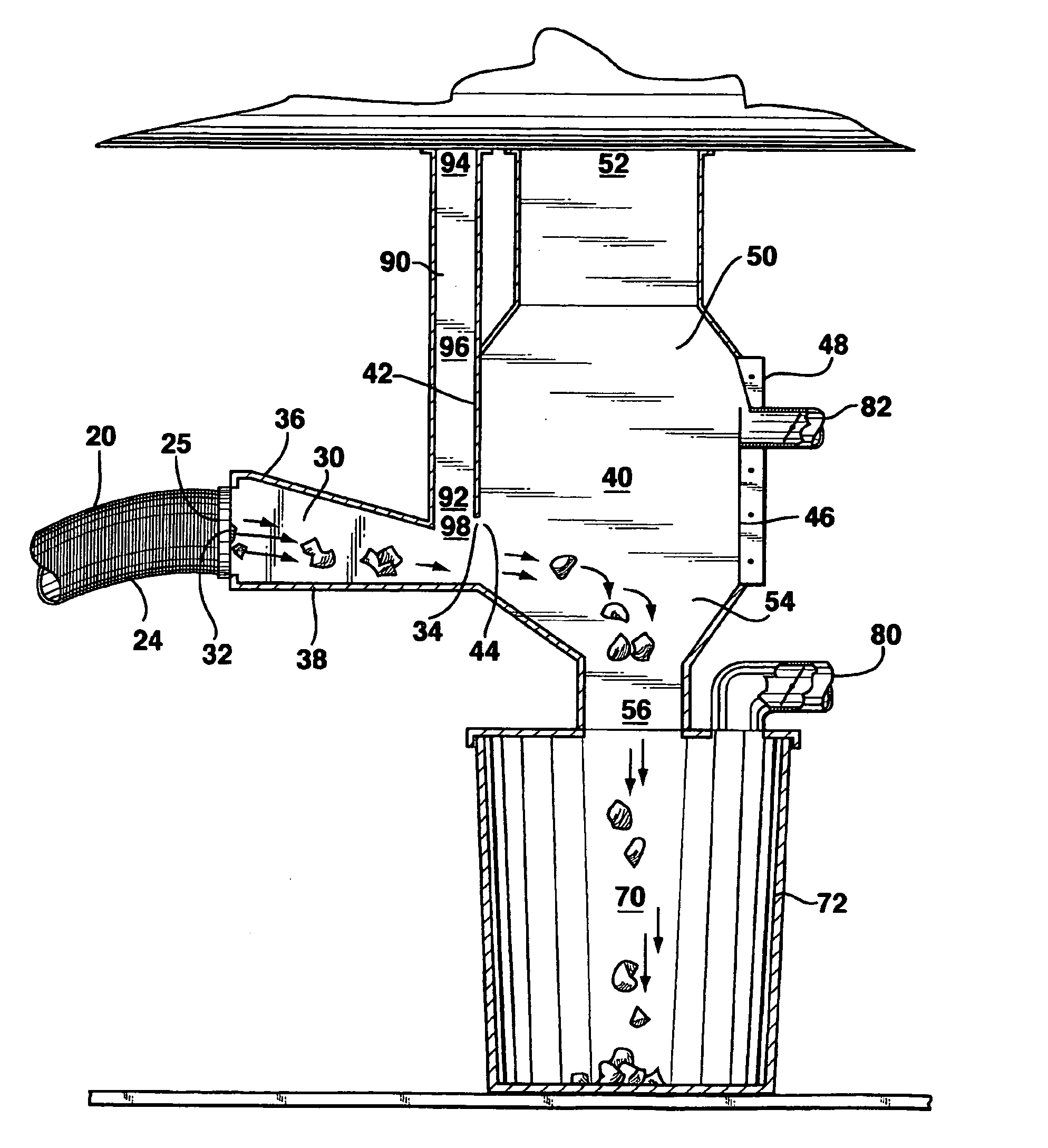

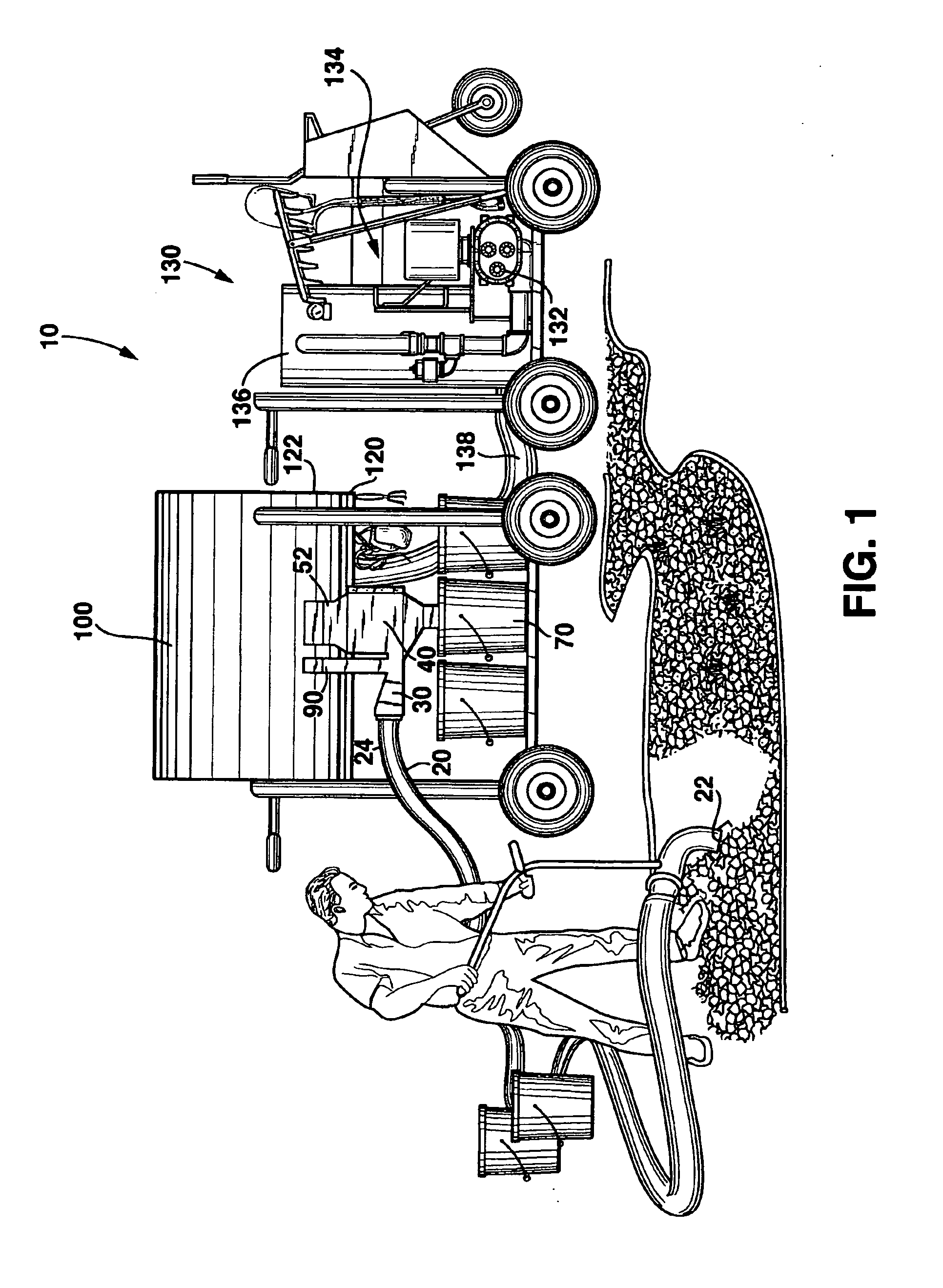

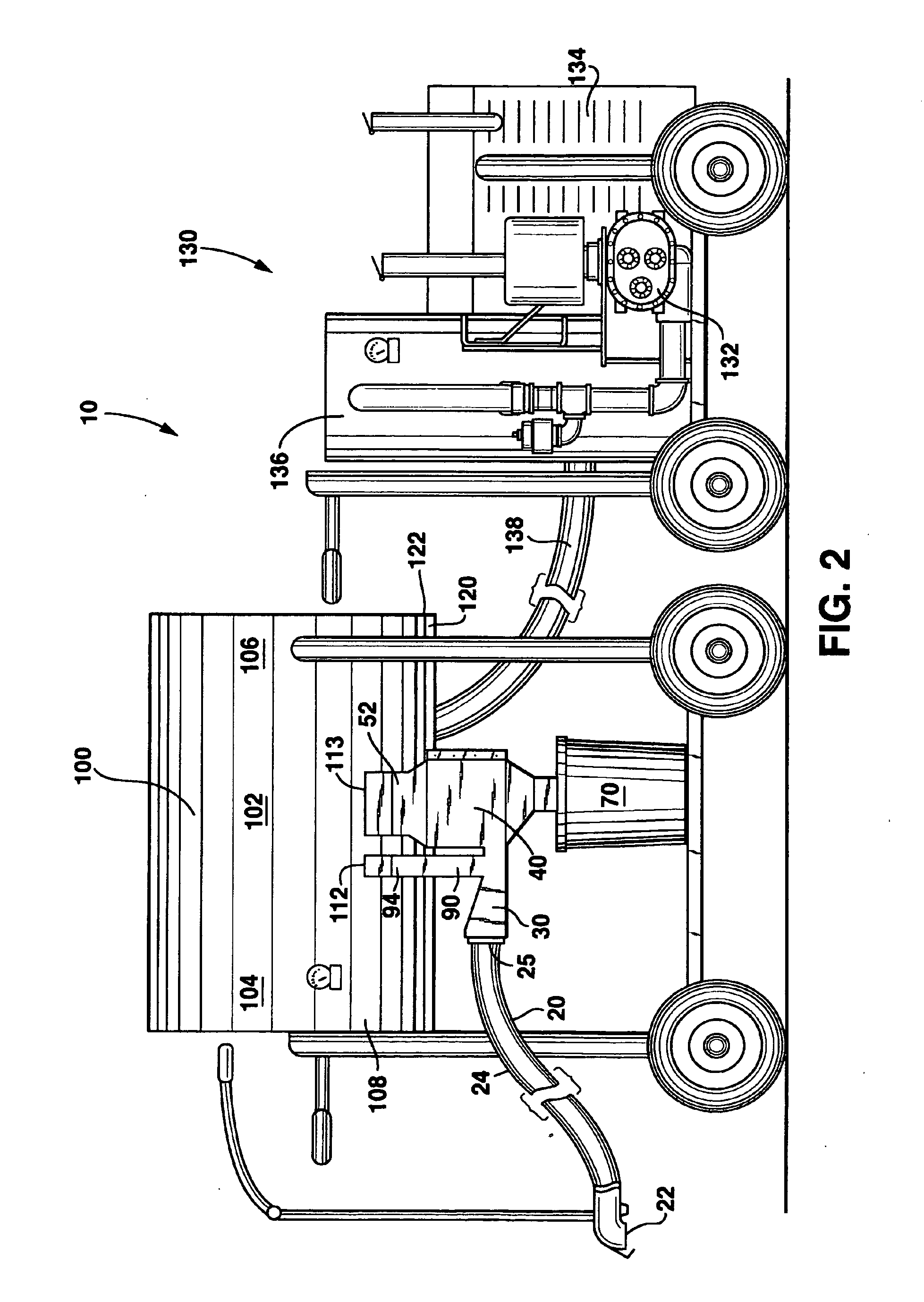

Pneumatic classification of mixtures of particulates

InactiveUS20110132814A1Shorten speedSupporting requirements are lowGas current separationDispersed particle filtrationParticulatesAir entrainment

Process for pneumatic classification of mixture of granular particulates by providing an apparatus, entraining mixture, reducing velocity of entraining airstream, and airwashing falling particulates of low aerodynamic support. Specific applications include a method separating mixed granular material based upon dissimilar specific gravities, useful in cleaning firearm ranges by separating lead from backstop material. Falling granular lead particulates can also be airwashed and negative pressure facilitates control of lead dust. Also disclosed are applications that pick up and clean or enrich precious metal bearing ore, and a broad range of applications from heavy mixtures, such as landscape rock, to light mixtures such as grain.

Owner:MILLER RICHARD L

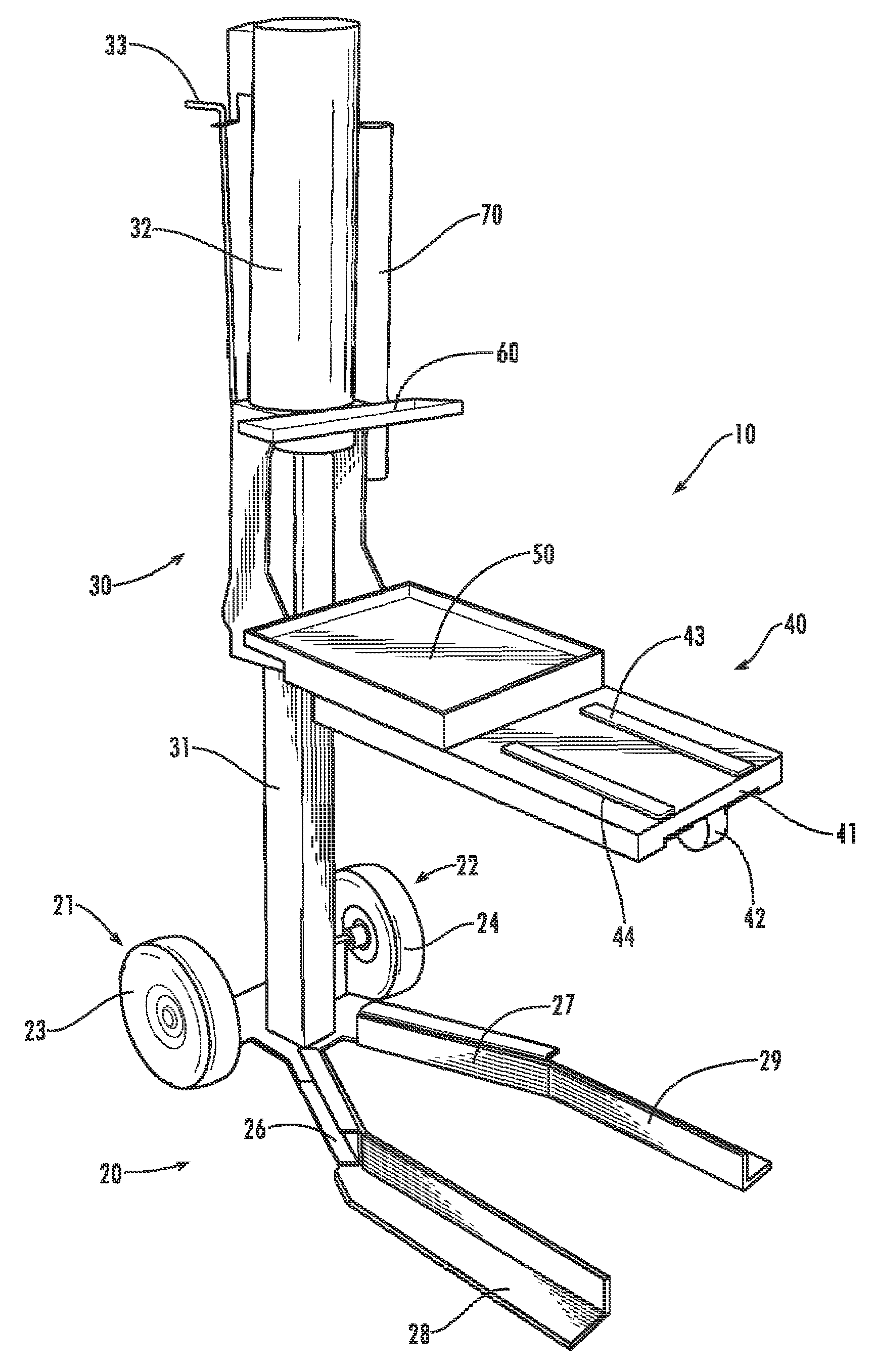

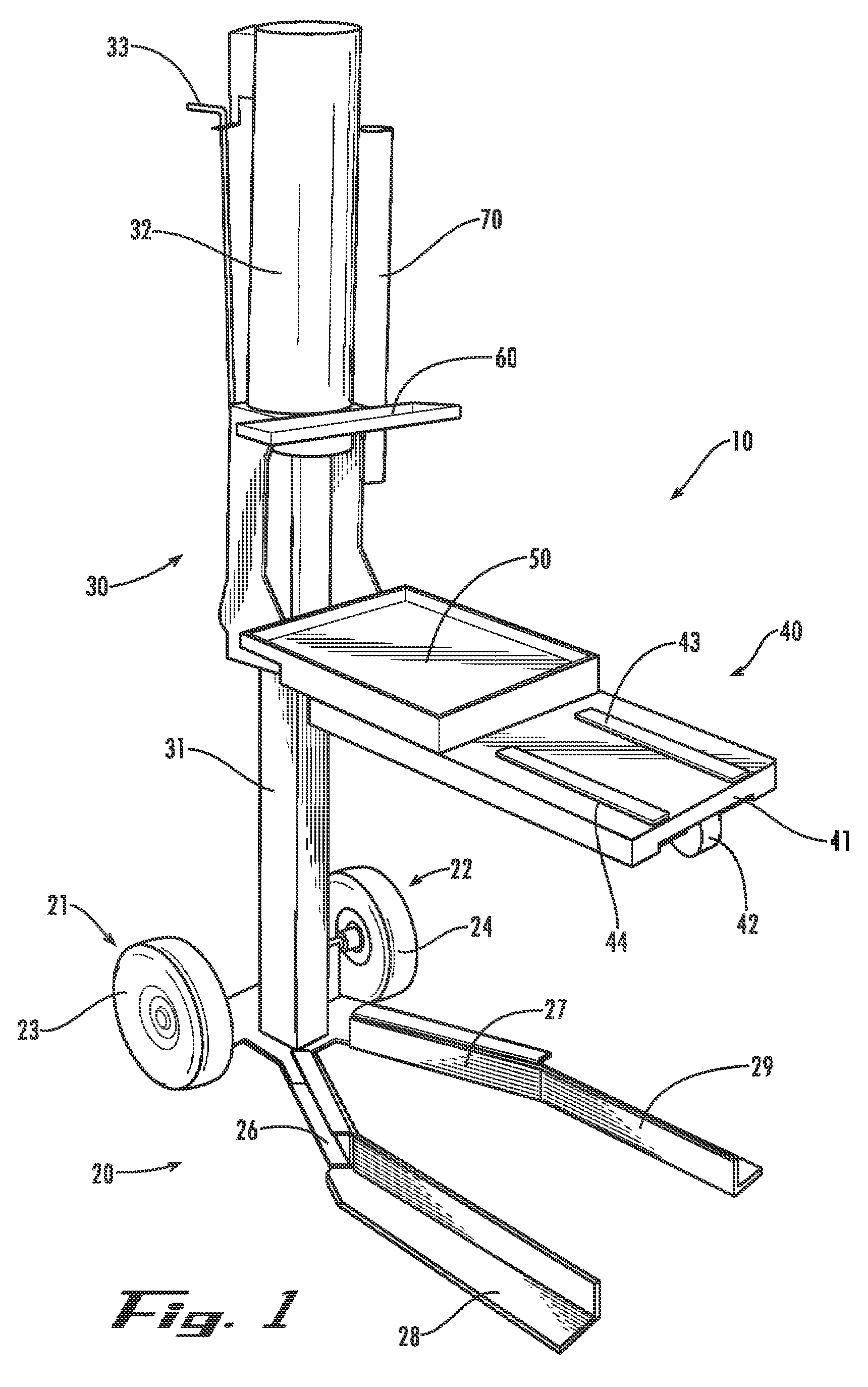

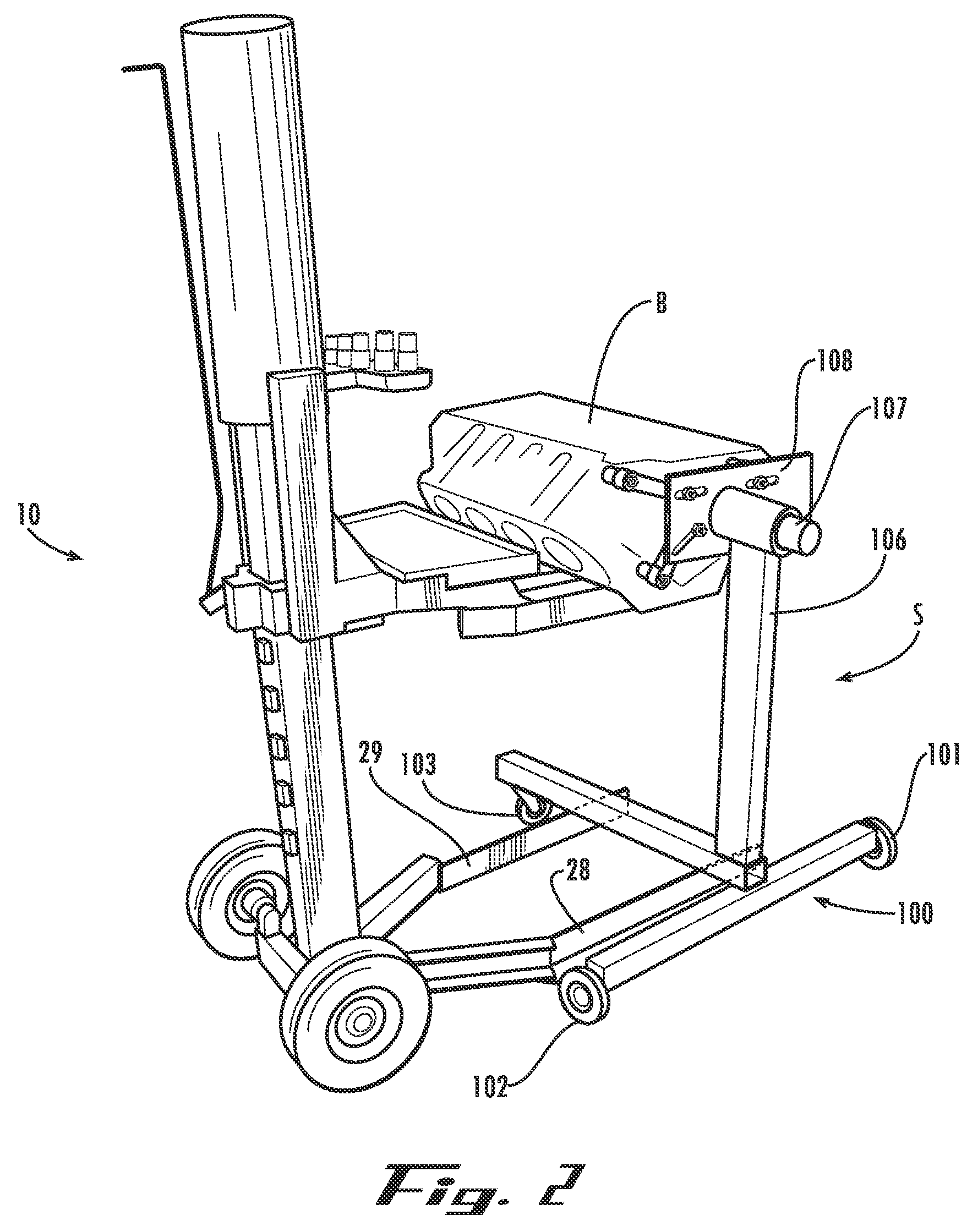

Engine lift

Owner:GOZA TOMMY J

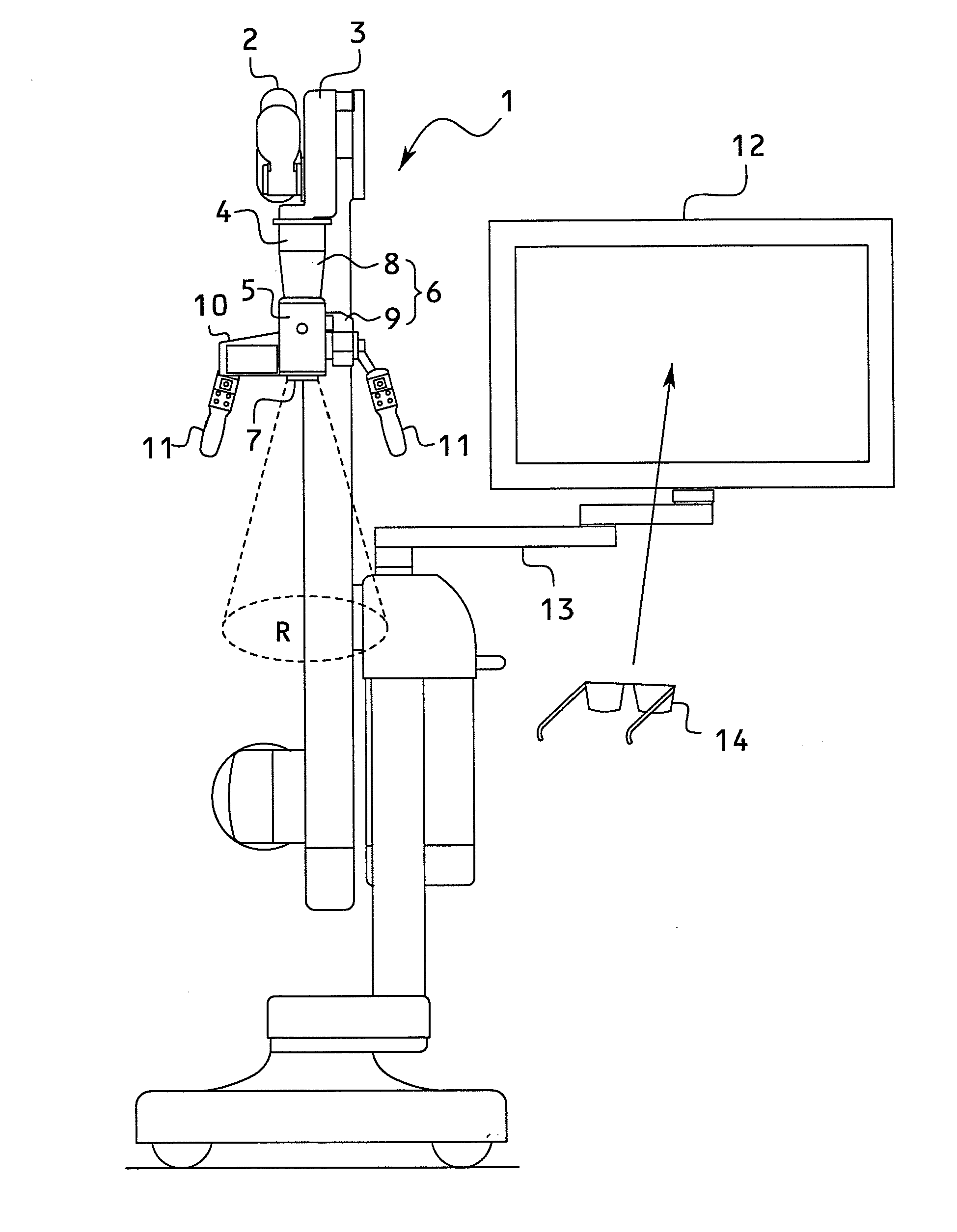

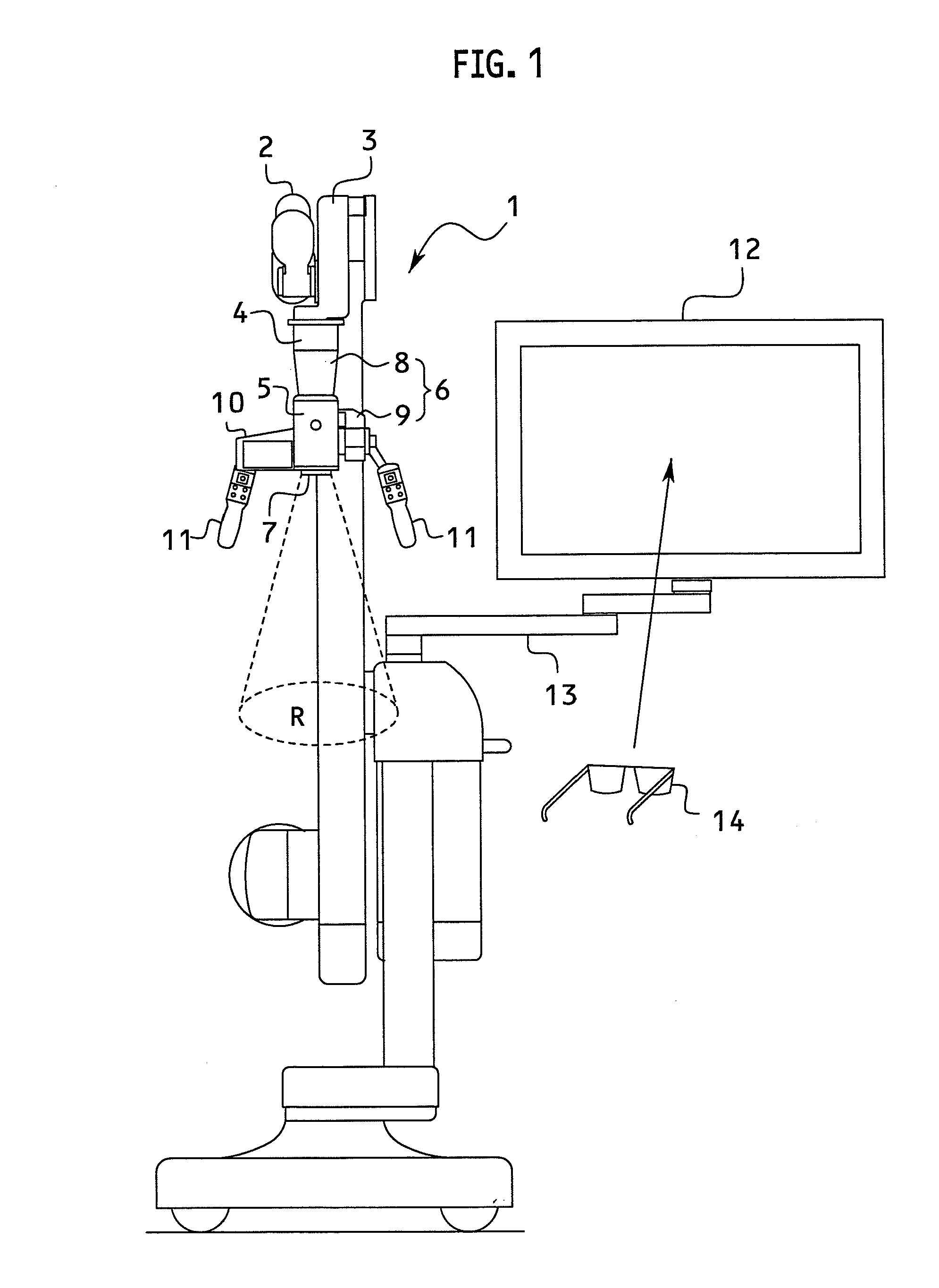

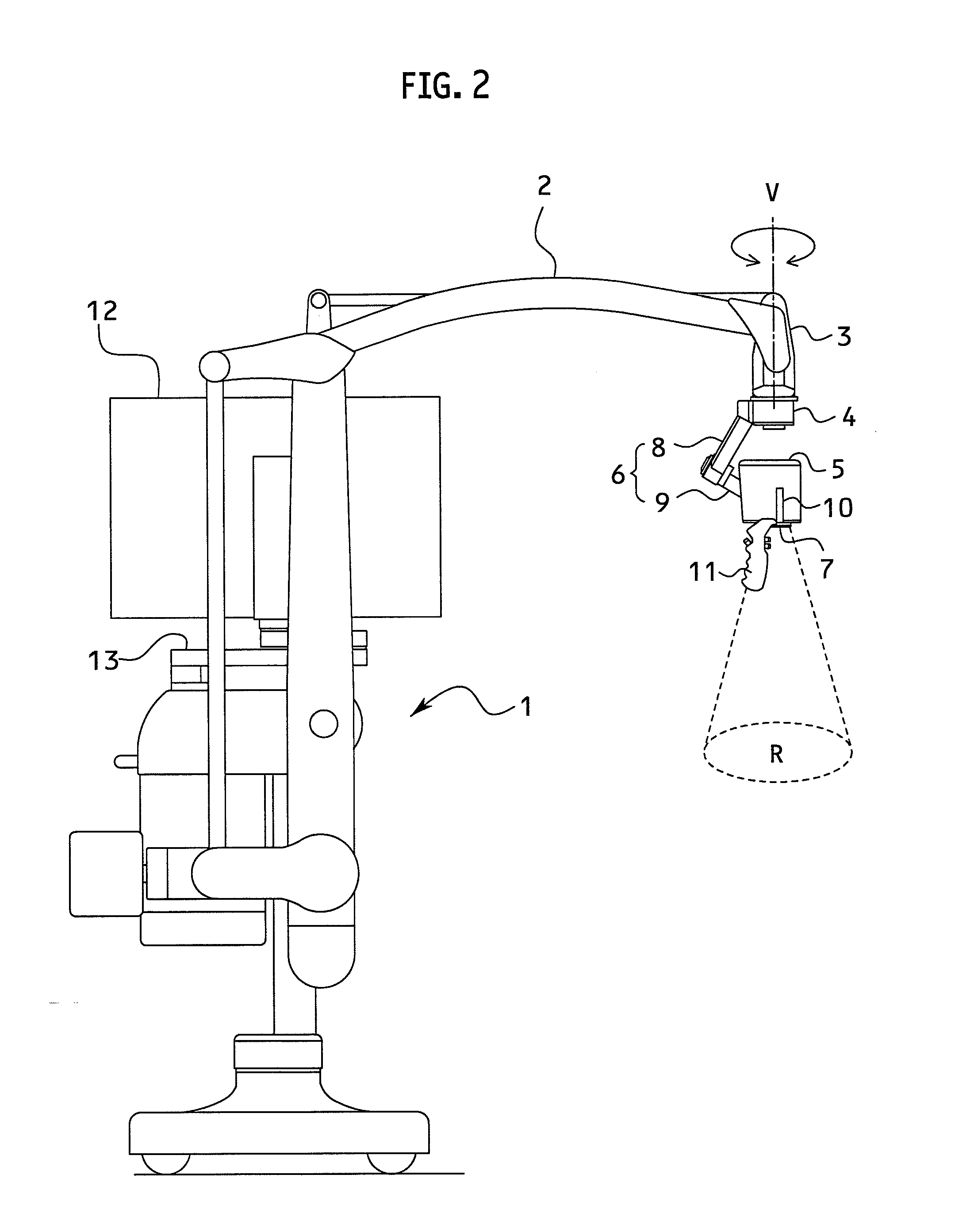

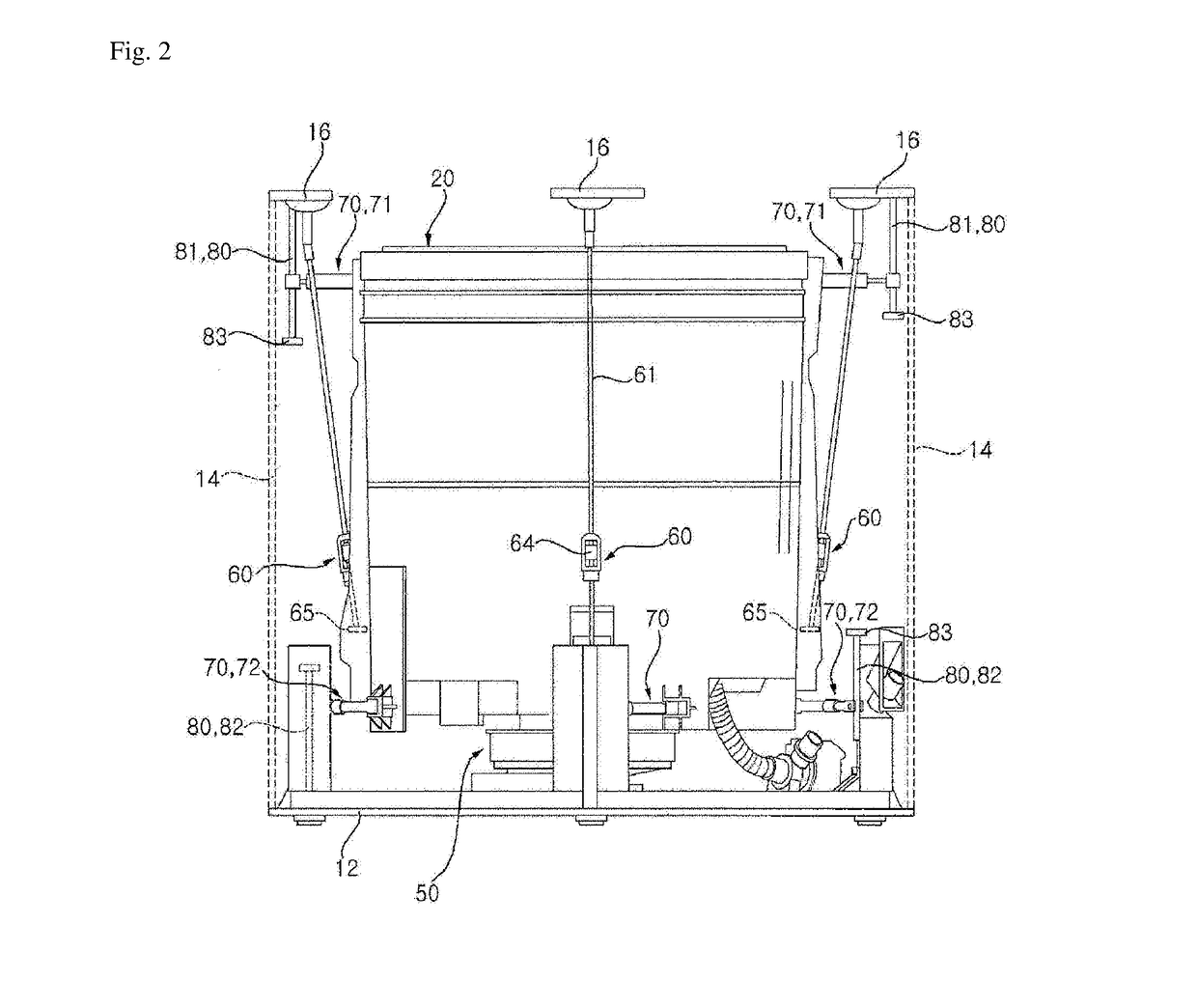

Surgical microscope system

InactiveUS20150301326A1Promote shakingImprove support rigidityTelevision system detailsSurgeryOphthalmologySurgical microscope

A surgical microscope system includes a camera that is rotatable around a first rotation axis and a second rotation axis, the rotation axes being orthogonal to each other, so that a photographing direction of the camera is changeable at a given position. The first rotation axis is inclined with respect to a vertical axis, and therefore, a lower end of a first member is able to be set at a height that does not interfere with the photographing direction when the camera is horizontally oriented.

Owner:MITAKA KOHKI

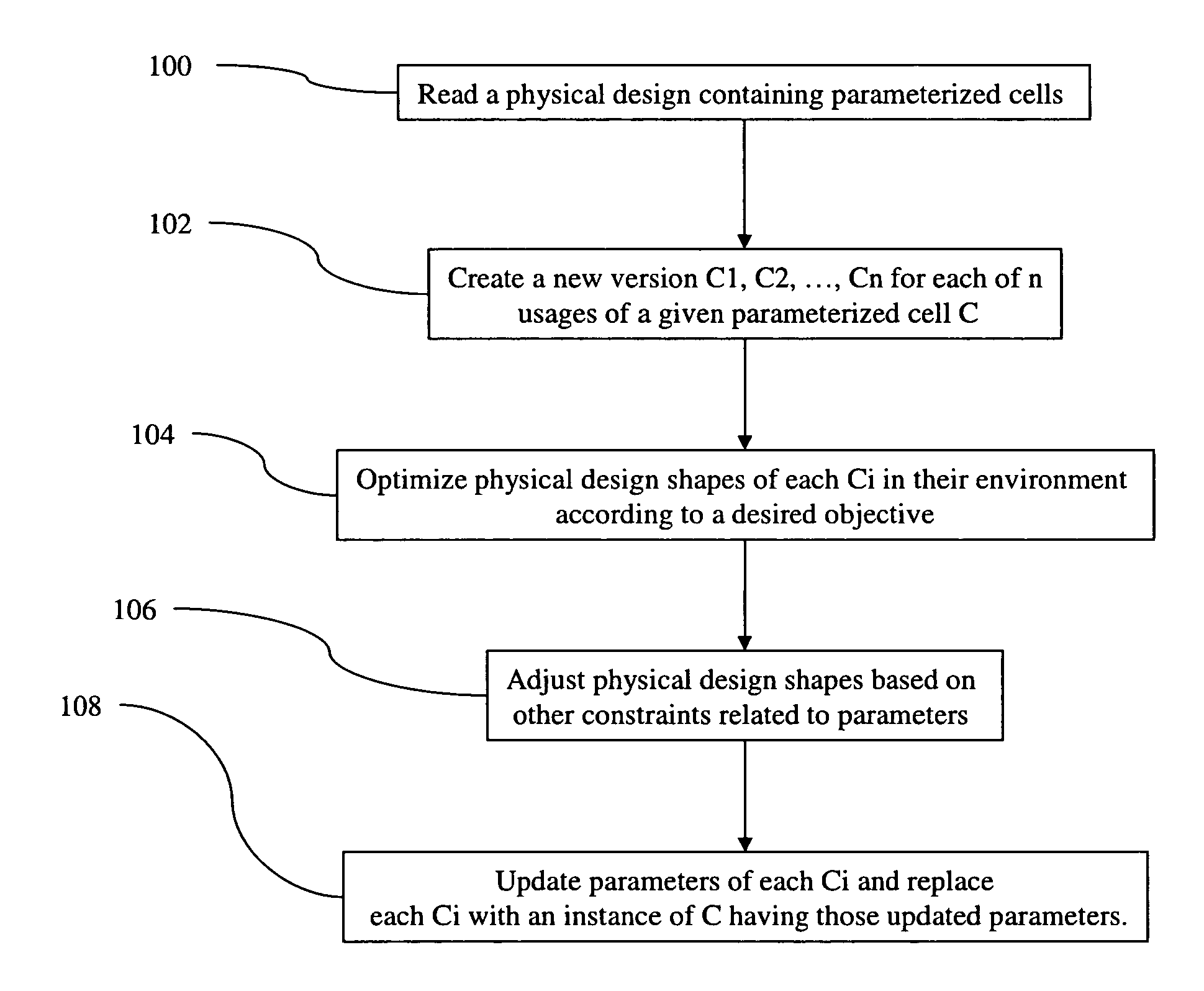

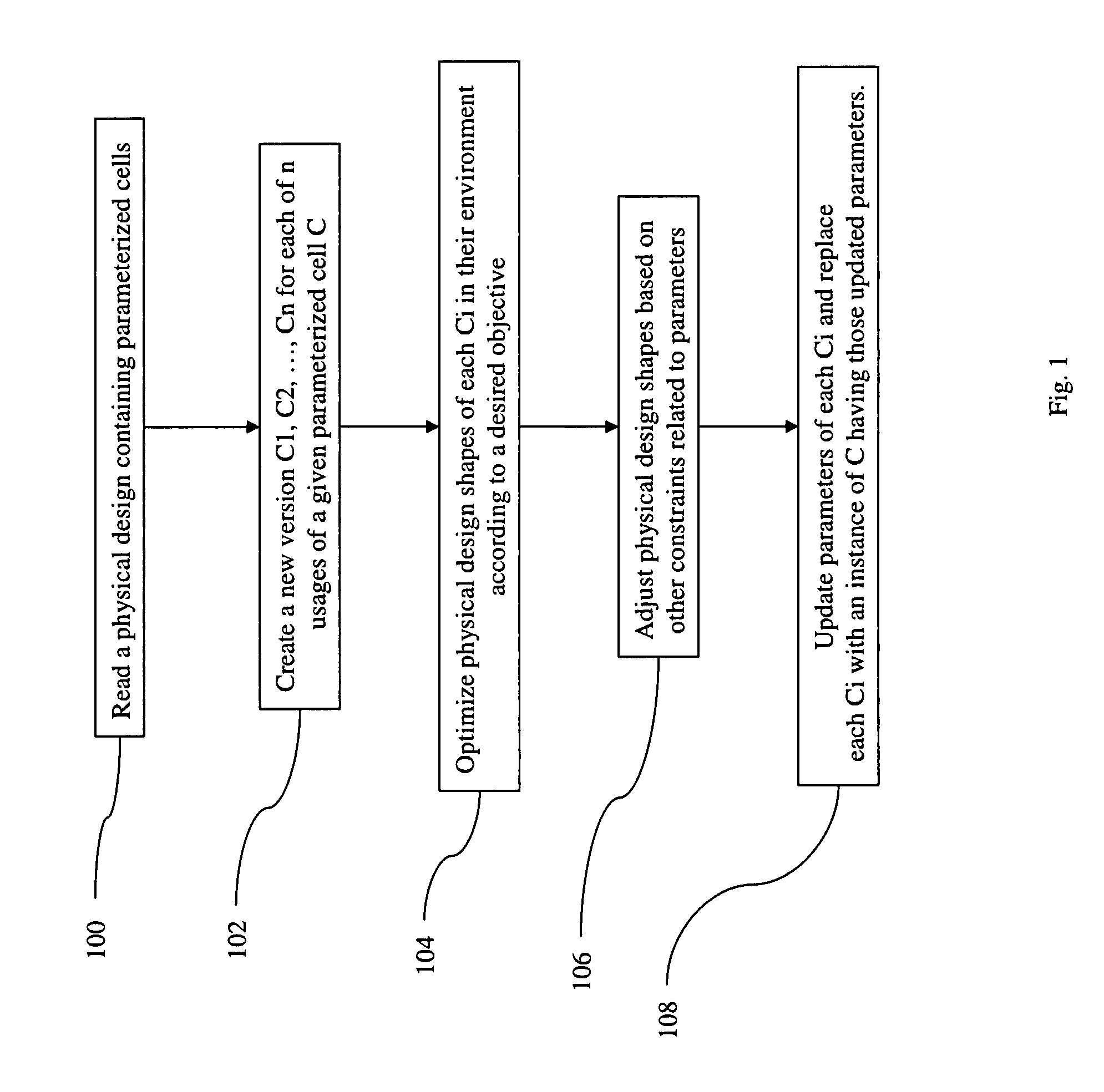

Layout Optimization Using Parameterized Cells

ActiveUS20090064061A1Reduce the required powerHigh frequencyComputer aided designSoftware simulation/interpretation/emulationComputer architecture

A method of layout optimization containing parameterized cells includes reading a physical design containing parameterized cells, creating a new version for each of usage of a given parameterized cell. The method optimizes physical design shapes of each new version of the parameterized cell by assigning variables to parameters of the parameterized cell according to a desired objective. Then, the method updates the parameters of each new version of the parameterized cell and replaces each new version of the parameterized cell with an instance of the parameterized cell having updated parameters. The method can optionally adjust physical design shapes based on constraints related to the parameters.

Owner:SIEMENS PROD LIFECYCLE MANAGEMENT SOFTWARE INC

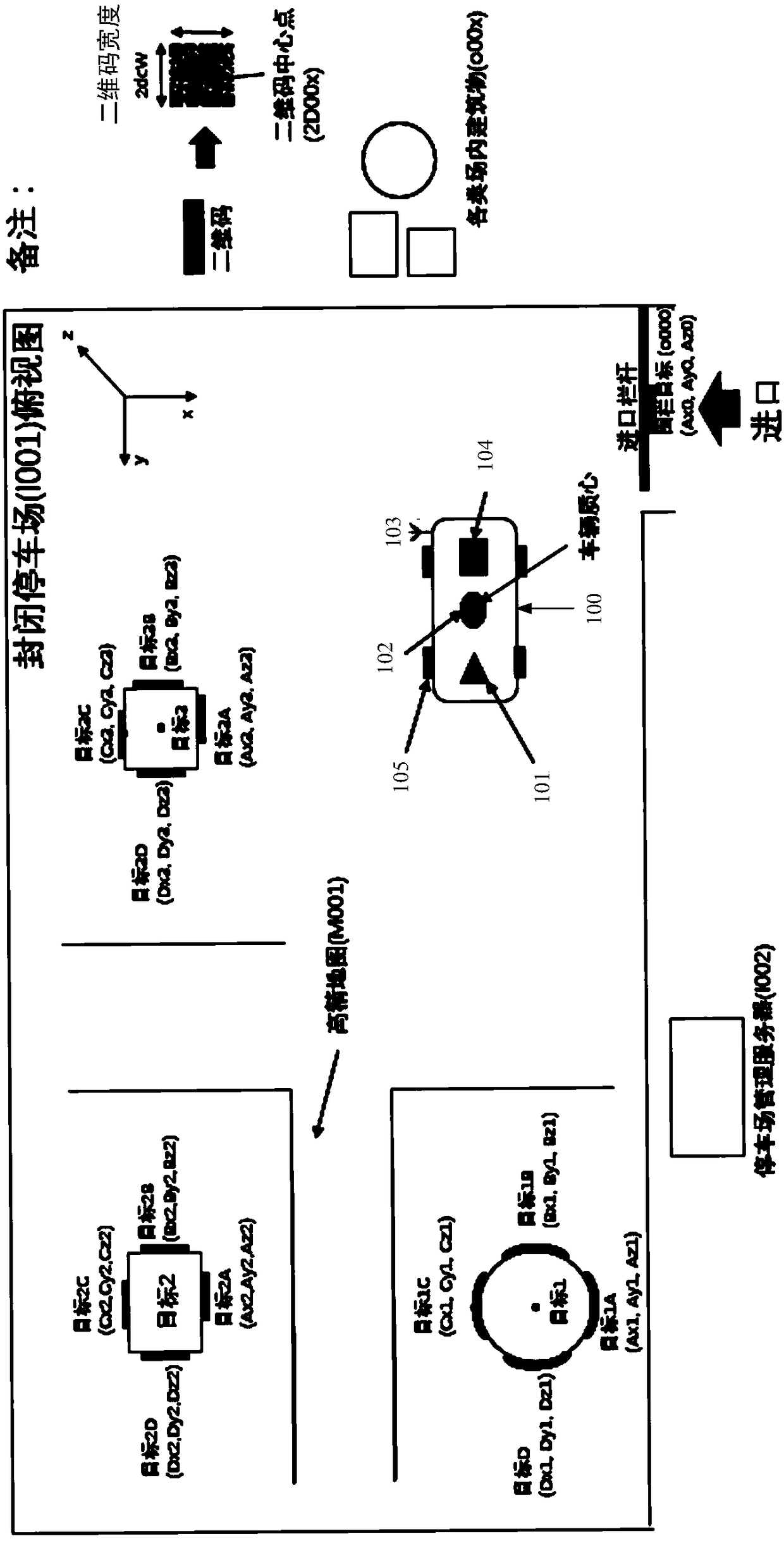

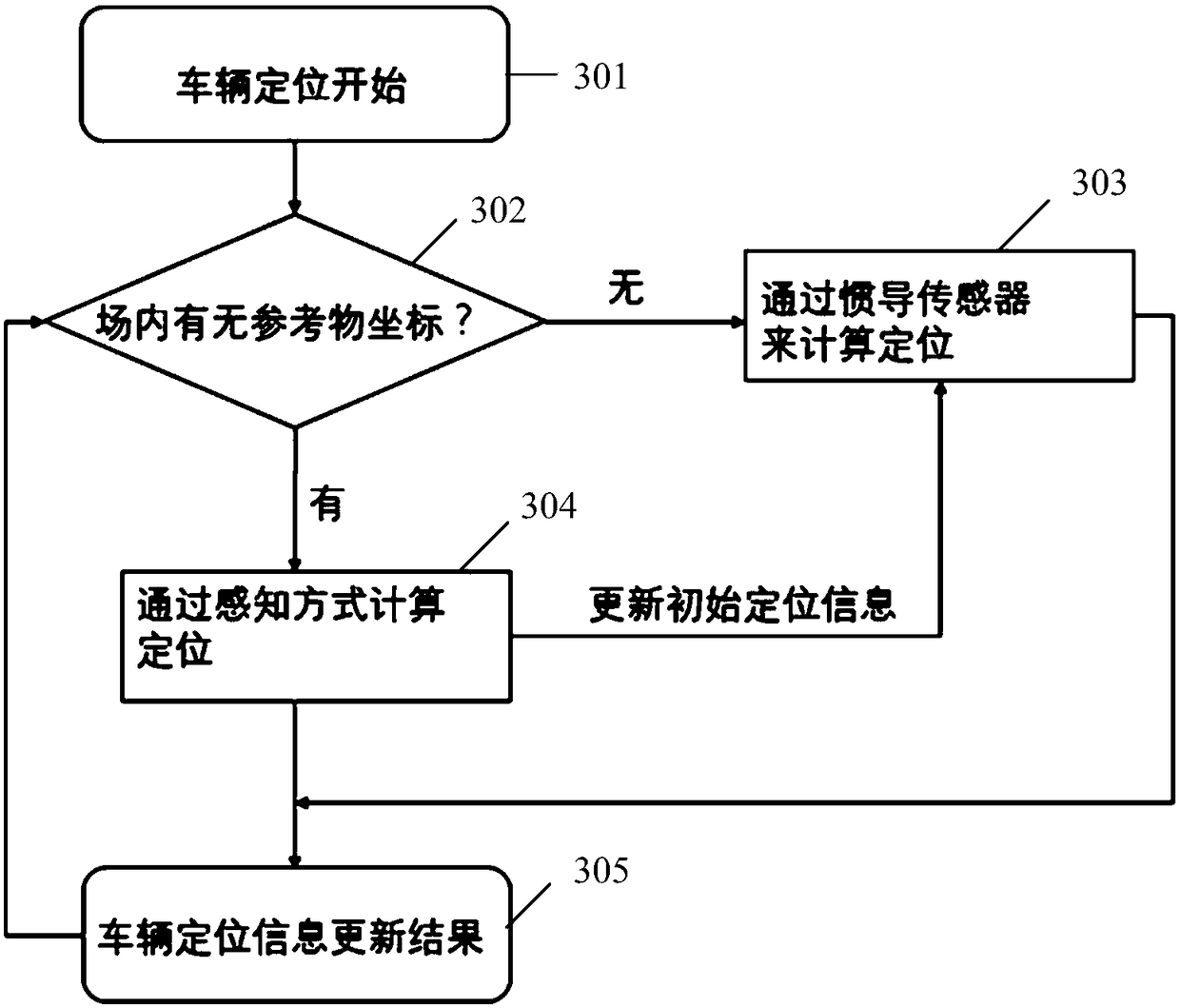

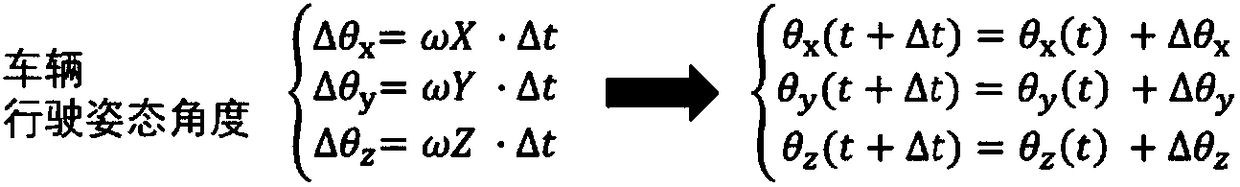

Method for positioning vehicle in enclosed area

InactiveCN109029418ASupporting requirements are lowAvoid Inaccurate PositioningNavigation by speed/acceleration measurementsPattern perceptionNo reference

A method of positioning vehicles in an enclosed area, comprising the following steps: a. determining whether a reference object coordinate exists in the enclosed area, and if the reference object coordinate exists in the closed area, executing the step b; if no reference object coordinate exists in the closed area, executing the step c; b. calculating vehicle positioning information by an inertialnavigation sensor of a vehicle inertial navigation system; c. respectively calculating vehicle positioning information using a perception sensor and the inertial navigation sensor, wherein the perception sensor periodically corrects positioning errors of the inertial navigation system according to the reference object coordinate; and d, updating the positioning information of the vehicle.

Owner:WM SMART MOBILITY (SHANGHAI) CO LTD

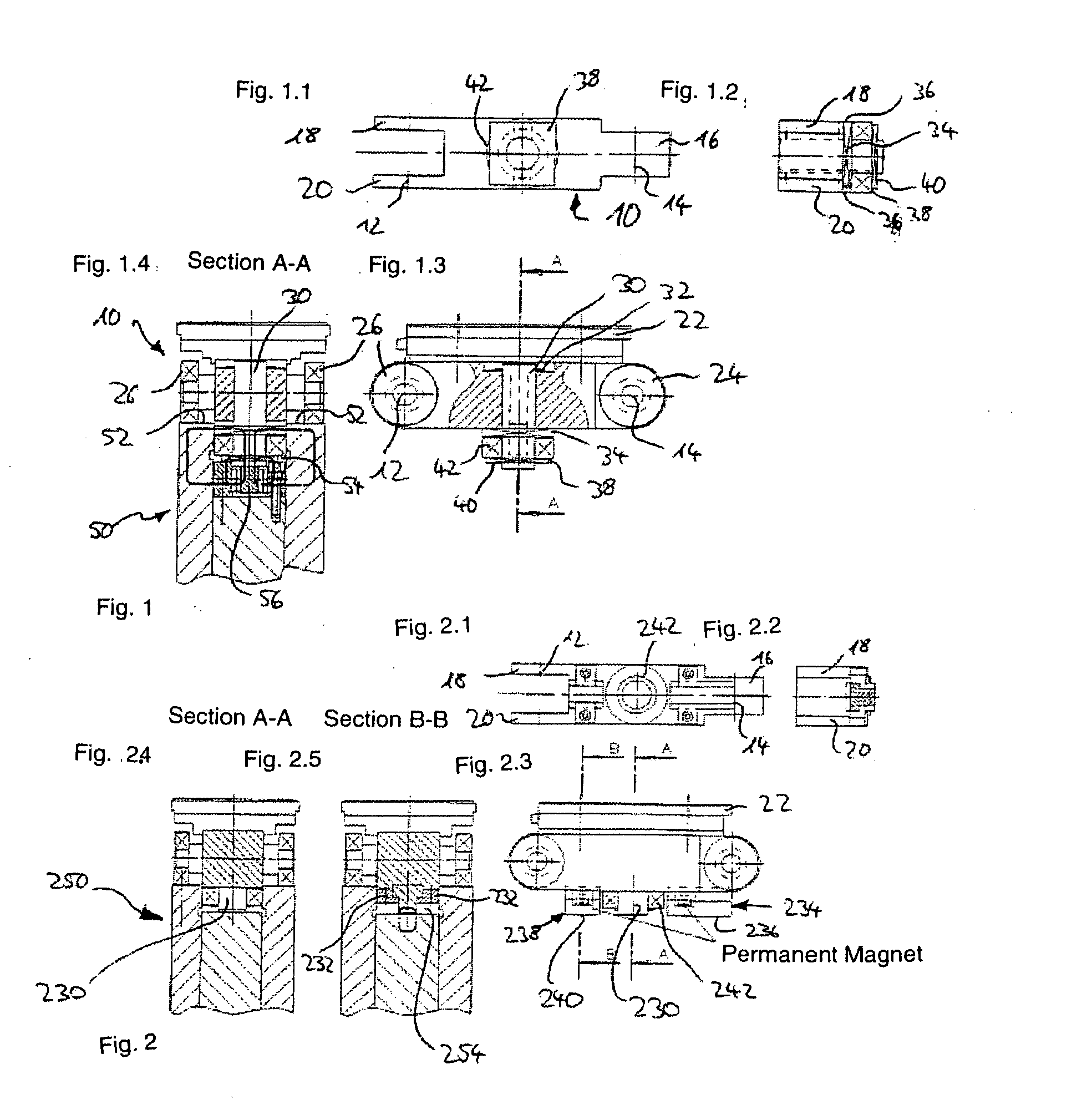

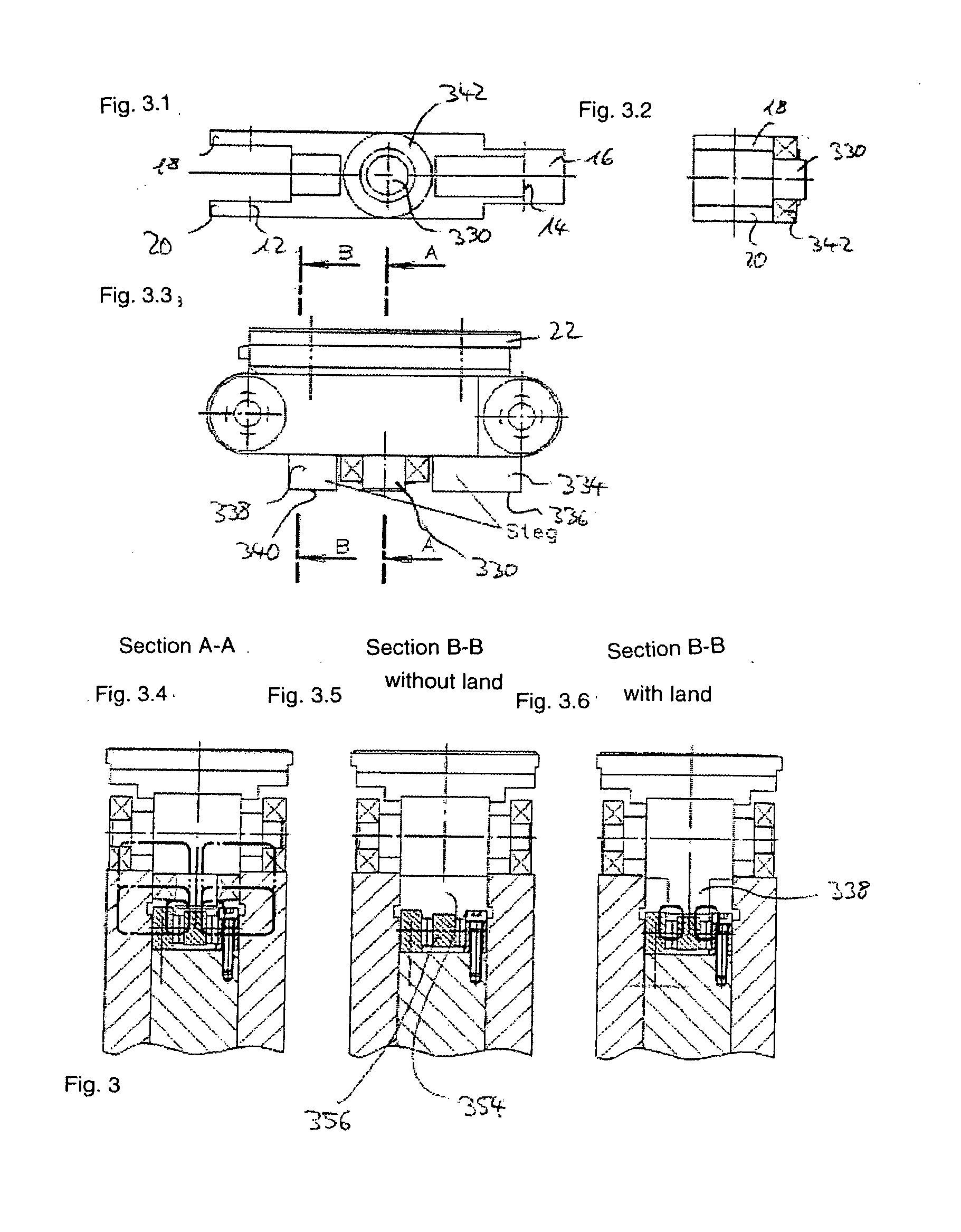

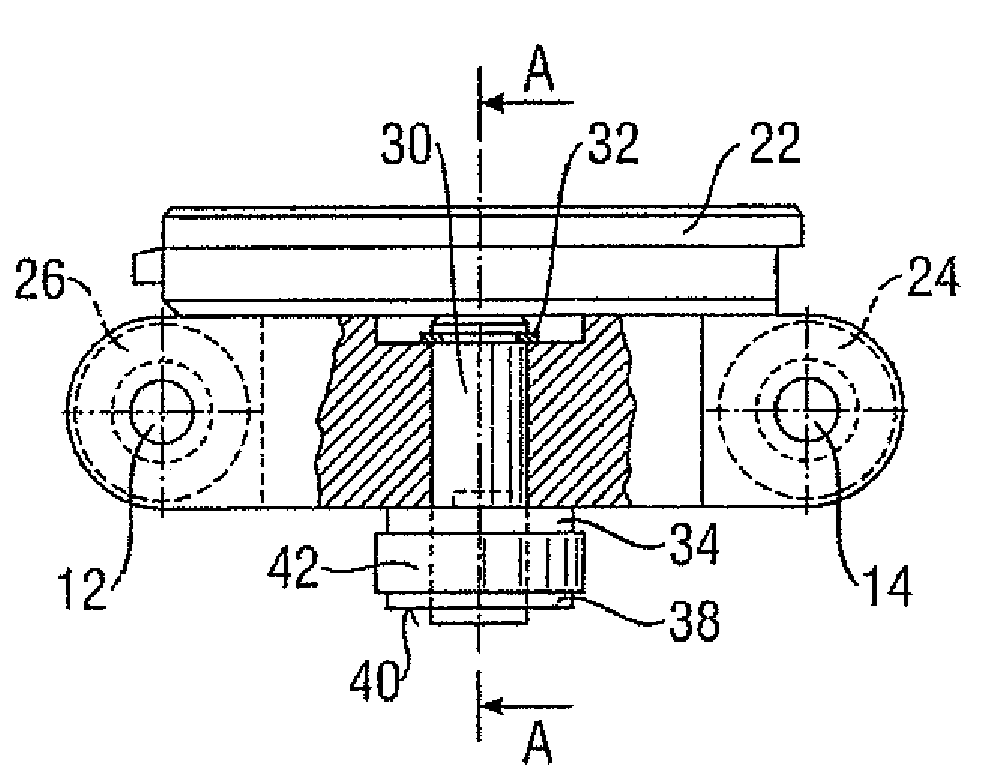

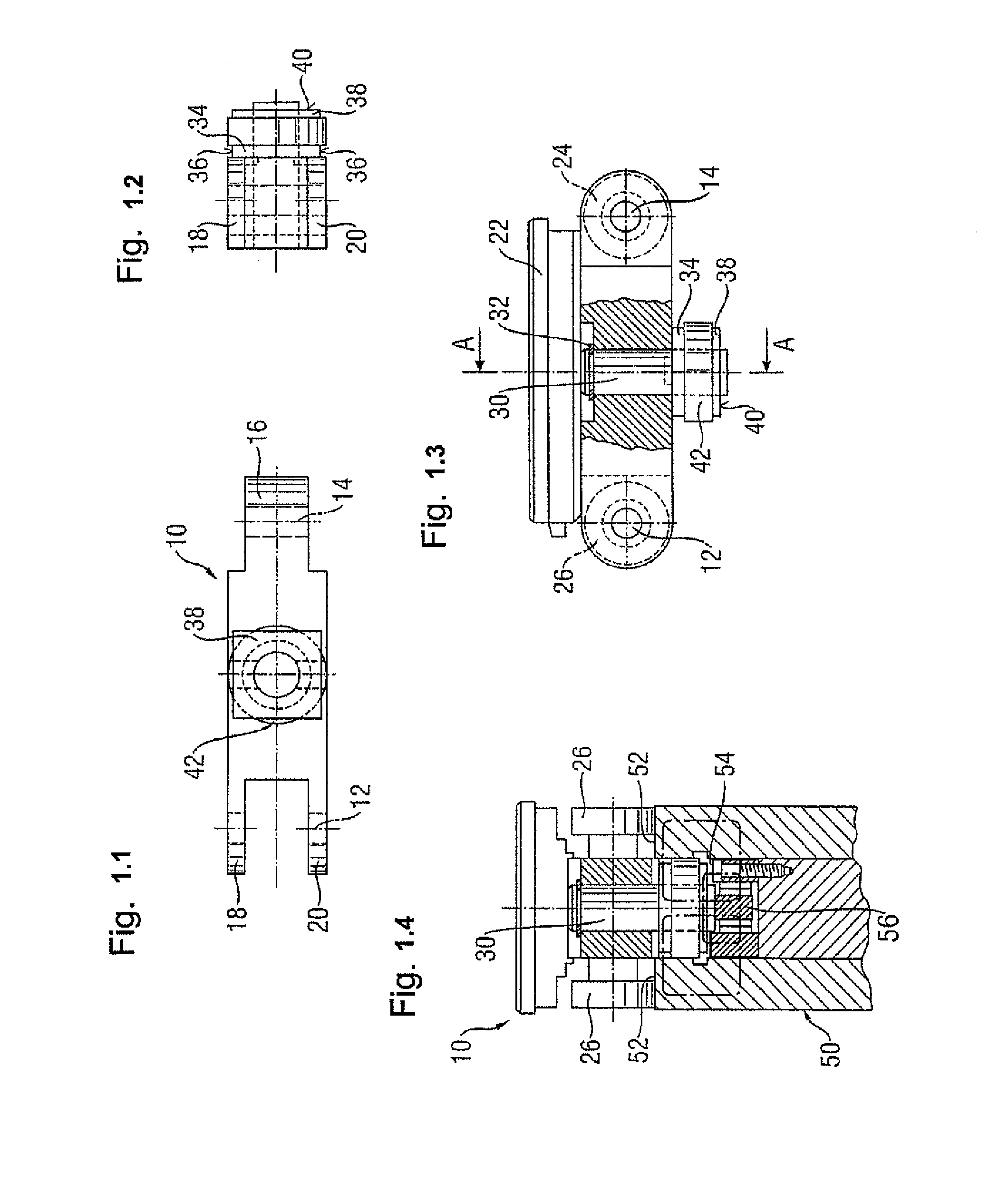

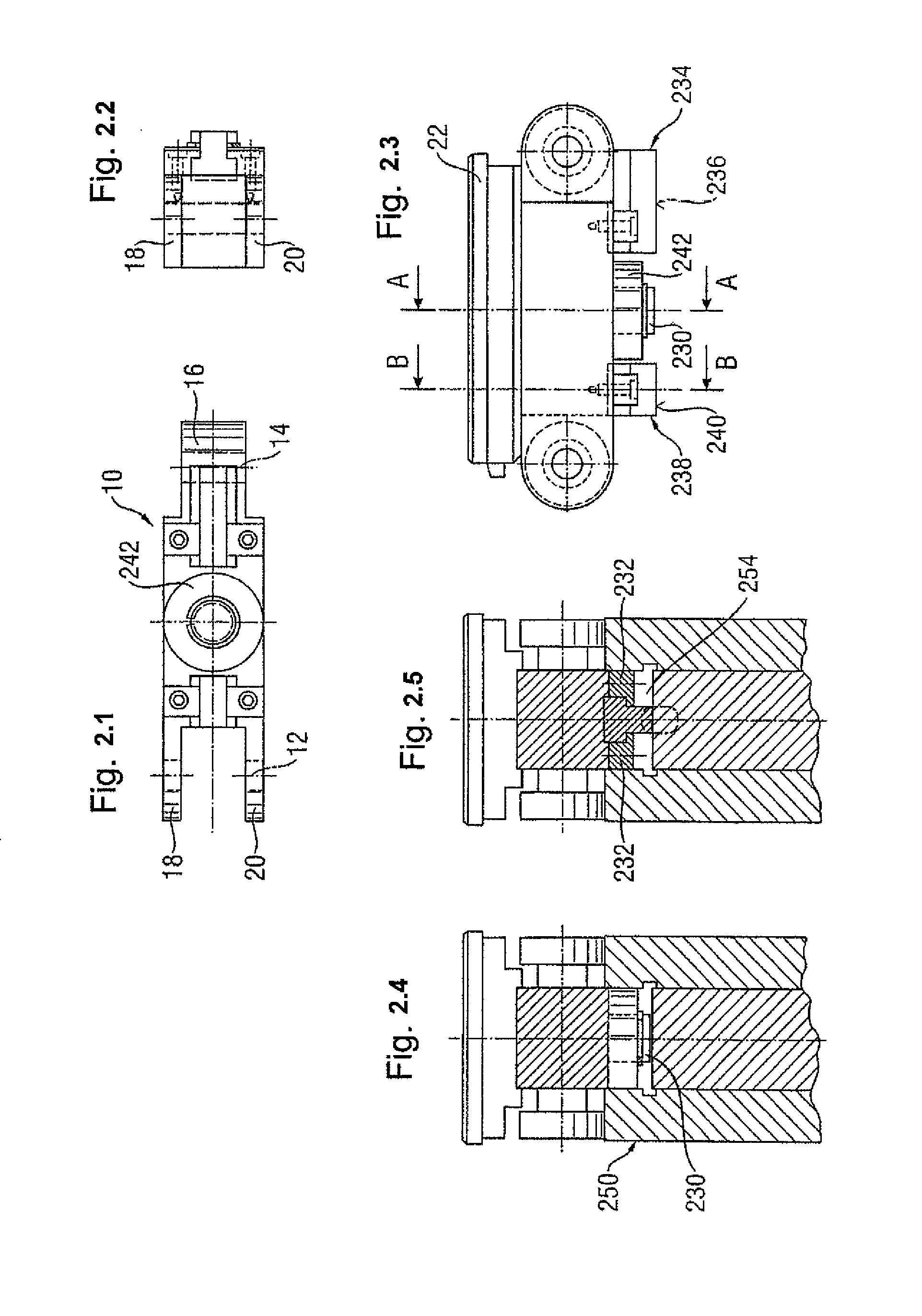

Chain link for a circulating transport of a machine tool, and double end tenoner with guide chain formed from said chain links

The present invention discloses chain links are proposed for the circulating transport chain of a machine tool, which comprise: a pair of rollers which determine the direction of circulation of the chain link by way of the direction in which they roll, over the rollers which is or are placed at a distance from the pair of rollers in the direction of circulation of the chain link and draw a plane as they roll against the roller pair; and a transverse guide, guiding the chain link transverse to its direction of circulation and is either free from rollers transverse to the direction of circulation of the chain link between the pair of rollers or has a transverse guide roller.

Owner:HOMAG HOLZBEARBEITUNGSSYST

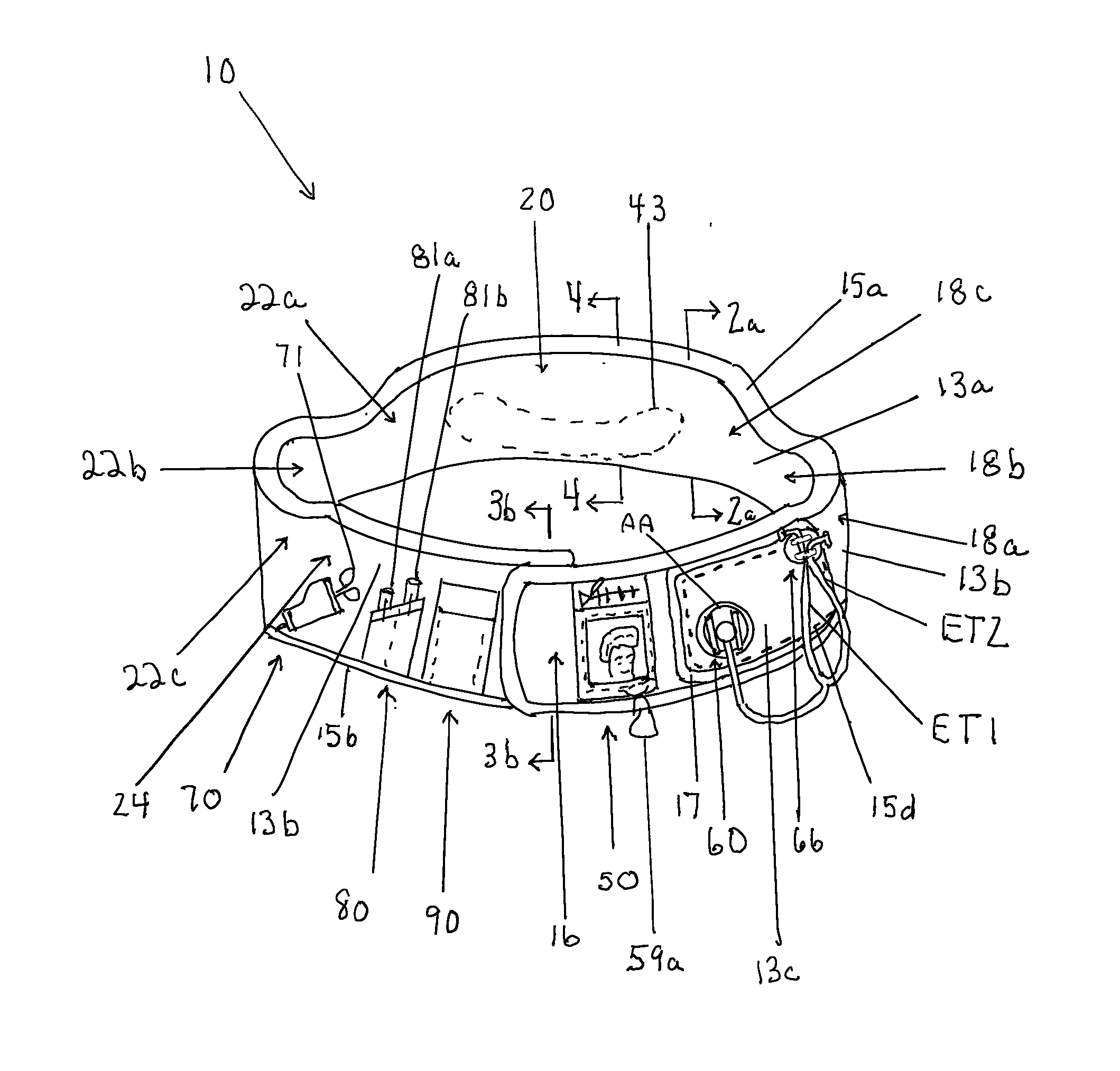

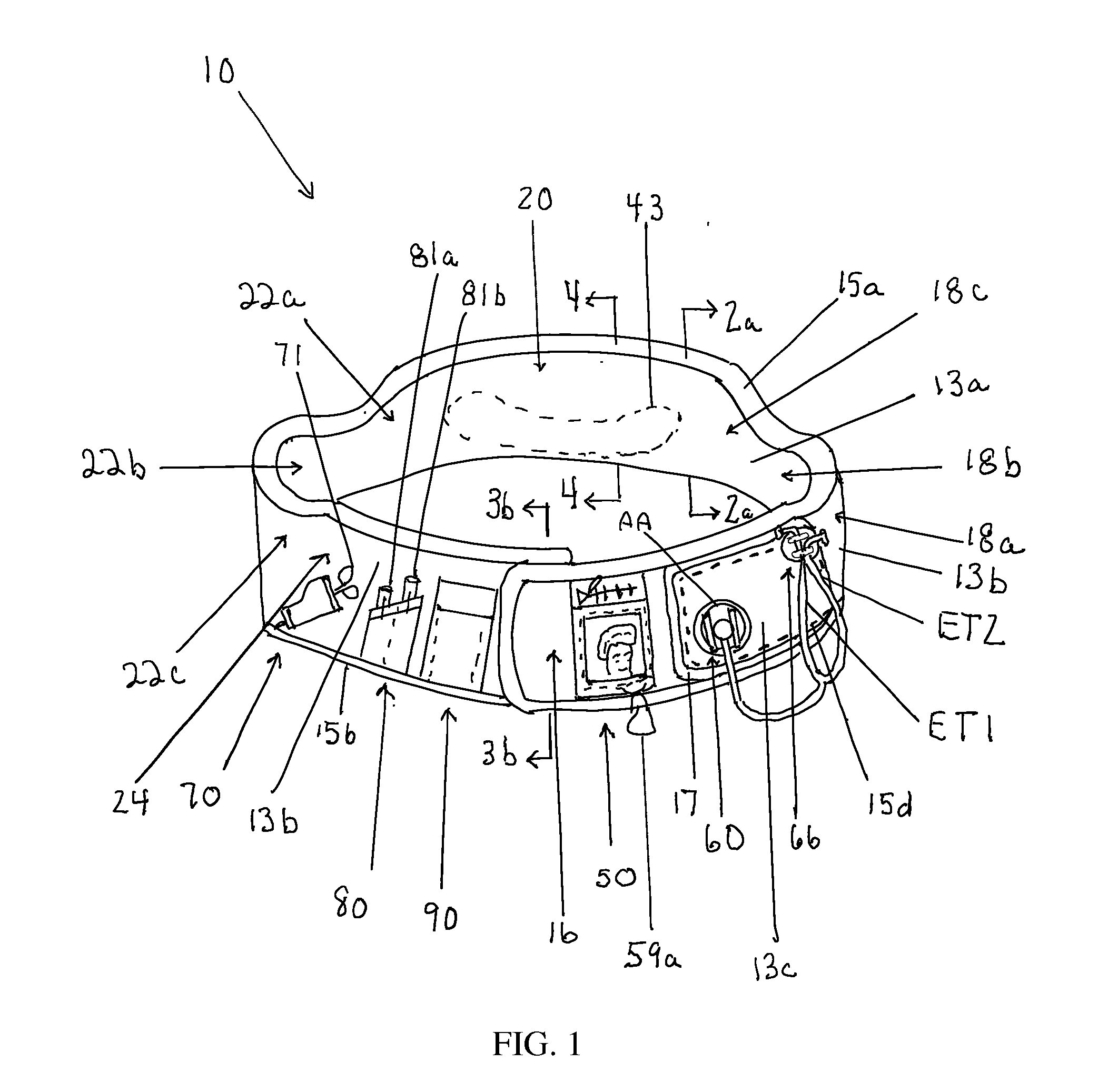

Trauma Utility Belt

ActiveUS20160066679A1Supporting requirements are lowAdd supportTravelling sacksTravelling carriersHigh densityEngineering

The present invention is a trauma utility device that includes an elongated belt having a plurality of compartments and devices for carrying and storing necessary equipment, a wide mid portion adjacent to the wearer's back with a high density foam pad for back support, and a scalloped upper edge at the wearer's hips, enhancing an individual's ability to freely turn and move while wearing the belt. The plurality of compartments and devices may include: a personal items pouch, a stethoscope chest piece holder, a stethoscope ear tube retainer, a communication compartment, a pen holder, and a trauma shears holster. The compartments and devices may be positioned on each side of the back mid portion around the longitudinal axis of the belt. Additionally, the belt and associated compartments and devices have an antimicrobial capability to help destroy and inhibit the growth of microorganisms and especially pathogenic microorganisms.

Owner:CAPPS REBECCA ANNE

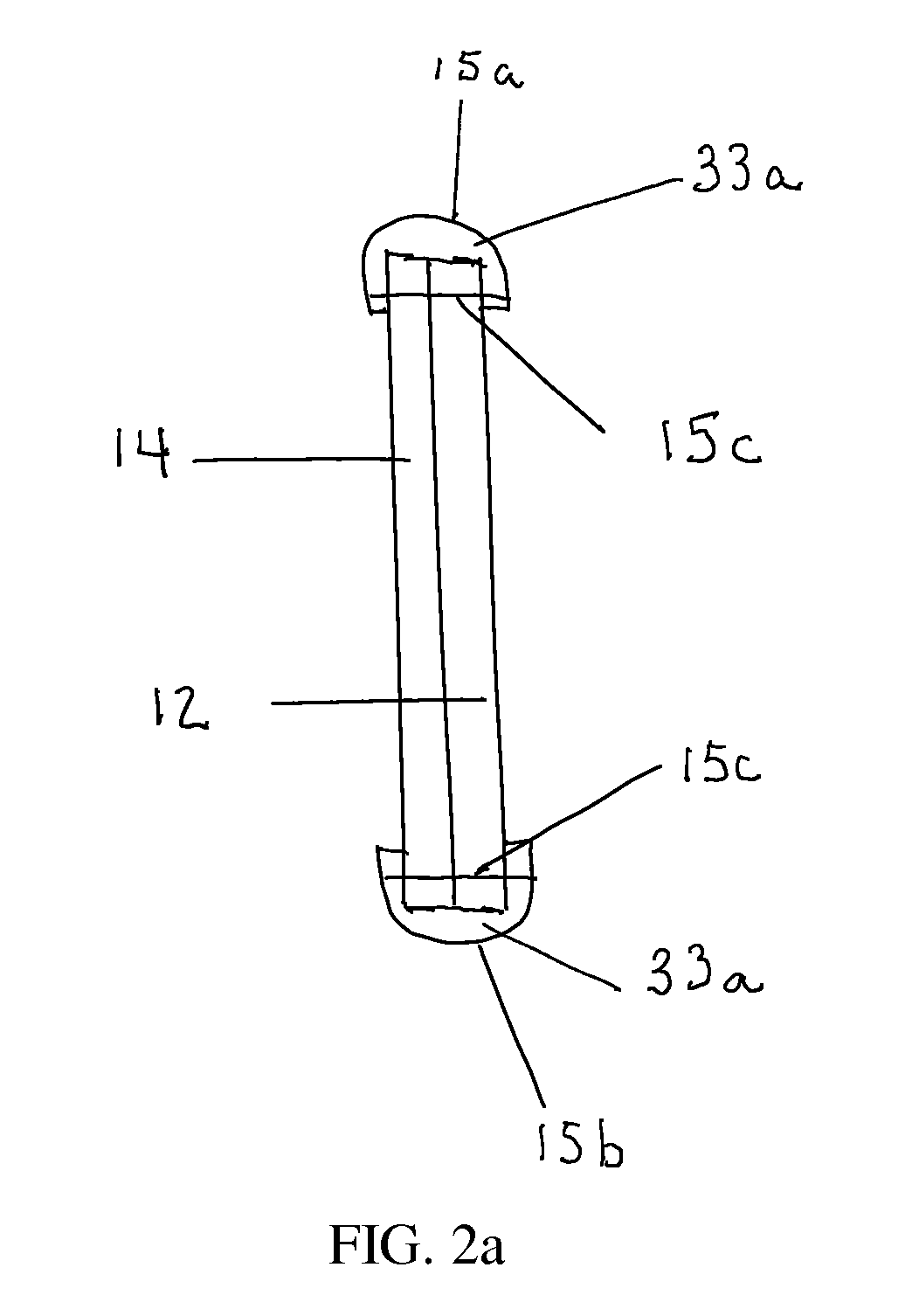

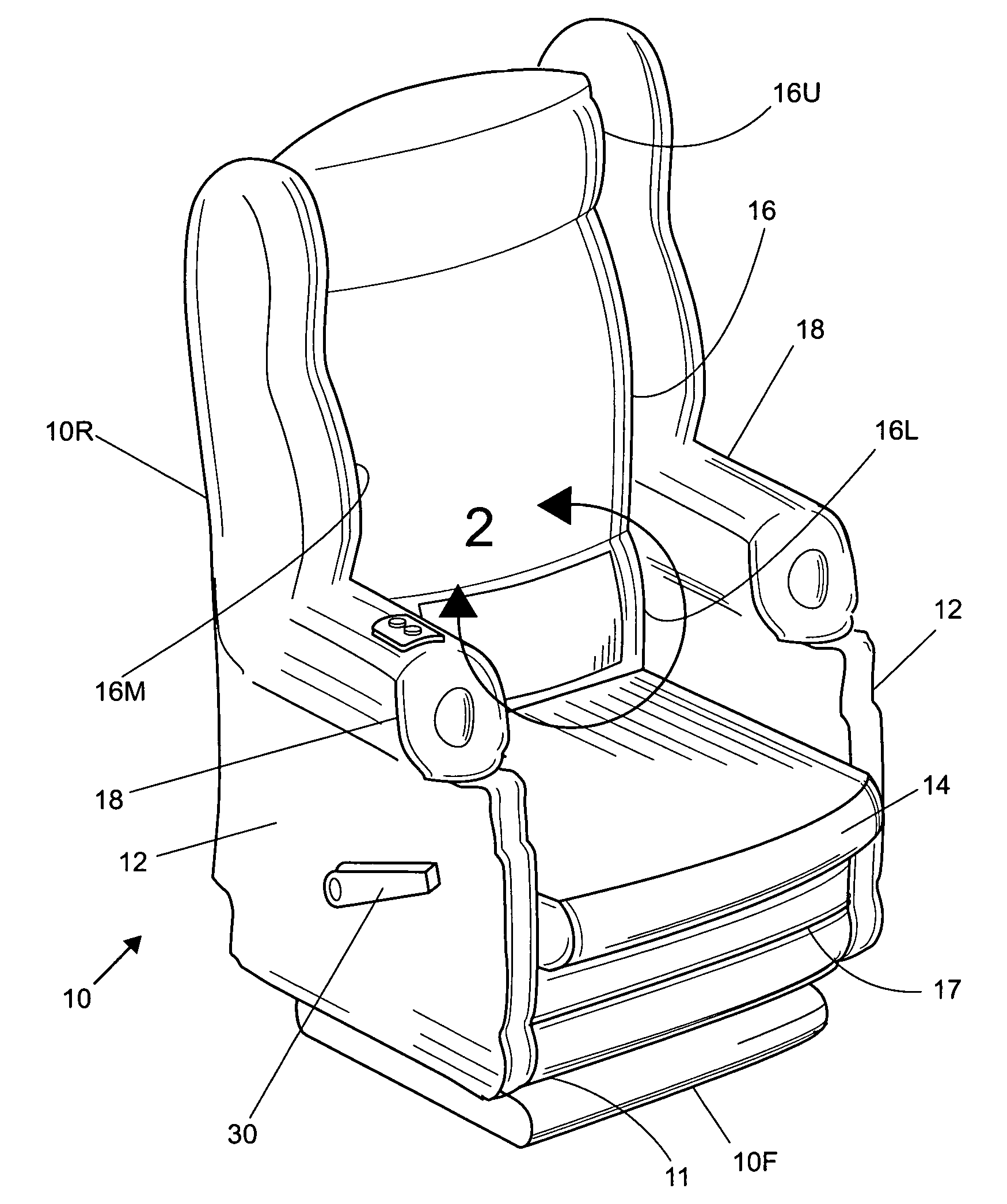

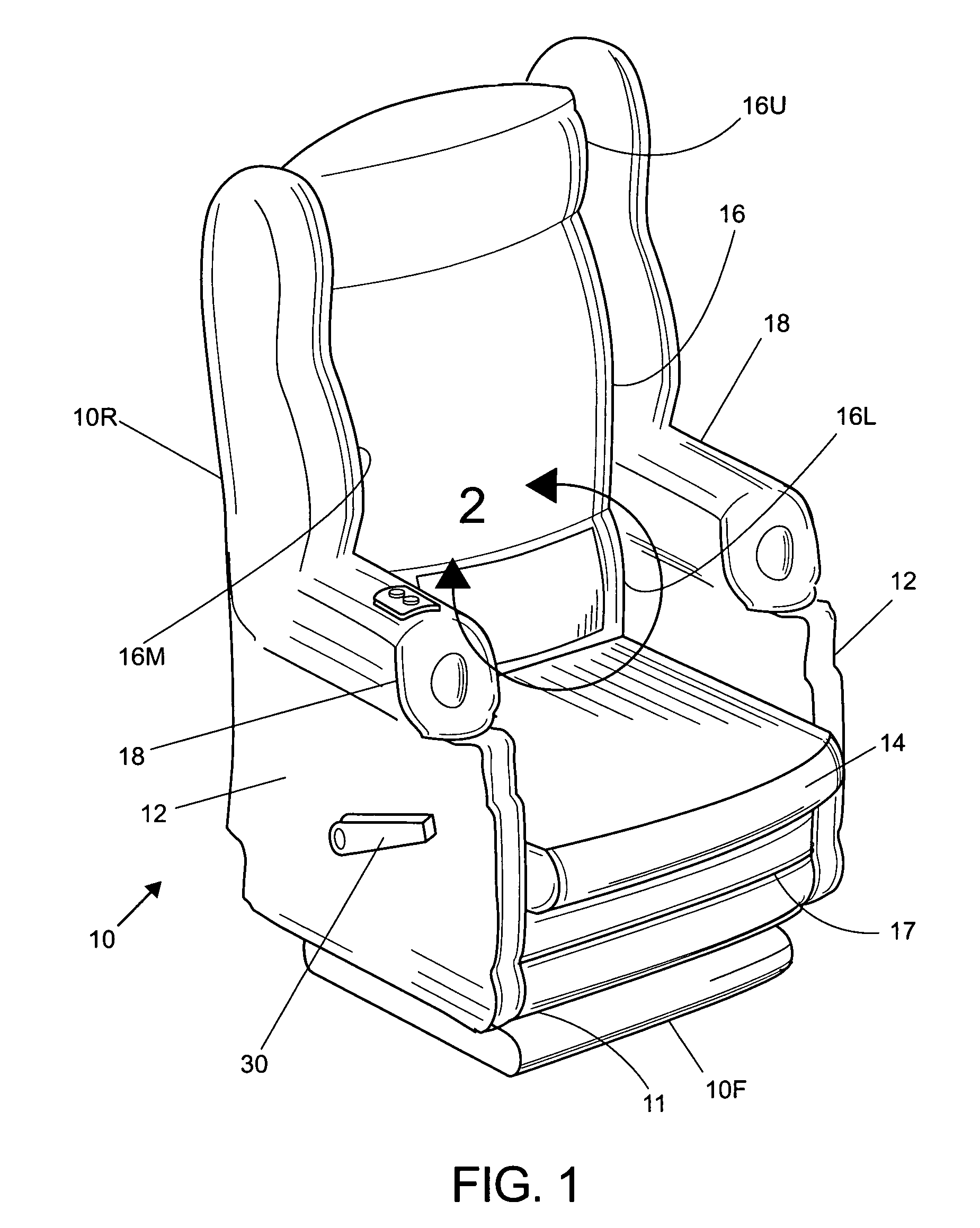

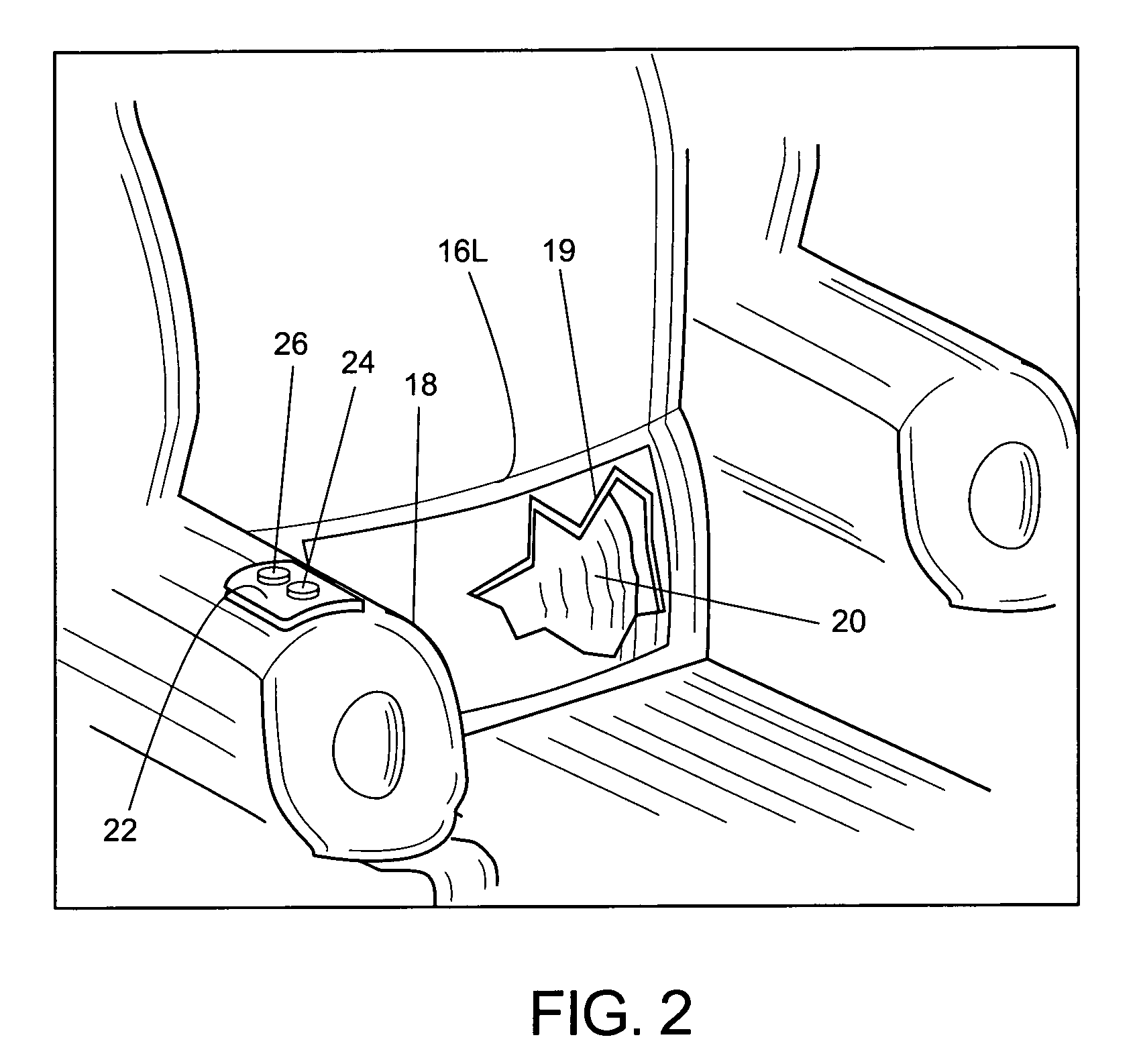

Reclining rocker chair with inflatable lumbar support

InactiveUS7350864B1Back support featureSupporting requirements are lowDismountable chairsFoldable chairsRemote controlEngineering

A reclining rocker chair, having a lower back support feature. The chair includes a base, a seat cushion, and a chair back extending upwardly from the base behind the seat cushion. The chair back has lower, middle, and upper sections. An inflatable chamber is located within the lower section of the chair back. A remote control provides the user with the option to inflate the inflatable chamber to provide lumbar support. A pressure sensor ensures that inflation pressure does not exceed predetermined limits for safely providing therapeutic support to the lower back.

Owner:BREWSTER SOPHIA

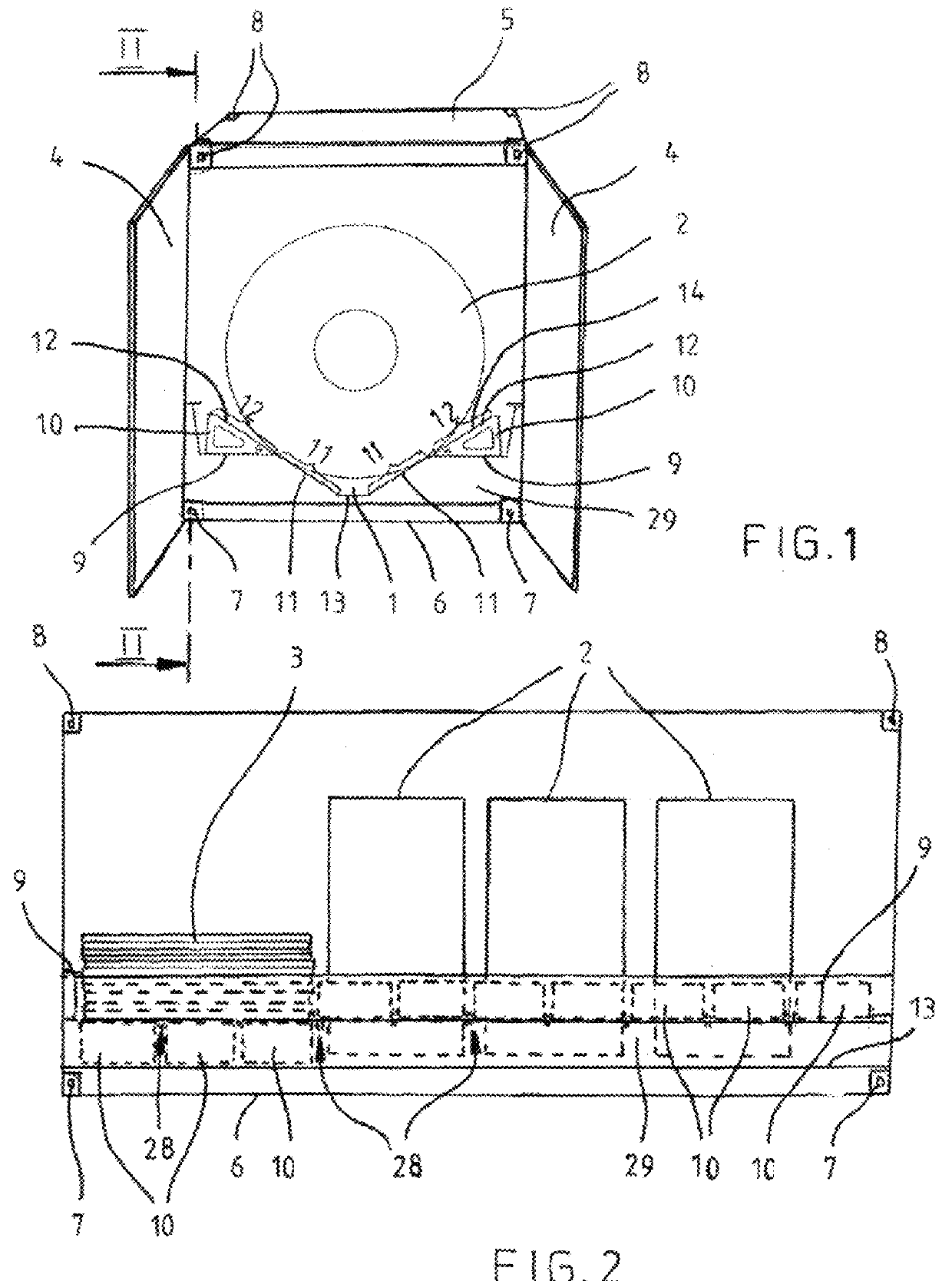

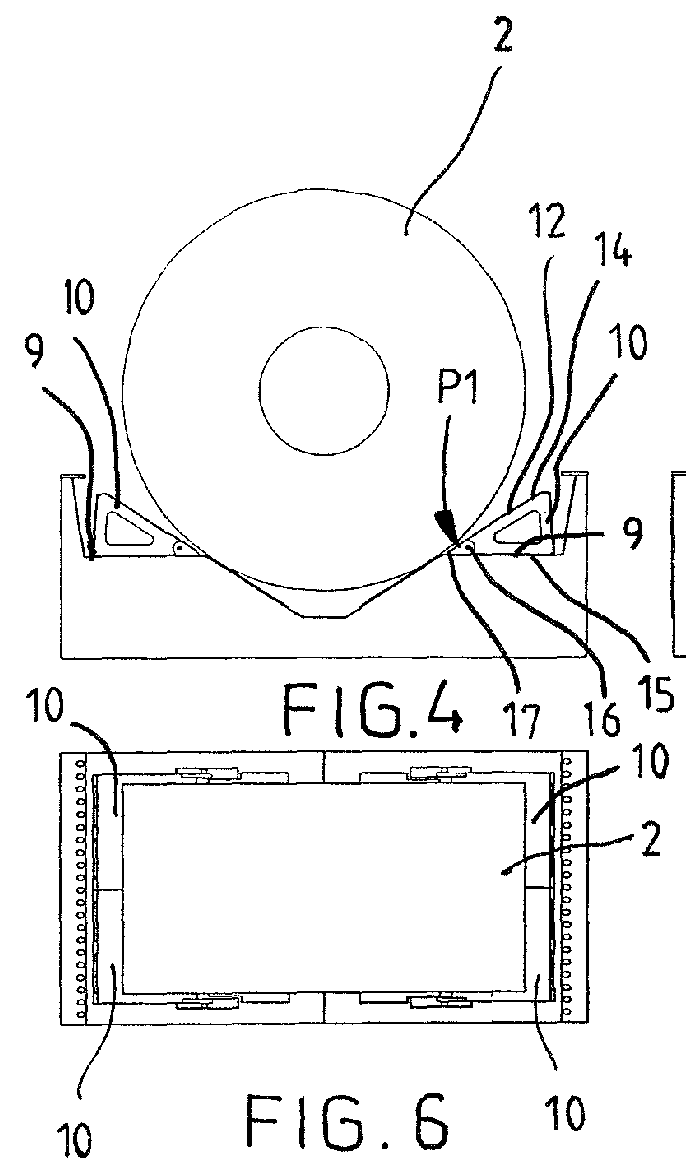

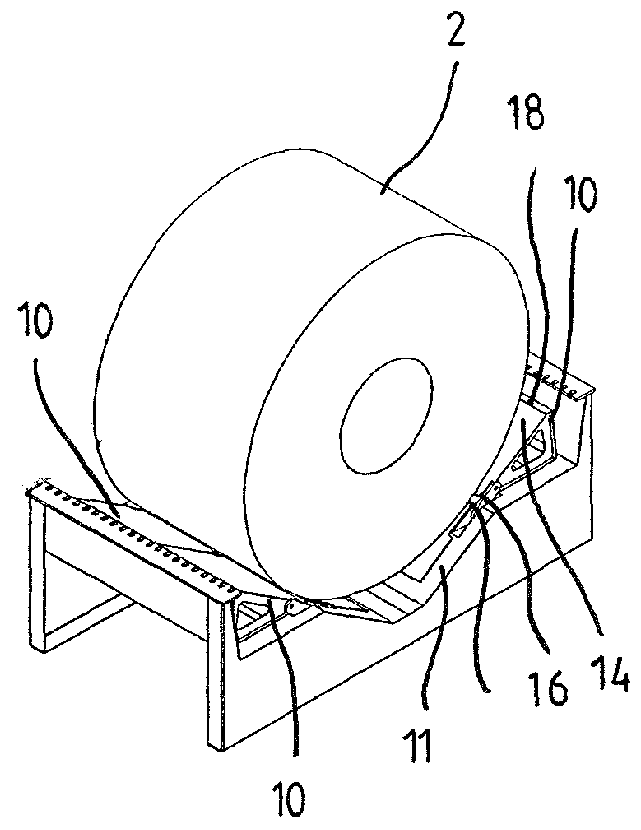

Container including object-supporting chute and pivot mechanism

ActiveUS9376236B2Easy to modifyImprove sturdinessContainers for annular articlesLarge containersEngineeringSupport plane

Owner:OY LANGH SHIP AB

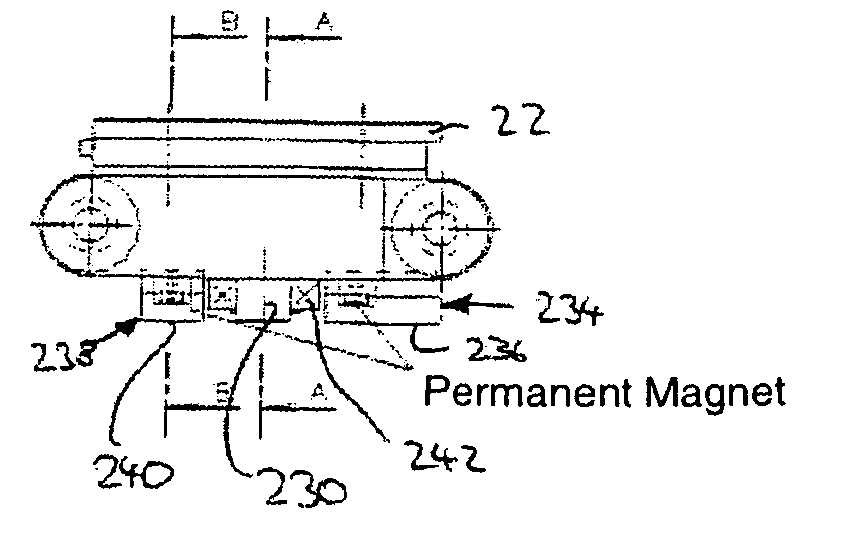

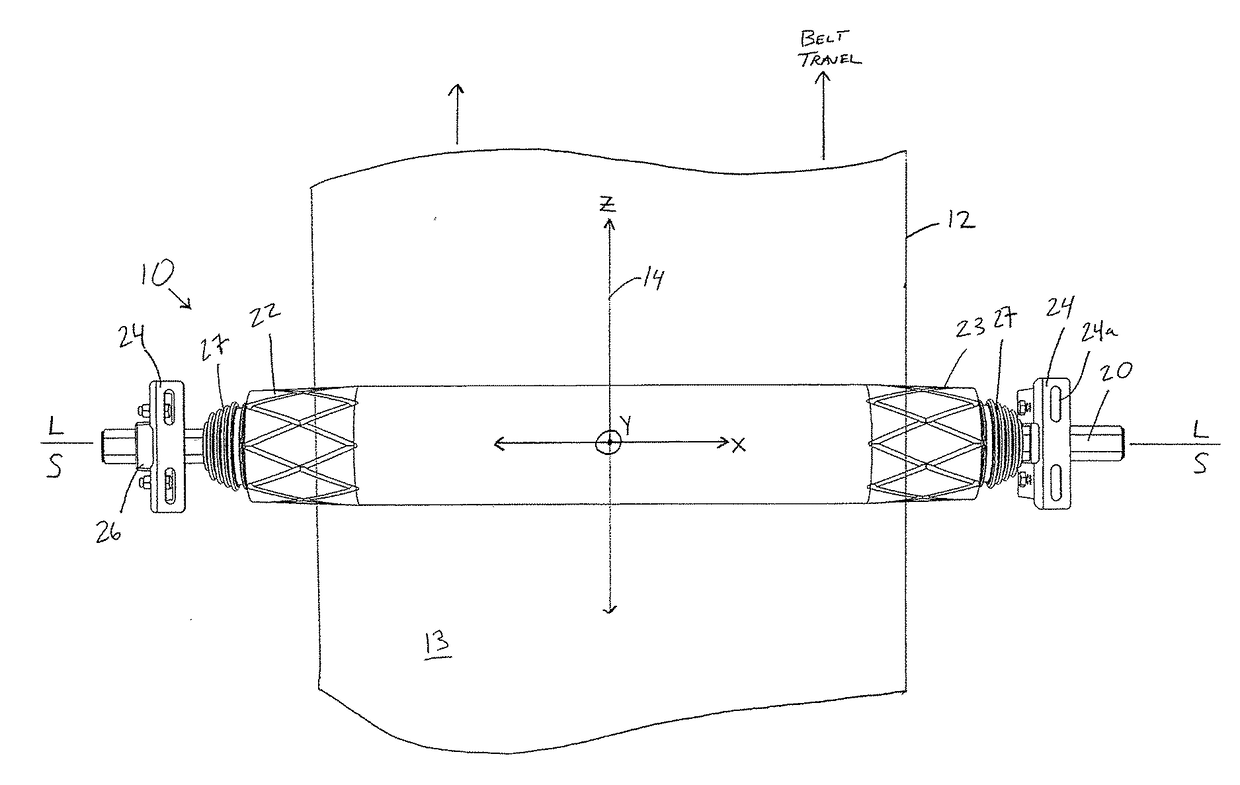

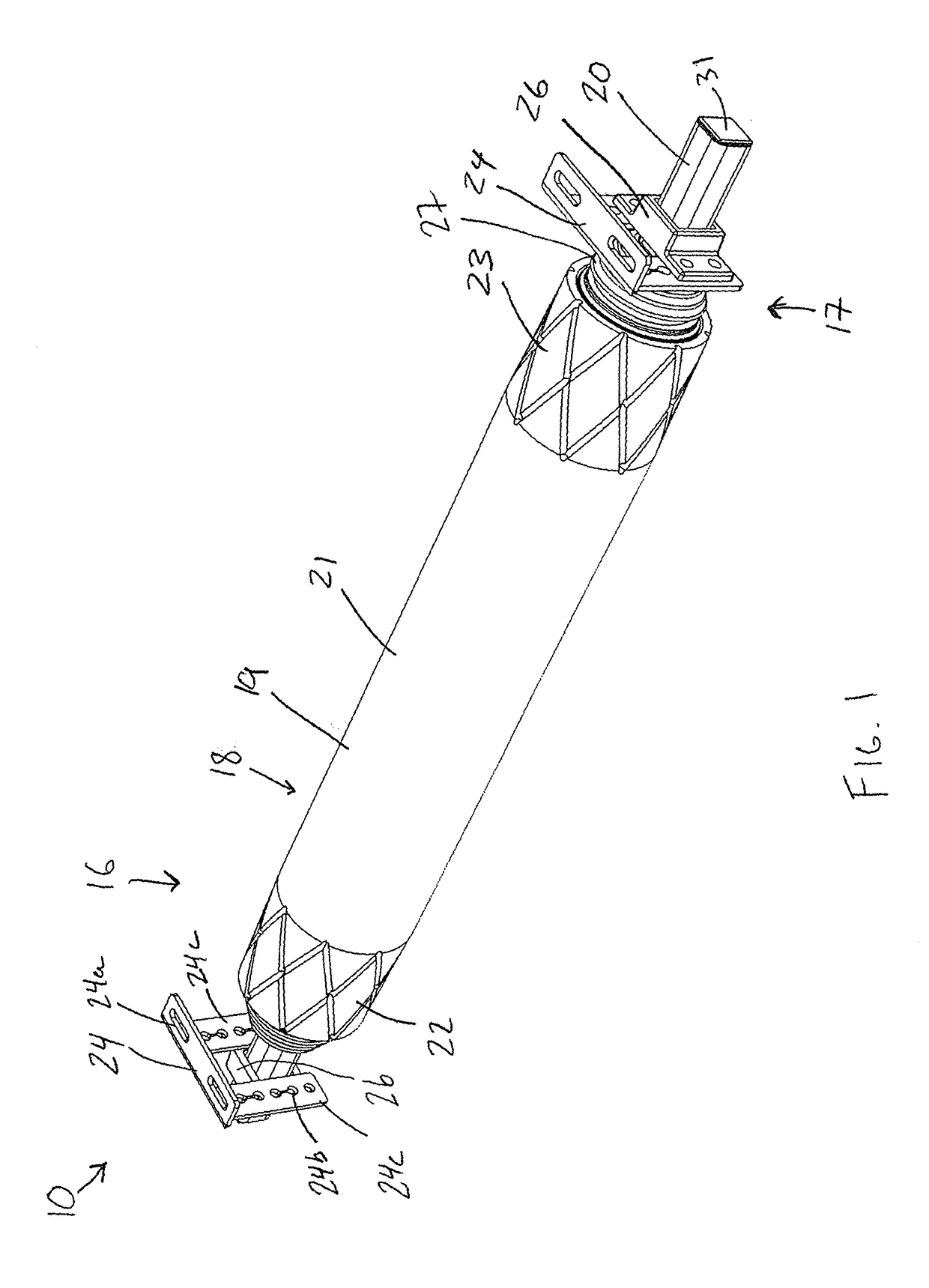

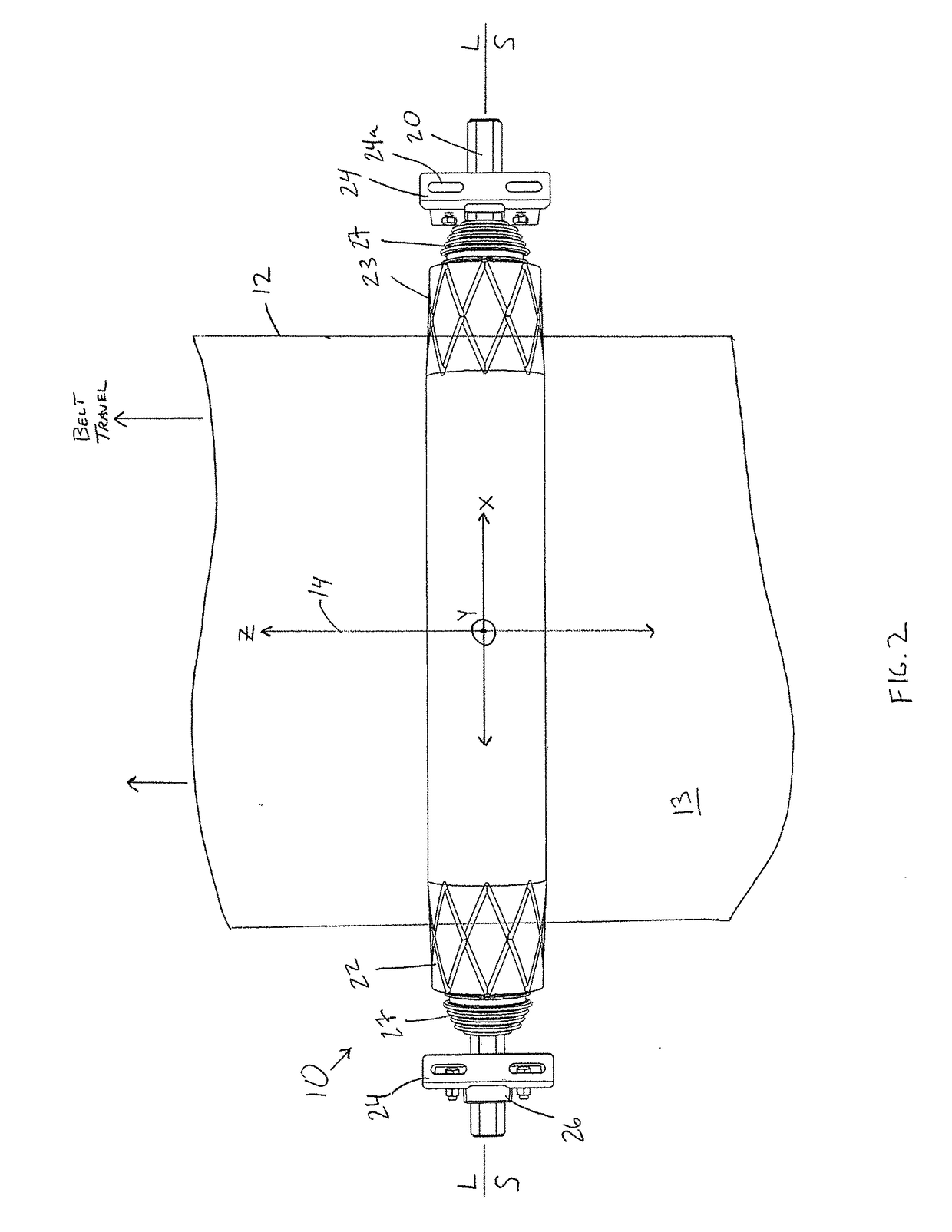

Apparatus and Method for Tracking Conveyor Belts

A tracking apparatus and method for urging a mistracking conveyor belt towards a correct travel path are disclosed. The apparatus and method utilize downstream shifting of an end portion of an idler roller due to mistracking of the conveyor belt for steering the belt back toward its correct travel path and a reaction force from the belt due to the steering thereof for energizing a tilting action of the idler roller to raise the downstream end portion thereof. The idler roller is mounted to the conveyor structure via a frame assembly including a tilt device mounted internally within the idler roller. The roller is rotatably mounted to an inner tube, and the inner tube member is pivotally mounted to the tilt device, which in combination allow the idler roller to pivot, shift, and tilt to steer a mistracking conveyor belt in relative proportion to degree of mistracking of the belt.

Owner:FLEXIBLE STEEL LACING

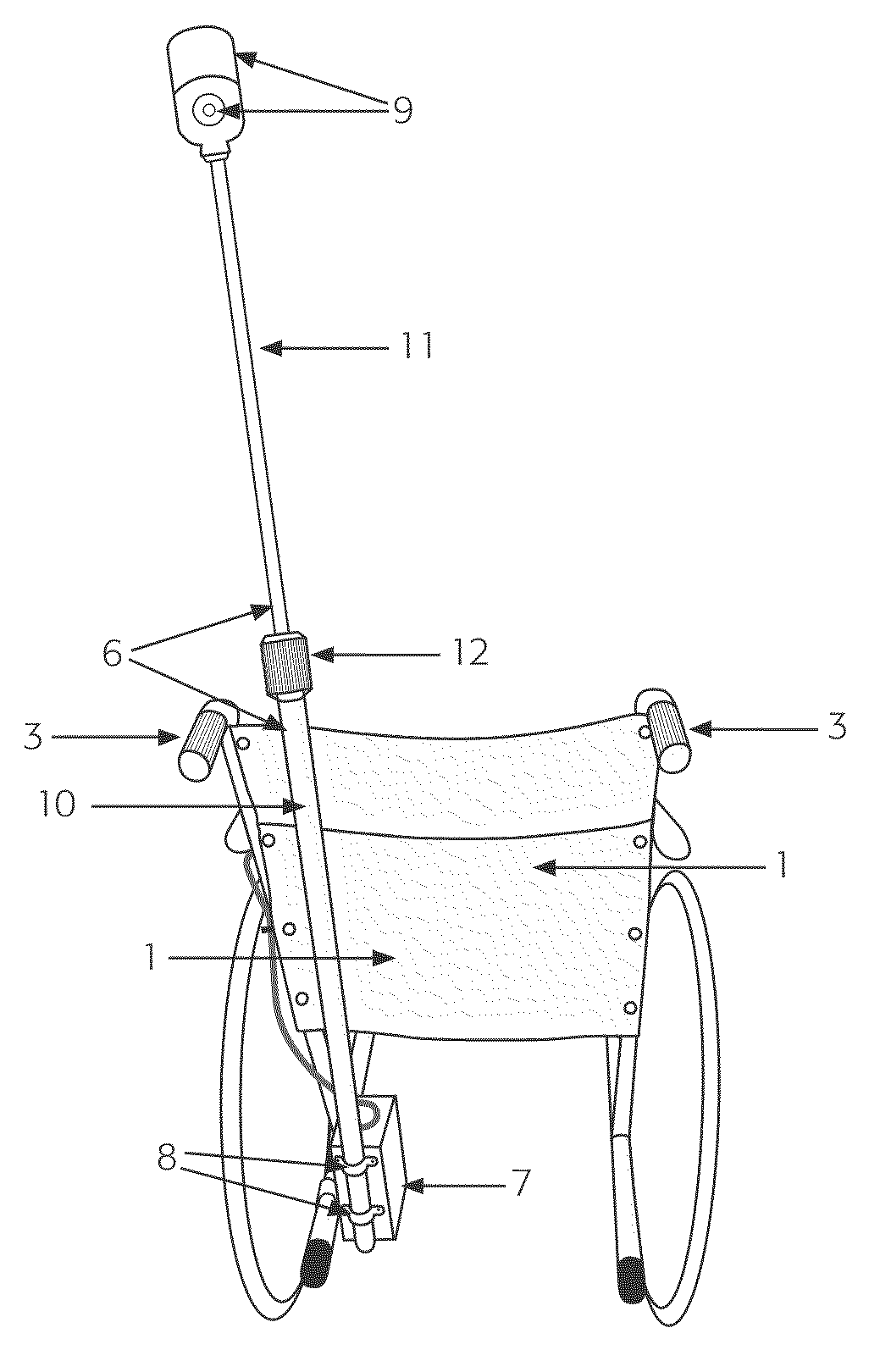

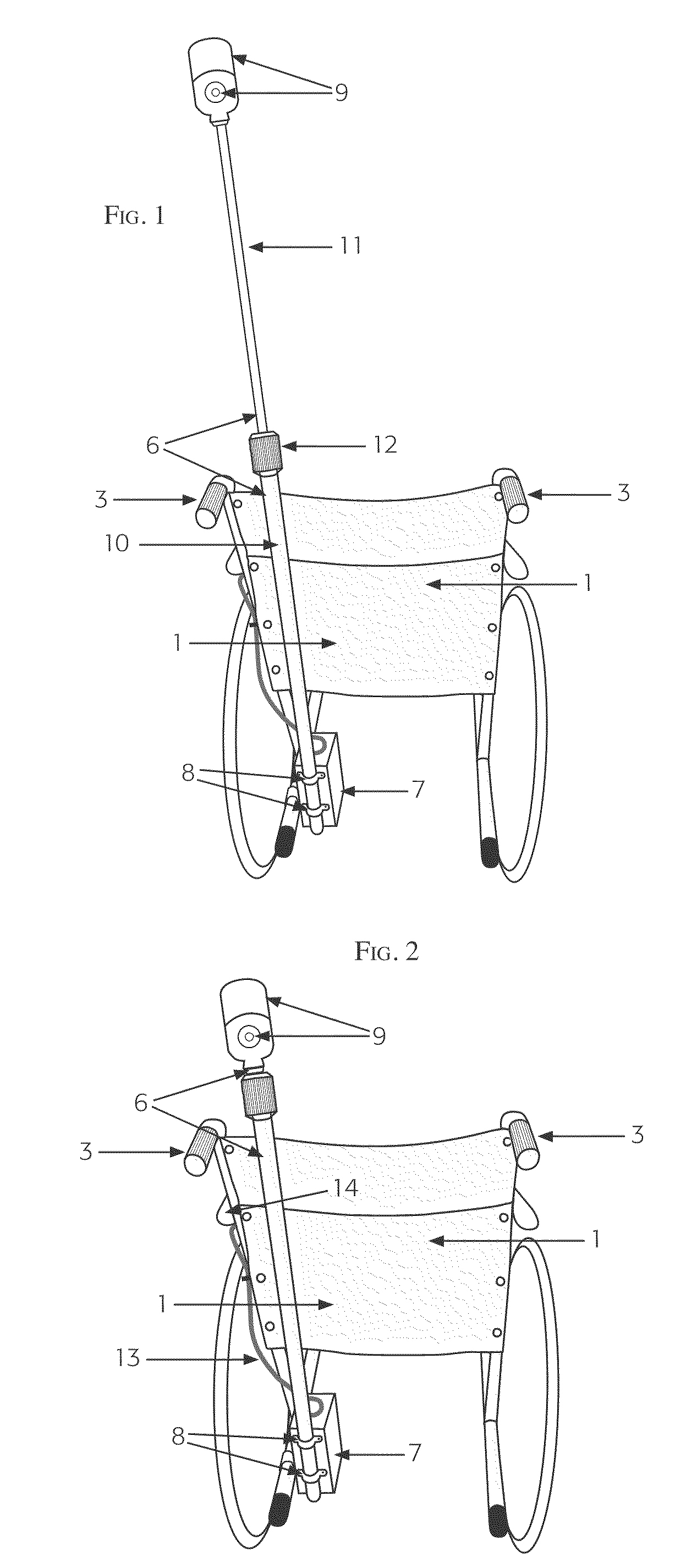

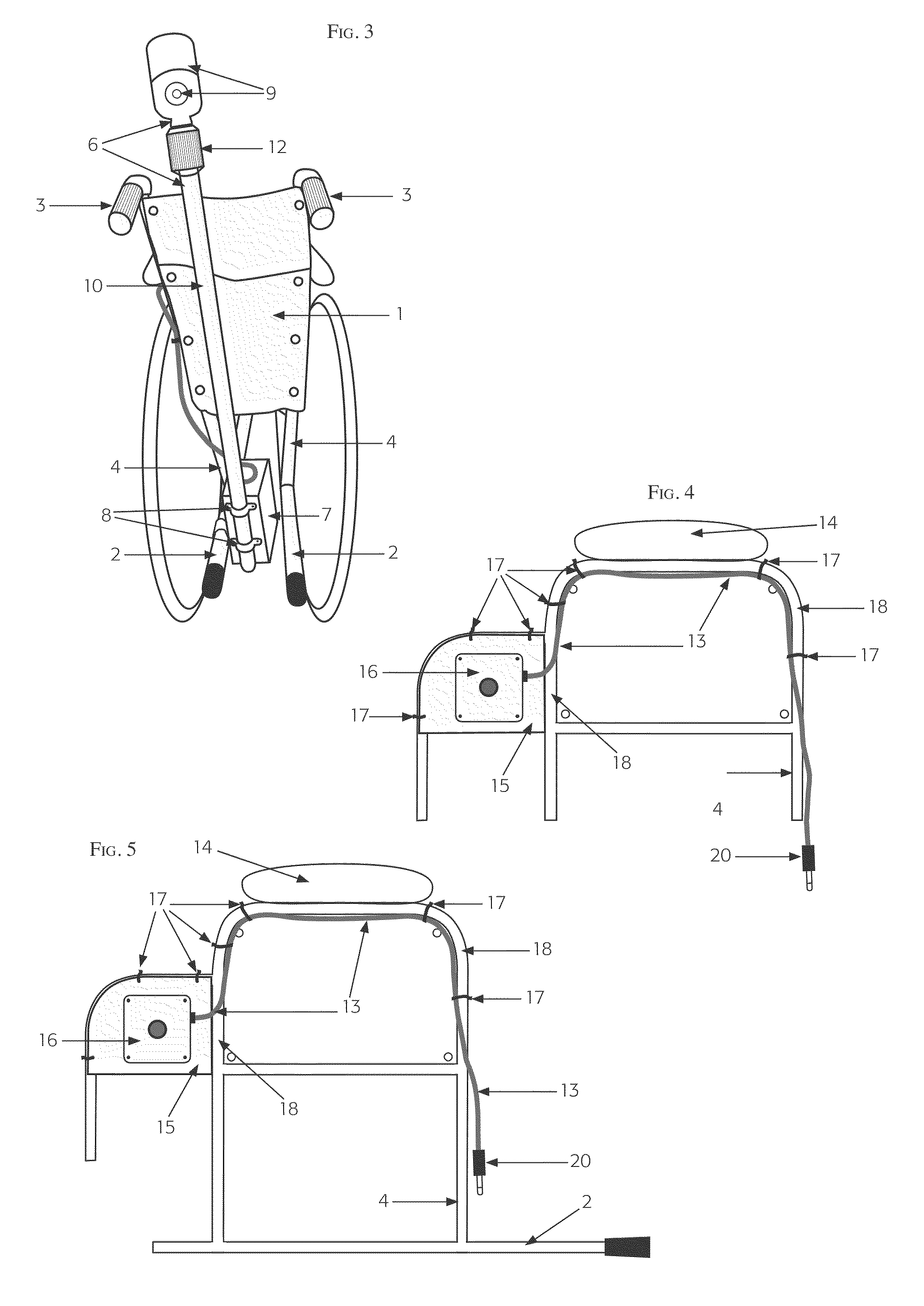

Wheelchair accessory

ActiveUS8134463B2Supporting requirements are lowFill the voidLighting support devicesRoad vehicles traffic controlWheelchair accessoryEngineering

My invention is an improvement upon the previously existing wheelchair warning lamp apparatus that fails to allow the wheelchair to fold and be used indoors when installed onto the wheelchair and require drilling to be installed. My apparatus, a clamp-on extendible and retractable cylinder shaped erected pole has a safety light and an audible alert equipment installed on top of the inner casing and a pole lock nut installed on the outer casing whereas the outer pole casing is attached to the battery housing support member with three C-Clamps vertically and horizontally attached on the battery housing allowing the pole and battery safety light assembly with audible alert apparatus to be clamped onto one side only of the wheelchair without drilling required and allows the chair to fold and be used indoors without removal of the installed pole and battery with safety light with audible alert apparatus from the wheelchair.

Owner:12U L L C

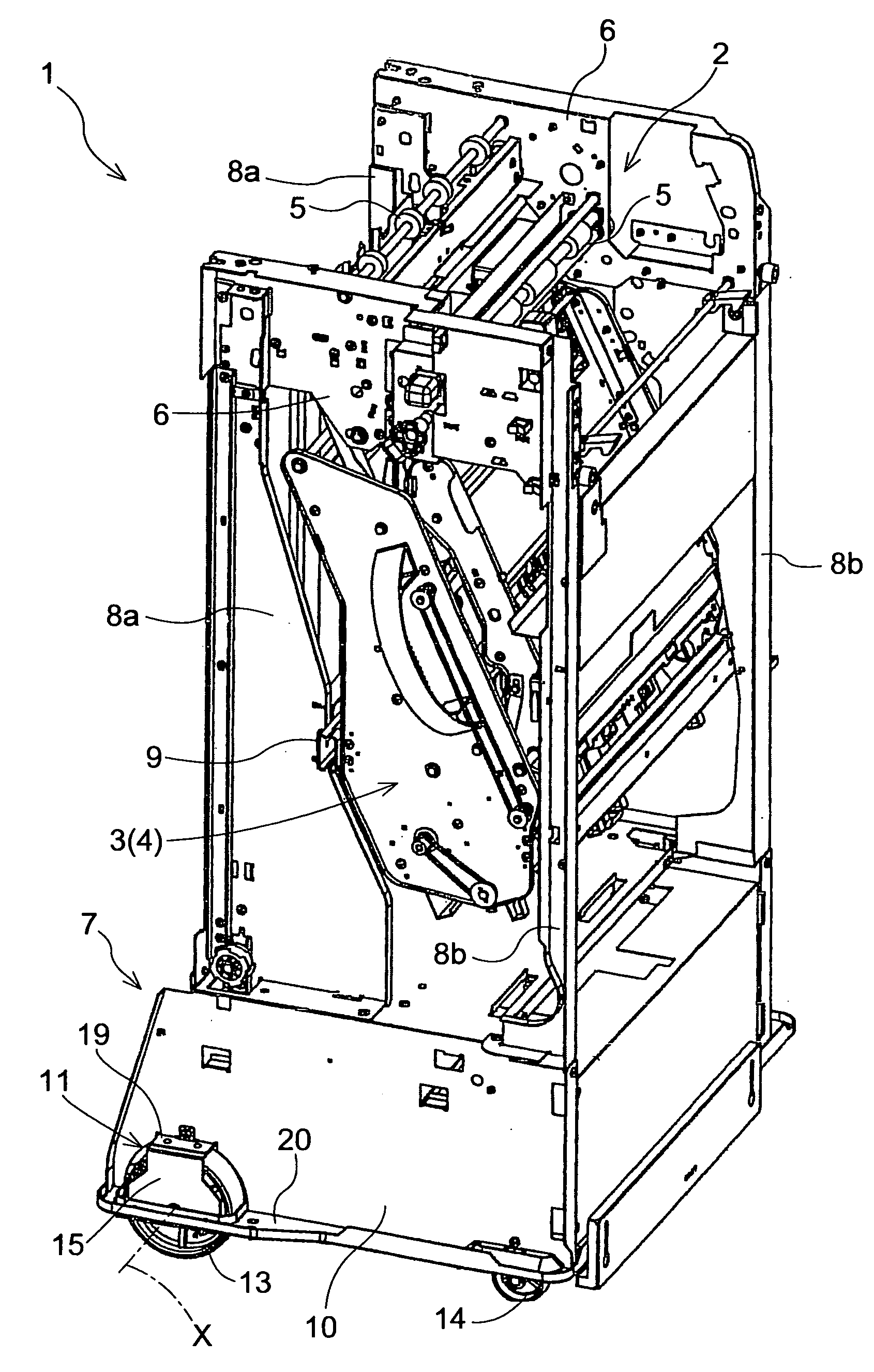

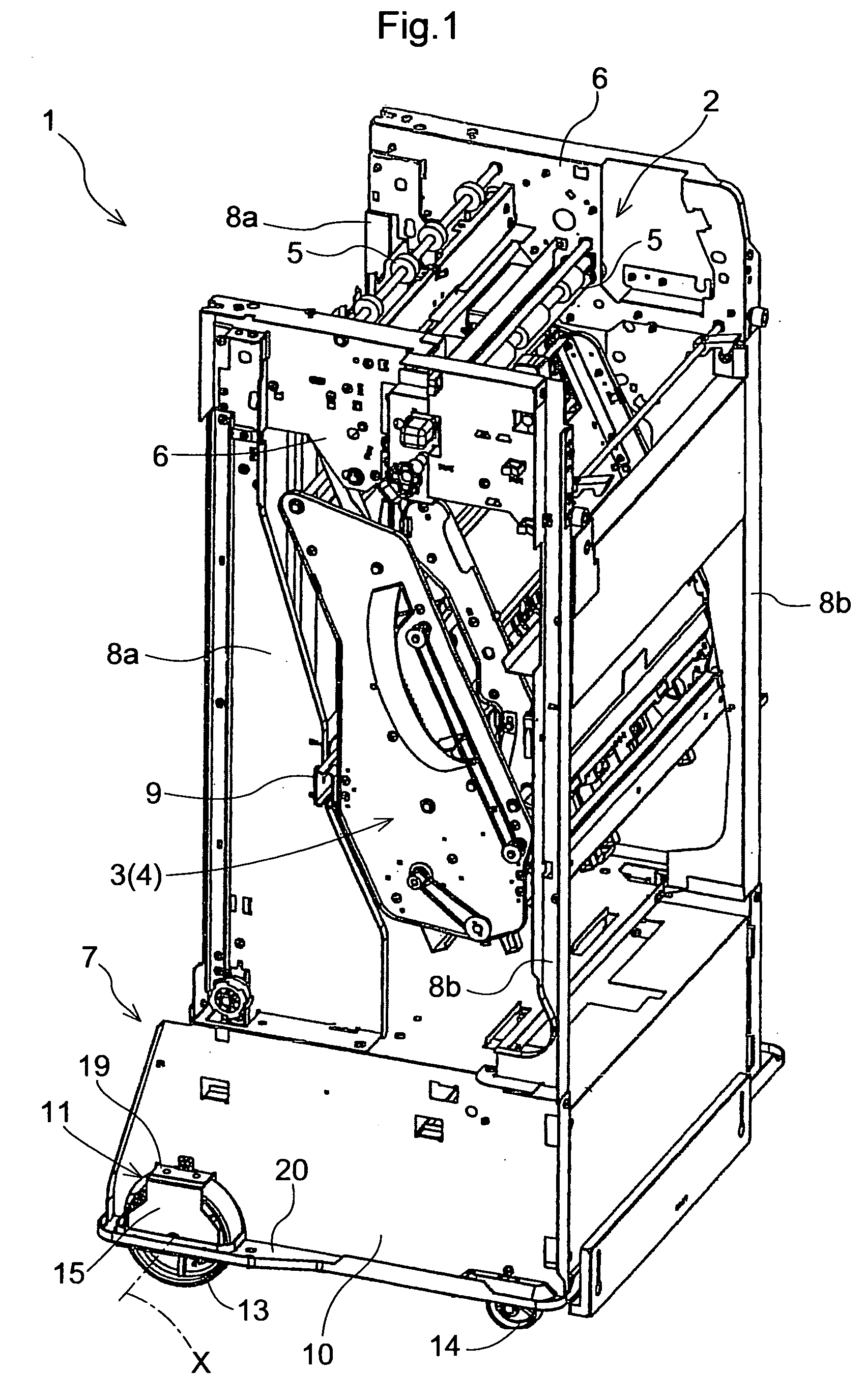

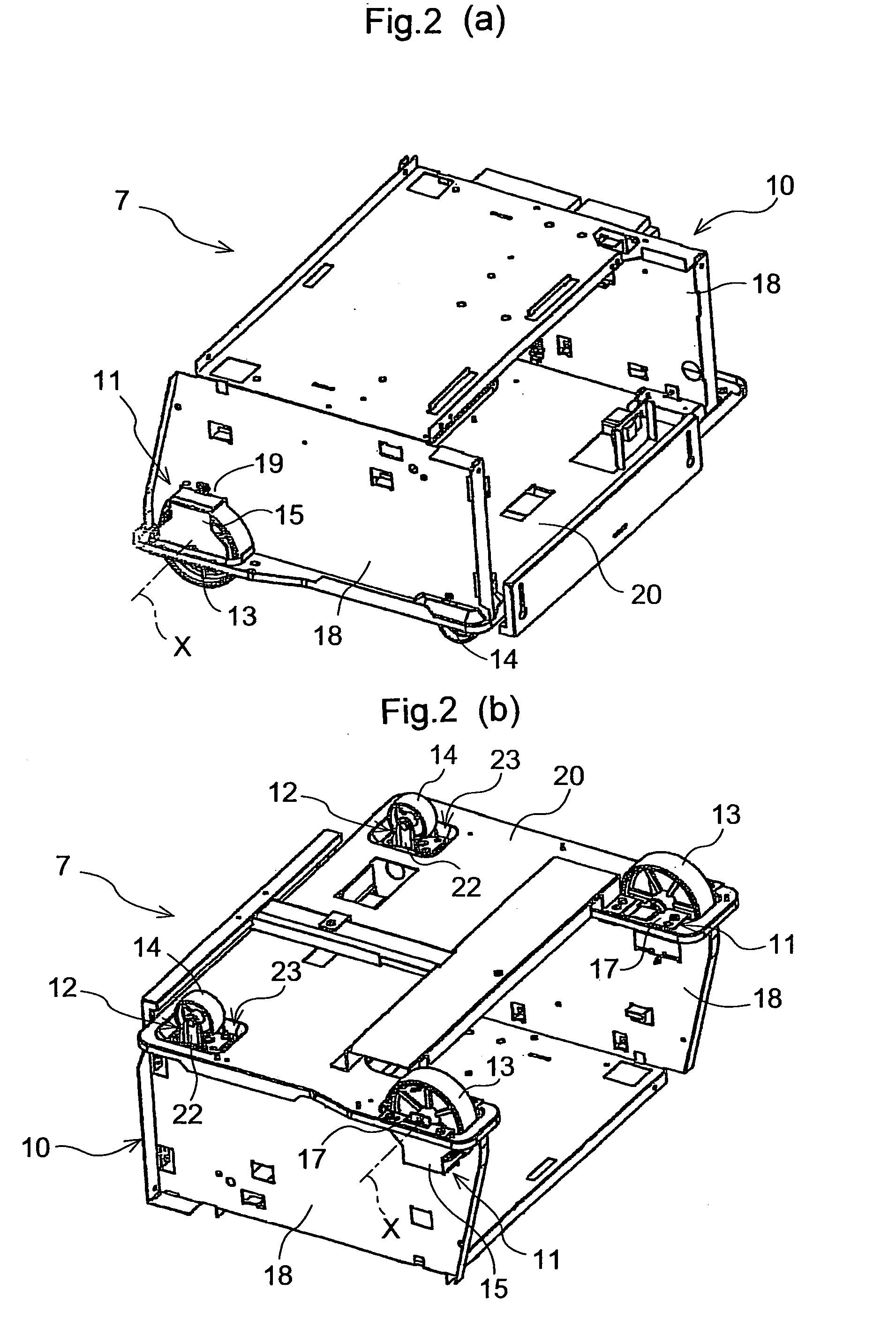

Office machine

InactiveUS20060237929A1Simple operation of cutInexpensive to manufactureStands/trestlesChildren carriages/perambulatorsEngineeringLower face

An office machine includes a housing body, a bearing unit secured to the housing body and a caster wheel supported to the bearing unit to be rotatable about a horizontal axis. The bearing unit is secured to a bottom plate forming a lower face of the housing body. The bottom plate defines an opening, through which the caster wheel is introduced to a position upwardly of the bottom plate to be supported to the bearing unit.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Chain link for a circulating transport of a machine tool, and double end tenoner with guide chain formed from said chain links

ActiveUS7721873B2Guaranteed smooth progressIncrease the air gapConveyorsSupporting framesEngineeringChain link

The present invention discloses chain links for the circulating transport chain of a machine tool, which comprise: a pair of rollers which determine the direction of circulation of the chain link by way of the direction in which they roll, over the rollers which is or are placed at a distance from the pair of rollers in the direction of circulation of the chain link and draw a plane as they roll against the roller pair; and a transverse guide, guiding the chain link transverse to its direction of circulation and is either free from rollers transverse to the direction of circulation of the chain link between the pair of rollers or has a transverse guide roller.

Owner:HOMAG HOLZBEARBEITUNGSSYST

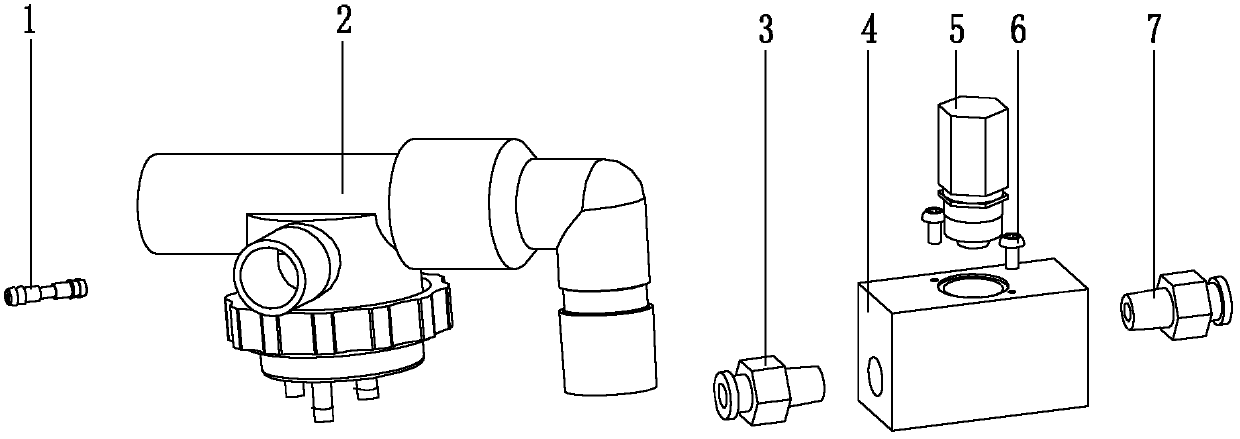

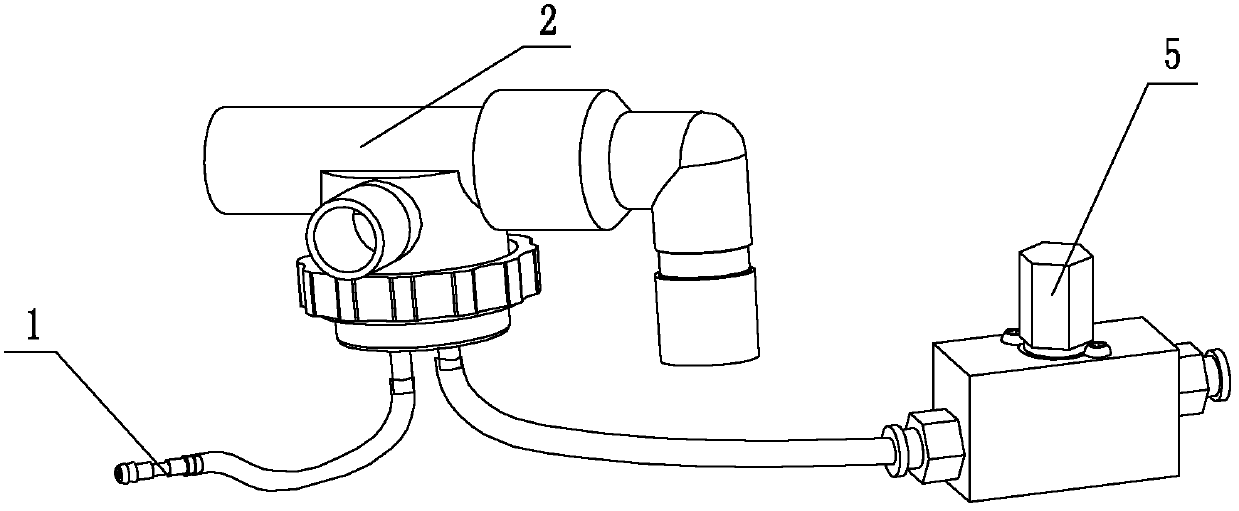

Positive end expiratory pressure valve pressure control device

The invention relates to a positive end expiratory pressure valve pressure control device which comprises an exhalation valve 2, a proportional valve installation base 4, a flow proportional valve 5 and a current-limiting capillary copper pipe 1, wherein one end of the proportional valve installation base 4 is connected with one end of the exhalation valve 2, the flow proportional valve 5 is arranged on the proportional valve installation base 4, and the current-limiting capillary copper pipe 1 is connected at the other end of the exhalation valve 2. The positive end expiratory pressure valve pressure control device is characterized in that the pressure control device is simple in design, only one current-limiting capillary copper pipe 1 is additionally arranged in the traditional structure, cost of the current-limiting capillary copper pipe 1 can be ignored, fixed low flow and pressure input are supplied in a positive end expiratory pressure (PEEP) cavity of the exhalation valve 2, and the flow proportional valve 5 is used for controlling the caliber of an exhaust port located in the PEEP cavity of the exhalation valve 2 so as to change the PEEP. Matching requirements on the flow proportional valve 5 and hardware platforms is correspondingly reduced, the exhaust end of the flow proportional valve 5 is directly connected with the air, fast response can be carried out along with valve adjustment, the delay time is shortened, and reliability of breathing machines is improved.

Owner:上海力申科学仪器有限公司

Color-sequential display method

InactiveUS7593007B2Reduce power consumptionSupporting requirements are lowCathode-ray tube indicatorsInput/output processes for data processingPower modeDisplay device

A display method for driving a color-sequential display of an electronic device is provided. When the electronic device is not at low power mode, a first image is displayed first by using a second color data and a first color data of the first image sequentially to drive the display. Next, a second image is displayed by using a second color data and a third color data of the second image sequentially to drive the display. When the electronic device is at low power mode, the respective luminance of the first and the second images are obtained. Then, the respective luminance of the first image and the second image are sequentially used to drive the display.

Owner:HIMAX TECH LTD

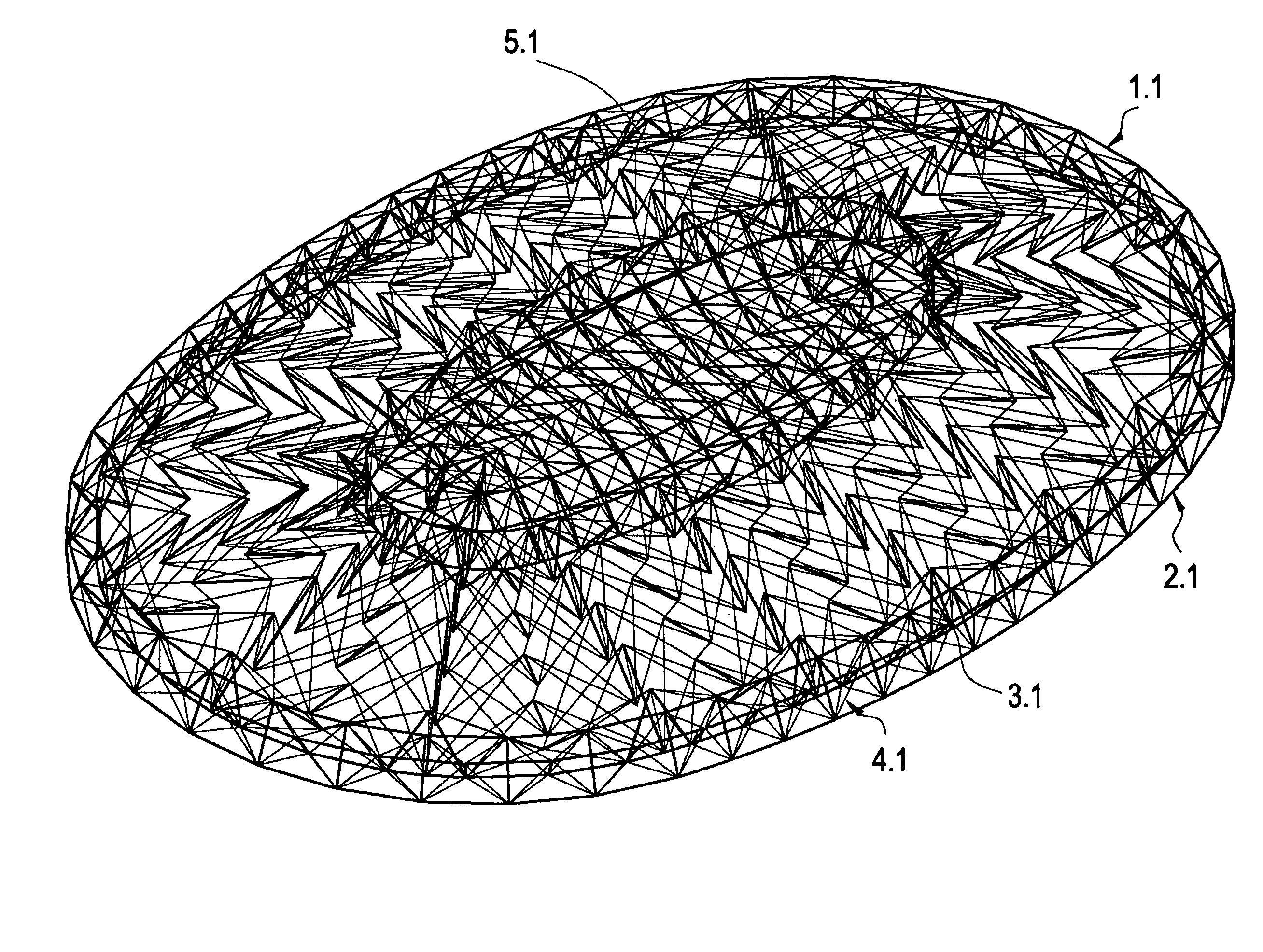

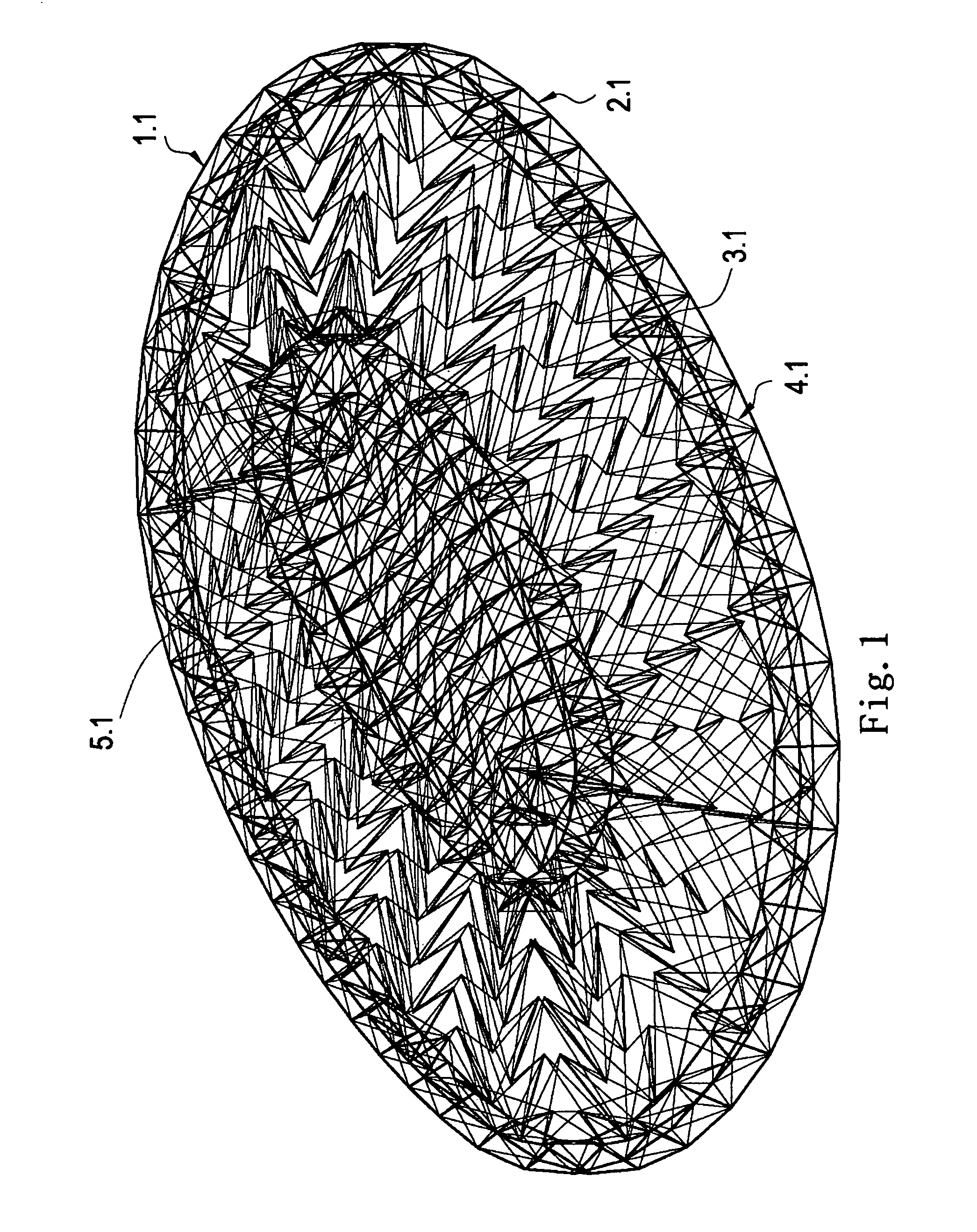

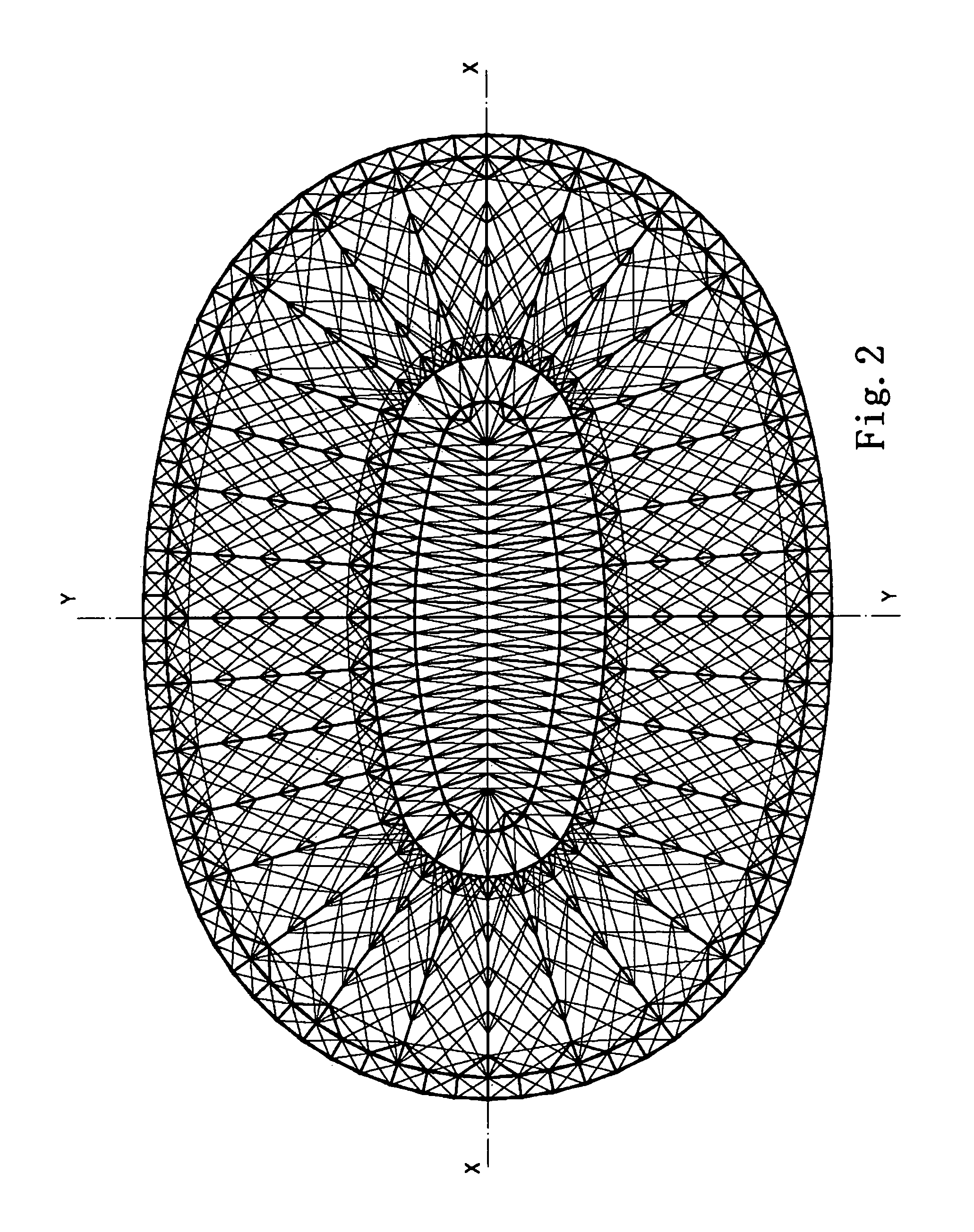

Double-layer cable-strut roof system

ActiveUS8074404B2Stable self equilibriumDescribe wellBuilding roofsBuilding reinforcementsEdge structureStructural unit

A double-layer cable-strut roof system includes a central structure and an edge structure, a plurality of sets of first diagonal struts and a plurality of sets of second diagonal struts provided between the two structures, each set of first diagonal struts being arranged alternately with one set of second diagonal struts. Or a plurality of sets of diagonal struts are provided between the two structures, each of which including a plurality of first diagonal struts and second diagonal struts joined together node to node, each first diagonal strut being arranged alternately with one second diagonal strut The roof structure may cover the underlying building space in its entirety or, alternatively, may cover a perimeter portion of the building space leaving the center area uncovered, or may be constituted by a plurality of structural units, which is adapted for spanning large areas devised for a wide range of building shapes.

Owner:XUE GUIBAO

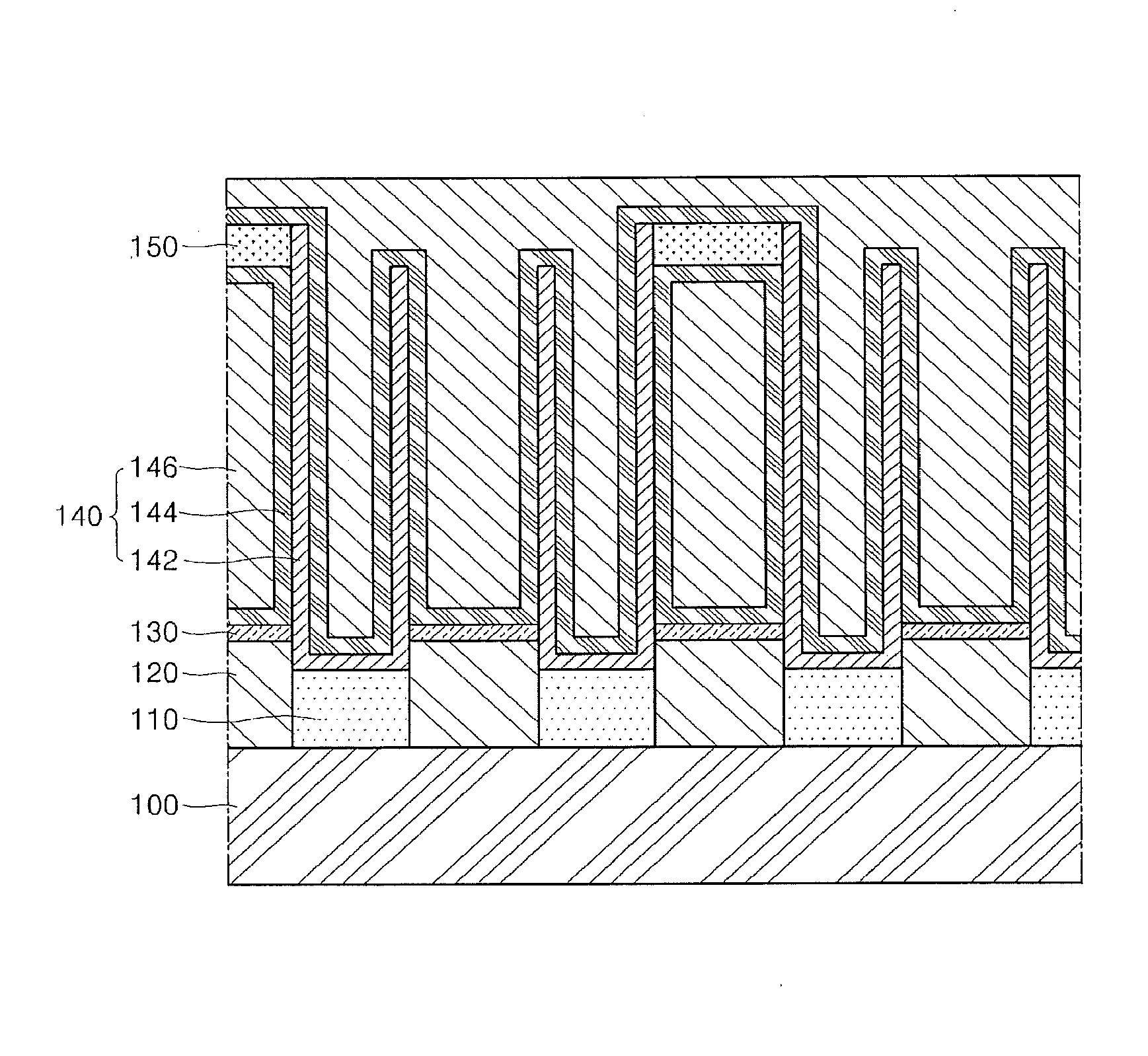

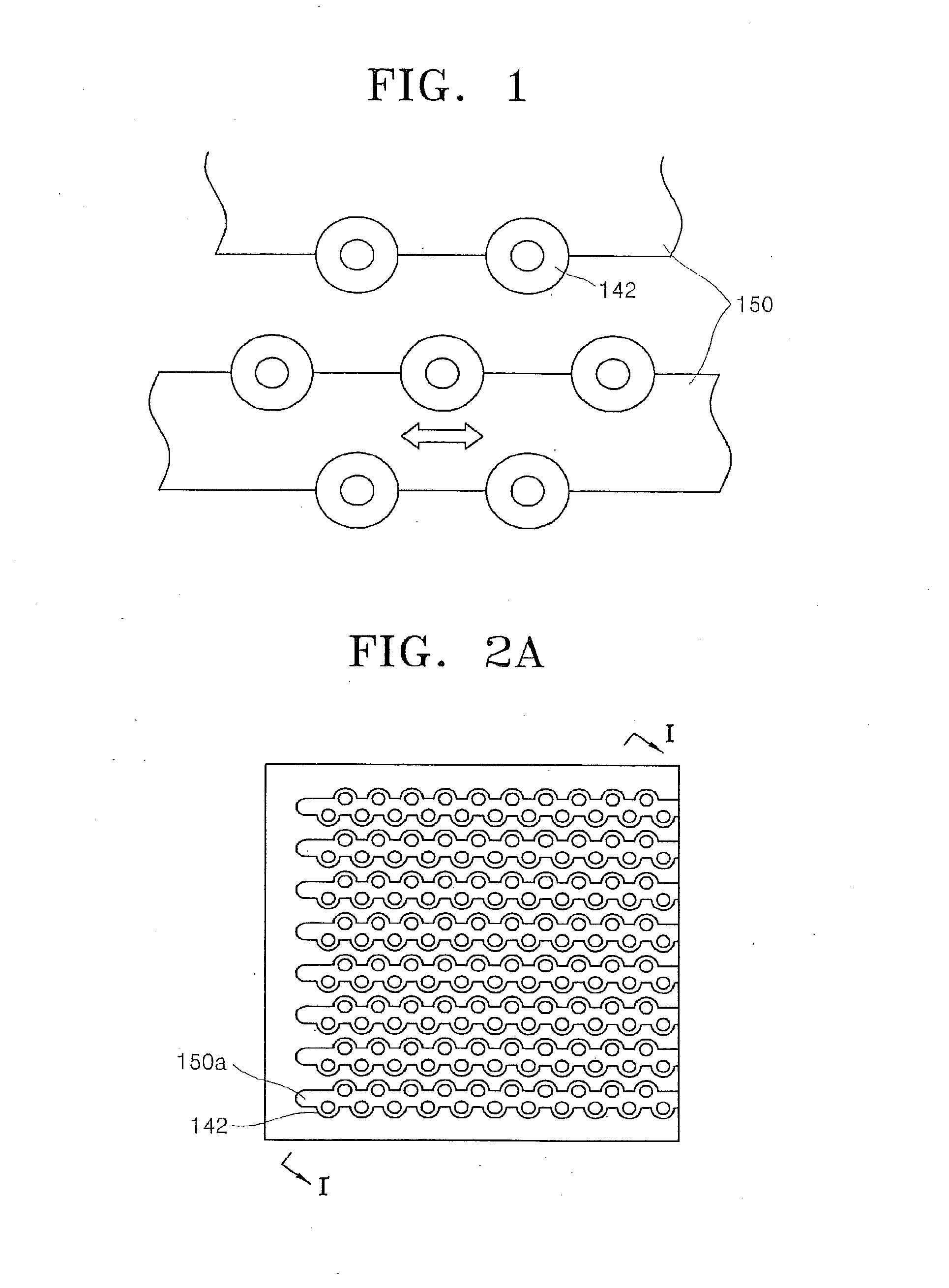

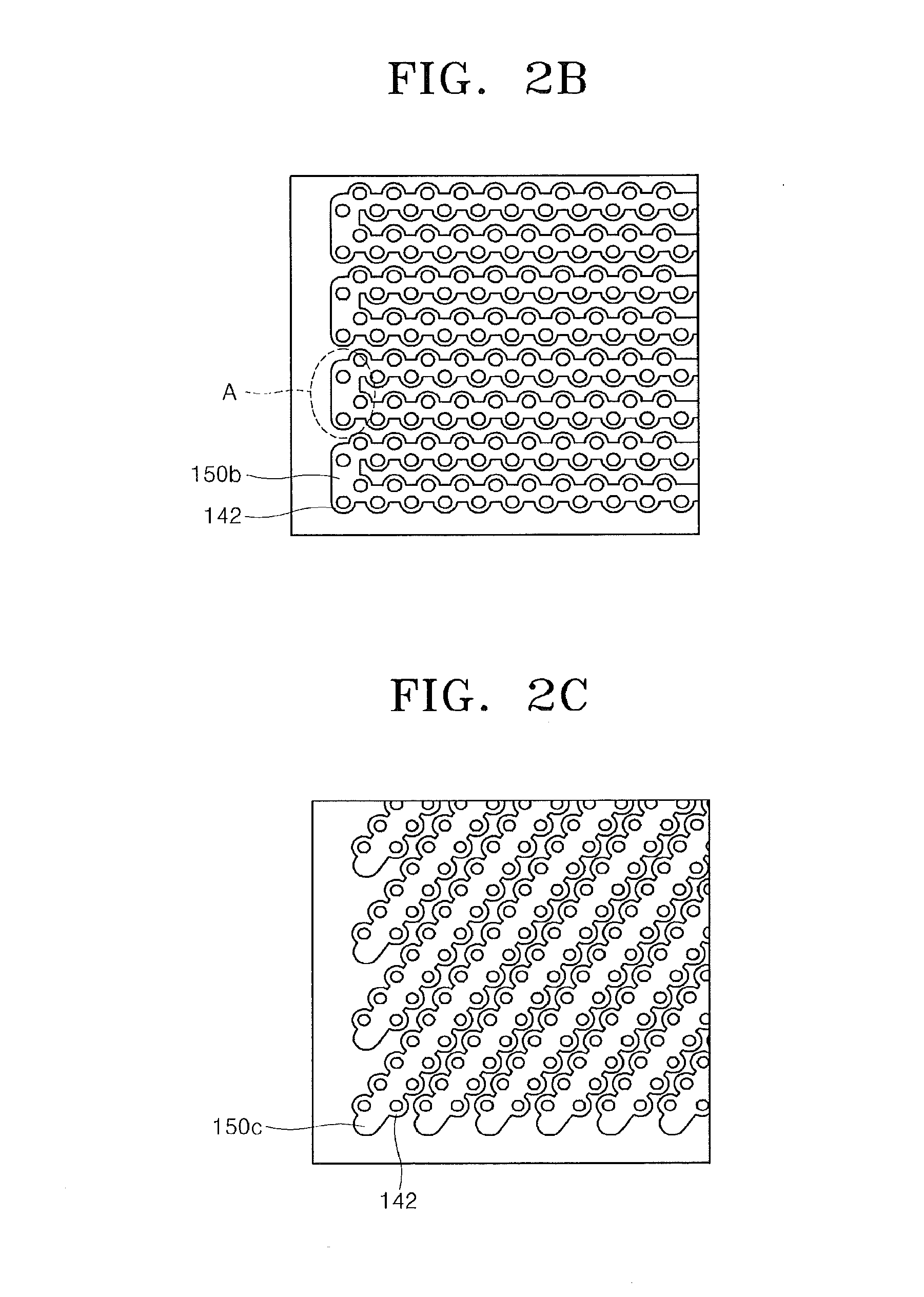

Semiconductor devices including capacitor support pads

ActiveUS20130292796A1Supporting requirements are lowRelieve pressureSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialEngineering

A semiconductor device may include a semiconductor substrate and a plurality of first capacitor electrodes arranged in a plurality of parallel lines on the semiconductor substrate with each of the first capacitor electrodes extending away from the semiconductor substrate. A plurality of capacitor support pads may be provided with each capacitor support pad being connected to first capacitor electrodes of at least two adjacent parallel lines of the first capacitor electrodes and with adjacent capacitor support pads being spaced apart. A dielectric layer may be provided on each of the first capacitor electrodes, and a second capacitor electrode may be provided on the dielectric layer so that the dielectric layer is between the second capacitor electrode and each of the first capacitor electrodes. Related methods are also discussed.

Owner:SAMSUNG ELECTRONICS CO LTD

Method and a system for assisting a driver of a vehicle during operation

ActiveUS8738231B2Reduce impactReduce torqueVehicle fittingsSteering initiationsEngineeringVehicle driving

A method for assisting a driver of a vehicle during operation in order to avoid an undesired situation based on a current driving scenario includes predicting if a first guiding force to a vehicle steering device is desired in order to avoid the undesired situation and, if the first guiding force is desired, predicting a total guiding force comprising the first guiding force, which would be applied to the steering device for avoiding the undesired situation, comparing the predicted total guiding force with a limit value, and if the predicted total guiding force exceeds the limit value, in advance, deciding whether to apply the predicted total guiding force to the steering device for avoiding the undesired situation or not.

Owner:VOLVO LASTVAGNAR AB

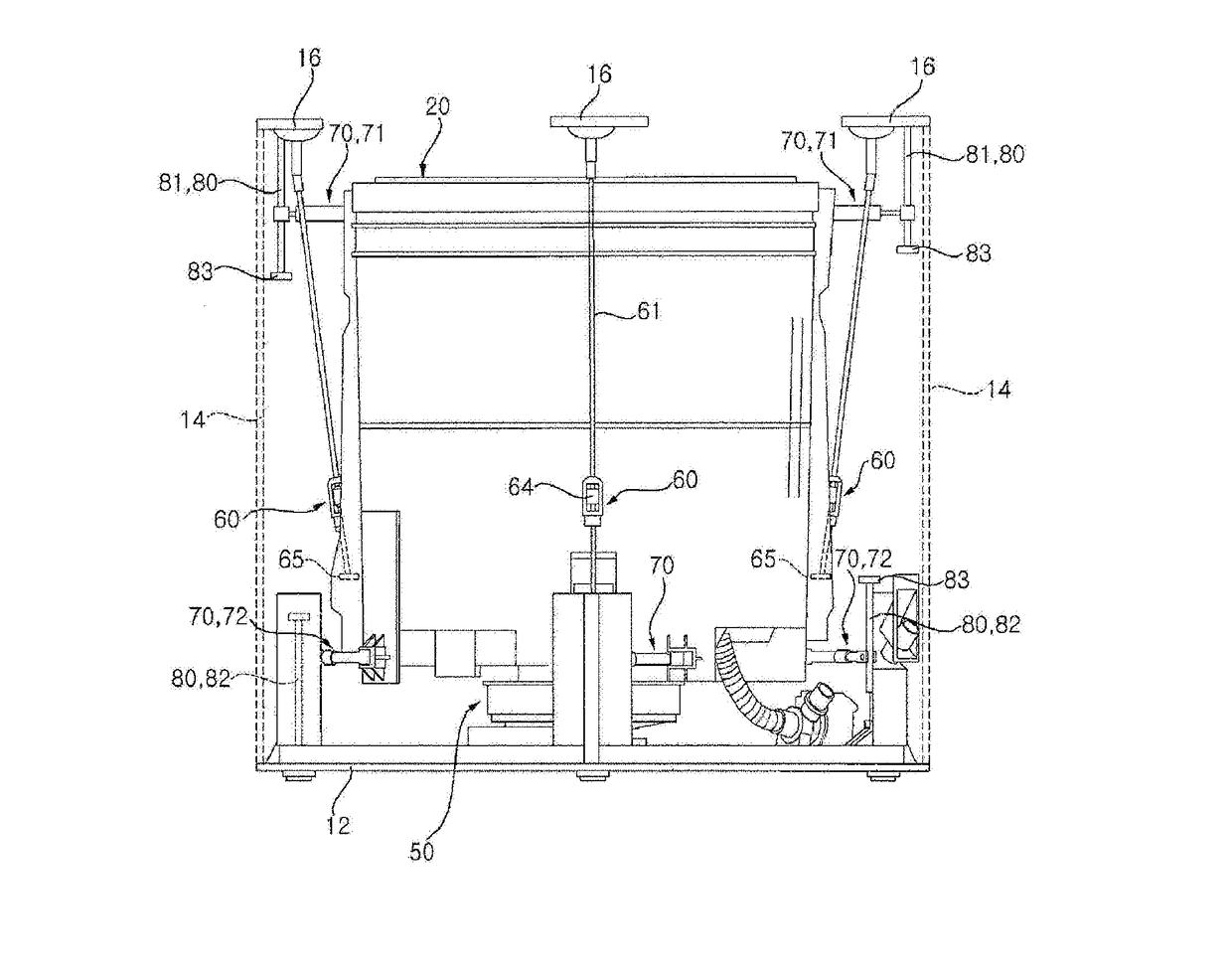

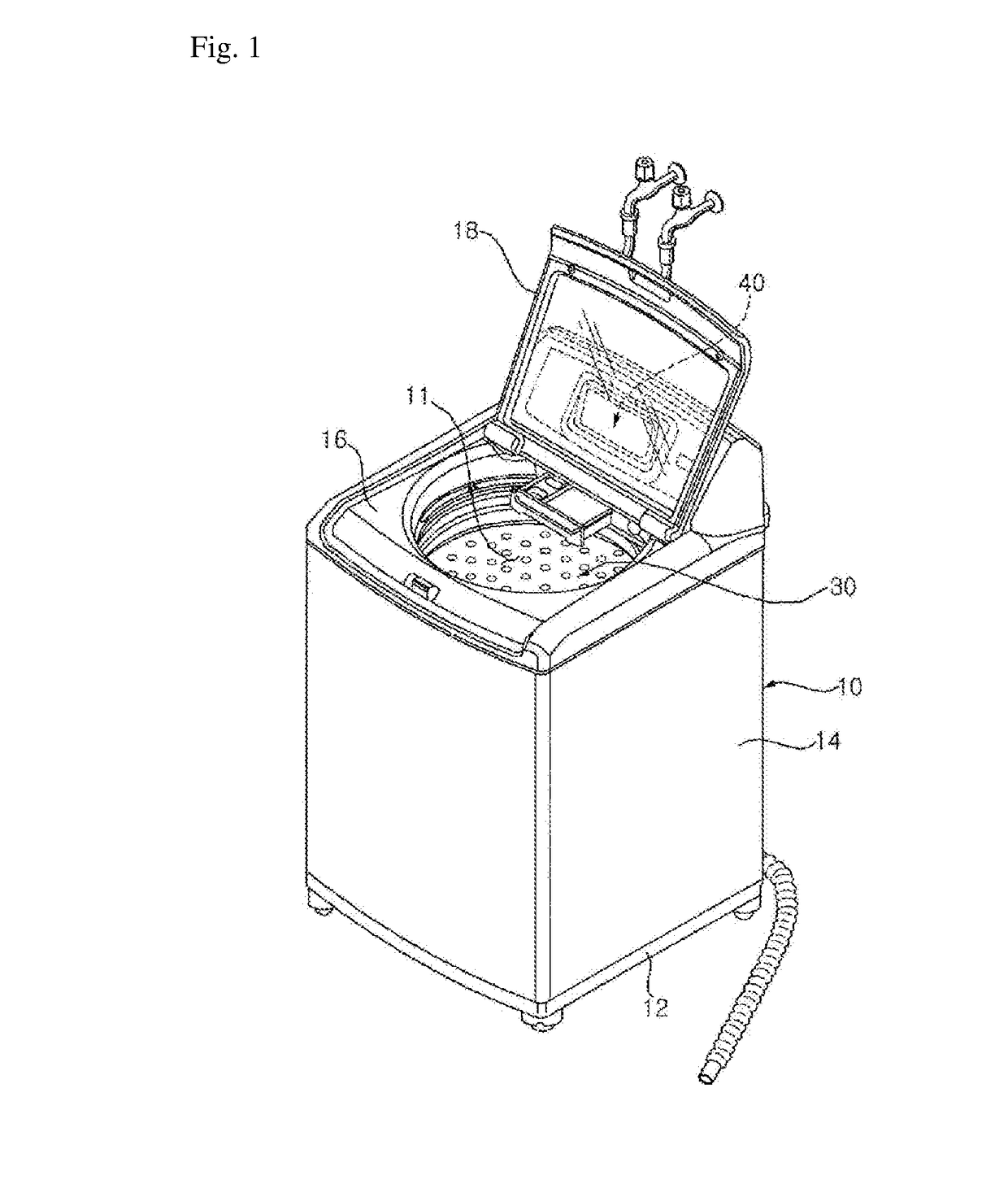

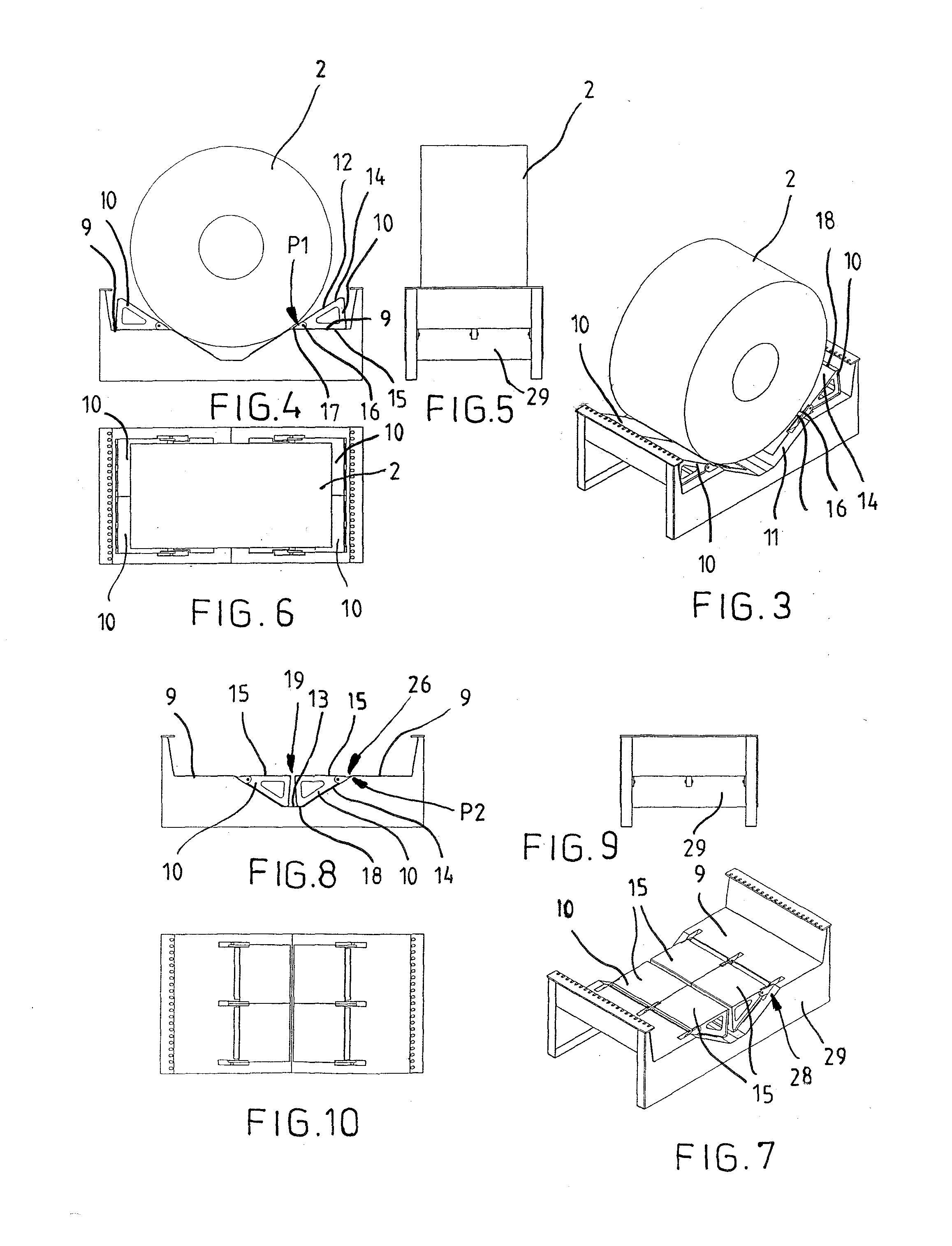

Laundry processing apparatus

ActiveUS20180112345A1Reduce horizontal vibrationEfficient reductionSpringsOther washing machinesLaundryEngineering

A laundry processing apparatus according to the present invention comprises: a cabinet; a tub, arranged in the interior of the cabinet, for storing laundry water; longitudinal dampers connecting the cabinet and tub and supporting the tub as same hangs from the cabinet; upper transverse dampers, connecting the upper part of the tub and cabinet, for reducing the horizontal vibration for the tub; and lower transverse dampers, connecting the lower part of the tub and cabinet, for reducing the horizontal vibration for the tub. The laundry processing apparatus according to the present invention allows the transverse dampers coupled structures, and when vibration occurs, the transverse dampers dampen the horizontal vibration and mitigates the vertical vibration through relative motion.

Owner:LG ELECTRONICS INC

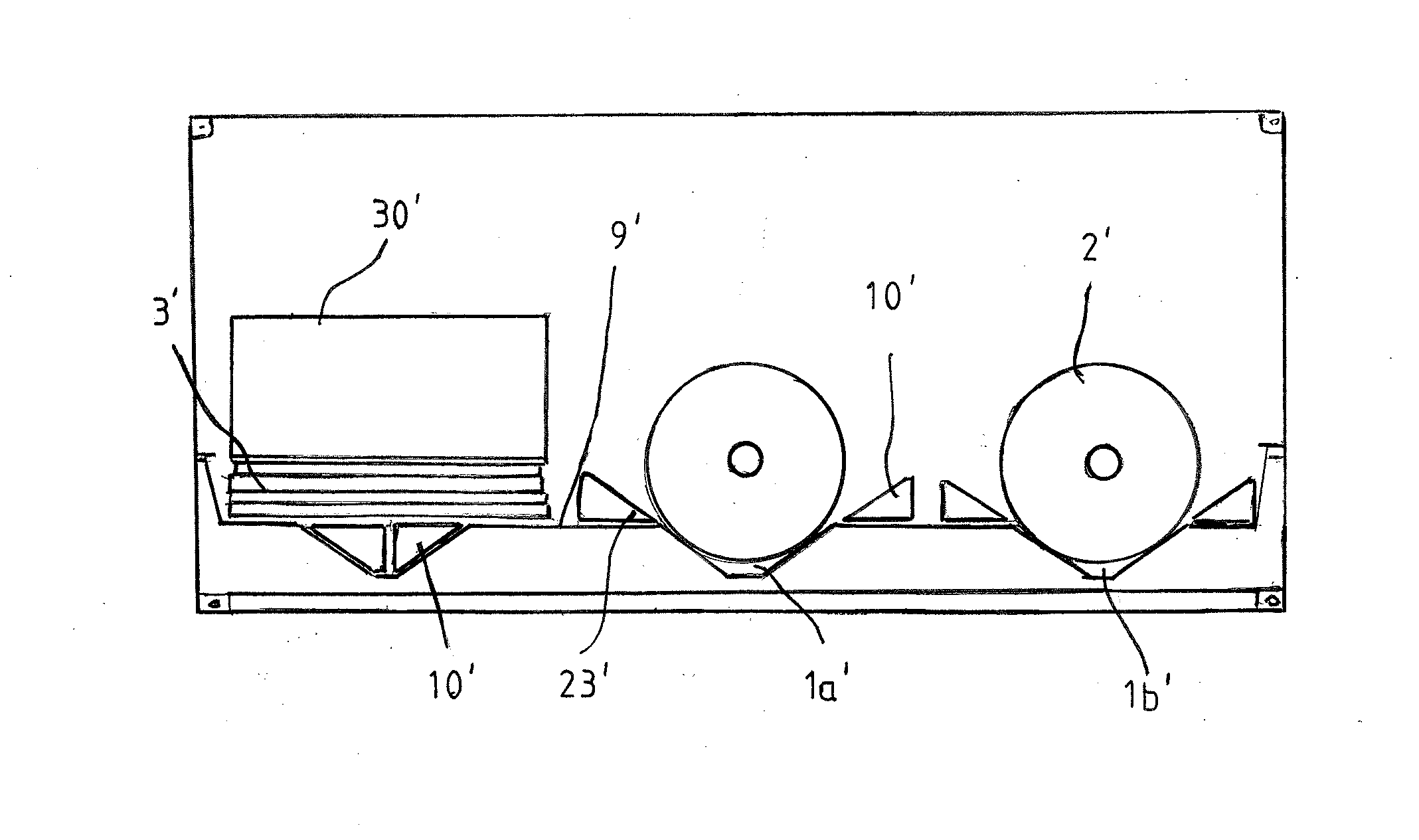

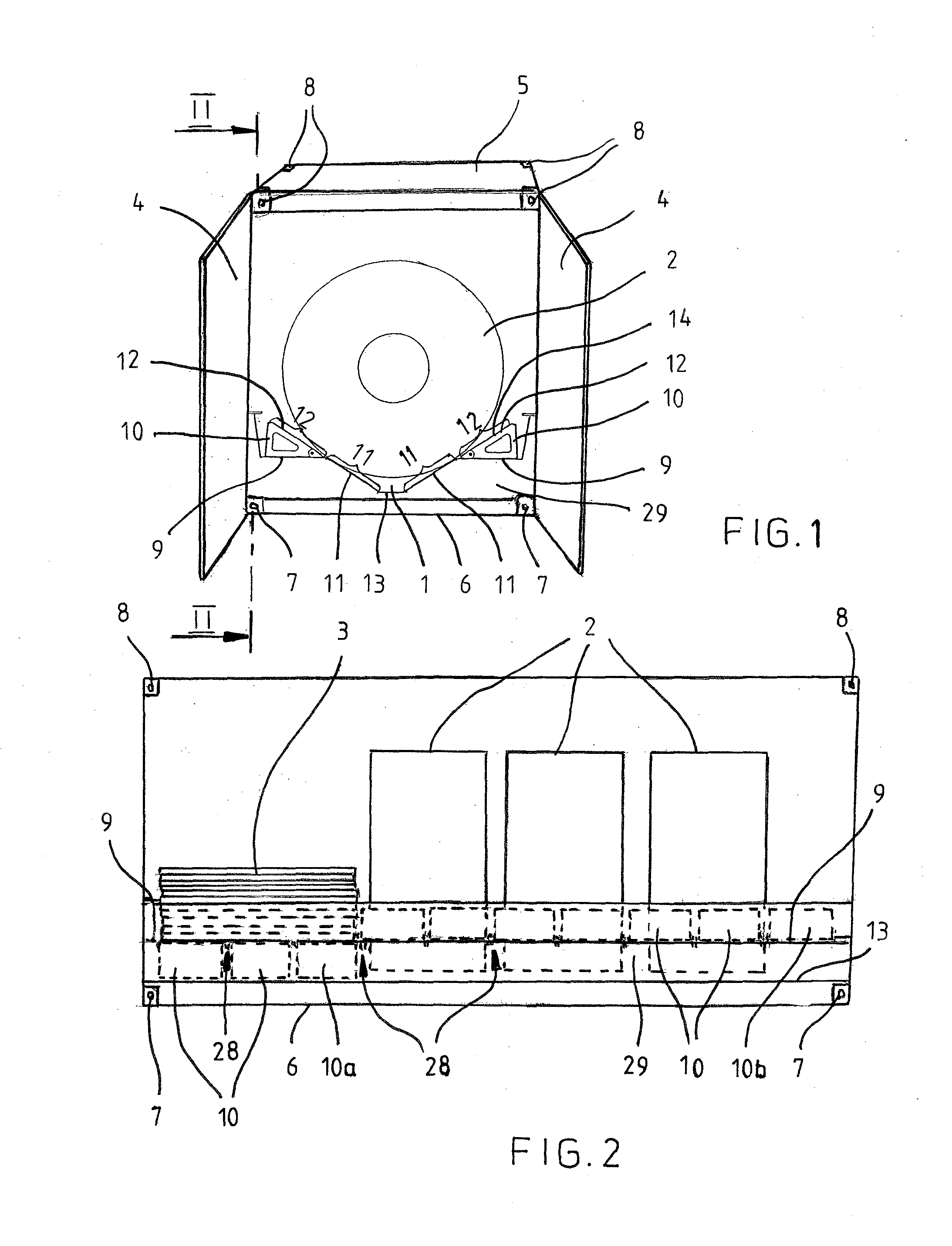

Container

ActiveUS20140027321A1Easy to modifyImprove sturdinessContainers for annular articlesLarge containersSupport removalBraced frame

A container includes a chute for supporting reels, the chute including a bottom, a lower wall zone, an upper wall zone, and a support frame for supporting the chute. The container has a horizontal support plane on both sides of the chute, the upper wall zone being formed by a first support surface of a wedge-like support member placed onto the support plane, a second support surface of the support member resting against the support plane when the support member is in a first use position; a pivot mechanism allowing the support member to be turned in relation to the support frame so that the first support surface sets against the lower wall zone of the chute and the second support surface sets onto the same height level as the support plane for forming a uniform loading plane and for placing the support member to a second use position.

Owner:OY LANGH SHIP AB

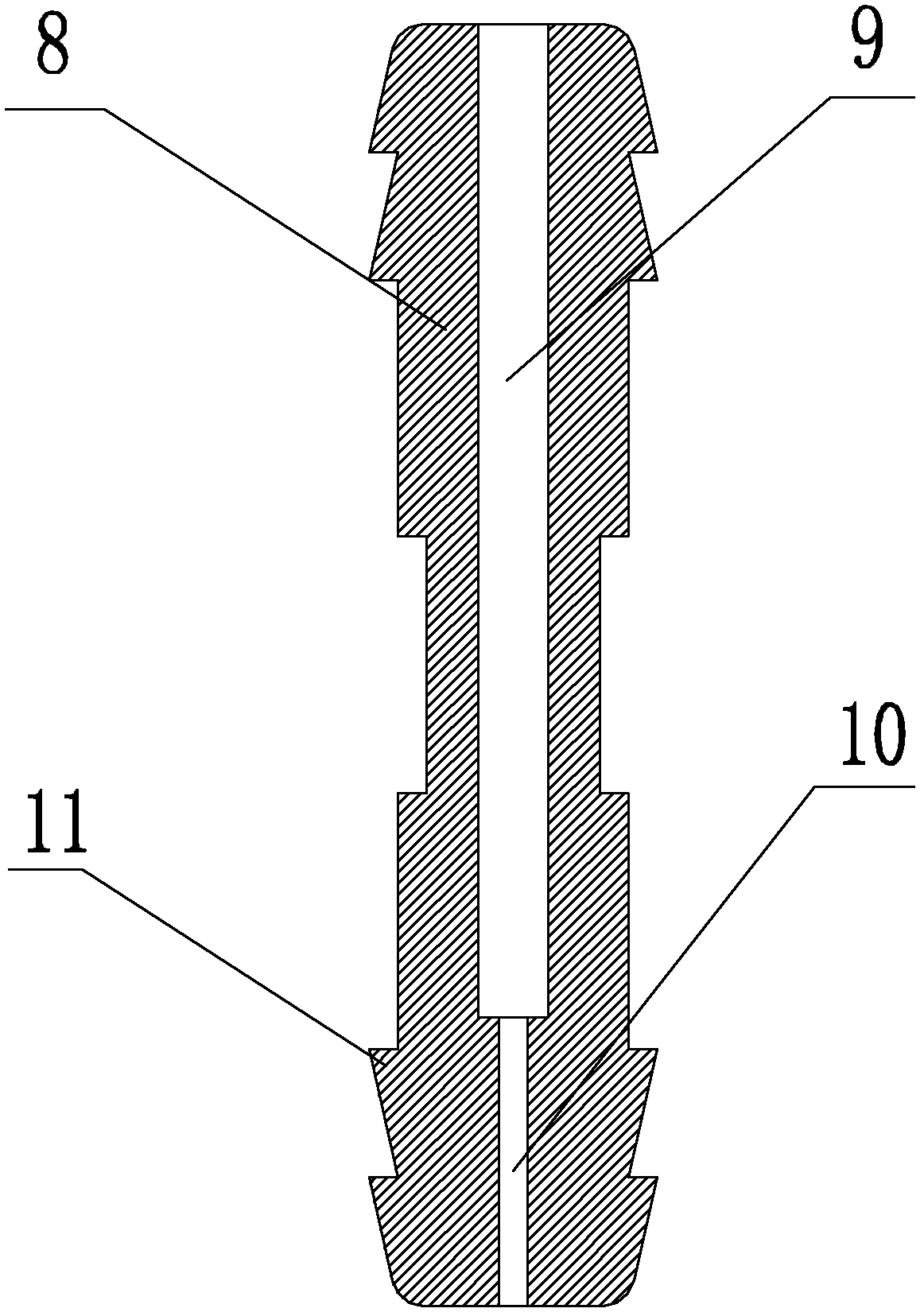

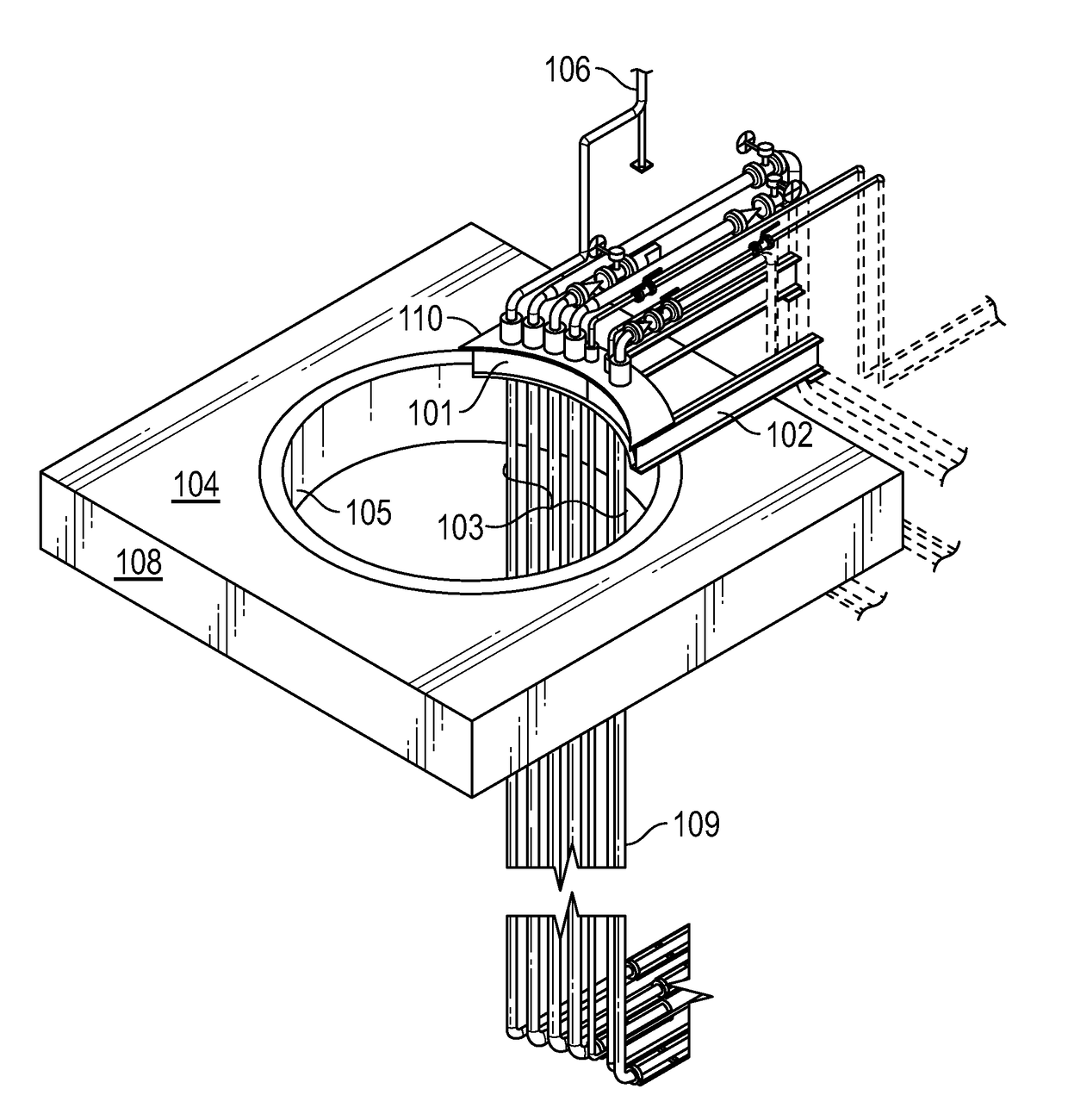

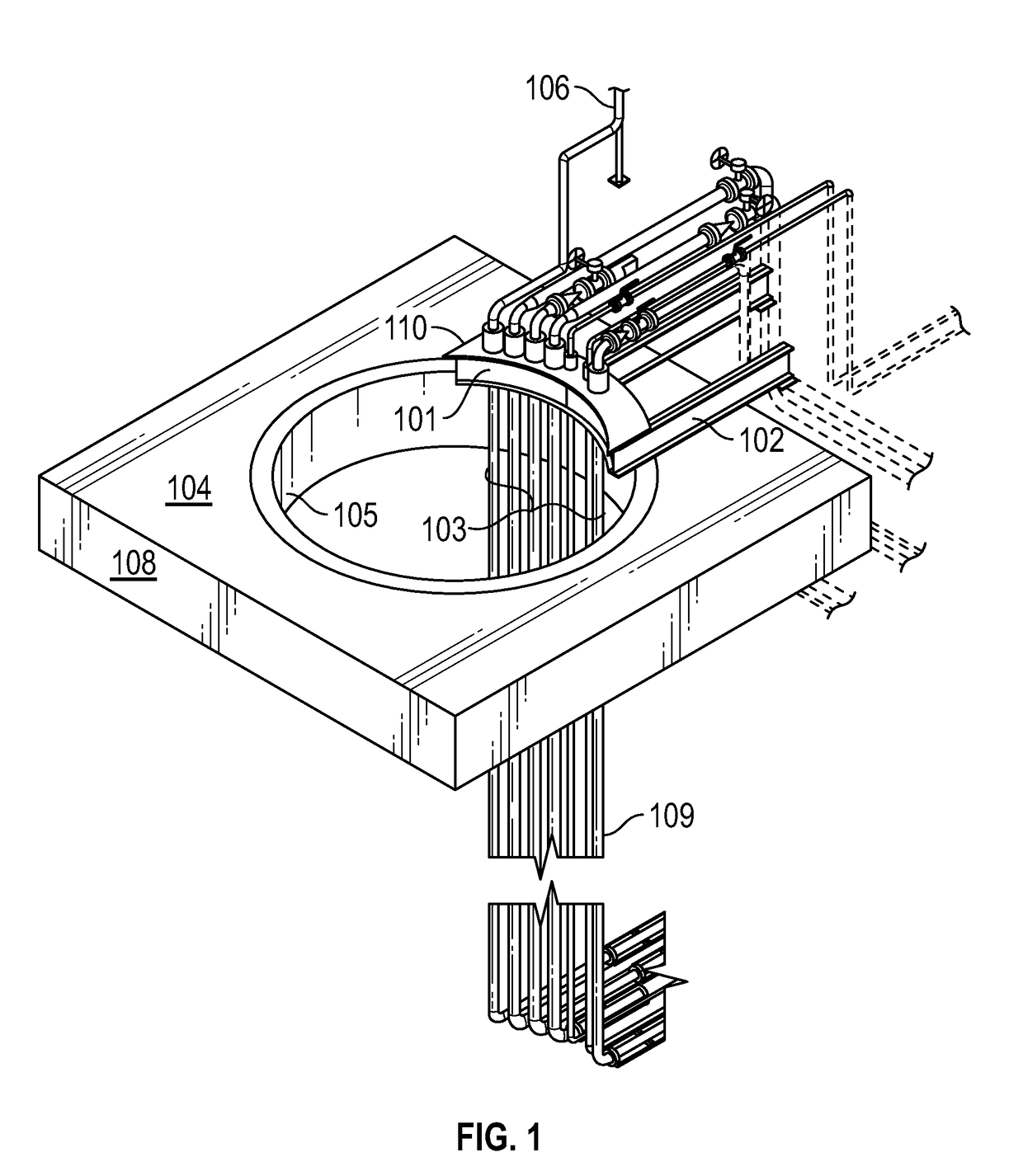

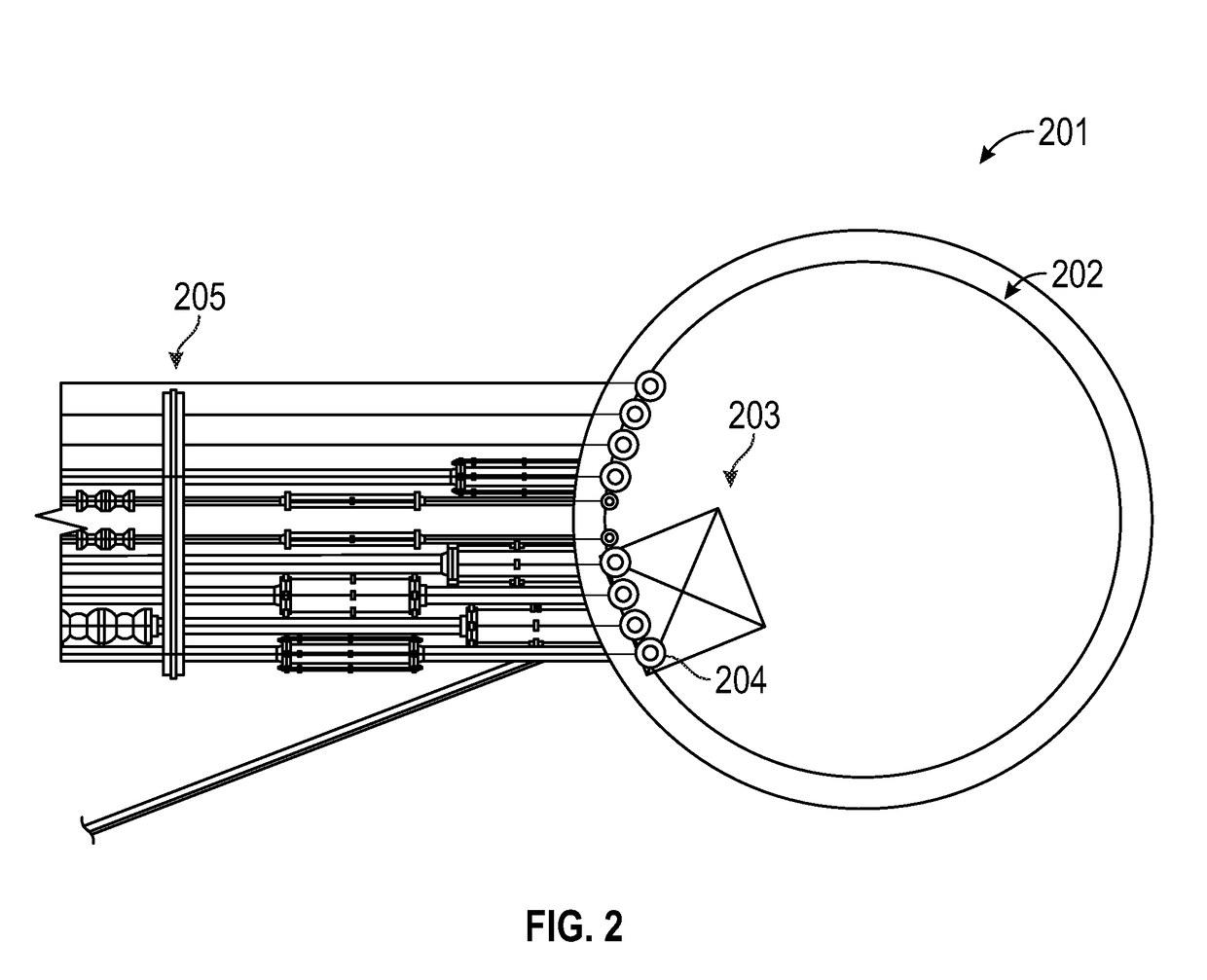

System and method for vertical piping suspension

InactiveUS20170146156A1Supporting requirements are lowMinimal spacePipe supportsMining devicesEngineeringShaft collar

Disclosed is a system and method for providing a steel structural support to bear the weight of one and / or multiple vertical pipe runs traveling down an extended length vertical shaft. The low profile support of the present invention requires minimal space for attachment inside the diameter of the shaft allowing for maximum space to accommodate hoisting and bulky lifts within the shafts. The system provides the means for supporting vertical pipe runs without the need for additional load bearing strapping or supports within the length of the shaft, further allowing for maximum clearance within the shaft and at the shaft collar.

Owner:ALLEGHANY CAPITAL

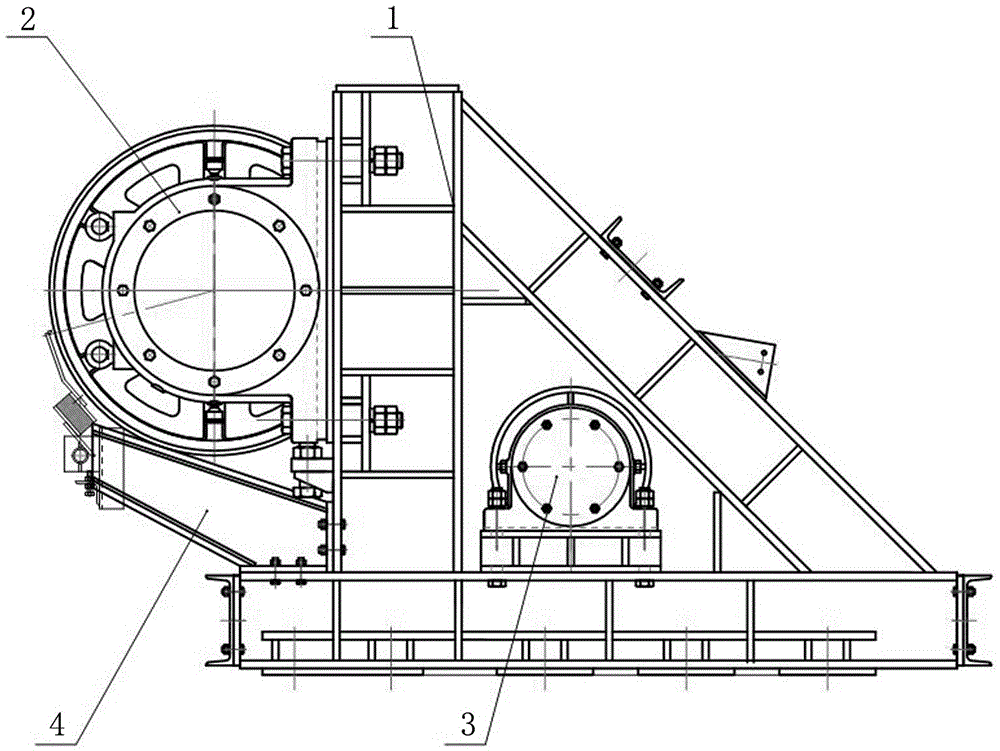

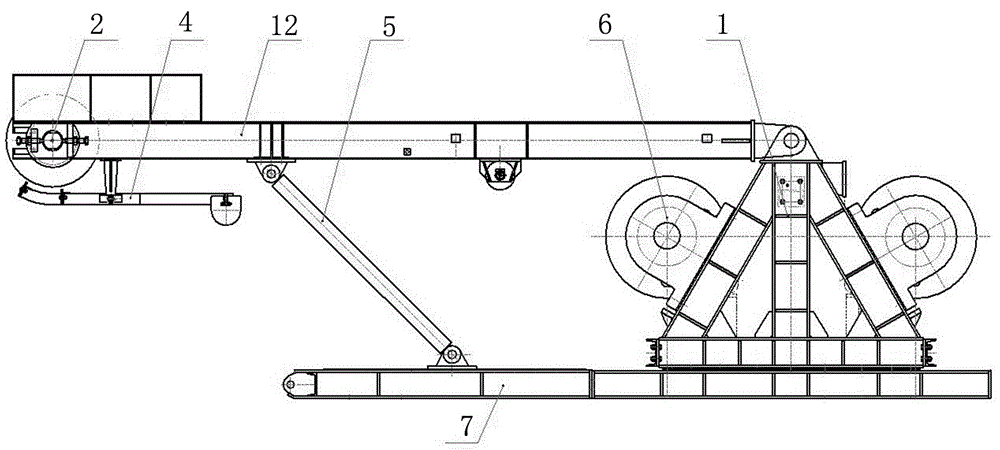

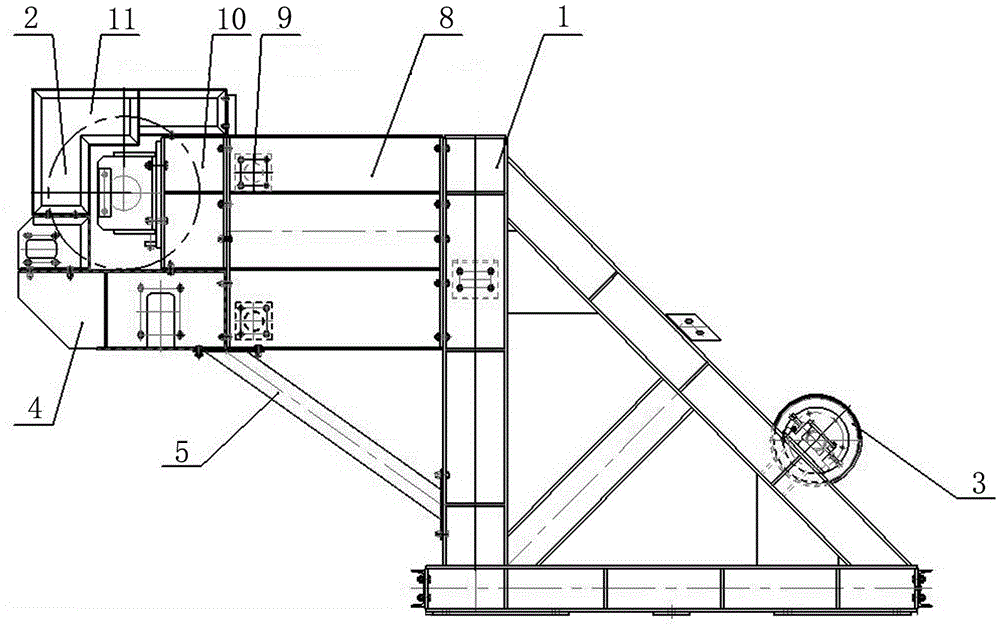

Coal unloading device for high-power belt conveyor

InactiveCN105460583AReasonable designIncrease stiffnessConveyorsCleaningEconomic benefitsEngineering

The invention relates to underground coal mine conveying arrangement, in particular to a coal unloading device suitable for an underground coal mine high-power belt conveyor. The coal unloading device comprises an unloading triangular rack (1), and a towing drum (3) is mounted on the unloading triangular rack (1). The coal unloading device for the high-power belt conveyor is characterized in that a connecting seat (8) is fixedly mounted on the upper part of the unloading triangular rack (1); a drum support (10) is mounted on the connecting seat (8); an unloading drum (2) is mounted in the drum support (10); a cleaner support (4) is mounted on the drum support (10); and an inclined strut (5) is arranged between the drum support (10) and the unloading triangular rack (1). The coal unloading device suitable for the underground coal mine high-power belt conveyor is reasonable in design, requirements of coal unloading of a coal house can be met or the head and the tail of a belt can overlap each other. The coal unloading device is reasonable in design, simple in structure, good in using effect, obvious in economic benefit and worthy of being popularized and used.

Owner:XISHAN COAL ELECTRICITY GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com