High-temperature coal gas desulfurizer using coal ash as carrier and desulfurization device thereof

A technology of fly ash and desulfurizer, which is applied in combustible gas purification, combustible gas purification/transformation, petroleum industry, etc., can solve the problems of low desulfurization activity of desulfurizer, complicated preparation process, low mechanical strength, etc., and achieve good desulfurization ability , Simplified preparation process and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

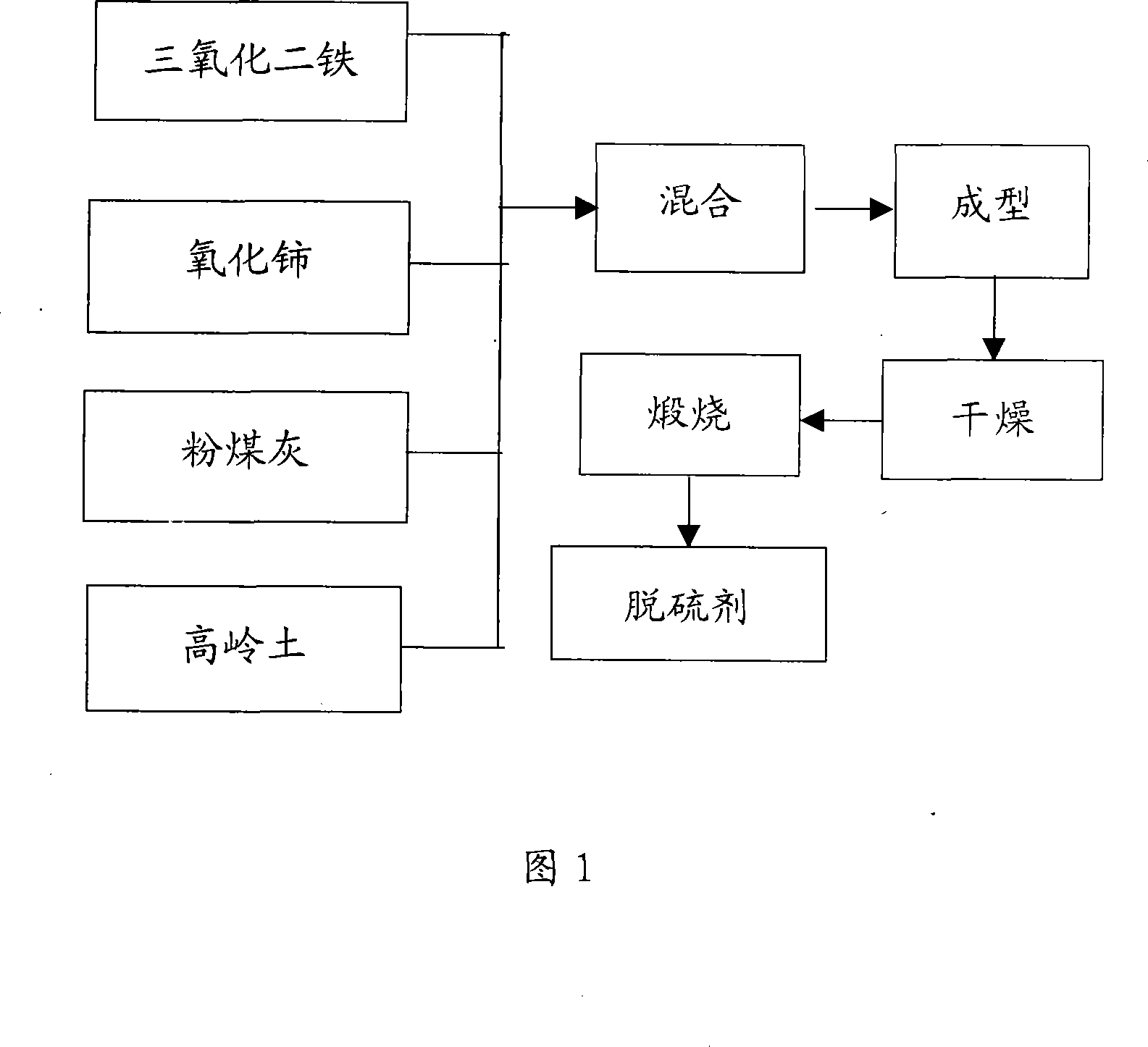

[0023] Embodiment 1: adopt mechanical mixing method to prepare the high-temperature gas desulfurizer with fly ash as carrier, the metal oxide (n of 50% Fe, Ce and Mo Fe : n Ce : n Mo =5:2:1) with 30% fly ash and 20% kaolin, add water to the uniformly mixed metal oxide, fly ash and binder components to obtain a paste mixture, put it into a desulfurizer to make In the cylinder of the granulator, the rods are extruded to obtain cylindrical particles of φ2×2mm. The formed desulfurizer is dried at 100°C and then calcined at 600°C. The calcined desulfurizer is directly used for high-temperature gas desulfurization.

Embodiment 2

[0024] Embodiment 2: adopt the mechanical mixing method to prepare the high-temperature gas desulfurizer with fly ash as carrier, the metal oxide (n of 80% Fe, Ce, Mo and La Fe : n Ce : n Mo : n La =4:2:1:1) and 10% fly ash and 10% kaolin are uniformly mixed, and the uniformly mixed metal oxide, fly ash and binder components are added with water to obtain a pasty mixture, which is loaded into a desulfurizer In the cylinder of the granulator, extrude to obtain cylindrical particles of φ2×2mm. The formed desulfurizer is dried at 200°C and then calcined at 1000°C. The calcined desulfurizer is directly used for high-temperature gas desulfurization.

Embodiment 3

[0025] Embodiment 3: adopt the mechanical mixing method to prepare the high-temperature gas desulfurizer with fly ash as carrier, the metal oxide (n of 65% Fe, Ce, Mo and La Fe : n Ce : n Mo : n La =4:1:1:1) and 30% fly ash and 5% kaolin are uniformly mixed, and the uniformly mixed metal oxide, fly ash and binder components are added with water to obtain a paste mixture, which is loaded into a desulfurizer In the cylinder of the granulator, extrude to obtain cylindrical particles of φ2×2mm. The formed desulfurizer is dried at 150°C and then calcined at 800°C. The calcined desulfurizer is directly used for high-temperature gas desulfurization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com