Patents

Literature

35results about How to "Reduce the amount of programming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

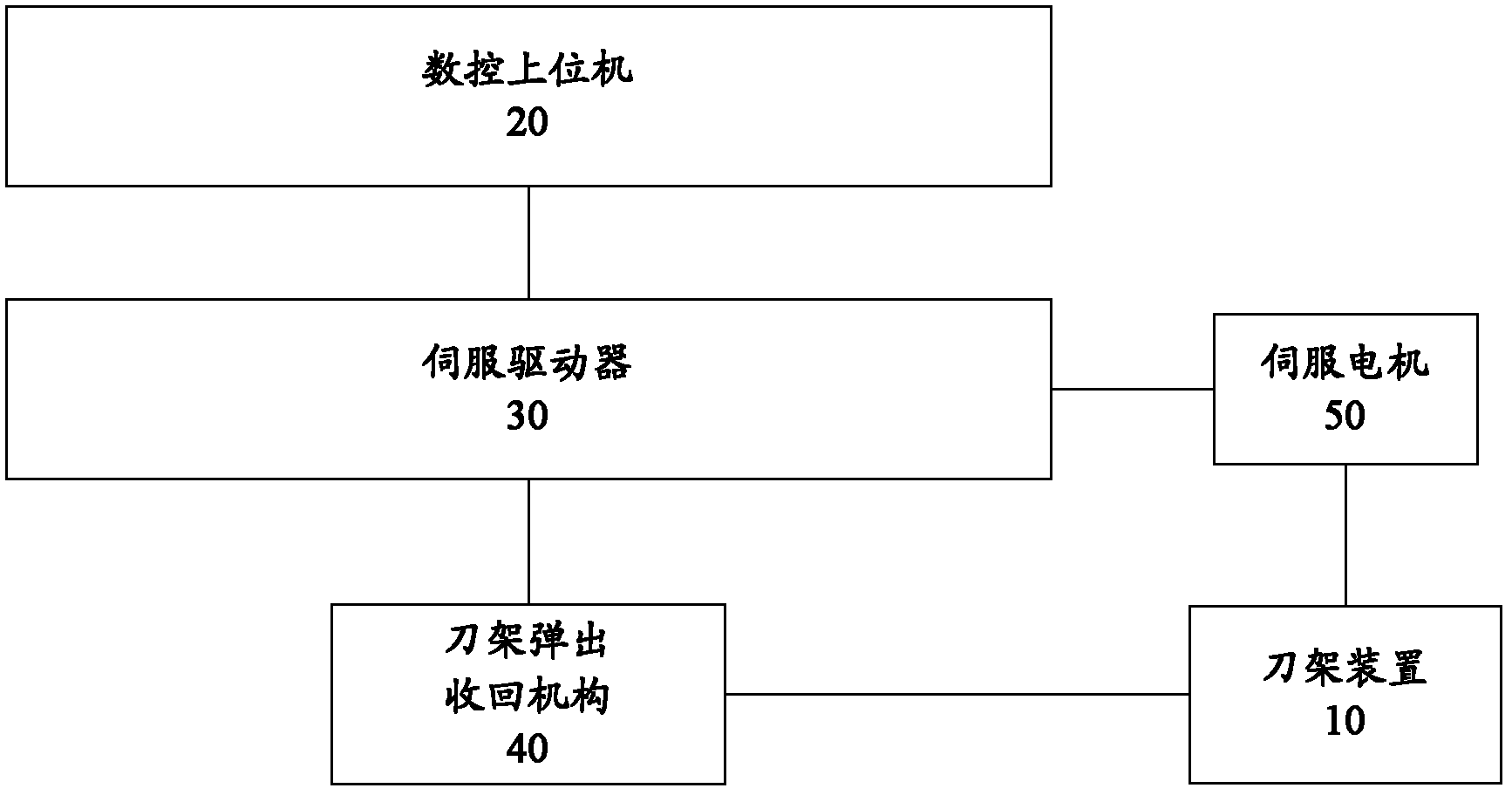

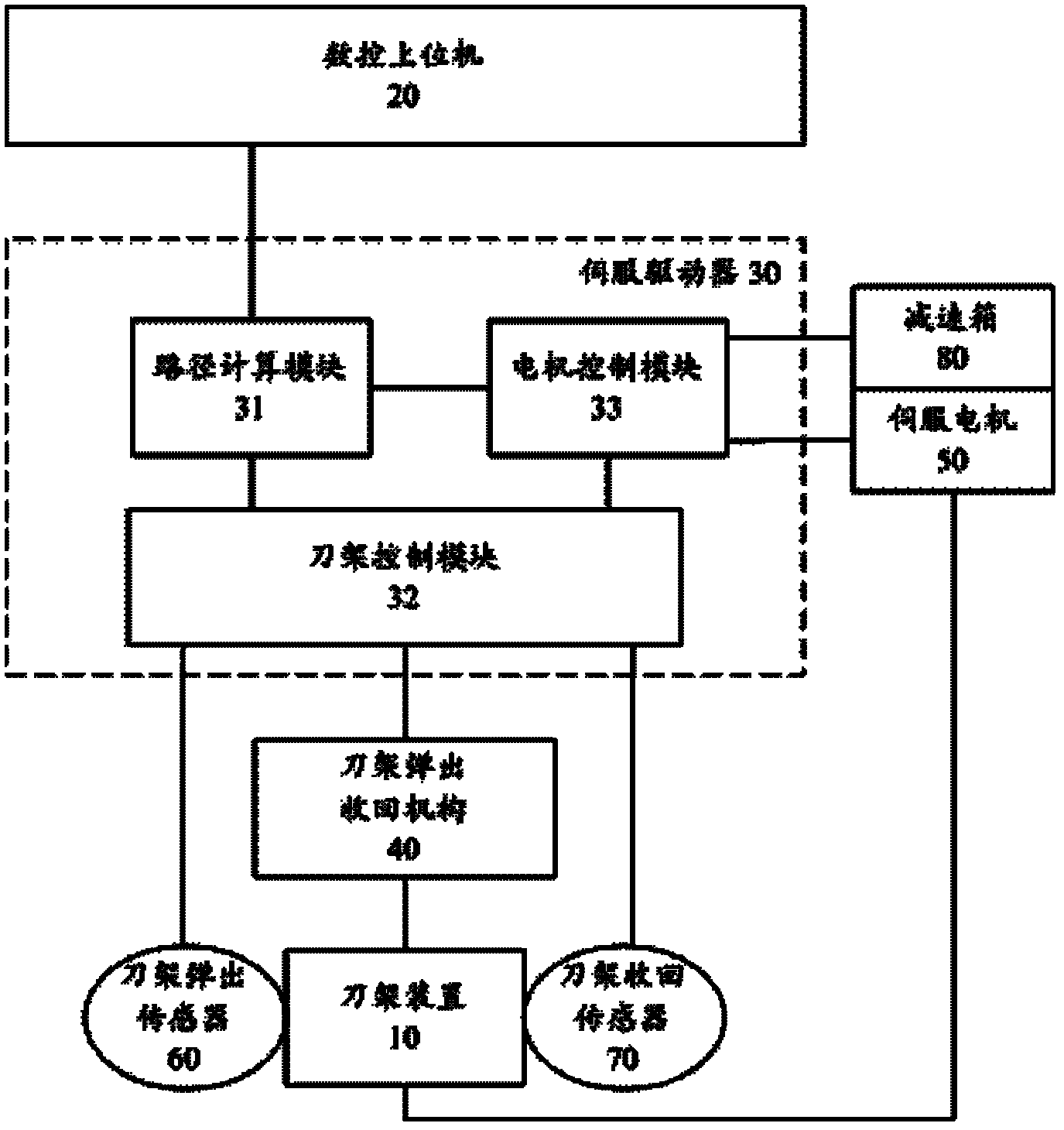

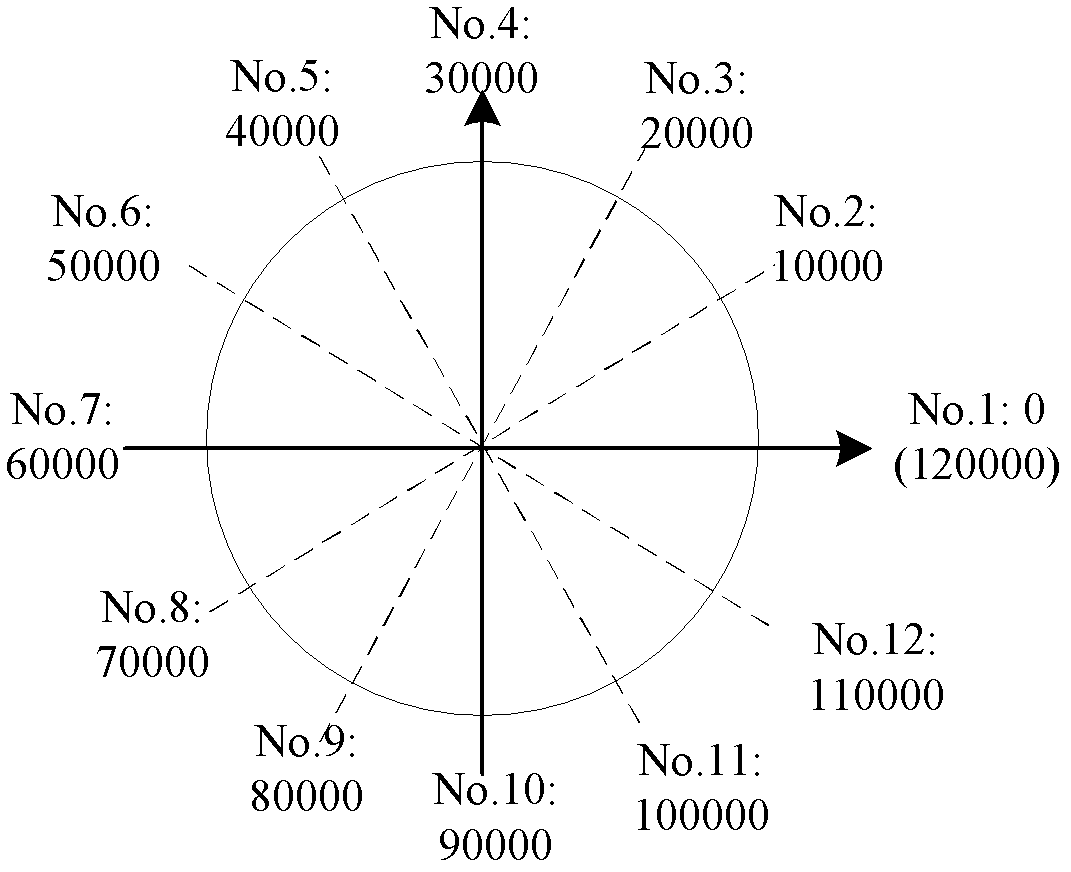

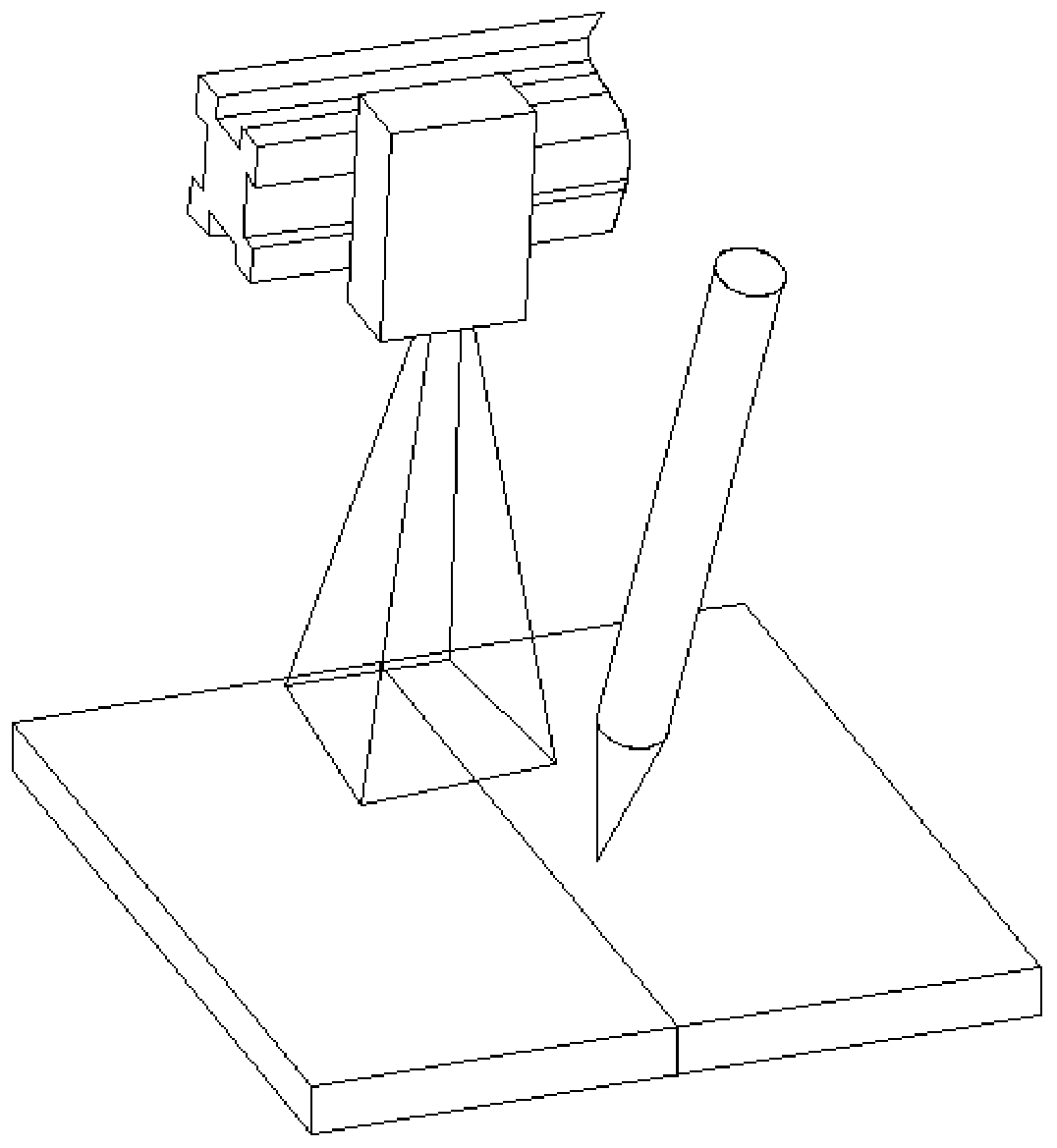

Servo drive system and servo drive method for numerically controlled tool rest

InactiveCN102621926AReduce interfaceReduce the amount of programmingNumerical controlEngineeringMotor control

The invention relates to a servo drive system and a servo drive method for a numerically controlled tool rest. The system comprises a numerically controlled upper computer, a servo driver, a tool rest popup and withdrawal mechanism, a servo motor and a tool rest device. The numerically controlled upper computer sends out tool changing orders including a target position of an appointed tool rest. The servo driver receives the tool changing orders, calculates the rotation direction and distance of the tool rest according to the current position and the target position of the tool rest, controls the tool rest popup and withdrawal mechanism to pop up the tool rest and generate motor control signals to the servo motor so as to control the tool rest to rotate to the target position, and controls the tool rest popup and withdrawal mechanism to withdraw the tool rest. The servo driver of the servo drive system directly receives the tool changing orders to generate internal position orders instead of receiving the pulse-form orders generated by the numerically controlled upper computer, so that inaccuracy in positioning caused by loss of pulse orders can be avoided. Further, programming quantity of the numerically controlled upper computer is reduced, and a tool rest controller is omitted.

Owner:SUZHOU INOVANCE TECH CO LTD +1

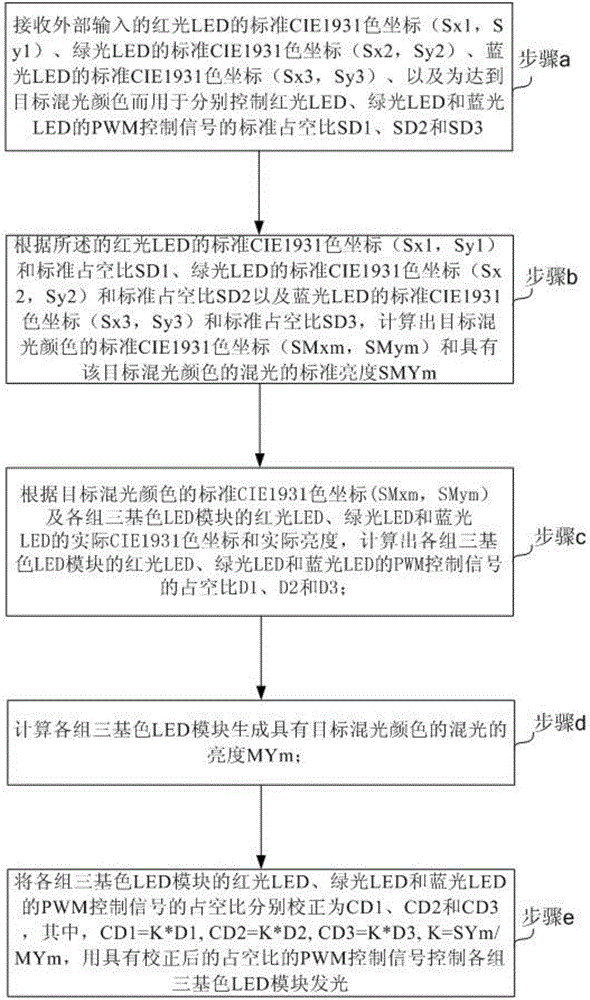

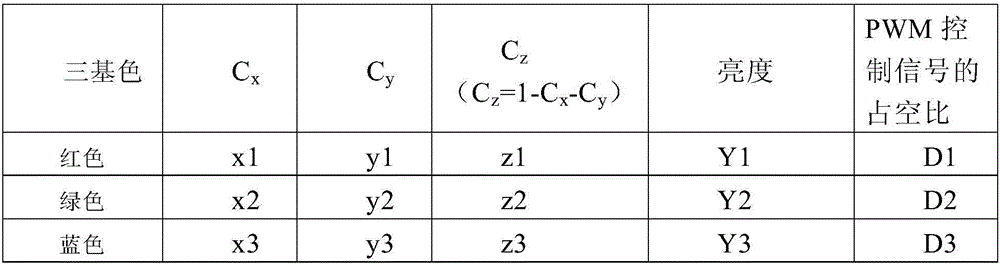

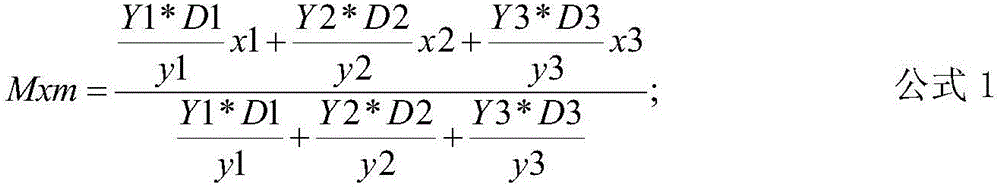

Brightness correction method of three primary color LED light source

ActiveCN106535406AImprove luminous performanceImprove experienceElectrical apparatusElectroluminescent light sourcesControl signalGreen led

A brightness correction method of a three primary color LED light source is provided which comprises steps of: computing the standard color coordinates (SMxm, SMym) and the standard brightness SMYm of target mixed light colors according to externally input data; according to the standard color coordinates of the target mixed light colors and the actual color coordinates and actual brightness of the red LED, green LED, and the blue LED of each group of three primary colors LED modules, computing the duty cycles D1, D2 and D3 of the control signals of the red, green and blue LEDs of each group of three primary colors LED modules; computing the brightness MYm of the mixed light with the target mixed light colors generated by each group of the three primary color LED module; correcting the duty cycles D1, D2 and D3 of the control signals of the red, green and blue LEDs of each group of three primary colors LED modules to CD1, CD2 and CD3 respectively, wherein CD1 = K * D1, CD2 = K * D2, CD3 = K * D3, K = SMYm / MYm. The method realizes that different three primary color LED modules keep the same brightness when giving light with the same color.

Owner:KEBODA TECH CO LTD

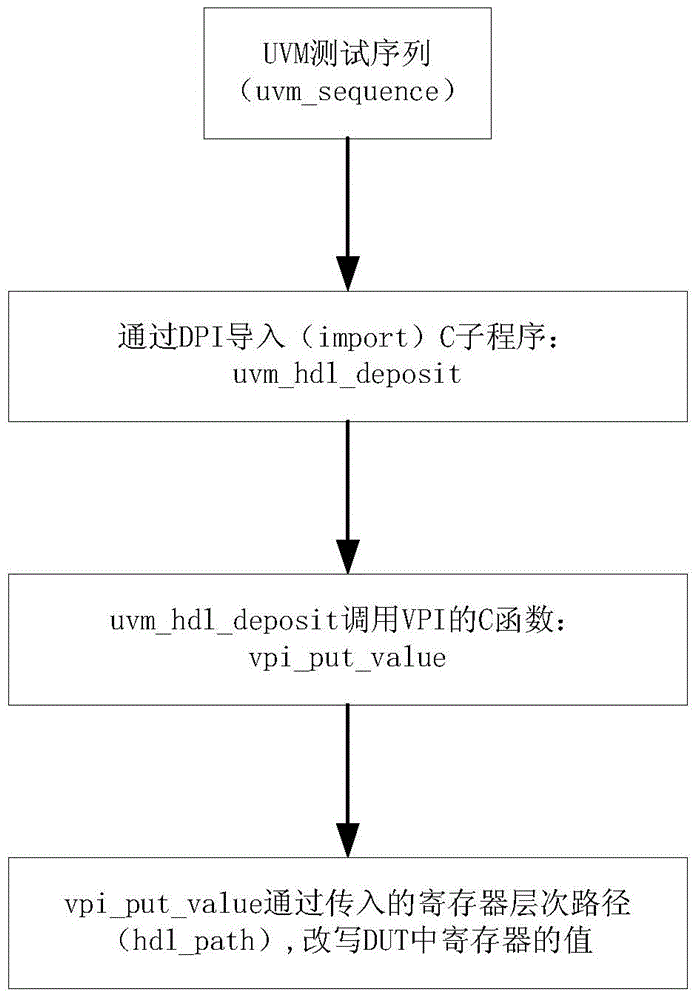

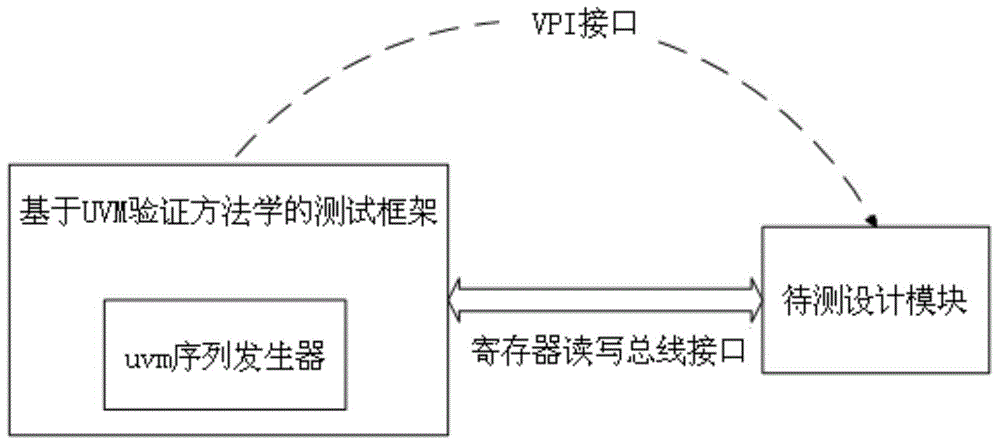

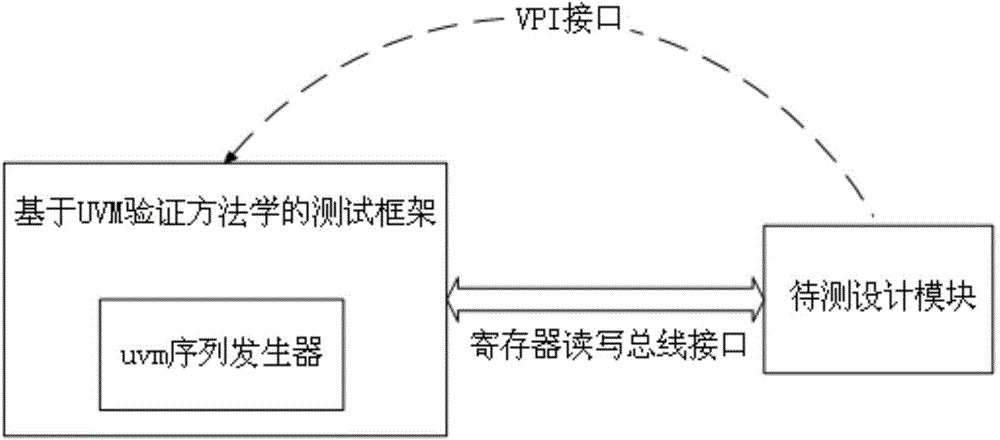

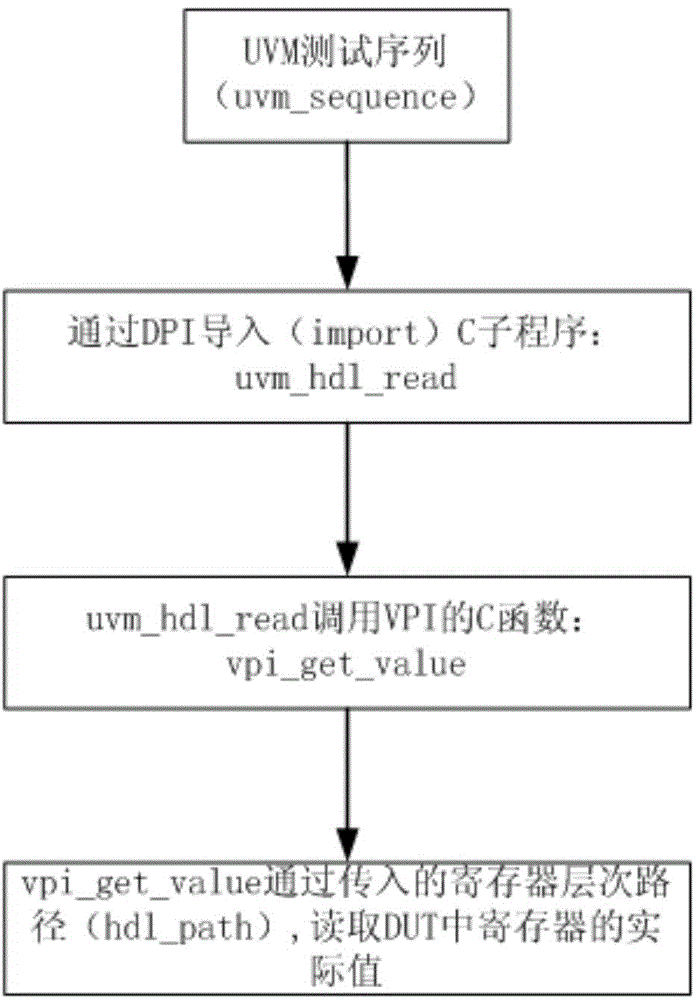

Read-only register verification test platform and verification method based on UVM (Universal Verification Methodology Manual)

InactiveCN105446844AEasy to buildReduce the amount of programming and programming difficultyFunctional testingBus interfaceTest sequence

The invention discloses a read-only register verification test platform based on a UVM (Universal Verification Methodology Manual). The read-only register verification test platform comprises a test frame based on the UVM and a design module to be tested, wherein the test frame comprises a UVM test sequence and a UVM sequence generator; the design module to be tested is a digital design module provided with a register and a register read-write bus interface; the test frame based on the UVM is connected with the design module to be tested through the register read-write bus interface; the UVM test sequence can call the UVM sequence generator; the UVM sequence generator drives the design module to be tested through the register read-write bus interface; and the UVM test sequence carries out assignment rewriting on an internal signal of the design module to be tested through a VPI (Verilog Programming Interface). The invention also discloses a read-only register verification method based on the UVM. Verification efficiency can be effectively improved, and a verification confidence level is improved.

Owner:SHANGHAI HUAHONG INTEGRATED CIRCUIT

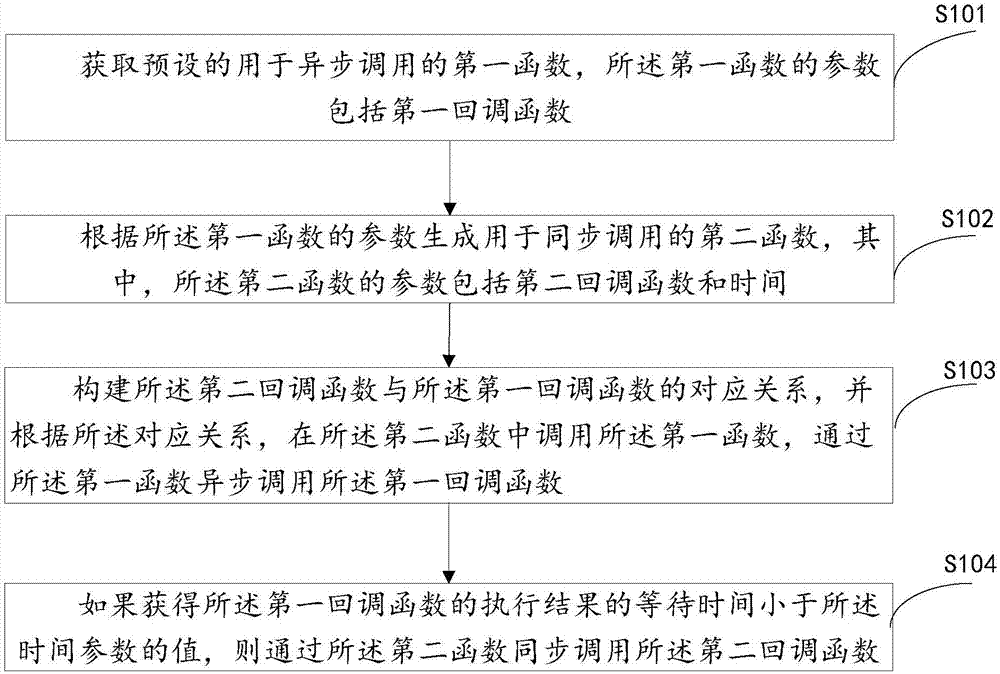

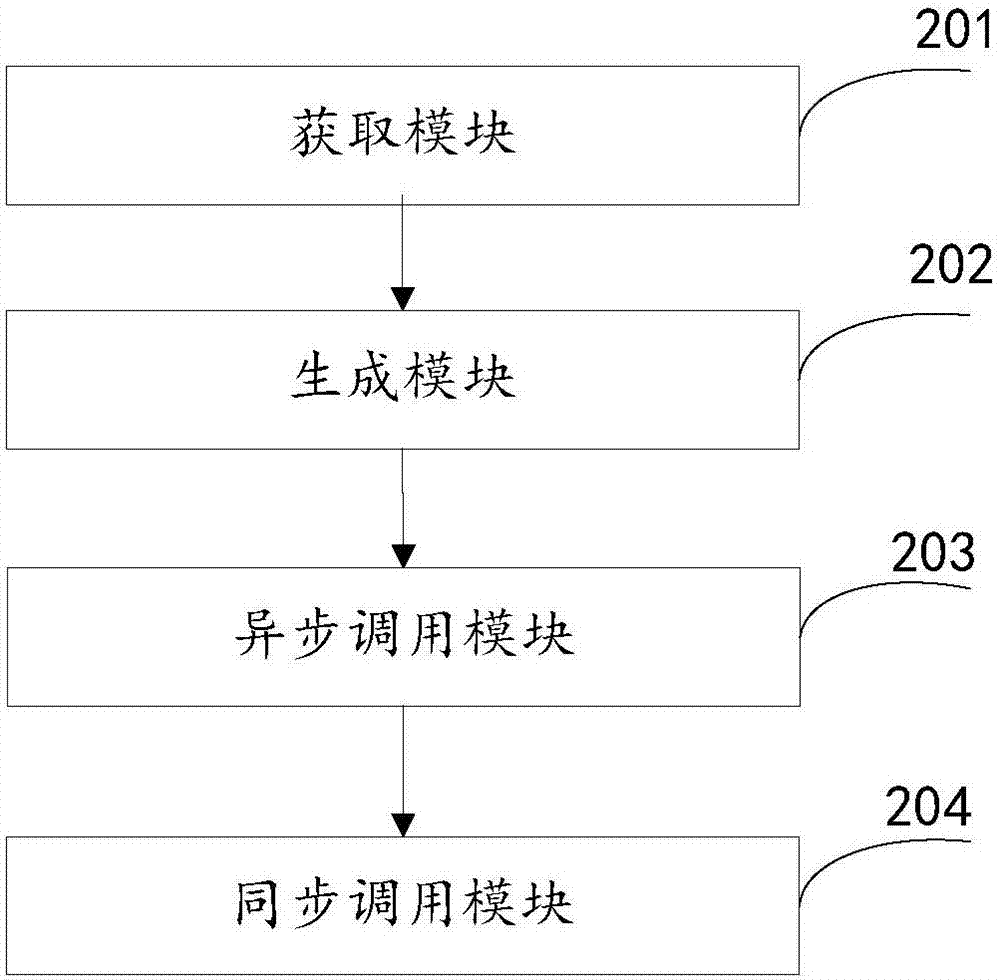

Processing method and device for achieving synchronous call based on asynchronous call

ActiveCN107479981AReduce the amount of programmingImprove development efficiencyProgram synchronisationWaiting timeTime parameter

The invention discloses a processing method and device for achieving a synchronous call based on an asynchronous call. The method includes the steps of obtaining a first function preset for the asynchronous call, wherein the parameters of the first function includes a first callback function; generating a second function used for synchronous call according to the parameters of the first function, wherein the parameters of the second function include a second callback function and time; constructing the corresponding relation between the second callback function and the first callback function, calling the first function in the second function according to the corresponding relation, and calling the first callback function asynchronously through the first function; if the wait time for obtaining the execution results of the first callback function is less than the value of the time parameter, calling the second callback function synchronously through the second function. According to the processing method and device for achieving the synchronous call based on the asynchronous call, the technical problem of security and synchronization caused easily by multithreading through using the asynchronous calling method in the existing technology can be solved.

Owner:WUHAN DOUYU NETWORK TECH CO LTD

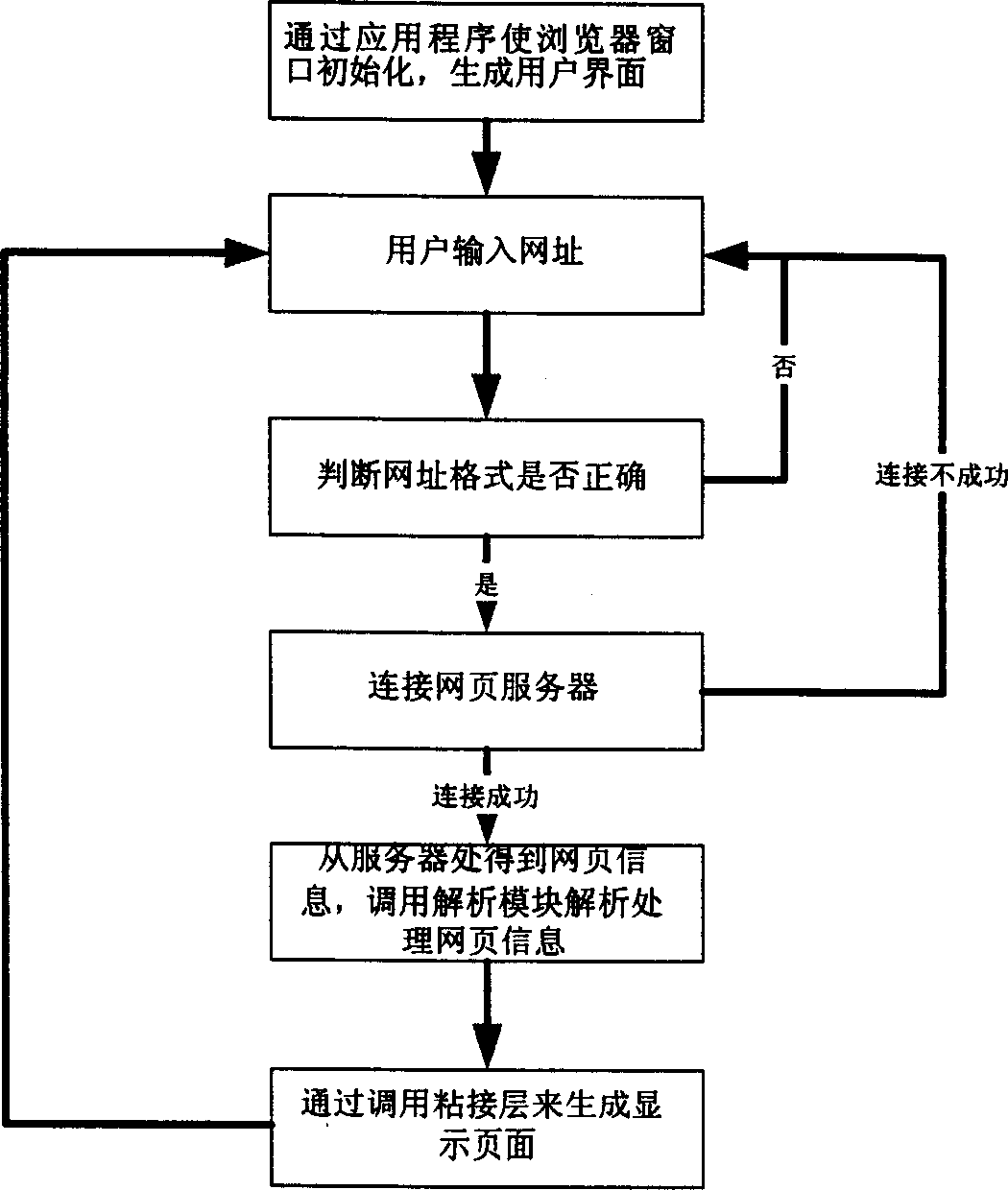

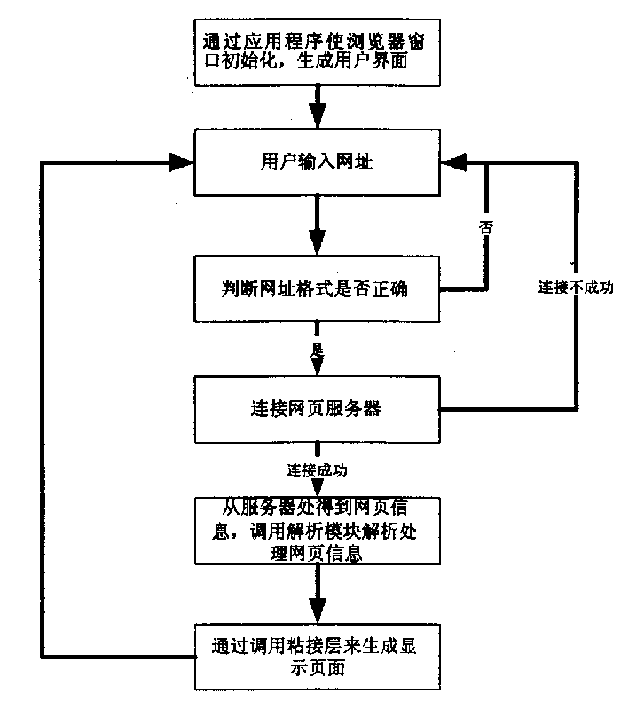

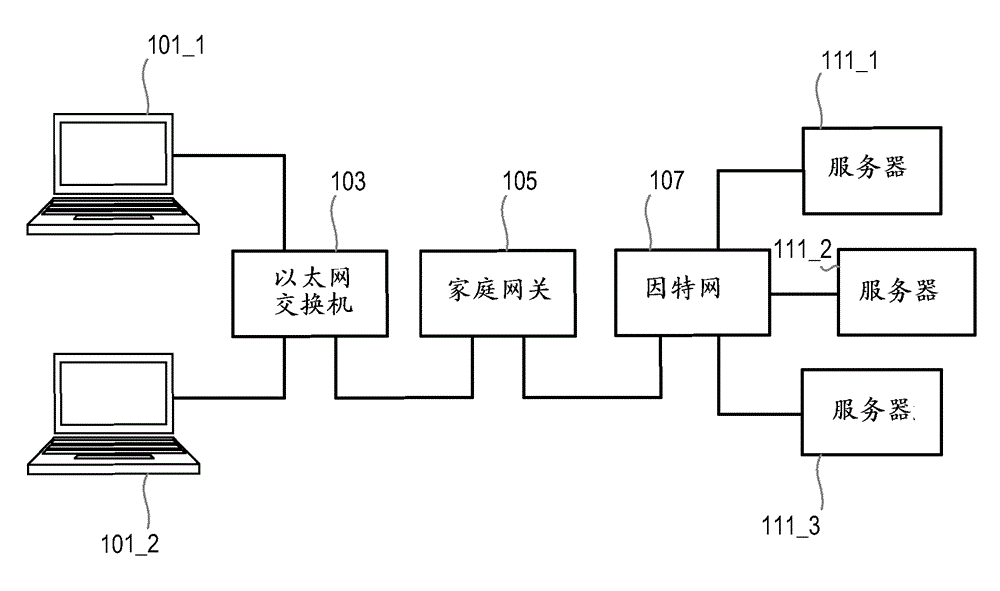

Webpage browsing method for embedded facilities

InactiveCN1456972AAdd graphics programEasy to customizeProgram control using stored programsSpecial data processing applicationsGraphicsNetwork connection

The method makes browser window initialization through application program to generate user boundary surface and user input network address. Whether the inputted network address format is correct or not is judged and the server is connected by calling network connection function if the format is correct, otherwise network address should be reinputted. The analytical processing for web page contnet taken from the server is carried out if the connection is normal, otherwise the network address should be reinputted. The analytical processed web page content can be generated to be display page through calling graphic routine program. Since the graphic routine program is added in the method, the user can carry on freely rade signal of boundary surface based on the normal browser to increase some new functions.

Owner:TSINGHUA UNIV +2

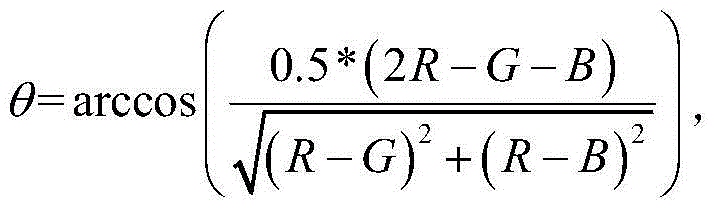

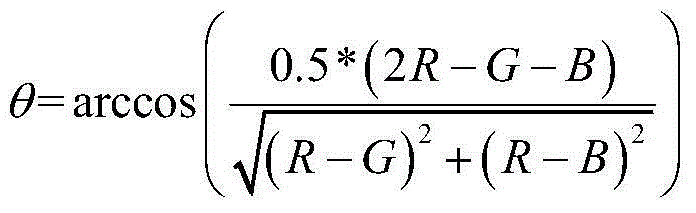

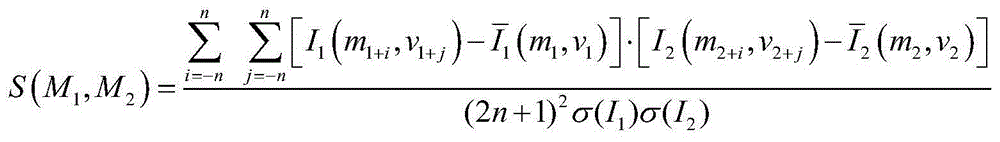

Three-dimensional face recognition method

InactiveCN104573628AHigh precisionReduce the amount of programmingThree-dimensional object recognitionPattern recognitionThree-dimensional face recognition

The invention discloses a three-dimensional face recognition method. The method comprises the following steps: calibrating eyes, noses and mouths of a collected left two-dimensional image and a collected right two-dimensional image, determining matched face feature points, then determining the three-dimensional coordinates of the feature points, and finally recognizing face features through a BP neural network algorithm. Compared with a two-dimensional recognition method, the three-dimensional face recognition method has relatively high precision, the amount of programming is greatly reduced, and the development efficiency is improved.

Owner:SUZHOU FUFENG TECH

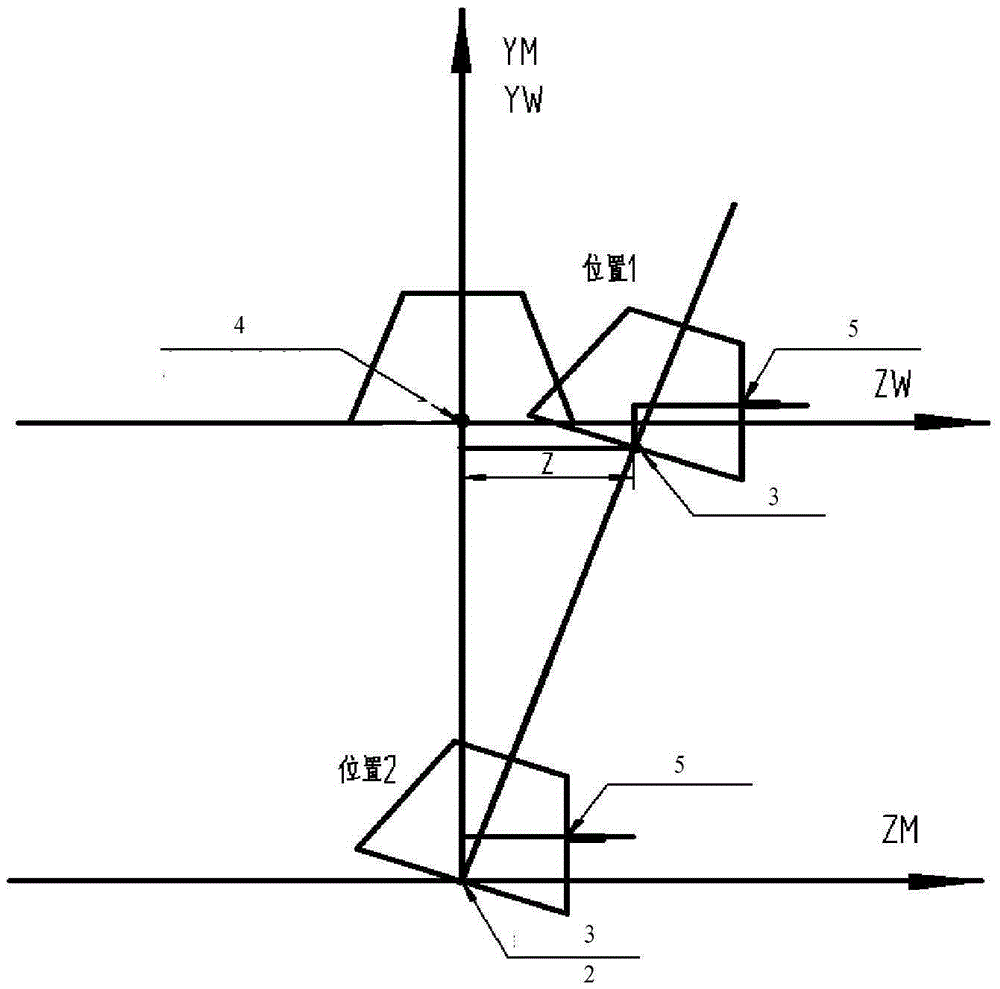

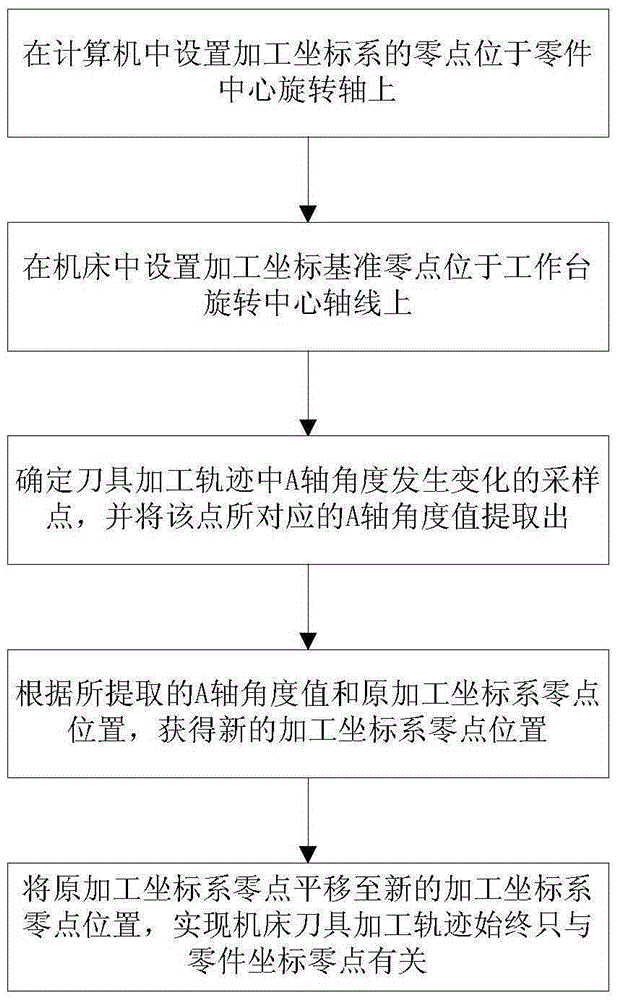

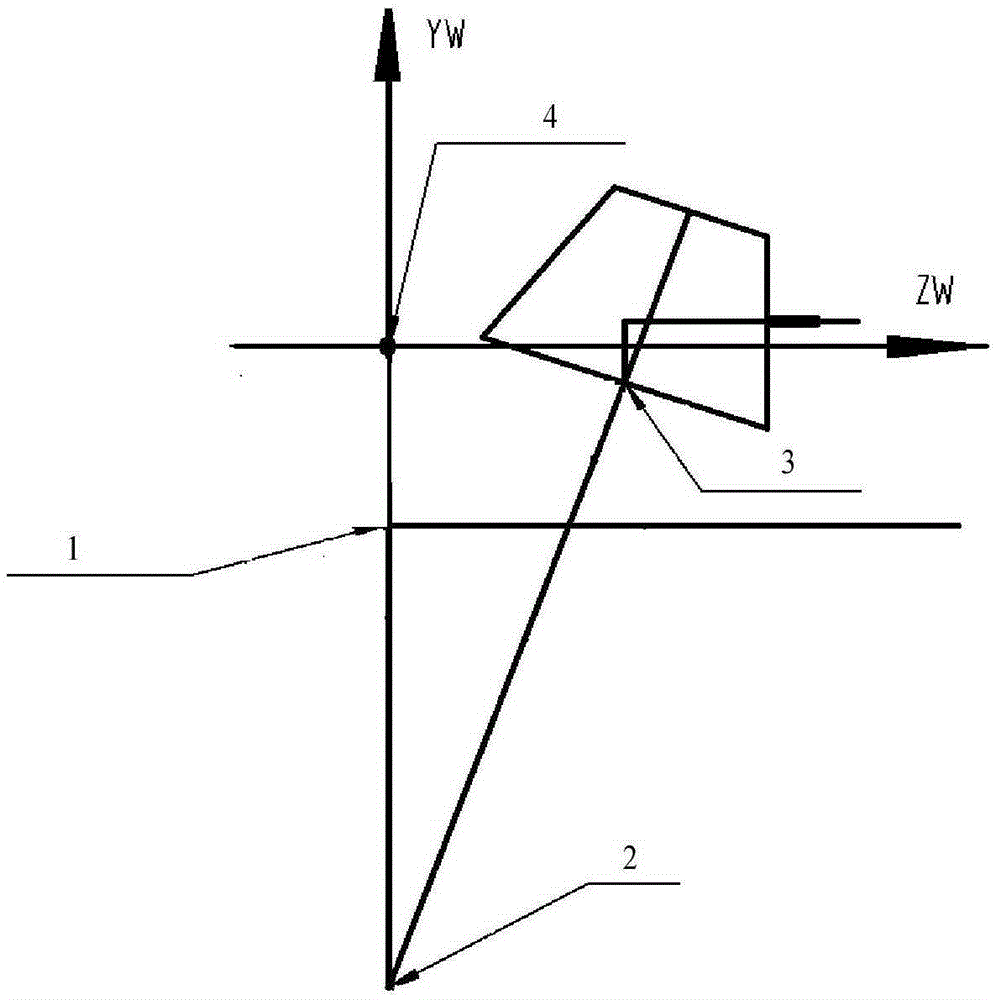

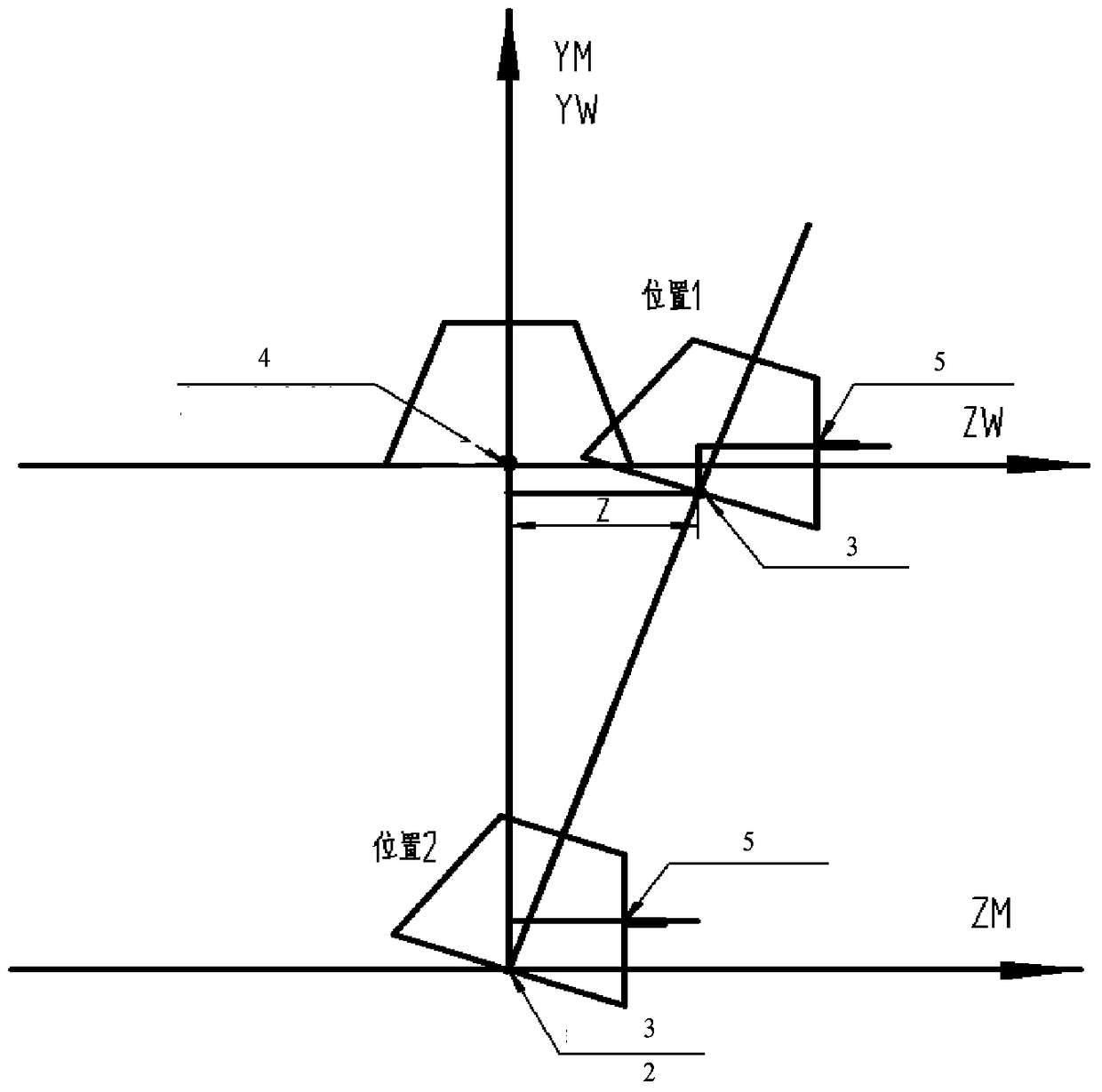

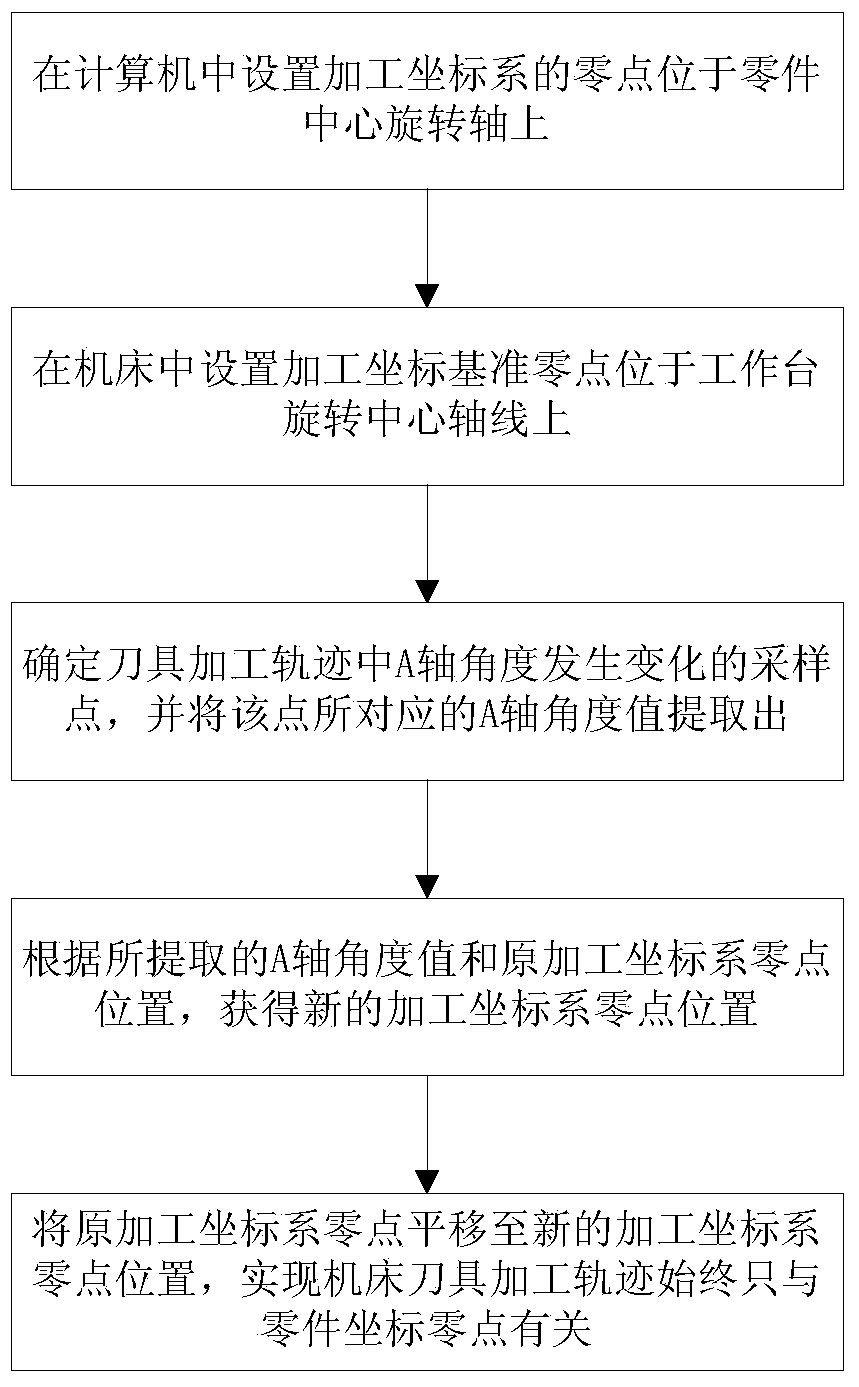

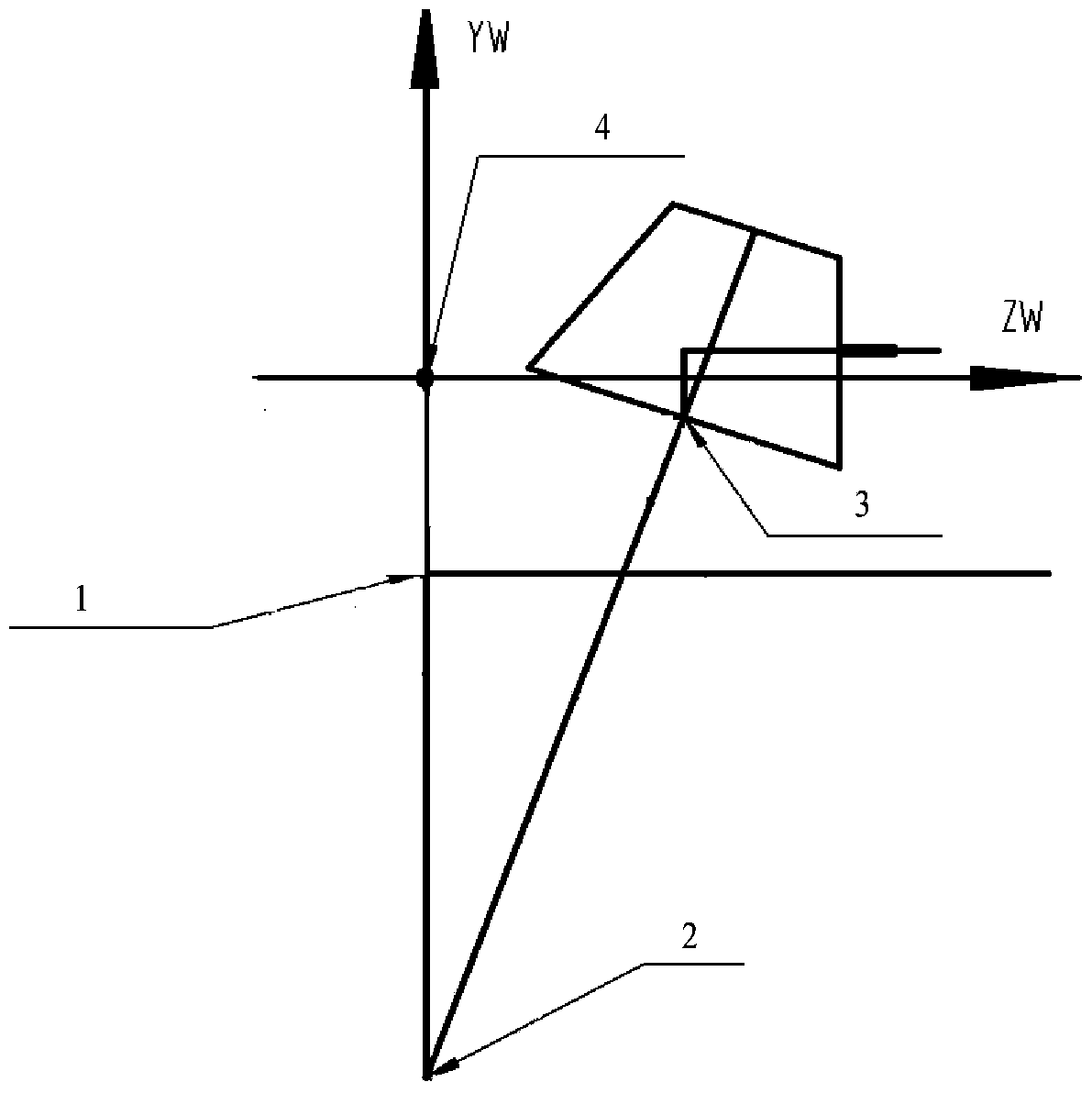

Numerical control machine tool processing method capable of eliminating height position difference

ActiveCN105302072AImprove CNC efficiencyReduce waiting timeProgramme controlComputer controlPoint trackingMachine tool

A numerical control machine tool processing method capable of eliminating height position difference belongs to the technical field of numerical control processing. According to the method, by determining a sampling point of which the A-axis angle changes in the process path of a cutter, extracting the A-axis angle value corresponding to the point, obtaining a new processing coordinate system zero position according to the extracted A-axis angle value and an original processing coordinate system zero position and translating the original processing coordinate system zero to the new processing coordinate system zero position, the process path of the machine tool cutter is always related to the coordinate zero of parts only. By adopting the method, the problem that the machine tool utilization rate is low and the height of a workbench and the height of a clamp must be taken into consideration during programming and processing as the old-version Siemens numerical control system machine tool has no cutter point tracking function is solved, and the amount of programming and the management risk are reduced. The method has been popularized and applied in exterior profile processing of complex crankcase parts. The numerical control efficiency of the numerical control machine tool is improved greatly, the waiting time for the machine tool is reduced, and arrangement of workshop production tasks is facilitated.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

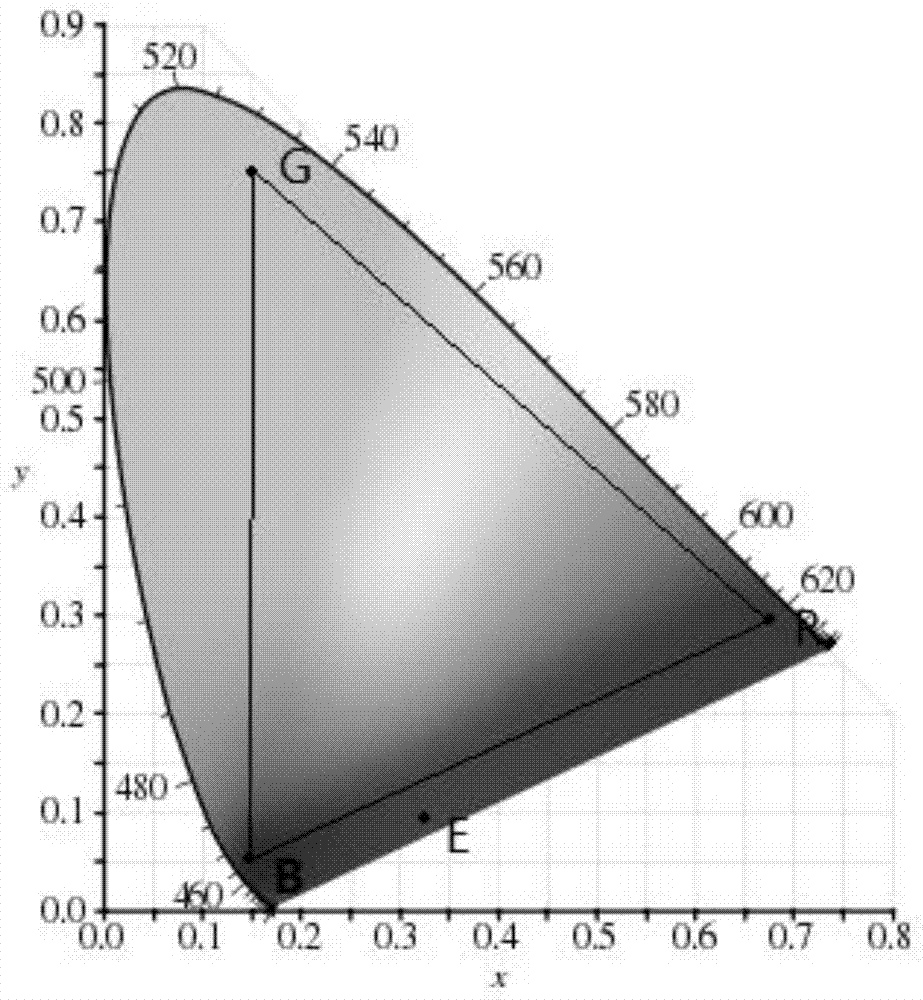

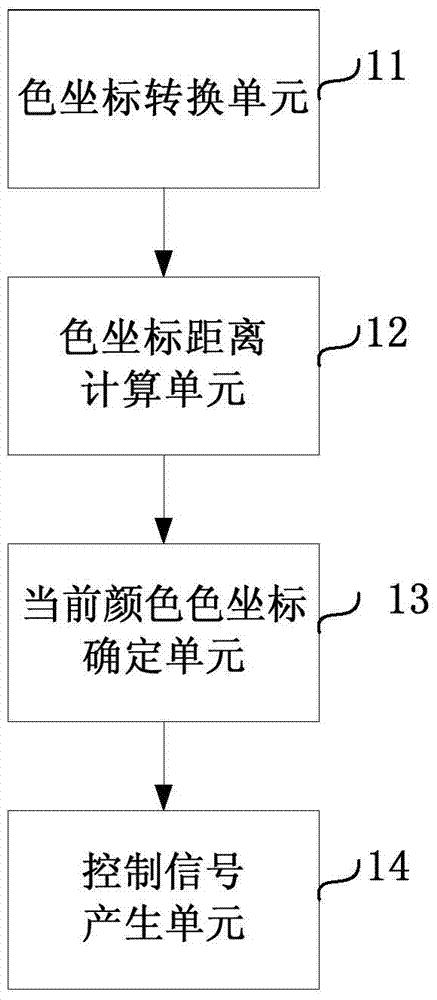

Method of realizing tricolor LED lamp color gradual change and device thereof

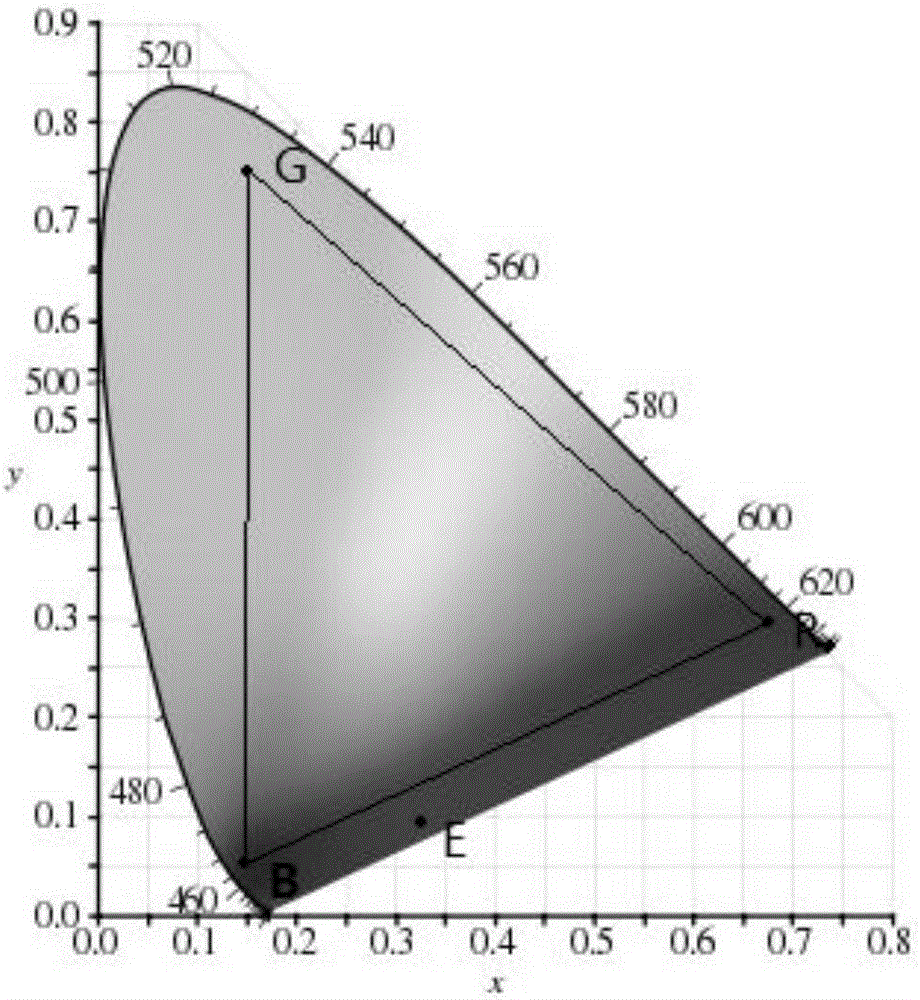

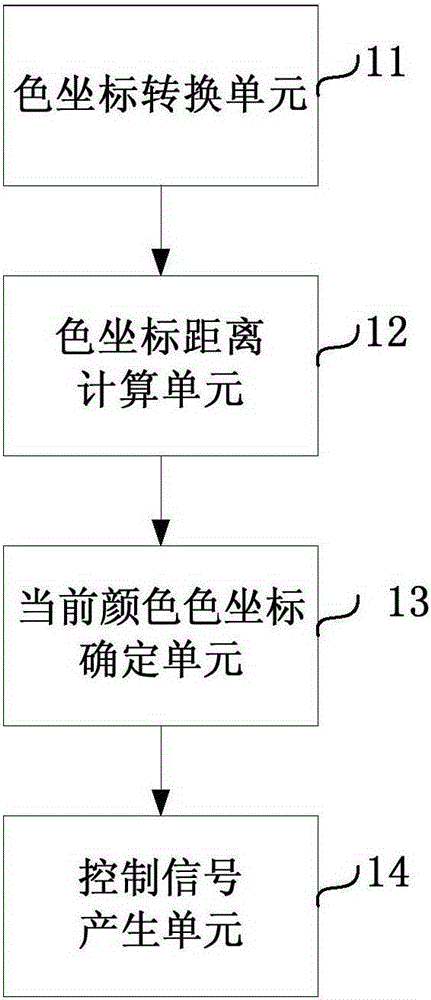

ActiveCN105263247AReduce the amount of programmingReduce resource usageElectric light circuit arrangementGamutControl signal

The invention discloses a method of realizing tricolor LED lamp color gradual change. The method comprises steps: color coordinates (T_x, T_y) and (N_x, N_y) of a target and an initial color are acquired; Lx=|T_x-N_x| and Ly=|T_y-N_y| are calculated; according to a color coordinate value change rate delta, color coordinates (Mj_x, Mj_y) of the current color are calculated; Mj_x=(T_x-N_x)*delta / (L_x+L_y)+Mj-1_x, and Mj_y=(T_y- N_y)*delta / (L_x+L_y)+Mj-1_y; duty ratios of three paths of PWM control signals outputted to a tricolor LED lamp driving circuit are calculated; and steps of c and d are repeated until |T_x- Mj_x|< / =|(T_x-N_x)*delta / (L_x+L_y)|, and the duty ratios of the three paths of PWM control signals are calculated according to the color coordinates of the target color. The invention also discloses a device for realizing the above method. During the color gradual change process, the color does not exceed a color gamut range.

Owner:KEBODA TECH CO LTD

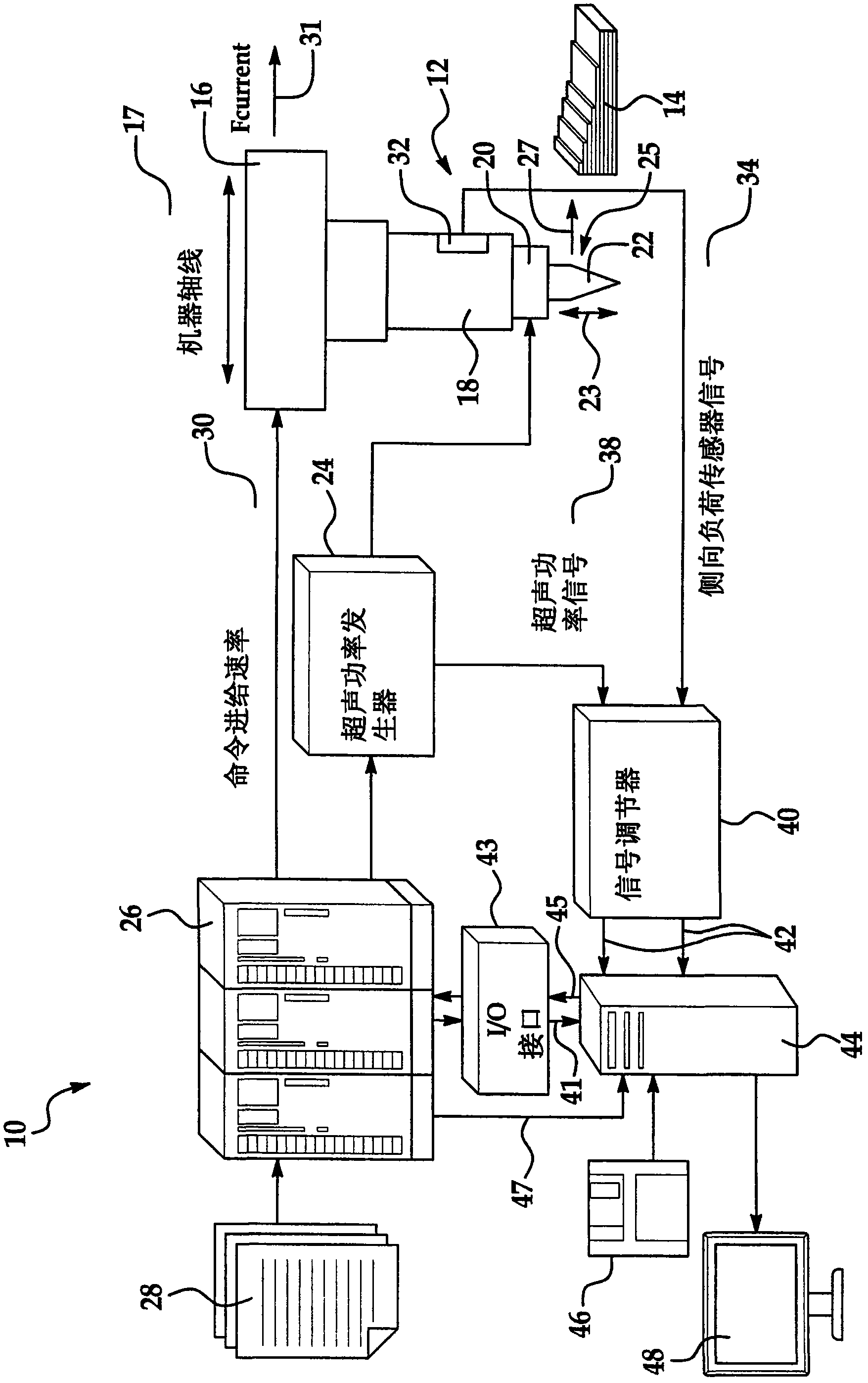

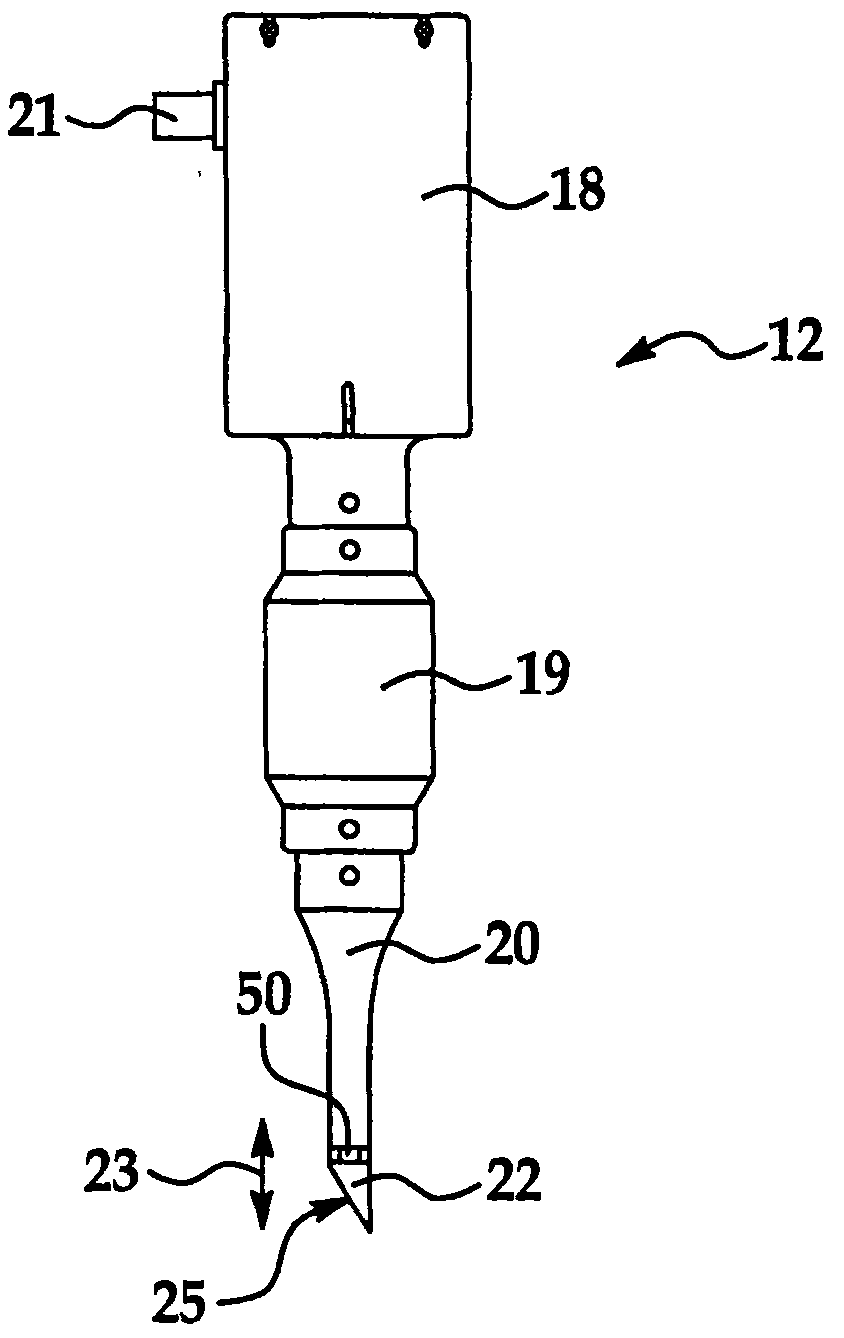

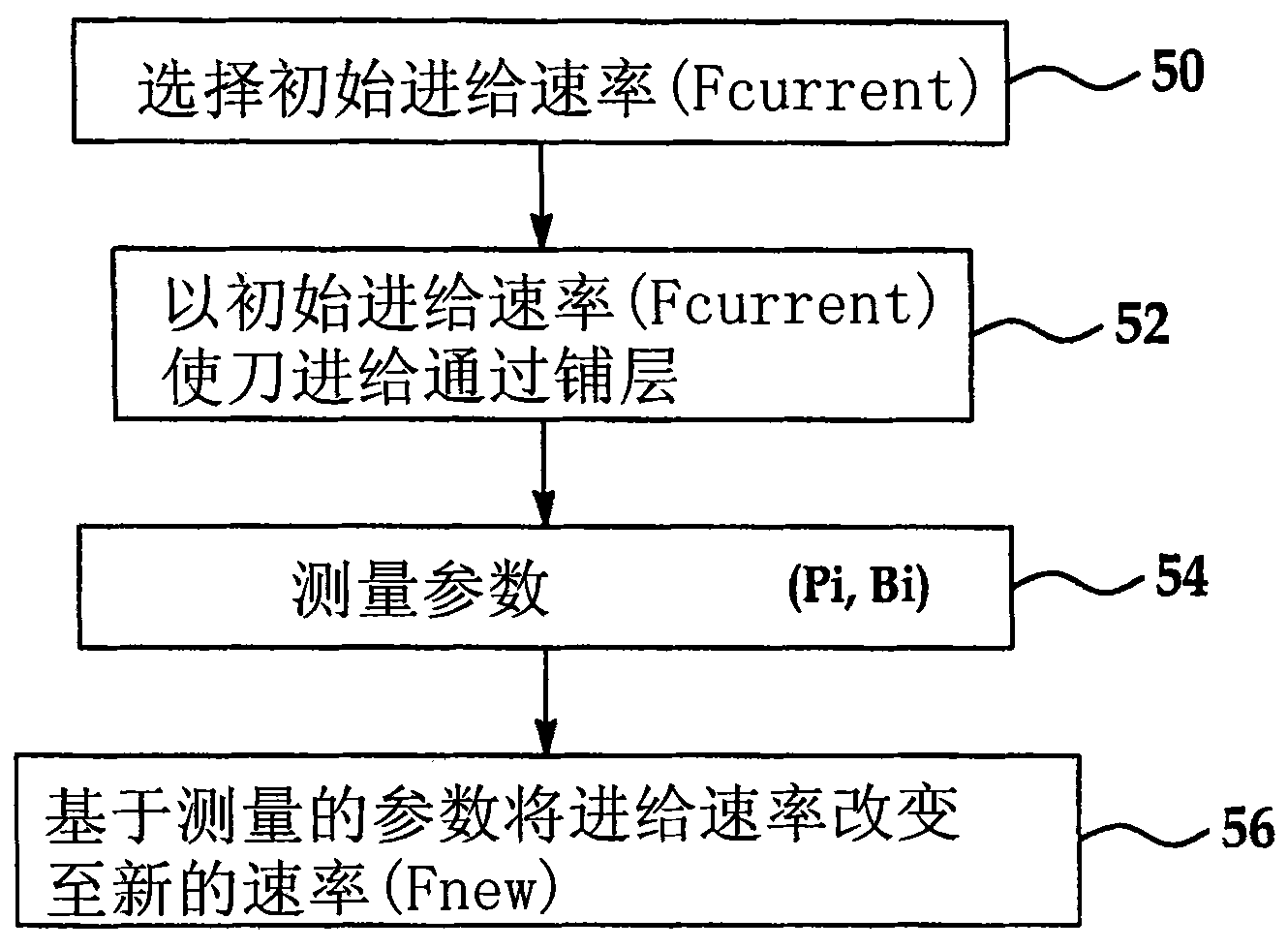

Adaptive control of composite plycutting

ActiveCN101990485AReduce the amount of programmingMaximize feed rateThin material handlingMetal working apparatusFeedback controlAdaptive control

The feed rate of an ultrasonic knife used to cut composite material is optimized using adaptive control. One or more parameters such as ultrasonic power or side load on the knife is sensed and used to generate feedback control signals. The feedback control signals are used to optimize the commanded feedrate of the knife.

Owner:THE BOEING CO

UVM (universal verification methodology) based write-only register verification test platform and verification method

InactiveCN105320583AReduce authoring timeReduce the introductionFunctional testingUniversal Verification MethodologyBus interface

The invention discloses a UVM (universal verification methodology) based write-only register verification test platform. The UVM based write-only register verification test platform comprises a UVM based test framework and a DUT (device under test) module, wherein the UVM based test framework comprises a UVM test sequence and a UVM sequencer; the DUT module is a digital design module provided with a register and a register read-write bus interface; the UVM based test framework is connected with the DUT module through the register read-write bus interface; the UVM test sequence can call the UVM sequencer, and the UVM sequencer excites the DUT module through the register read-write bus interface according to a test requirement; the UVM test sequence accesses internal signals of the DUT module through a VPI (Verilog programmatic interface). The invention further discloses a UVM based write-only register verification method. According to the UVM based write-only register verification test platform and the verification method, the verification efficiency can be effectively improved, and the verification creditability is improved.

Owner:SHANGHAI HUAHONG INTEGRATED CIRCUIT

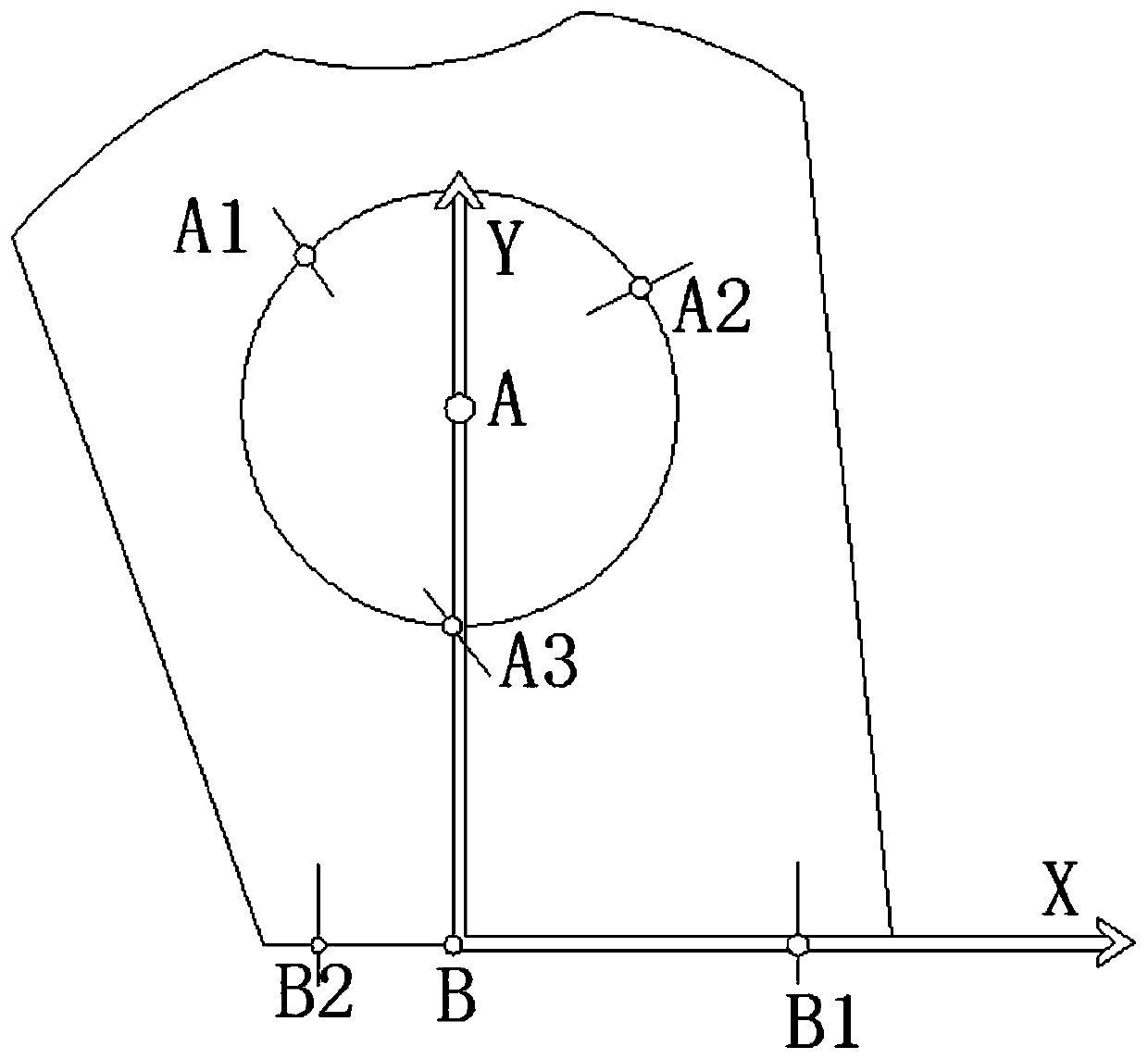

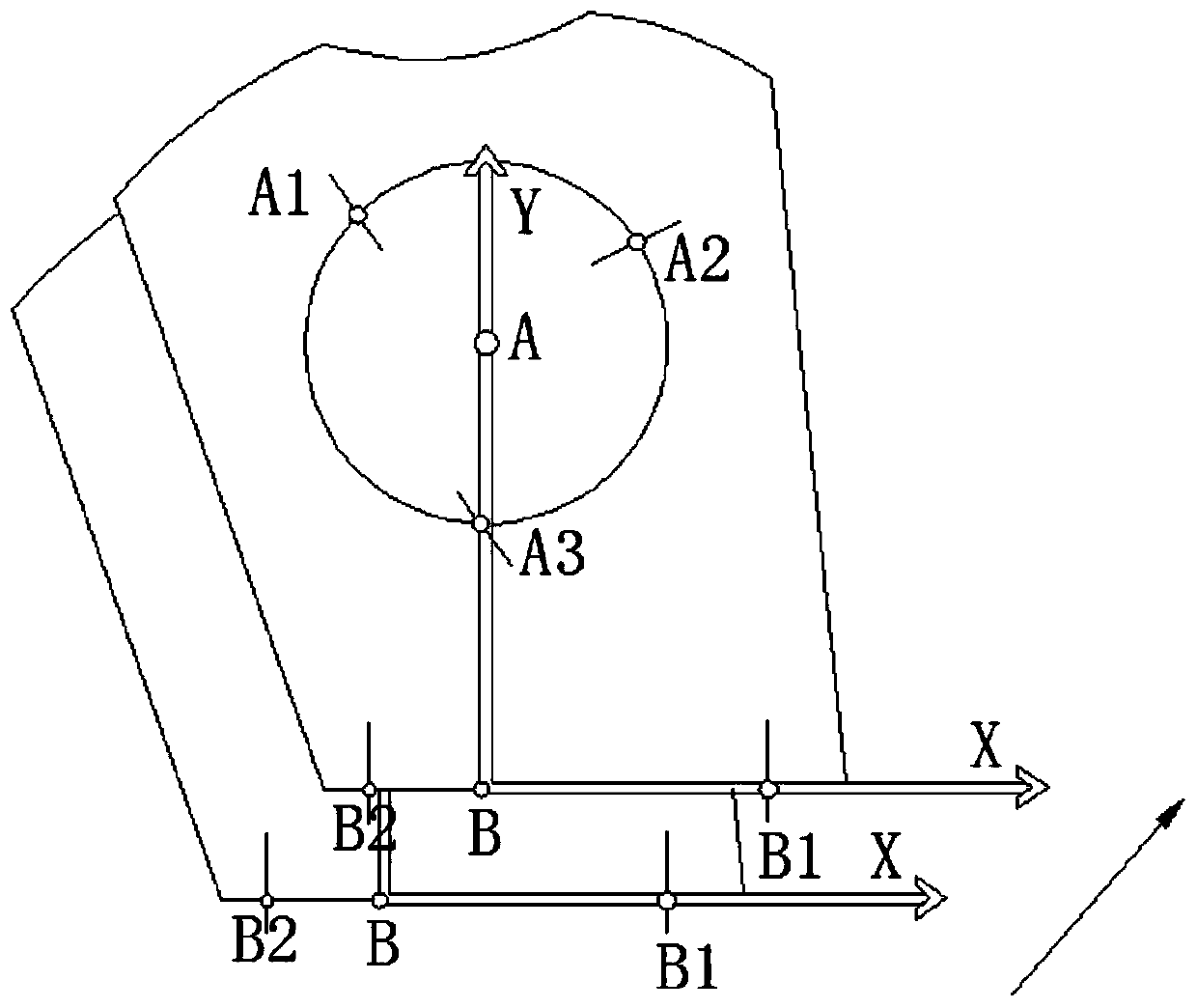

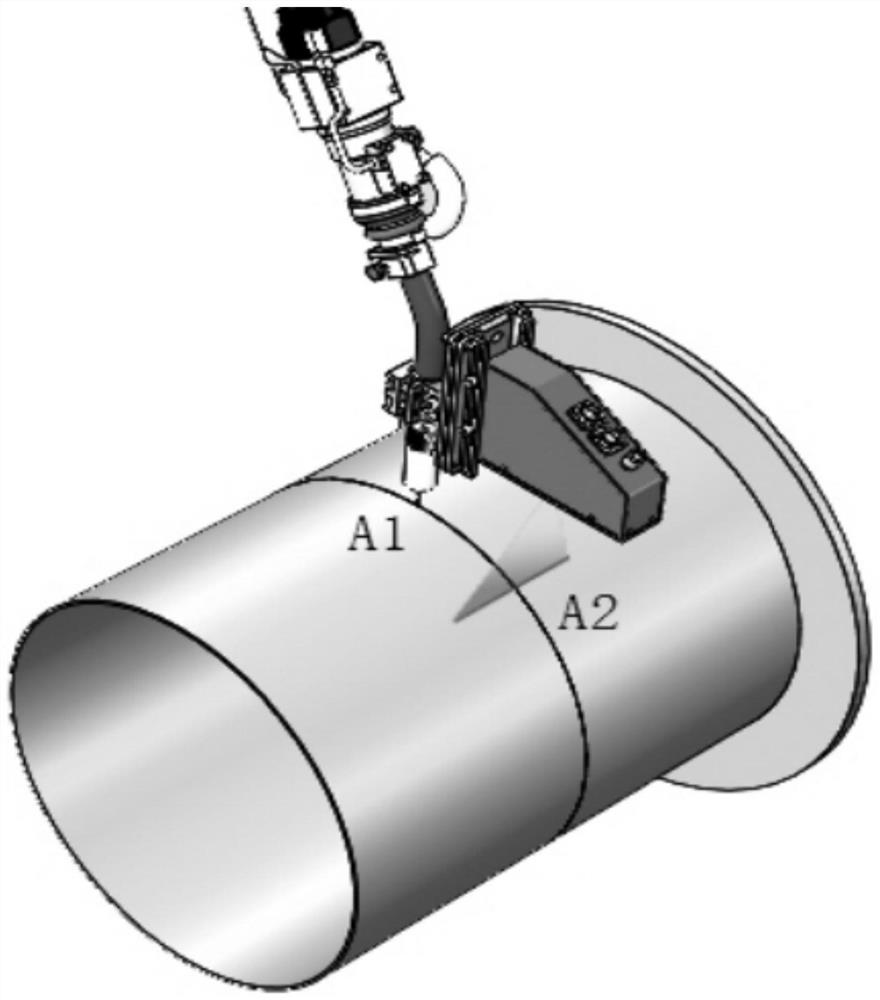

Laser vision positioning correction method for cutting complex workpiece by robot

ActiveCN111376270AReduce the amount of programmingEasy to understandProgramme-controlled manipulatorPlasma welding apparatusOphthalmologyEngineering

The invention discloses a laser vision positioning correction method for cutting a complex workpiece by a robot. The method comprises the following steps of step 1, changing a coordinate system, namely switching a coordinate system of the robot into a world coordinate system; step 2, confirming coordinates preliminarily, namely carrying out trial teaching on three scanning positions of a laser vision sensor on the inner circle of the workpiece in the world coordinate system, randomly determining three points and finding coordinates of the points A1, A2 and A3; and step 3, calculating a centerposition, namely calculating a center point A. The invention relates to the technical field of plasma cutting industrial robots. According to the laser vision positioning correction method for cuttingthe complex workpiece by the robot, a cutting track is cut in the workpiece coordinate system, a laser vision positioning system is applied, a workpiece coordinate system is established, and the trail teaching is carried out on the cutting (welding) track on the basis of the workpiece coordinate system, so that the welding track can be corrected only by repositioning the workpiece coordinate system through the laser vision positioning system when the workpiece is replaced, and the method is small in programming amount and easy to understand.

Owner:TANGSHAN YINGLAI SCI & TECH

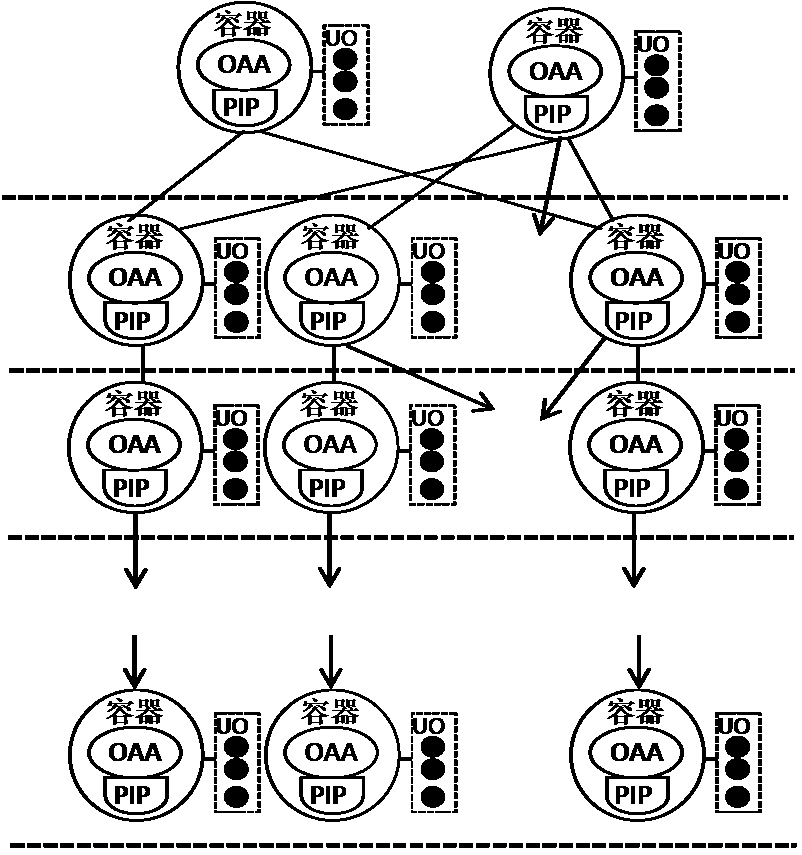

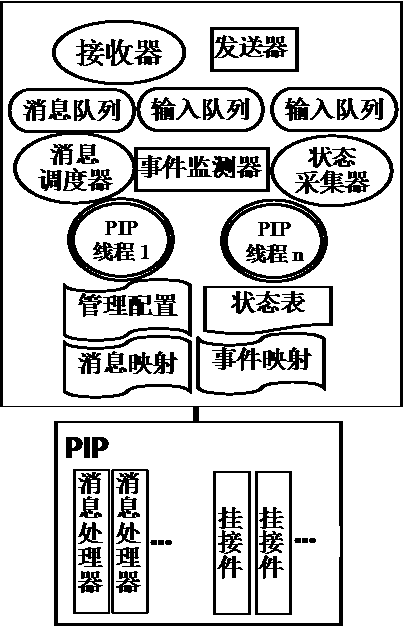

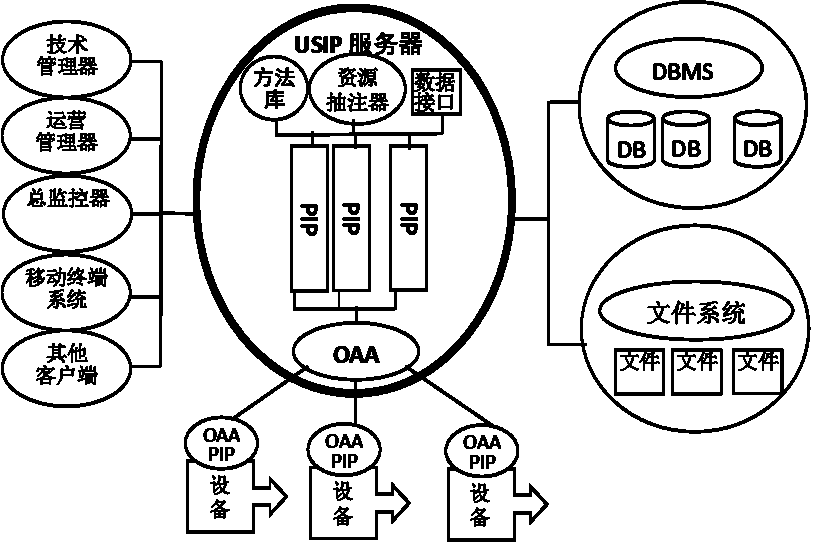

Software constituting method based on ubiquitous object three-section assembly

InactiveCN108415689ASimplify development workQuality improvementSoftware designTransmissionUser needsModel dynamics

The invention discloses a constituting method of a computer system. Members of software are summarized into three types of a supply member, a demand member and a hanging member, three-section assemblyof 'R-AAS-AS' of a user based on the three members is supported, the computer system working in a 'center kitchen' mode is constituted, and modeled dynamic assembly, mutual operation and aggregated development of a ubiquitous object including soft and services, instrument equipment, data resources and the like are achieved. The supply member is an operation accessing proxy and business logic assembly model of an internet-of-things object, the hanging member is a module describing user demand logic, and the demand member is a supporting environment for the user to access the supply member. Themethod is also used for longitudinal merging of a given 'calculation mode based on form field merging' ('a lattice member' for short) and is also used as an implementing method as a given EIO framework. The method can make 'internet-of-things+' development modeled, system dynamic extension is achieved, and the development efficiency and the system reliability are improved.

Owner:齐德昱

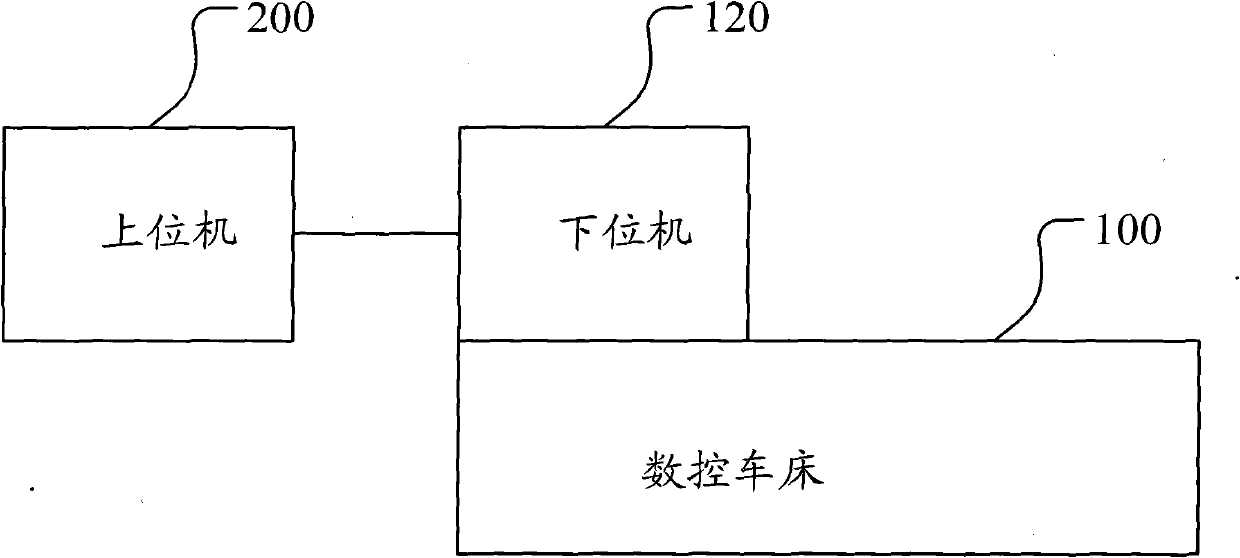

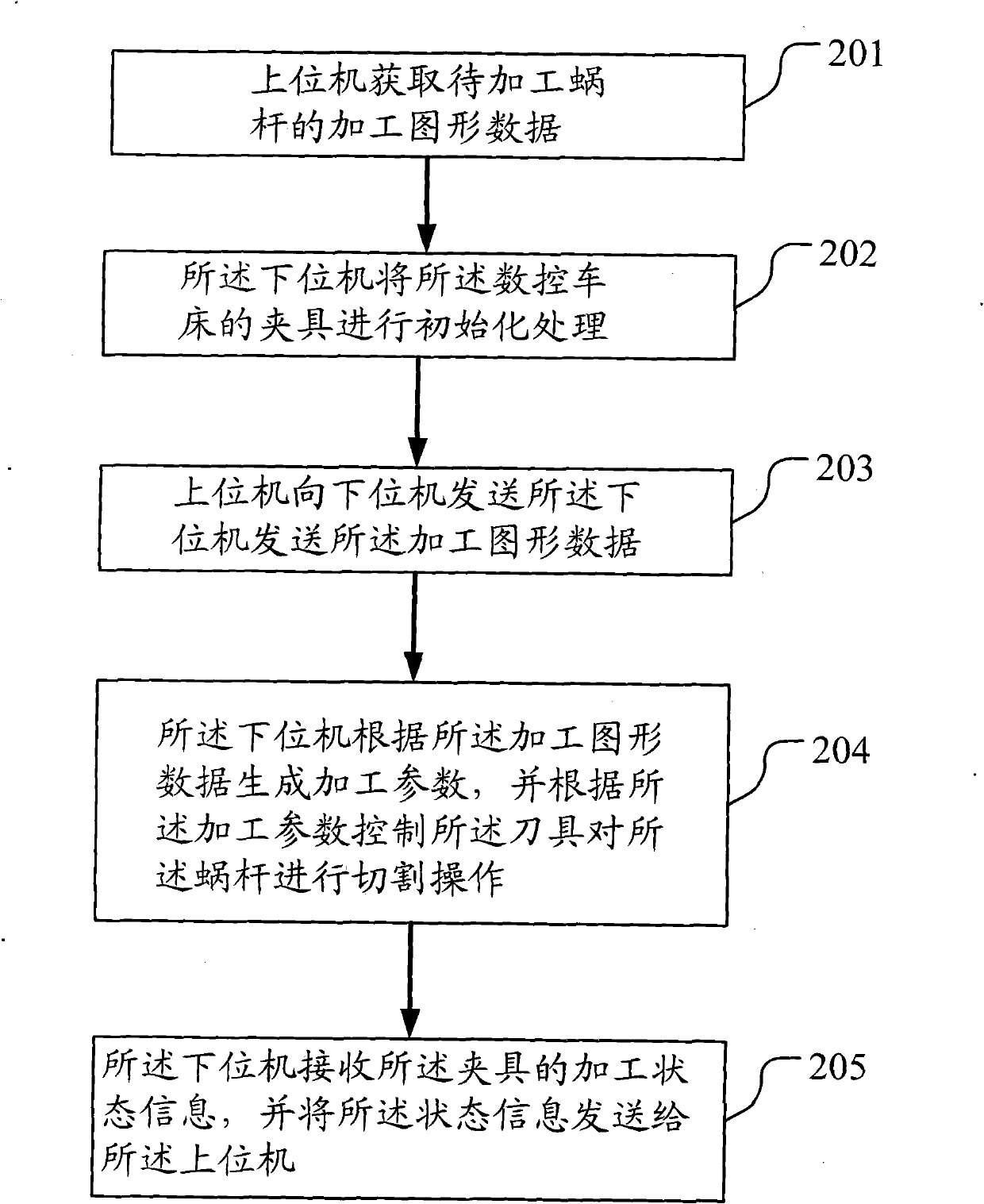

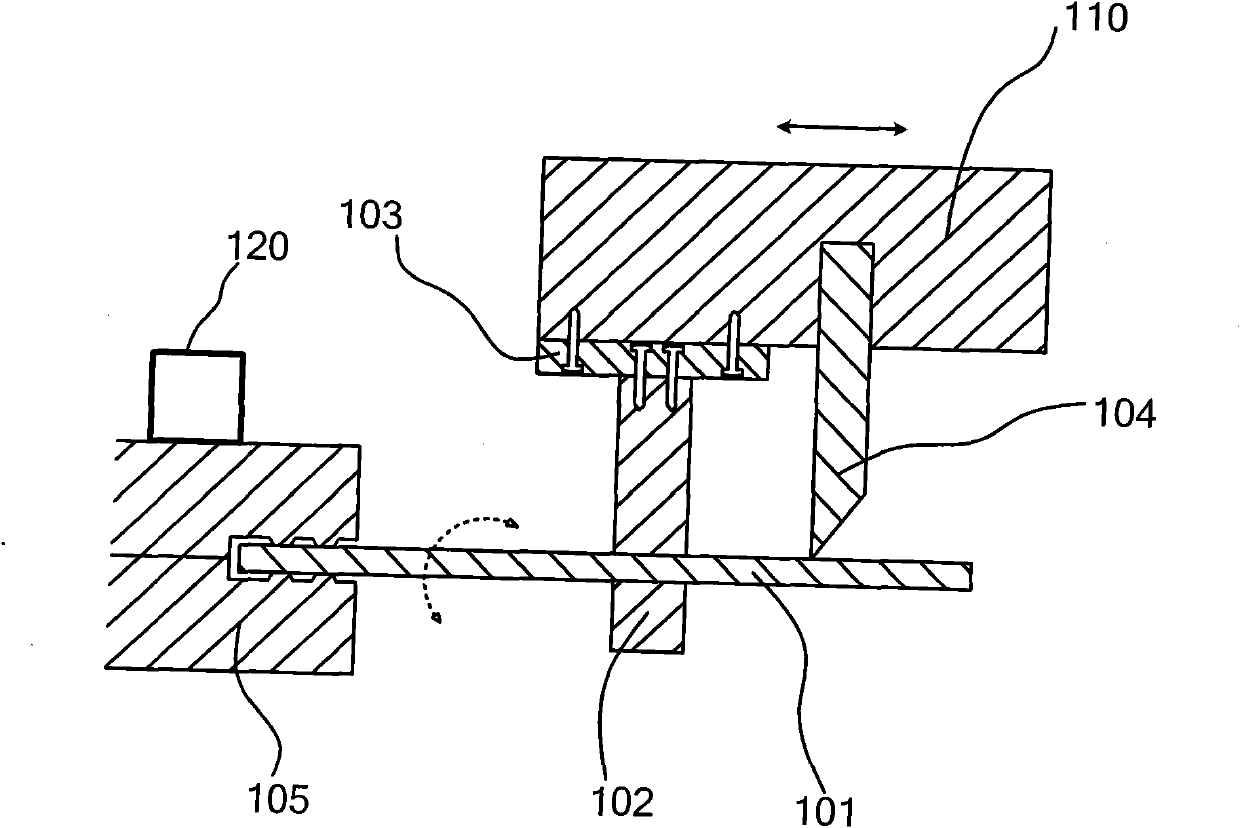

Intelligent control system for numerically controlled lathe for machining worm and machining method

InactiveCN102085584AStable and precise machiningReduce the amount of programmingAutomatic control devicesFeeding apparatusGraphicsParameter control

The invention provides an intelligent control system for a numerically controlled lathe for machining a worm and a machining method. The machining method comprises the following steps that: an upper computer acquires machining graphic data of a worm to be machined; the upper computer sends the machining graphic data to a lower computer; and the lower computer generates a machining parameter according to the machining graphic data, and controls a cutter to cut the worm according to the machining parameter. By the intelligent control system and an intelligent control method for the numerically controlled lathe, single-head or multi-head long and thin worms can be machined stably and accurately.

Owner:孙玲玲

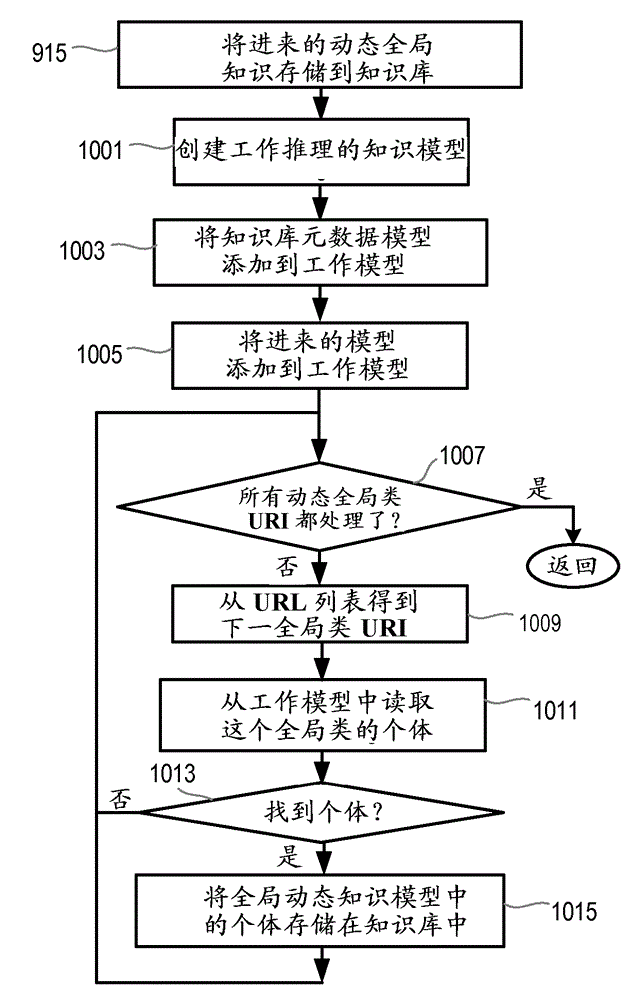

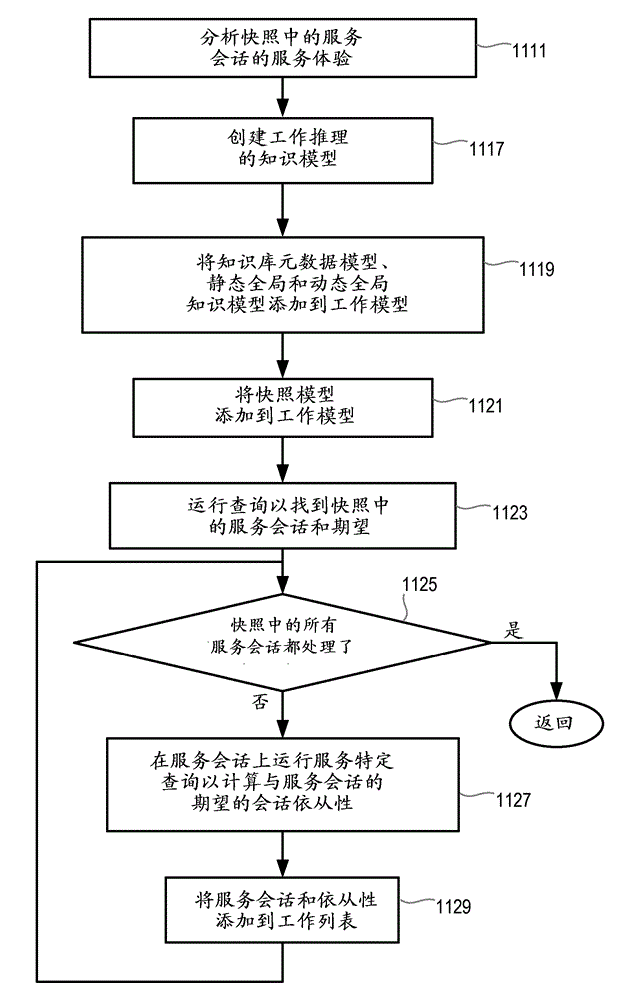

A method and apparatus for analyzing a service in a service session

InactiveCN104662840AReduce the amount of programmingKnowledge representationData switching networksEnd userReal-time computing

A service provided to an end user in a service session is analysed. A plurality of measurements of at least one performance parameter of a network providing a service to an end user in a service session is received (501). The received plurality of measurements of the at least one performance parameter are divided (503) into a plurality of snapshots. The service is analysed (505) by determining the compliance of the received measurements to the expectations of the end user for that service session within a snapshot.

Owner:TELEFON AB LM ERICSSON (PUBL)

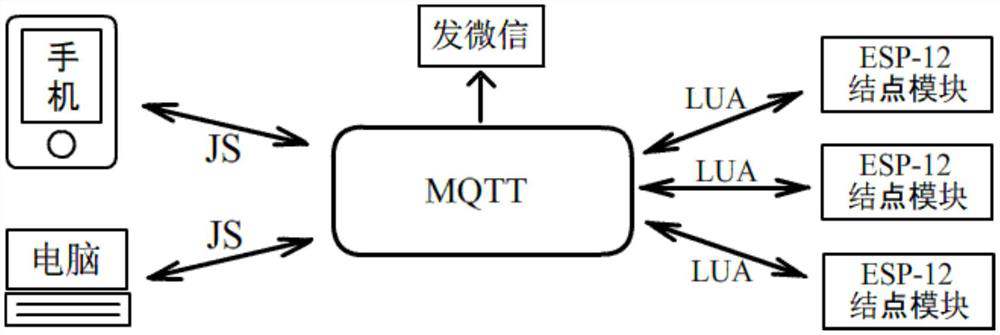

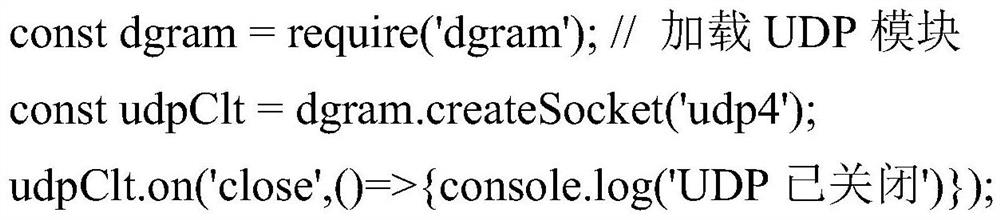

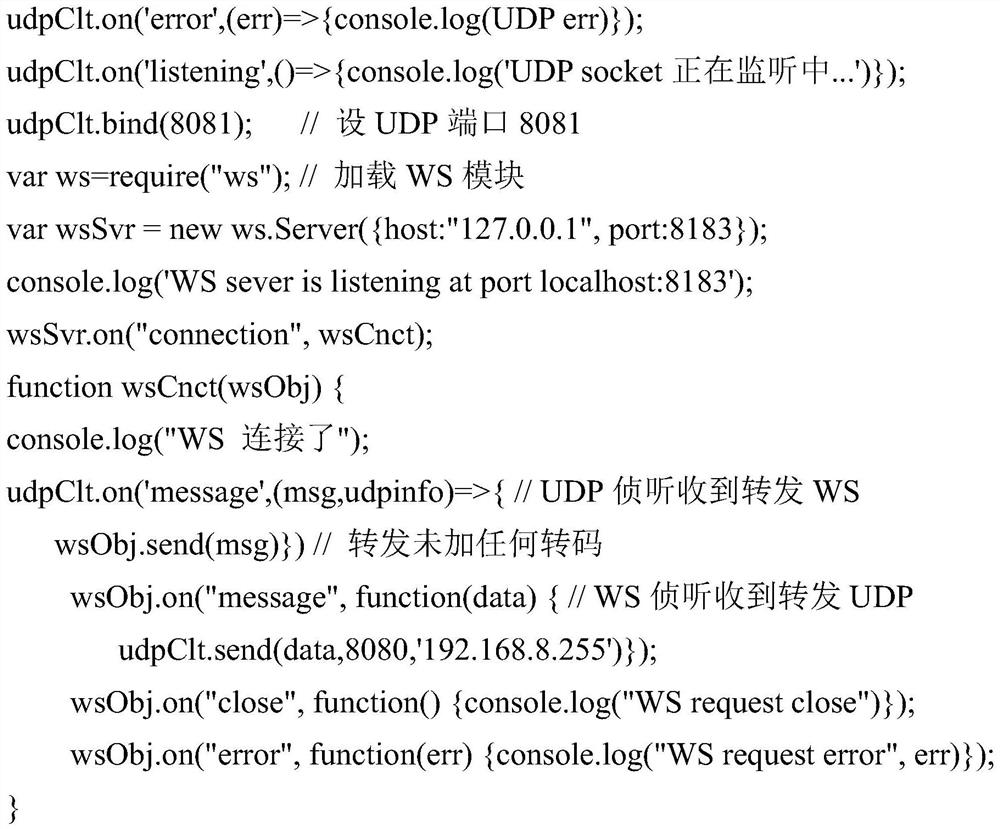

Internet of Things byte transparent transmission method based on H5JS local programming

PendingCN113824783AReduce the amount of programmingLess programmingNetwork topologiesMessaging/mailboxes/announcementsMobile endNetwork communication

Owner:杭州合学教育科技有限公司

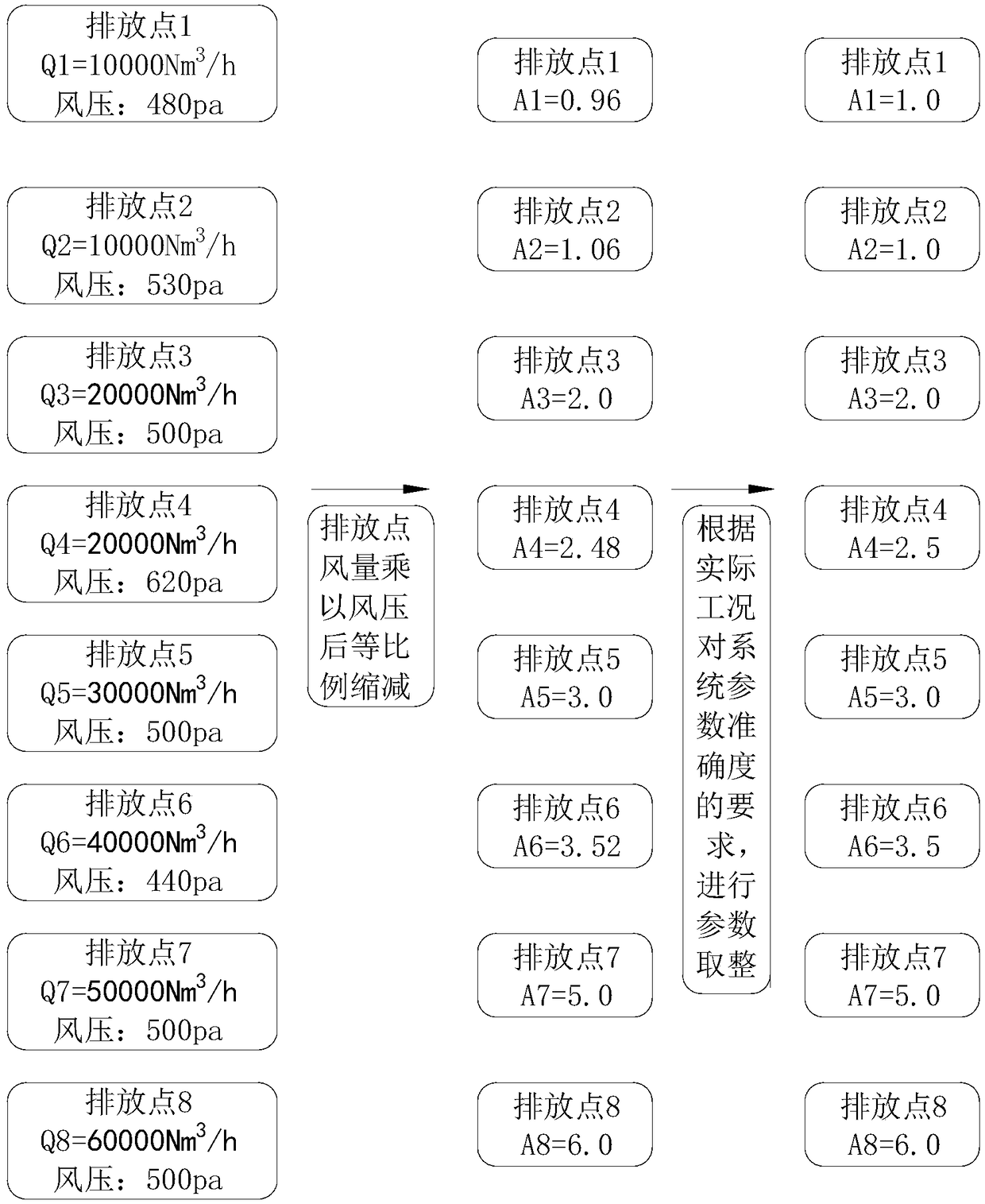

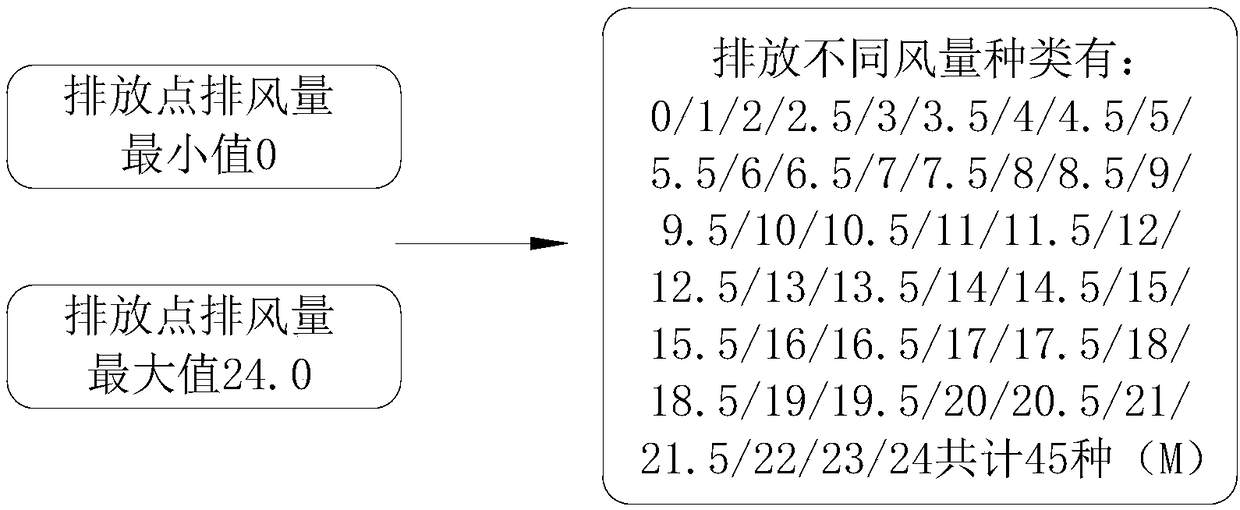

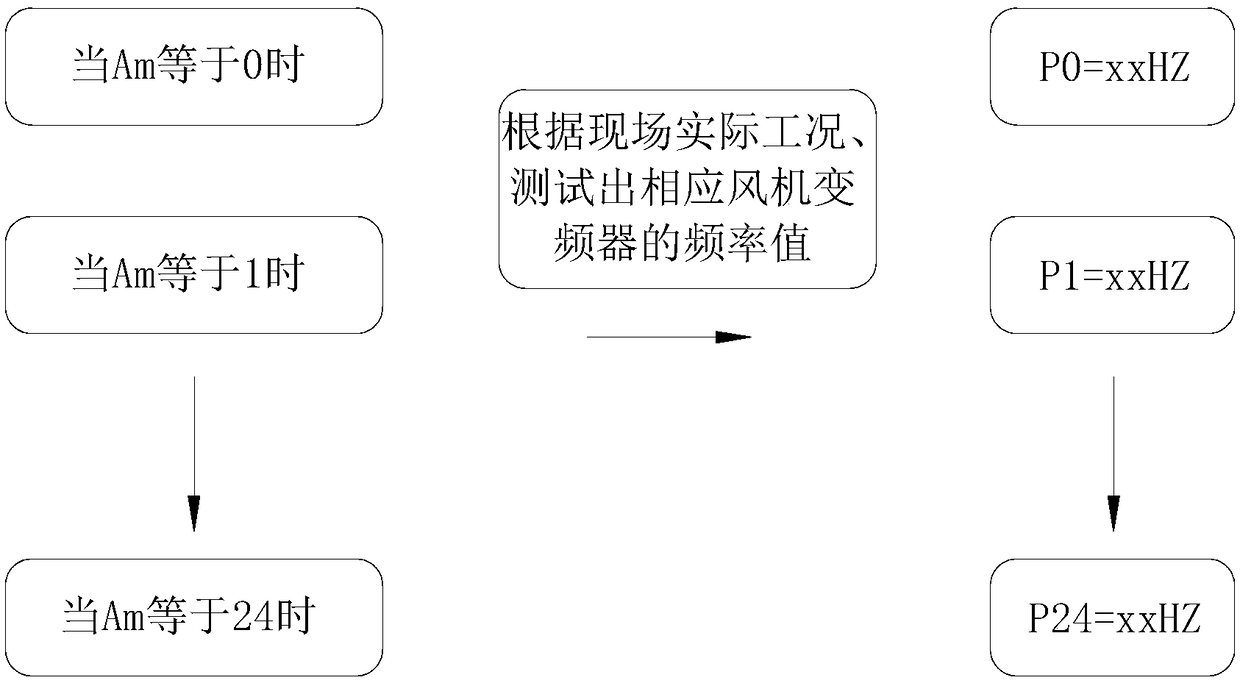

Multiple emission point exhaust gas volume matching collection and processing method

ActiveCN108906836ASolve the cumbersomeSolve the problem of energy consumptionDirt cleaningHigh energyAlgorithm

The invention provides a multiple emission point exhaust gas volume matching collection and processing method. The method solves the problems in prior art of cumbersome system and high energy consumption. The method comprises the step S1 of measuring the volume at each emission point to obtain values Q1, Q2... QN; the step S2 of scaling down the values obtained in the step S1 to obtain values A1,A2... AN; the step S3 of summarizing and counting all possible different emission values between 0 and the sum of all the values obtained in step S2 in M kinds in total; the step S4 of assigning the Mkinds of different emission values in the step S3 to corresponding fan frequencies according to the site working conditions; the step S5 of taking operation signals of all emission points in a system, if the emission points operate, assigning the corresponding values in the step S2 to the corresponding emission points; if the emission points do not operation, assign zero; the step S6 of adding the emission values of all the emission points in the step S5; the step S7 of assigning the values obtained in the step S6 to the corresponding fan frequencies according to the assignment relation in the step S4, wherein the fan frequencies change in real time.

Owner:SHANDONG HOLONE ENVIRONMENT TECH

Laser visual tracking correction method for welding of non-body external shaft of robot

PendingCN113695714AReduce the amount of programmingEasy to understandWelding accessoriesRobot positionEngineering

The invention discloses a laser visual tracking correction method for welding of a non-body external shaft of a robot. The laser visual tracking correction method specifically comprises the following steps that S1, before welding is started, a power source is turned on, a system starts to work, a program starts to run, the position of a welding gun at the tail end of a robot is adjusted through the position searching function of a sensor, and the tip of the welding gun at the tail end of the robot runs to a current arcing point A1. The invention relates to the technical field of welding laser correction. According to the laser visual tracking correction method for welding of the non-body external shaft of the robot, the arcing point is searched through the position searching function in the sensor, so that the tip of the welding gun at the tail end of the robot runs to the arcing point; compared with a traditional laser visual welding seam tracking system, the laser visual welding seam tracking system records the position of the robot at the arcing point and the position of the laser at the moment, and the position of the robot is compensated to realize automatic tracking of the welding gun on the welding seam position; and the laser vision welding seam tracking system has the advantages that the programming quantity is small, the system is easy to understand, and only a position searching point needs to be demonstrated.

Owner:TANGSHAN YINGLAI SCI & TECH

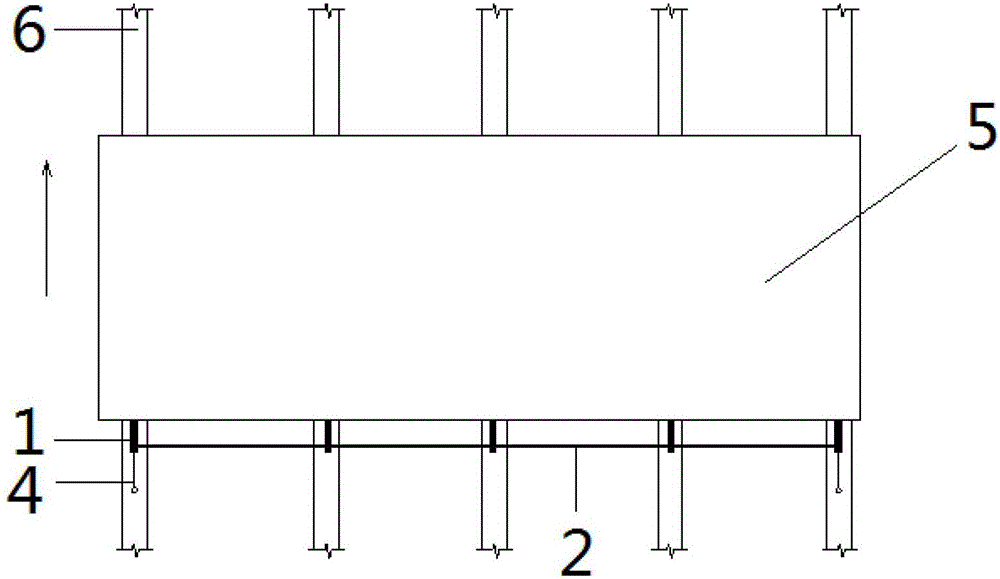

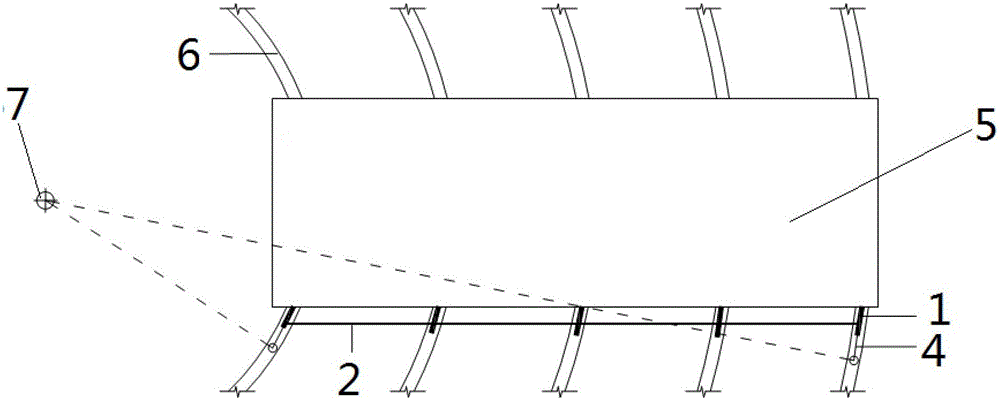

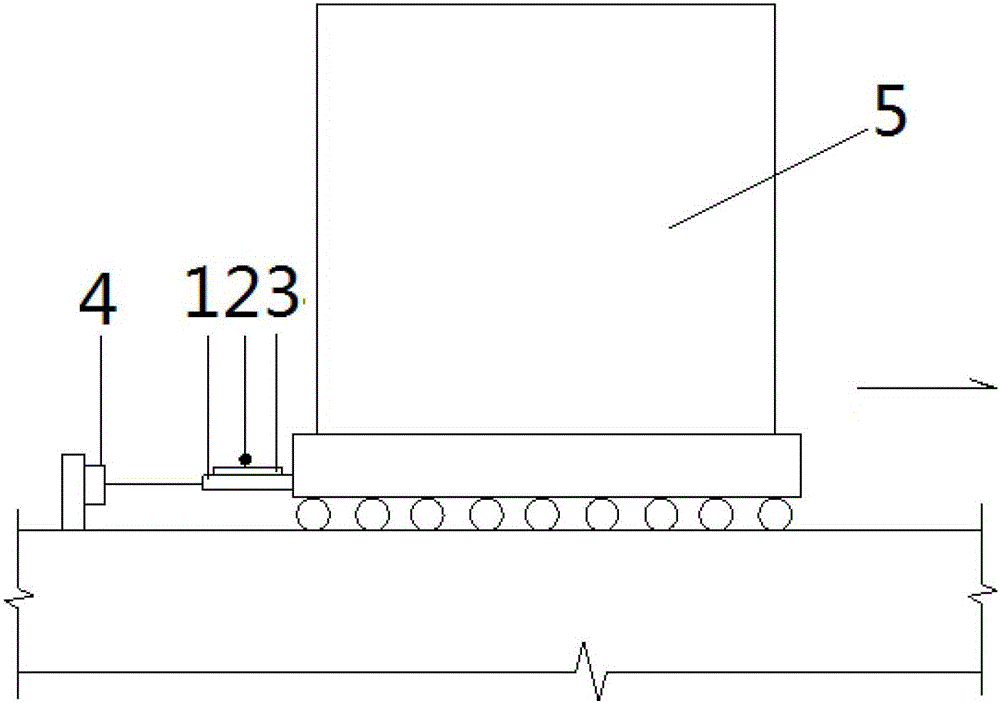

A Simple Monitoring Method for Building Displacement and Attitude

ActiveCN103398697BSmall collinear errorReduce the number of settingsHeight/levelling measurementMechanical solid deformation measurementsEngineeringMonitoring methods

The invention discloses a method for carrying out simple monitoring on the displacement postures of buildings. The invention belongs to the technical field of building posture monitoring. A method for carrying out simple monitoring on the displacement postures of buildings is characterized by comprising the following monitoring steps of arranging a measure point positioning component on a moved building or an underpinning structure thereof, setting a monitoring line between building measure points, applying a pretension force to the monitoring line, so that the monitoring line is kept in a horizontal state, and arranging a displacement sensor at each building measure point; and when the building is moved, monitoring the displacement of the building measure points through the displacement sensors, and according to the displacement range and change data of the building measure points, carrying out real-time monitoring on the displacement postures of the building. The method disclosed by the invention has the advantages of simple facilities, easiness for operation, simple method, low cost, intuitive results, and the like, and can be widely applied to the simple and rapid real-time monitoring on the displacement postures of buildings.

Owner:天津城建集团特种工程有限公司 +1

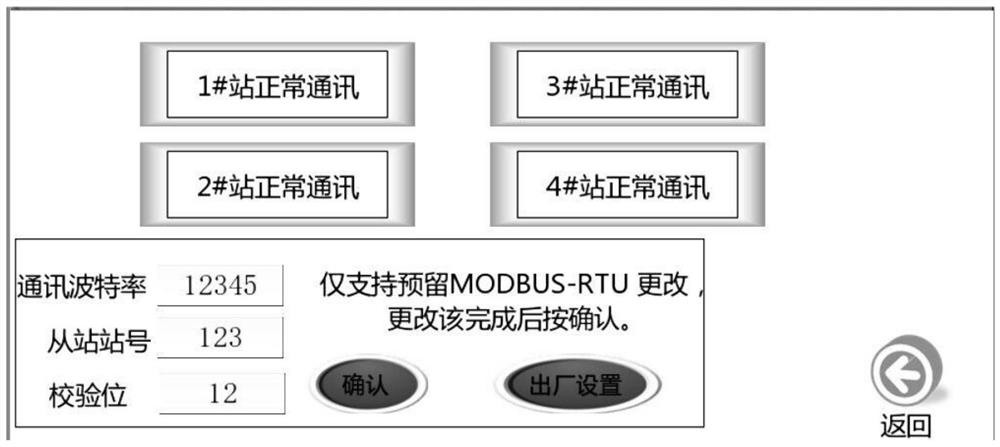

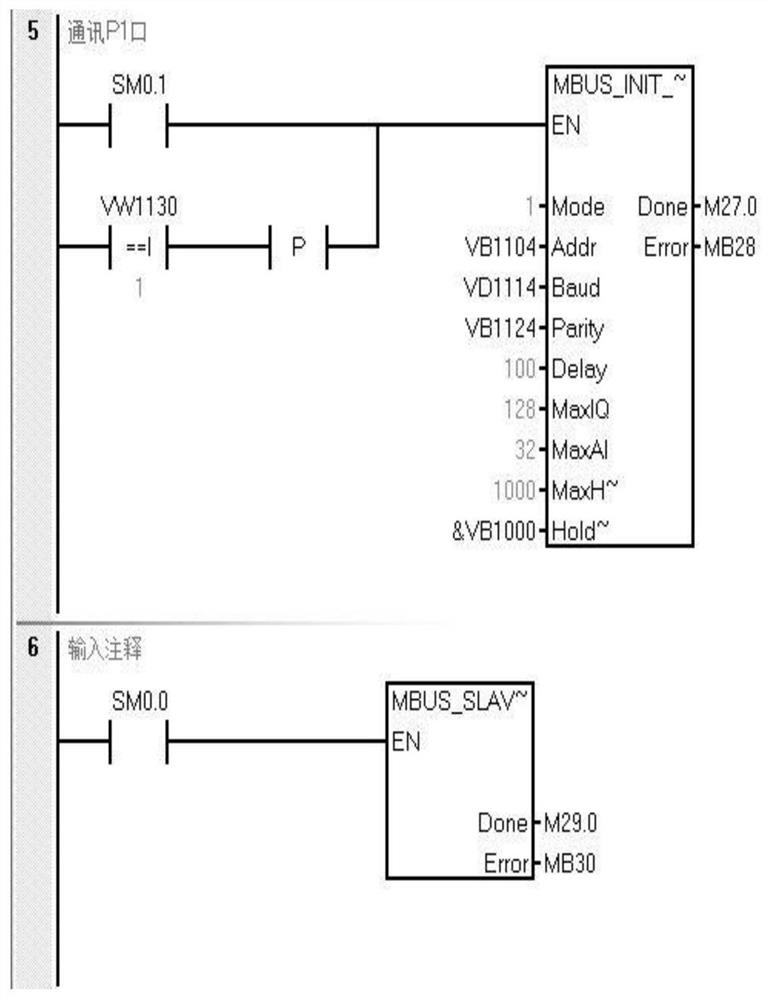

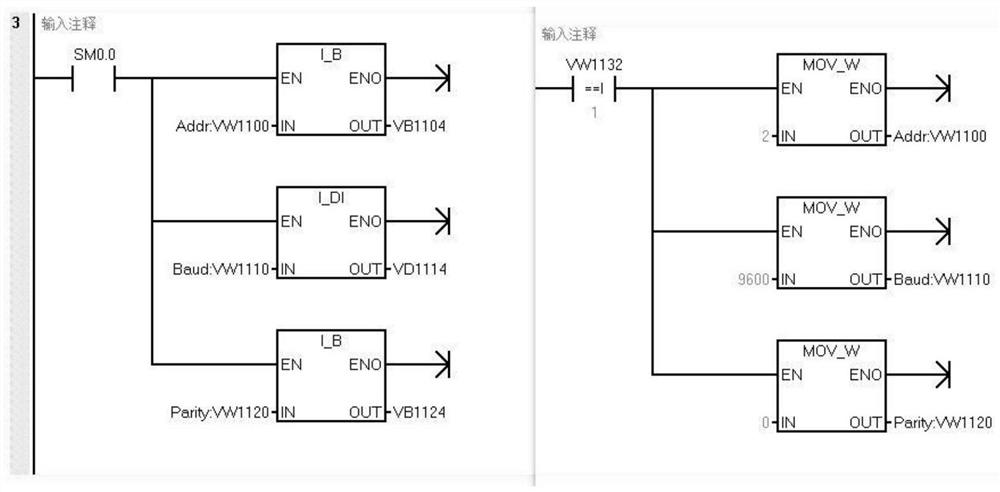

PLC reserved open type communication interface processing

InactiveCN111666022AReduce the amount of programmingReduce workloadProgramme control in sequence/logic controllersInput/output processes for data processingCommunication interfaceProgrammable logic controller

The invention discloses PLC reserved open type communication interface processing. The operation steps of PLC reserved open type communication interface processing comprise communication data configuration, human-computer interface editing, configuration information writing and PLC serial port data writing, so as to configure an open communication interface. The arrangement can reserve a communication interface at a batch project in use; through the arrangement, the programming amount can be reduced, and the workload can be reduced, and the work efficiency is improved, and an upper computer information management platform can process problems conveniently. According to PLC reserved open type communication interface processing, an open communication configuration format is adopted, so thathuman-computer interface resources can be effectively called, thus being simple and convenient to use; and usage of the open type interface is safe and reliable after a long time of testing and operating; and the problem of inconvenience in use due to the fact that programs need to be modified and a PLC (programmable logic controller) needs to be replaced when communication station numbers are repeated and conflicted can be greatly solved by the aid of the open type interface.

Owner:SHANGHAI EAST PUMP(GRP) CO LTD

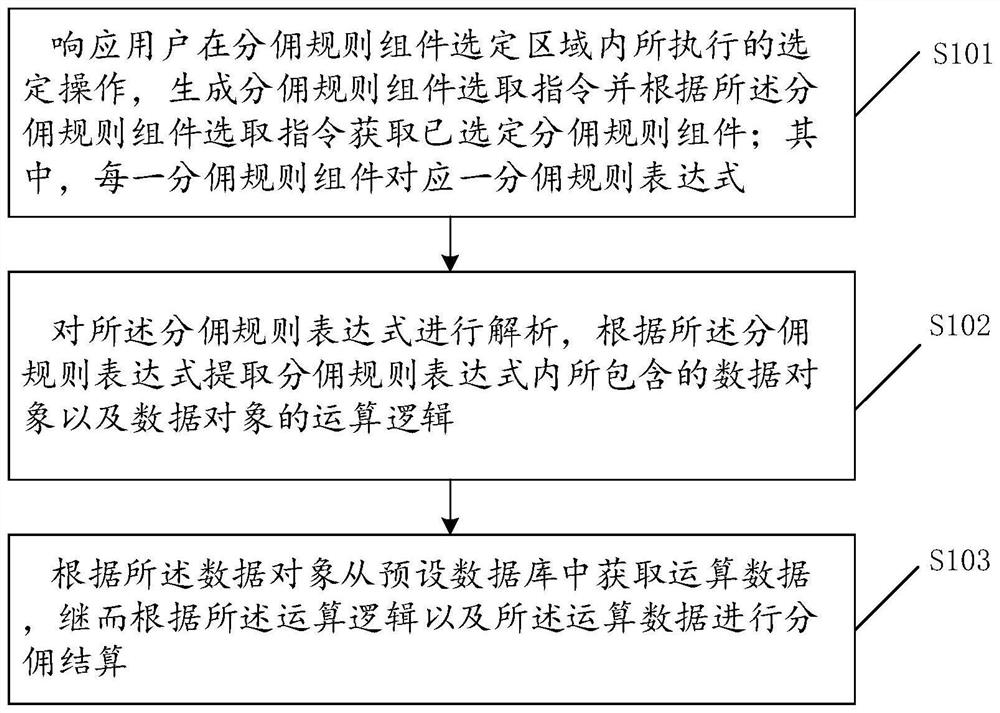

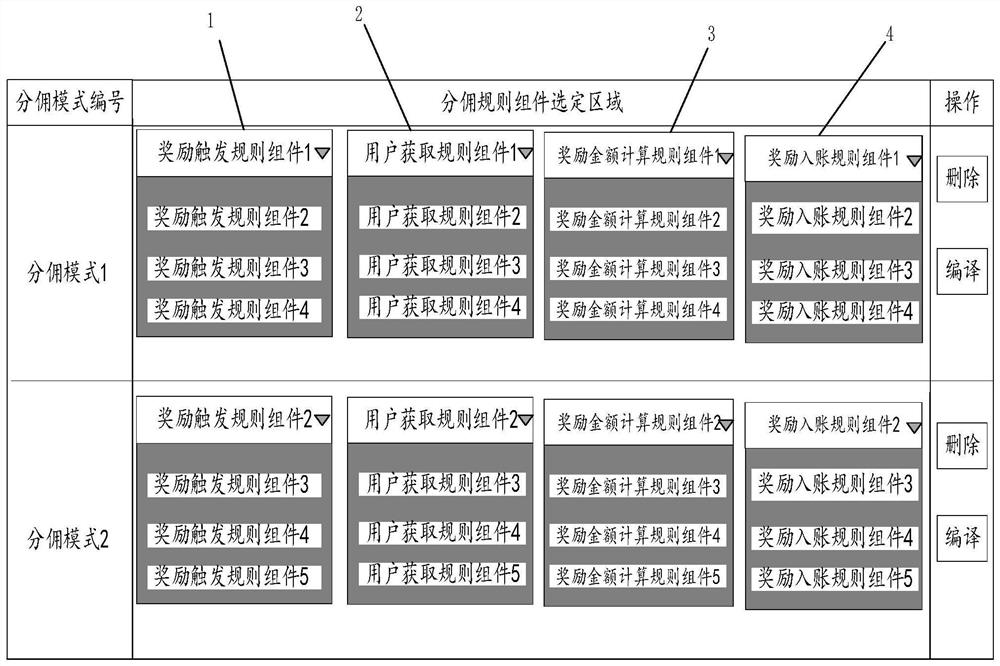

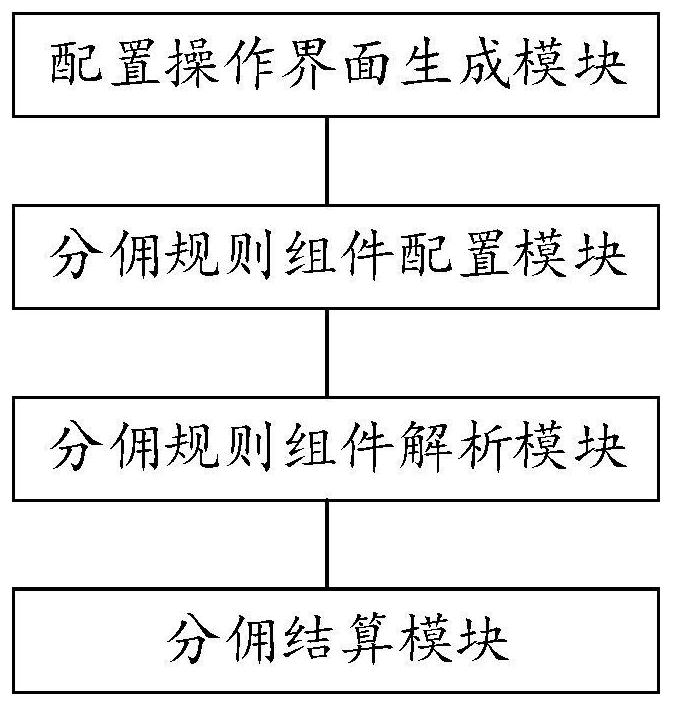

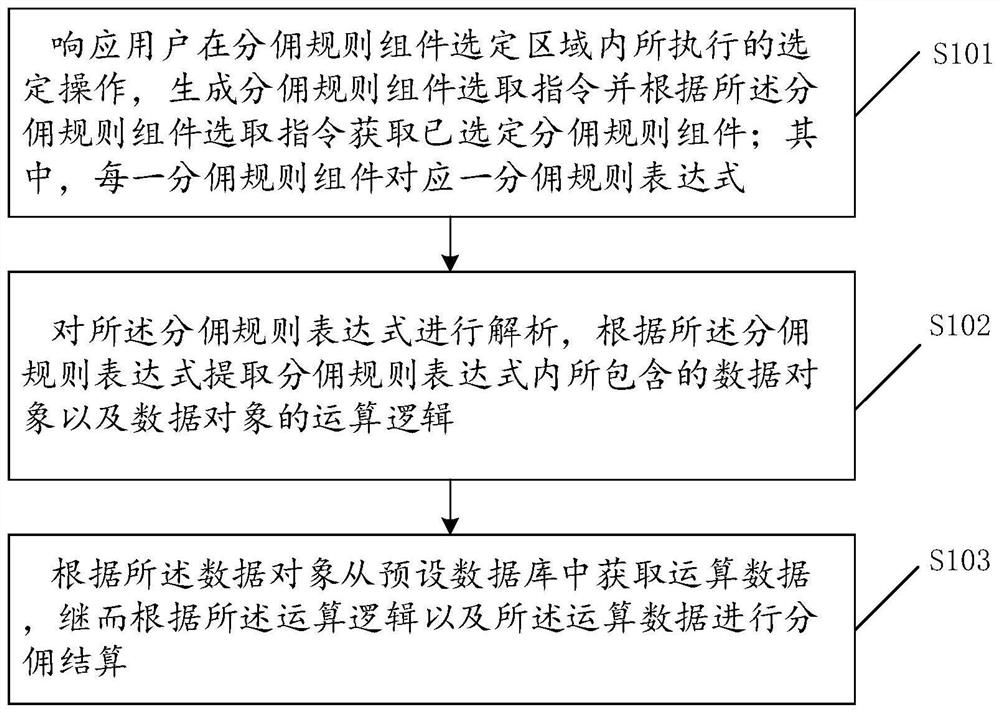

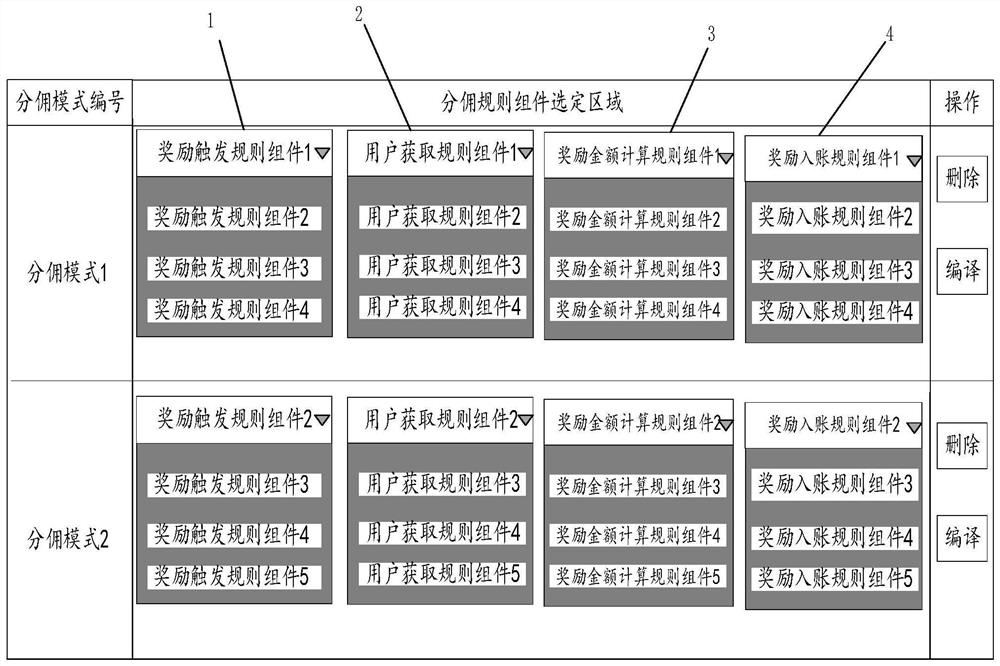

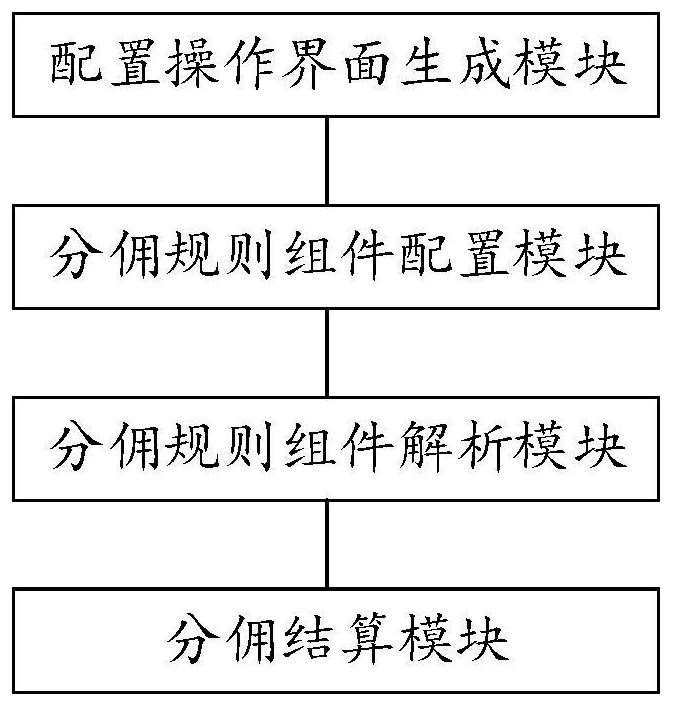

A Configurable Commission Settlement Method, Device, and Computer-Readable Storage Medium

ActiveCN113391800BQuick buildReduce the amount of programmingDiscounts/incentivesVisual/graphical programmingSoftware engineeringDatabase

The invention discloses a configurable commission settlement method, device and computer-readable storage medium. The method includes: generating a commission rule component in response to a selected operation performed by a user in a selected region of the commission rule component Select the command and obtain the selected commission rule component according to the selection command of the commission rule component; wherein, each commission rule component corresponds to a commission rule expression; analyze the commission rule expression, according to the commission rule expression Extract the data objects contained in the commission rule expression and the operation logic of the data objects; obtain the operation data from the preset database according to the data objects, and then perform the commission settlement according to the operation logic and operation data. Development efficiency can be improved by implementing the present invention.

Owner:广州有信科技有限公司

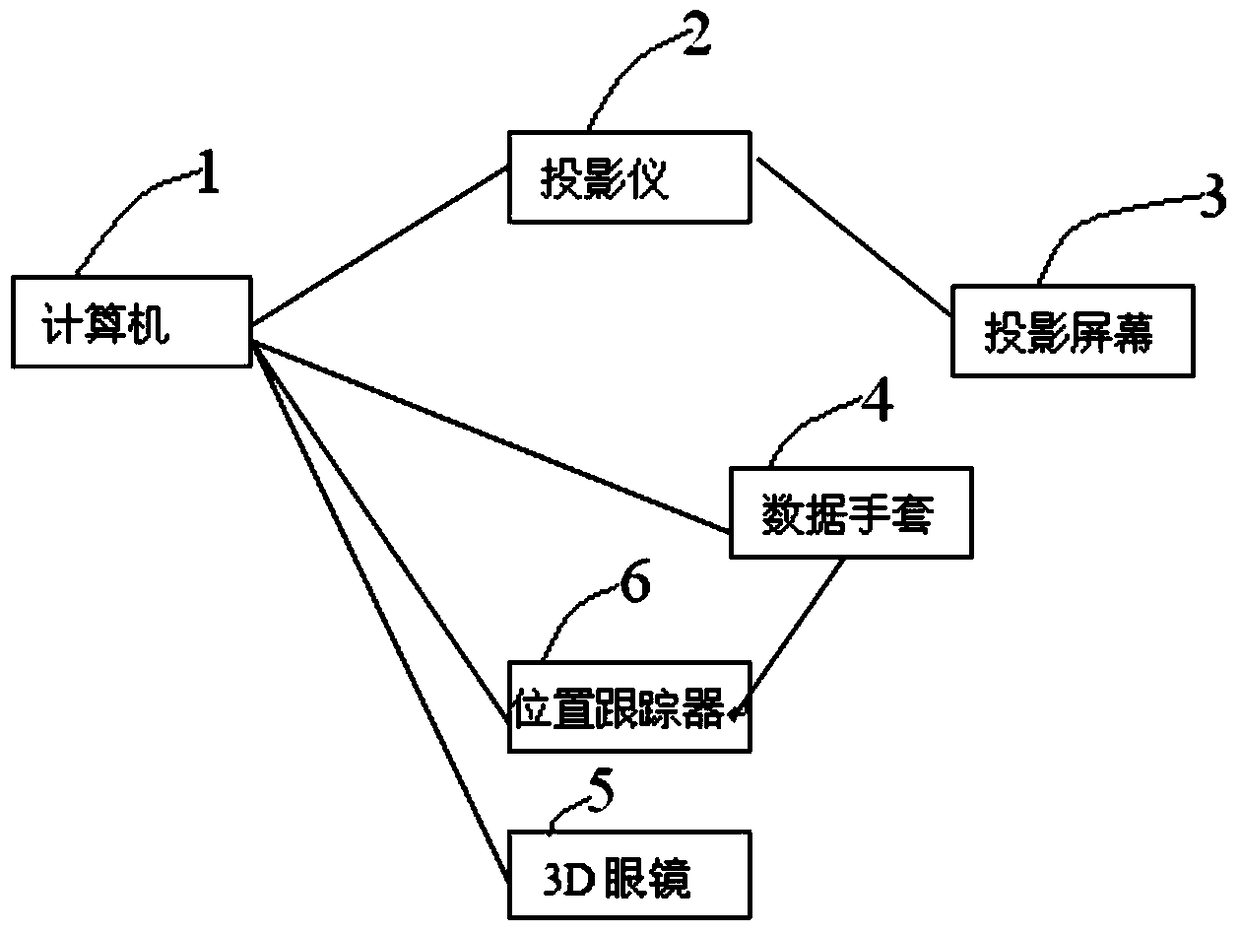

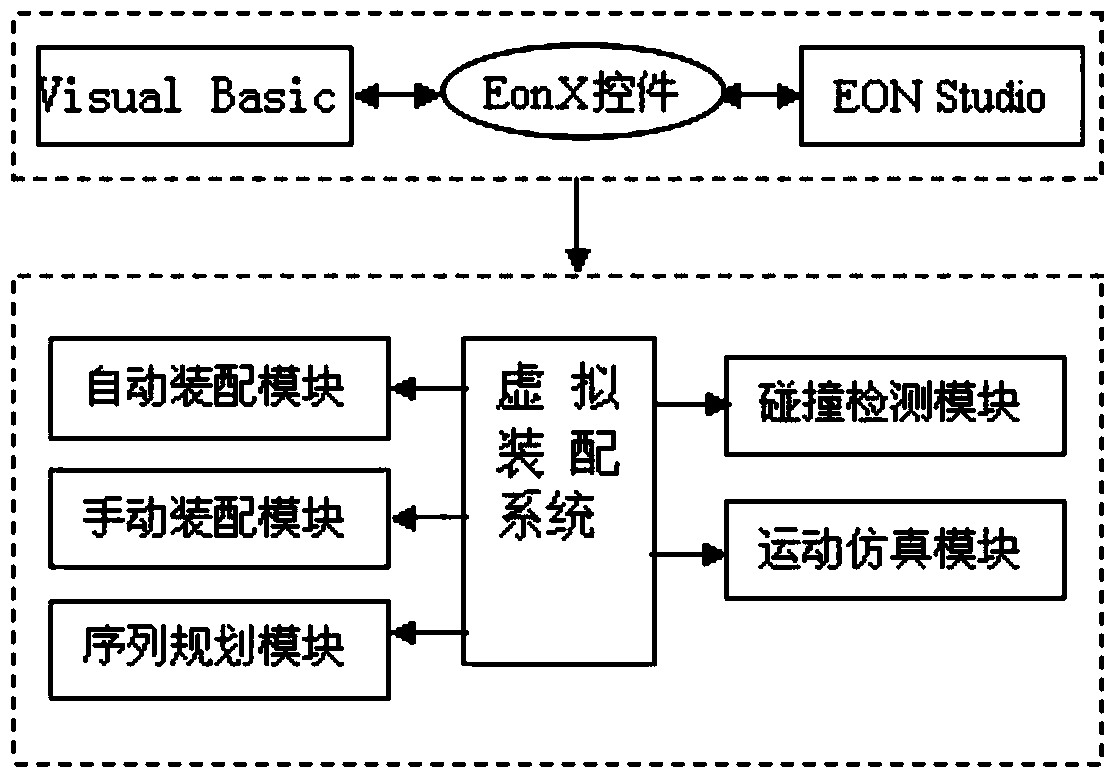

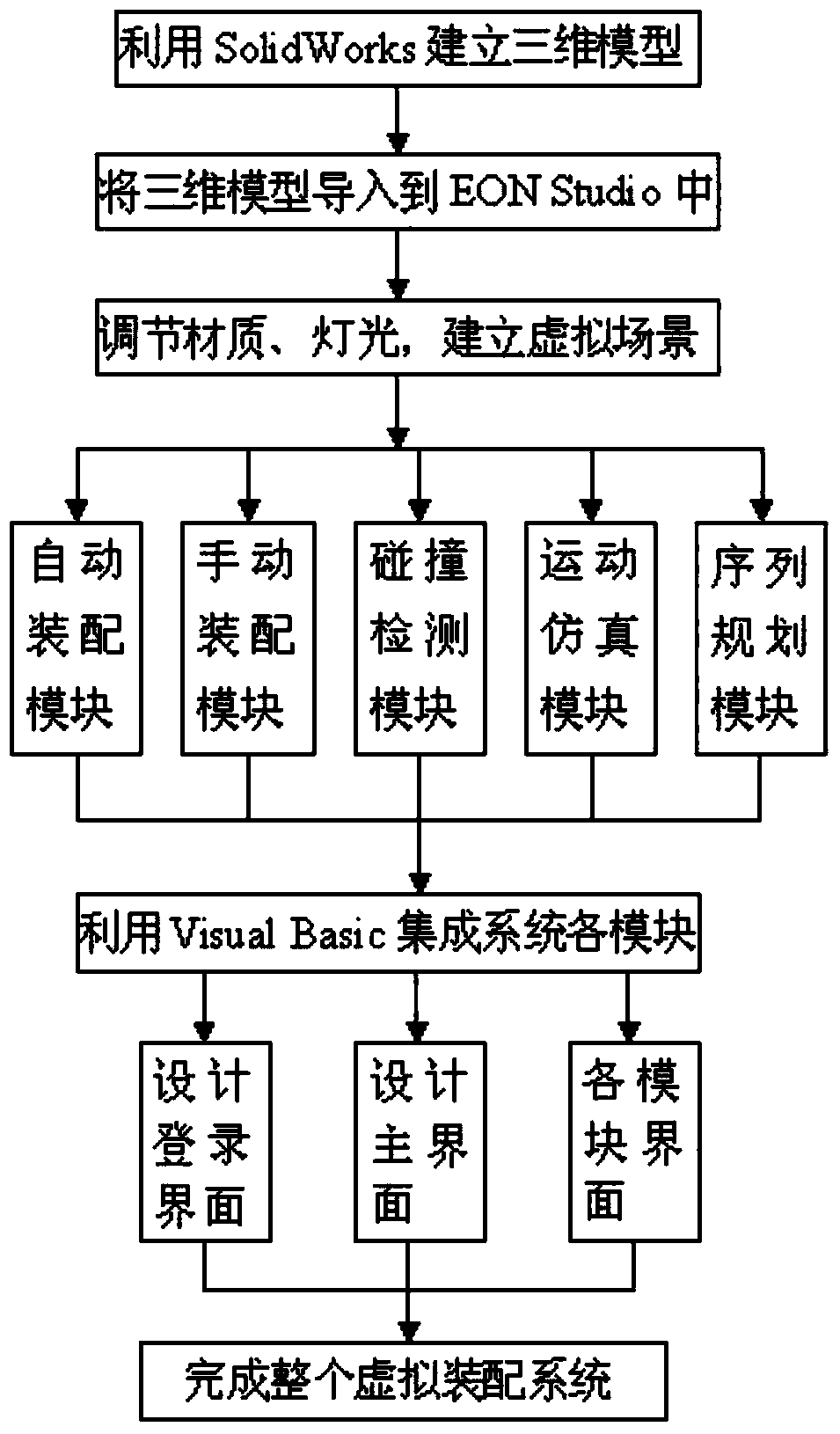

An auxiliary teaching system and teaching method based on eon

ActiveCN105278685BTheoretical knowledge deepeningImprove practical application abilityInput/output for user-computer interactionElectrical appliancesLocation trackingAnimation

The invention provides an assistant instructing system and an assistant instructing system method based on EON. A three-dimensional model of a mechanical product and a three-dimensional model of a virtual hand are established, up and down motions, left and right motions, front and back motions and rotation of the three-dimensional model of the virtual hand are achieved by a position tracker, a data glove grabs and releases the three-dimensional model of the mechanical product according to gesture change of the virtual hand, namely students master contents narrated by teachers by animation demonstration, and the students can form a brand new understanding on constituent parts, an internal structure, a disassembly process, an assembly process and the like of the mechanical product from a three-dimensional angle by means of 3D glasses through 3D demonstration parts. The assistant instructing system and the assistant instructing system method provided by the invention can be used for achieving the purposes of animation demonstration, manual disassembly, manual assembly, motion simulation and 3D demonstration, compensating the shortcomings in practical teaching of colleges and universities at present, and enabling the students to carry out manual operations when learning theoretical knowledge, which is helpful for the students to deepen the theoretical knowledge and improve the practical application ability.

Owner:湛江市佰圣信息科技有限公司

Method and device for realizing color gradient of three-primary-color LED lamp

ActiveCN105263247BReduce the amount of programmingReduce resource usageElectric light circuit arrangementGamutControl signal

The invention discloses a method of realizing tricolor LED lamp color gradual change. The method comprises steps: color coordinates (T_x, T_y) and (N_x, N_y) of a target and an initial color are acquired; Lx=|T_x-N_x| and Ly=|T_y-N_y| are calculated; according to a color coordinate value change rate delta, color coordinates (Mj_x, Mj_y) of the current color are calculated; Mj_x=(T_x-N_x)*delta / (L_x+L_y)+Mj-1_x, and Mj_y=(T_y- N_y)*delta / (L_x+L_y)+Mj-1_y; duty ratios of three paths of PWM control signals outputted to a tricolor LED lamp driving circuit are calculated; and steps of c and d are repeated until |T_x- Mj_x|< / =|(T_x-N_x)*delta / (L_x+L_y)|, and the duty ratios of the three paths of PWM control signals are calculated according to the color coordinates of the target color. The invention also discloses a device for realizing the above method. During the color gradual change process, the color does not exceed a color gamut range.

Owner:KEBODA TECH CO LTD

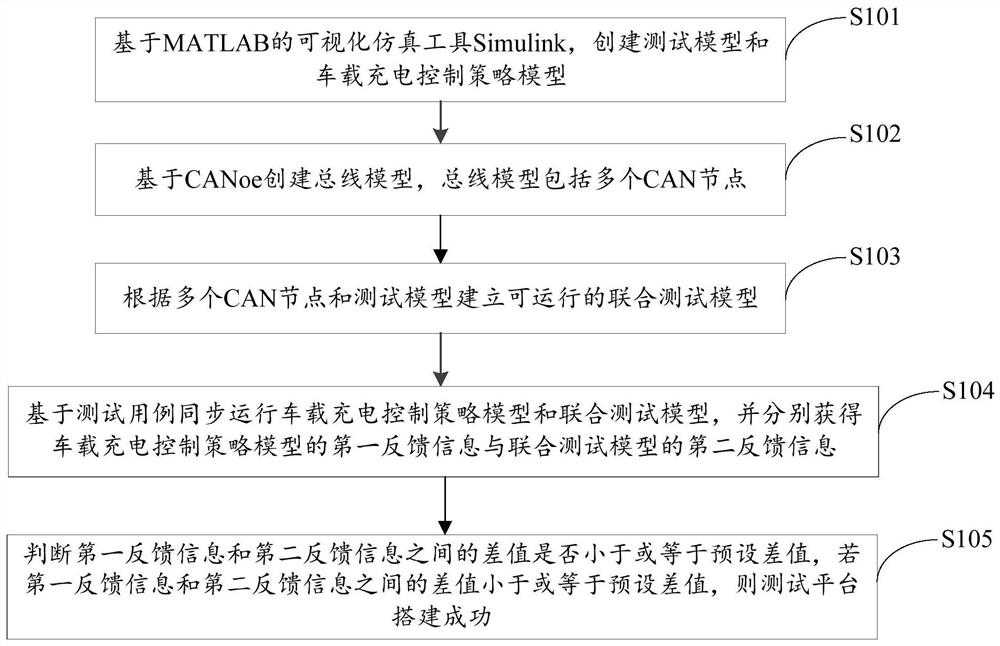

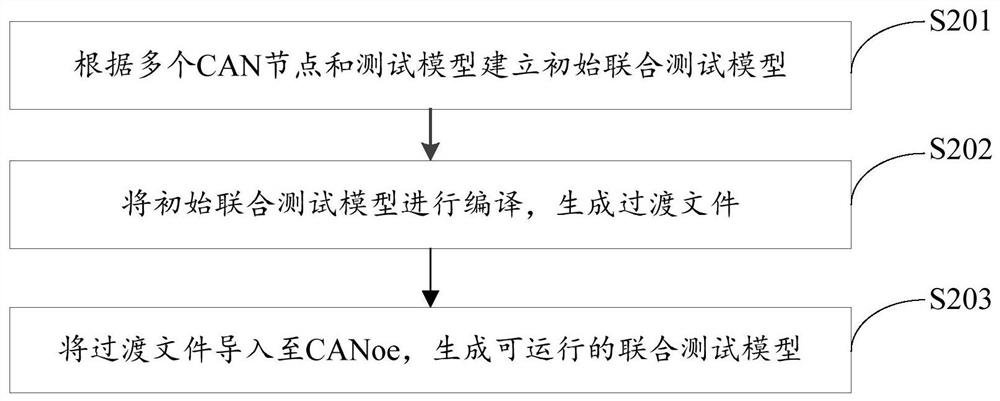

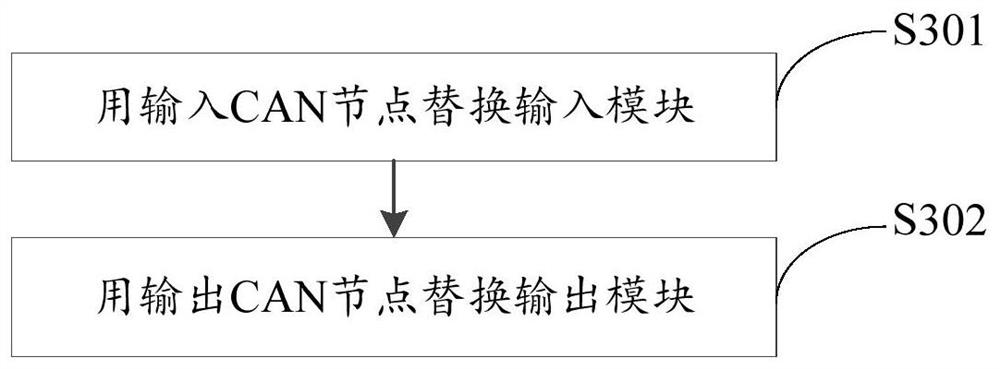

Electric vehicle electronic and electrical architecture test platform building method and device and readable storage medium

PendingCN113360370AReduce the amount of programmingImprove test efficiencySoftware testing/debuggingDesign optimisation/simulationIn vehicleElectric vehicle

The invention provides an electric vehicle electronic and electrical architecture test platform building method and device and a readable storage medium, and the method comprises the steps: building a test model and a vehicle-mounted charging control strategy model based on a visual simulation tool Simulink of MATLAB; creating a bus model based on the CANoe, wherein the bus model comprises a plurality of CAN nodes; establishing an operable joint test model according to the CAN nodes and the test model; synchronously operating the vehicle-mounted charging control strategy model and the joint test model based on the test case, and respectively obtaining first feedback information of the vehicle-mounted charging control strategy model and second feedback information of the joint test model; judging whether the difference value between the first feedback information and the second feedback information is smaller than or equal to a preset difference value or not, and if the difference value between the first feedback information and the second feedback information is smaller than or equal to the preset difference value, regarding that the test platform is successfully built. According to the method and device, the test model is created by using the Simulink with the capability of constructing the complex function model, so that the programming quantity of bus developers is reduced, and the test efficiency is improved.

Owner:WUHAN UNIV OF TECH

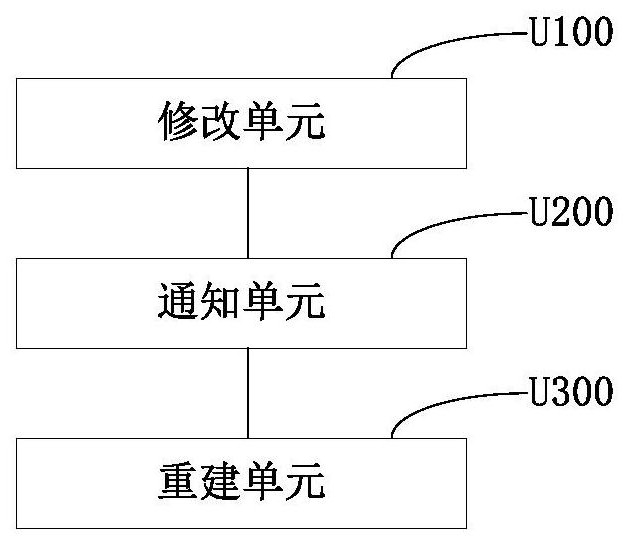

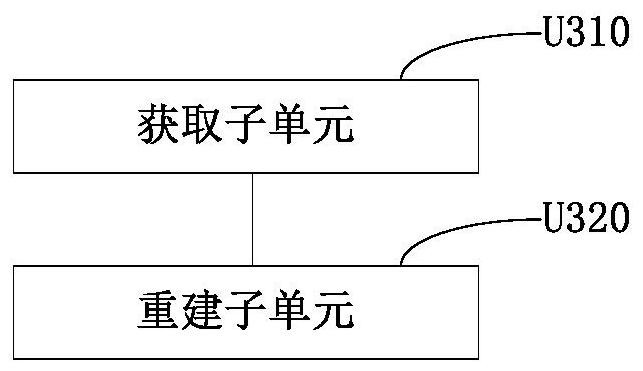

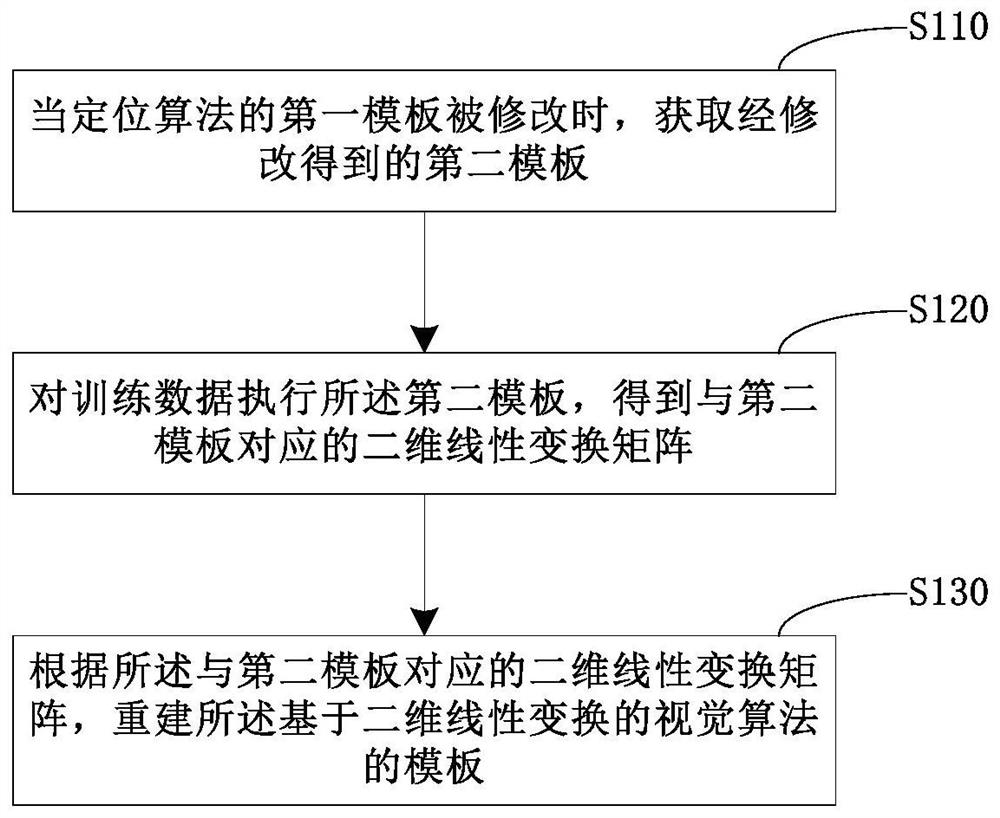

A template reconstruction device and method based on two-dimensional linear transformation

ActiveCN109509229BReduce the amount of programmingEasy to handleImage analysisComplex mathematical operationsVision algorithmsTheoretical computer science

The invention discloses a apparatus and method for template reconstruction based on two-dimensional linear transformation. Firstly, a modifying unit modifies a first template of a positioning algorithm to obtain a second template. Holding a second template for training data and outputting a two-dimensional linear transformation matrix corresponding to the second template; Secondly, when the firsttemplate of the positioning algorithm is modified, the notification unit sends a reconstruction instruction to the reconstruction unit. The reconstruction unit reconstructs the template of the visionalgorithm based on the two-dimensional linear transformation according to the new two-dimensional linear transformation matrix. By adopting the device and the method of the present application, templates of other vision algorithms based on two-dimensional linear transformation are passively modified according to the templates of the modified positioning algorithm, thereby reducing the programmingamount and the data processing amount of software in the system and reducing the maintenance cost of the system. At the same time, for the distributed visual software which can be debugged independently, it avoids the abnormal situation that only the location algorithm is modified but not the corresponding other visual algorithms.

Owner:BEIJING LUSTER LIGHTTECH

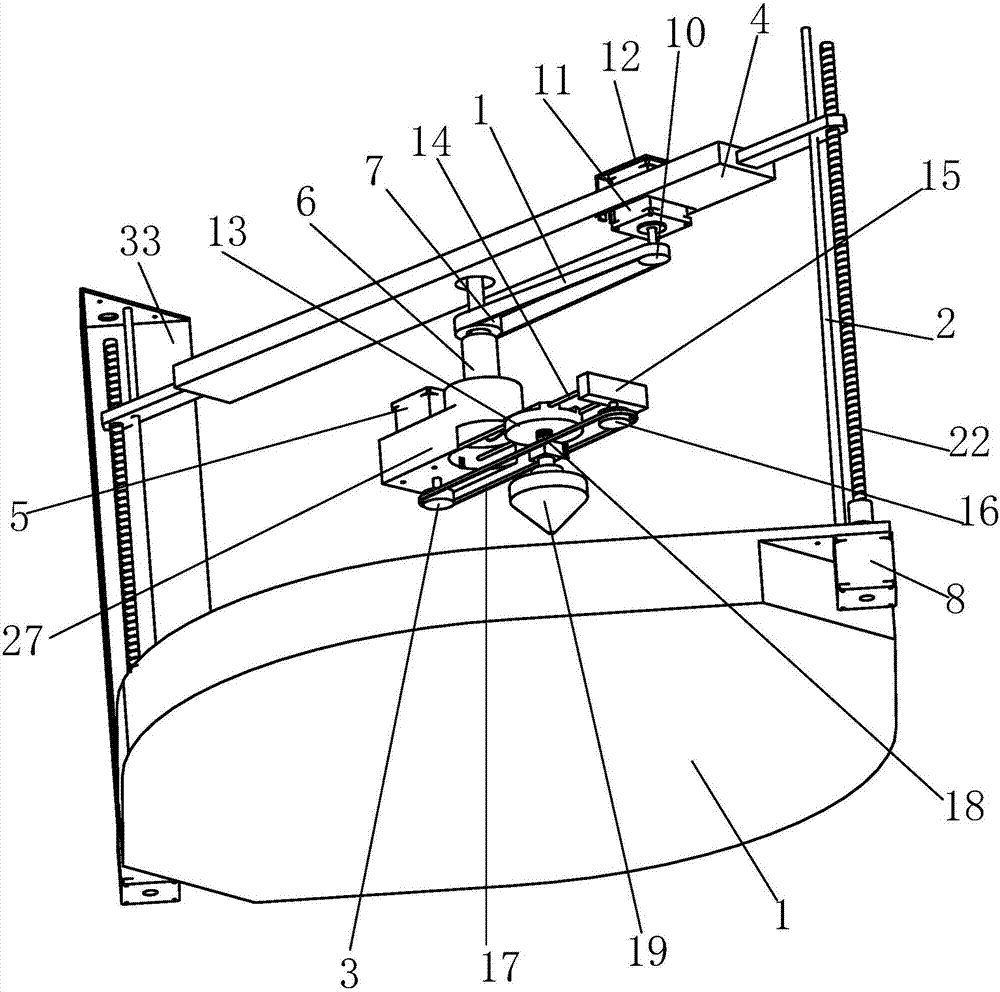

A beam type polar coordinate 3D printer

The invention relates to a cross beam type polar coordinate 3D printer. The cross beam type polar coordinate 3D printer comprises a base, the left side and the right side of the base are each fixedly provided with a vertical shaft, and the left side and the right side of the base are each fixedly provided with a side motor; shafts of the side motors are each provided with a bolt rod through a coupler; the bolt rods are parallel to the vertical shafts on the corresponding sides, and a cross beam is jointly mounted on the upper portions of the vertical shafts and the upper portions of the bolt rods; a square through hole is formed in the left side of the cross beam, and a center hole is formed in the middle side of the cross beam; a bending part is mounted in the square through hole, and a first motor is mounted on the bending part; an angle driving wheel is connected to a shaft of the first motor, and a rotating shaft is mounted in the center hole; and an angle driven wheel is mounted on the lower portion of the rotating shaft in a key connection manner, and a first conveying belt is connected between the angle driving wheel and the angle driven wheel. Drawing of a complex curve arc is achieved, the printer has the beneficial effects that the printing speed is high, the precision of the size of a printed curve is high, and the surface quality is good, the automation degree is high, and the production efficiency can be greatly improved.

Owner:WUHU HIT ROBOT TECH RES INST

Configurable commission distribution settlement method and device and computer readable storage medium

ActiveCN113391800AQuick buildReduce the amount of programmingDiscounts/incentivesVisual/graphical programmingData miningDatabase

The invention discloses a configurable commission distribution settlement method and device and a computer readable storage medium, and the method comprises the steps: responding to a selection operation executed by a user in a commission distribution rule component selection region, generating a commission distribution rule component selection instruction, and obtaining a selected commission distribution rule component according to the commission distribution rule component selection instruction, wherein each commission distribution rule component corresponds to one commission distribution rule expression; analyzing the commission distribution rule expression, and extracting data objects contained in the commission distribution rule expression and arithmetic logic of the data objects according to the commission distribution rule expression; and obtaining operation data from a preset database according to the data object, and then carrying out commission distribution settlement according to the operation logic and the operation data. By implementing the method, the development efficiency can be improved.

Owner:广州有信科技有限公司

A Virtual Assembly System Based on Visual Basic and EON Studio

ActiveCN105138315BEasy to masterReduce the amount of programmingSoftware designSpecial data processing applicationsVisual BasicSequence planning

Owner:SHAANXI UNIV OF SCI & TECH

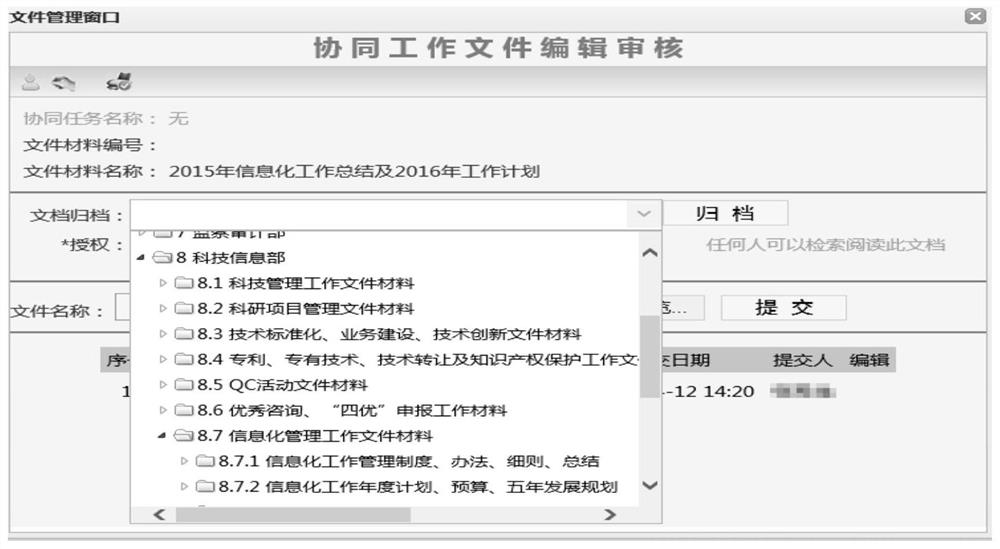

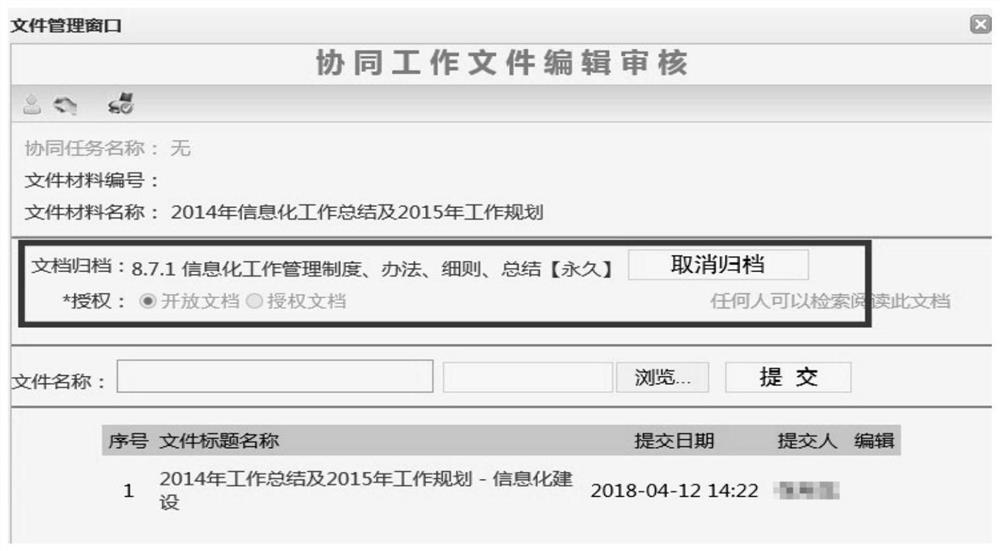

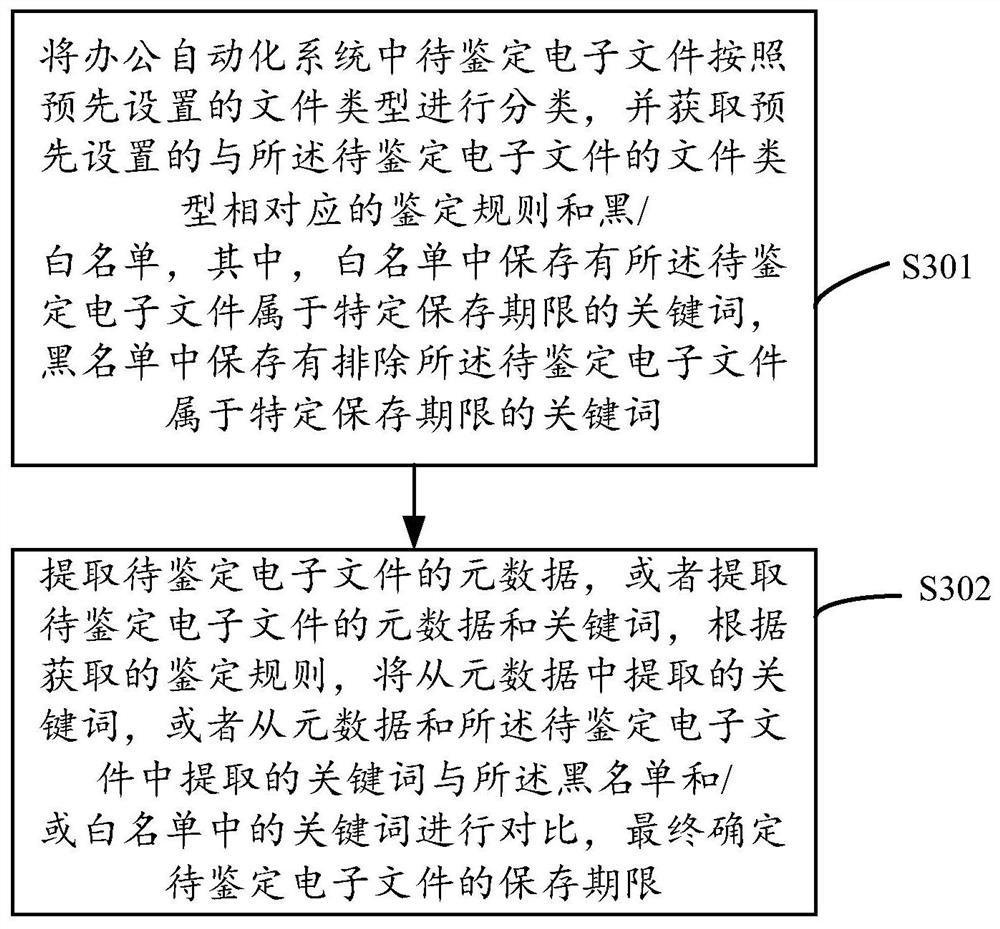

File identification method, system and device based on black and white lists

InactiveCN111858499AImprove accuracyEasy to implementFile metadata searchingTransmissionEngineeringWhitelist

The invention discloses an archive identification method, system and device based on a black list and a white list. The method comprises the following steps: classifying electronic files to be authenticated in an office automation system according to a preset file type, and obtaining the identification rule and the black / white list which are set in advance and correspond to the file type of the electronic file to be identified, wherein the keywords of the electronic file to be identified belonging to a specific storage life are stored in the white list, and the keywords of the electronic fileto be identified excluding the electronic file to be identified belonging to the specific storage life are stored in the black list; extracting metadata of the electronic file to be authenticated; orextracting metadata and keywords of the to-be-authenticated electronic file, comparing the keywords extracted from the metadata or the keywords extracted from the metadata and the to-be-authenticatedelectronic file with the keywords in the black list and / or the white list according to the obtained authentication rule, and finally determining the storage life of the to-be-authenticated electronicfile. According to the invention, the accuracy of archived electronic file identification is further improved.

Owner:王洋

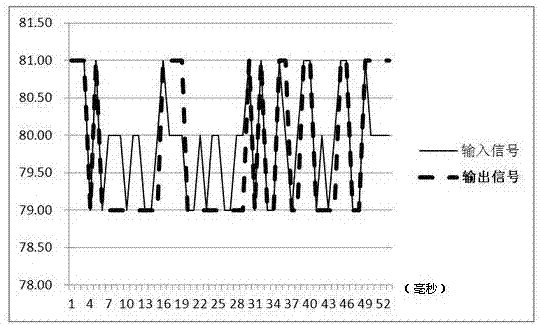

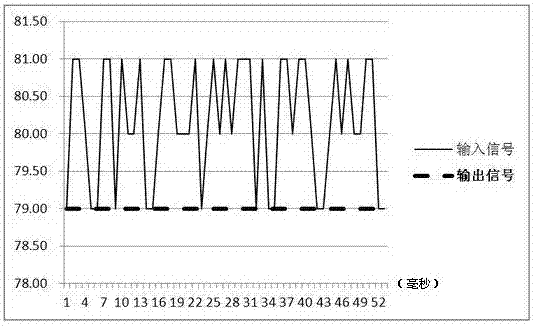

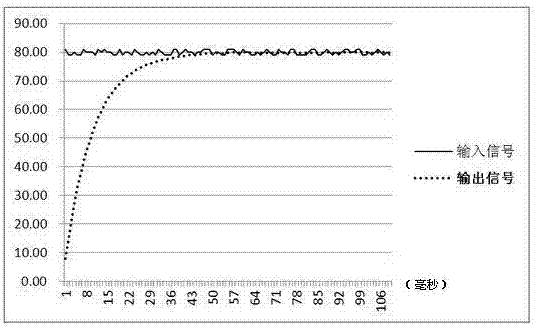

A pwm signal filtering method for automotive lighting system

ActiveCN104853490BImprove securityHigh precisionElectric light circuit arrangementEngineeringLighting system

Disclosed in the invention is a PWM signal filtering method for an automotive illumination system. The automotive illumination system comprises a controller. The controller compares a quantized value AD_in of an input PWM signal sampled currently with a quantized value AD_out1 of an output PWM signal filtered last time. If a relation that | AD_in- AD_out1| is less than or equal to Threshold 1 is met , a current output PWM signal quantized value AD_out is equal to AD_out1; if AD_in minus AD_out1 is larger than Threshold 1, a current output PWM signal quantized value AD_out is equal to a value of AD_in minus Threshold 1. If a relation that AD_out1 minus AD_in is larger than Threshold2, a current output PWM signal quantized value AD_out is equal to a value of AD_in plus Threshold2. The Threshold 1 and the Threshold2 are set threshold values. According to the invention, after filtering, the PWM signal outputted by the controller has high precision and high stability.

Owner:KEBODA TECH CO LTD

A Machining Method of Numerical Control Machine Tool to Eliminate Height Position Difference

ActiveCN105302072BImprove CNC efficiencyReduce waiting timeProgramme controlComputer controlCrankcasePoint tracking

A numerical control machine tool processing method capable of eliminating height position difference belongs to the technical field of numerical control processing. According to the method, by determining a sampling point of which the A-axis angle changes in the process path of a cutter, extracting the A-axis angle value corresponding to the point, obtaining a new processing coordinate system zero position according to the extracted A-axis angle value and an original processing coordinate system zero position and translating the original processing coordinate system zero to the new processing coordinate system zero position, the process path of the machine tool cutter is always related to the coordinate zero of parts only. By adopting the method, the problem that the machine tool utilization rate is low and the height of a workbench and the height of a clamp must be taken into consideration during programming and processing as the old-version Siemens numerical control system machine tool has no cutter point tracking function is solved, and the amount of programming and the management risk are reduced. The method has been popularized and applied in exterior profile processing of complex crankcase parts. The numerical control efficiency of the numerical control machine tool is improved greatly, the waiting time for the machine tool is reduced, and arrangement of workshop production tasks is facilitated.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com