Positive end expiratory pressure valve pressure control device

A positive end-expiratory pressure, pressure control technology, applied in respirator and other directions, to achieve the effect of simple design, improved reliability, and shortened lag time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

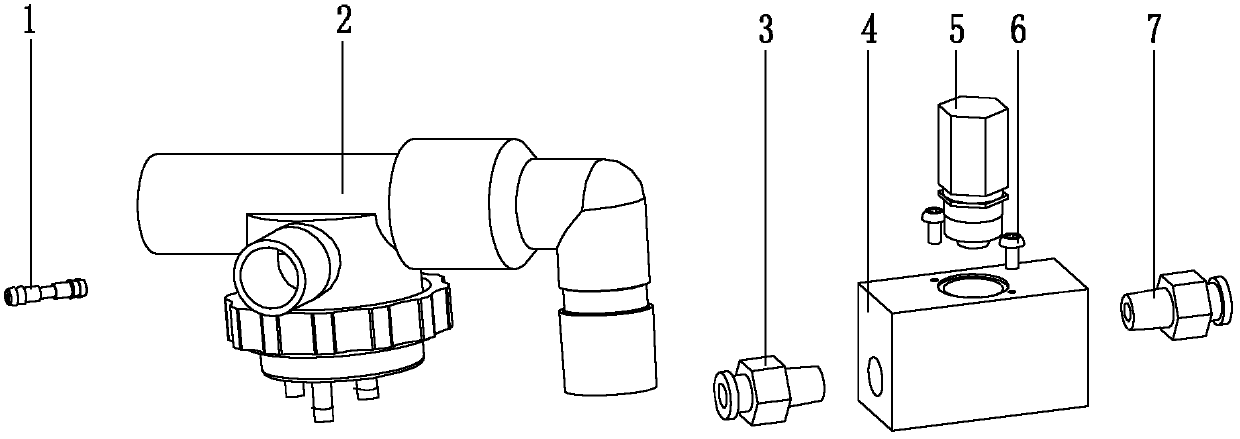

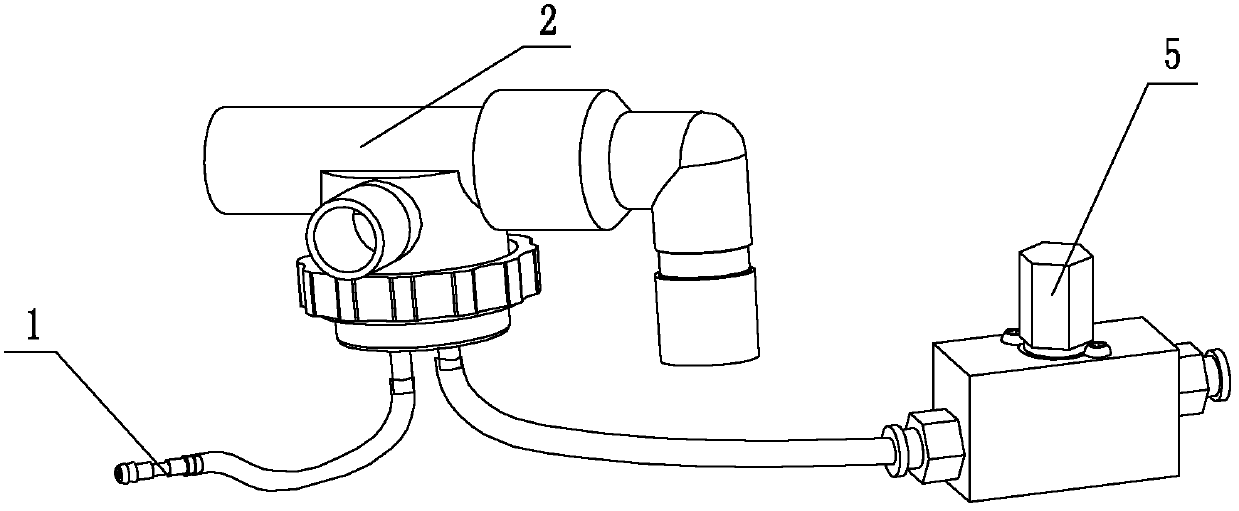

[0022] The pressure control device for the positive end-expiratory pressure valve of the present invention will be further described in detail below in conjunction with the accompanying drawings.

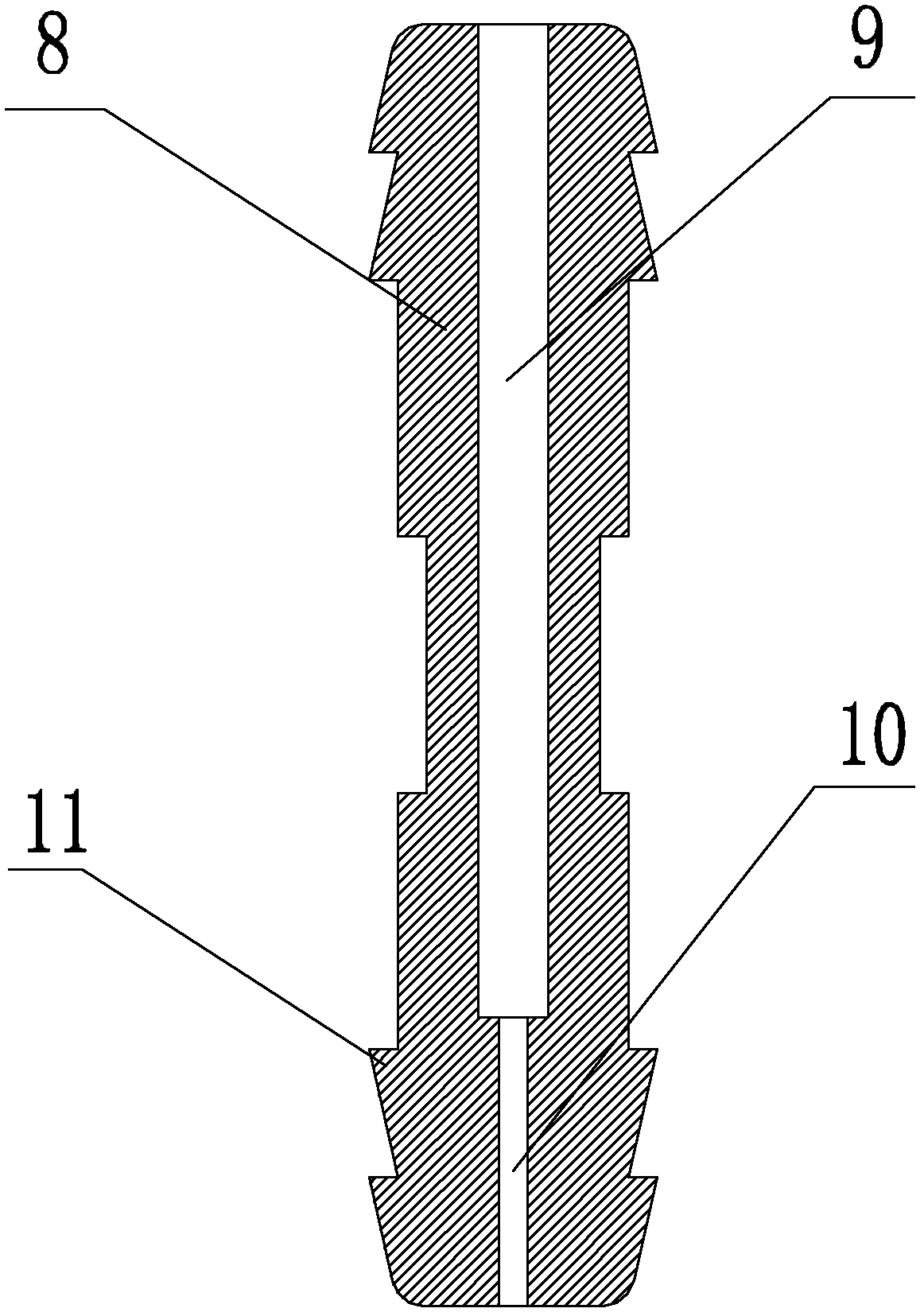

[0023] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the positive end-expiratory pressure valve pressure control device of the present invention includes: a flow-limiting capillary copper tube 1, an exhalation valve 2, and a proportional valve mounting seat 4 connected to each other in sequence, and the first quick-change joint 3 is fixedly connected to the proportional valve. On the seat 4, it is connected with the PEEP chamber of the exhalation valve 2 through a hose, and the periphery of the flow-limiting capillary copper tube 1 is a pagoda-shaped double-layer barb, which can be sealed and connected with the gas pipeline. The flow proportional valve 5 is installed on the proportional valve mounting seat 4 through two fixing screws 6 , and a second qui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com