Multiple emission point exhaust gas volume matching collection and processing method

A processing method and technology of discharge point, applied in cleaning methods and utensils, chemical instruments and methods, and smoke and dust removal, etc., can solve the problems of cumbersome system and high energy consumption, reduce the amount of program design, reduce the consumption of electricity and natural gas, and simplify The effect of operating mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

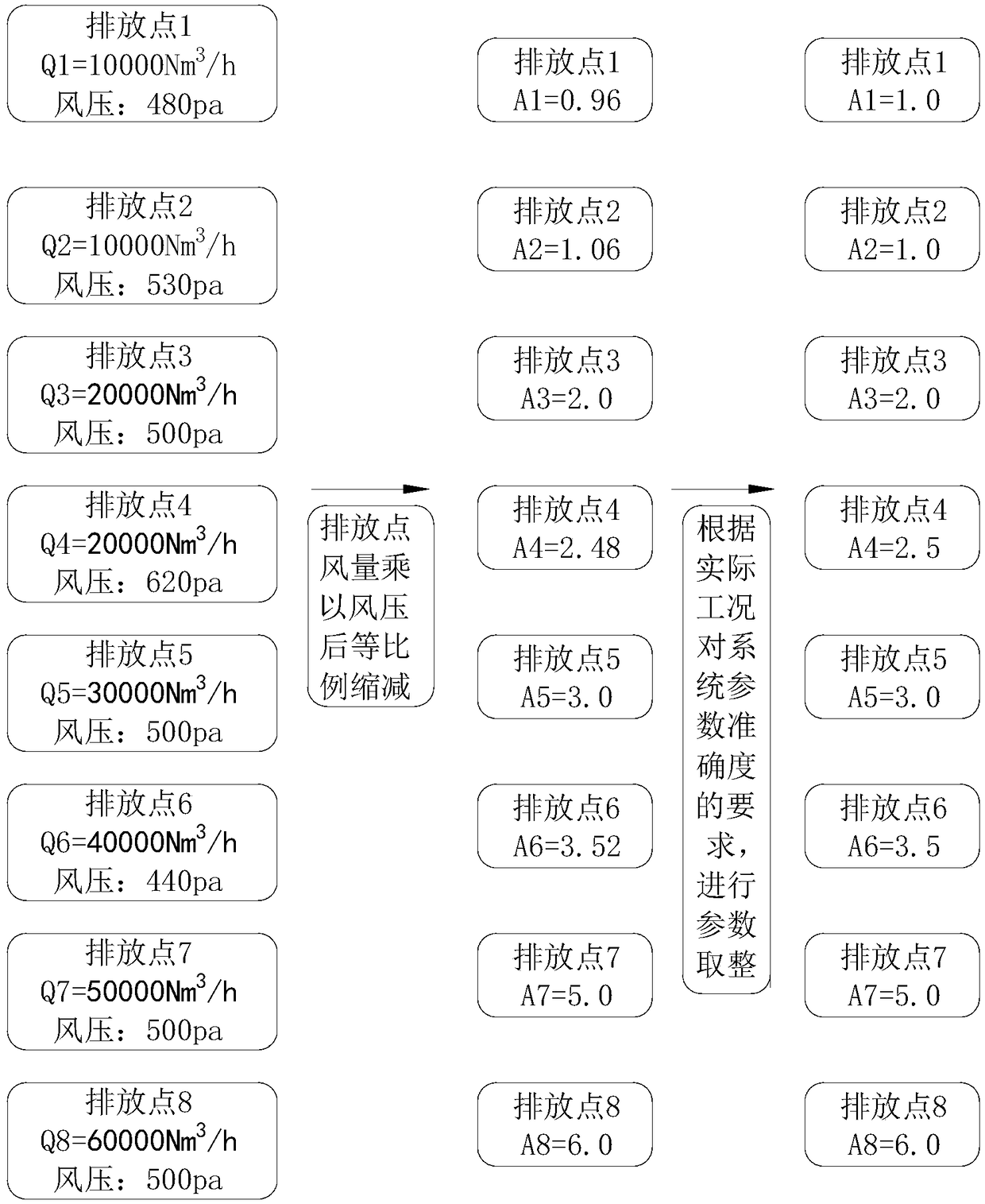

[0030] This embodiment has 8 discharge points.

[0031] first step, such as figure 1 As shown, the air volume and wind pressure at each discharge point are measured, usually an anemometer can be used directly. In this embodiment, the measured air volume and wind pressure at each discharge point are as follows:

[0032]

Air volume (Q)

wind pressure (p)

Emission point 1

10000Nm 3 / h

480Pa

Emission point 2

10000Nm 3 / h

530Pa

Emission point 3

20000Nm 3 / h

500Pa

Emission point 4

20000Nm 3 / h

620Pa

Emission point 5

30000Nm 3 / h

500Pa

Emission point 6

40000Nm 3 / h

440Pa

Emission point 7

50000Nm 3 / h

500Pa

Emission point 8

60000Nm 3 / h

500Pa

[0033] The above-mentioned air volume and air pressure are fixed values during the working process, and generally do not change. The reason why the air volume and wind pressure are measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com