A Machining Method of Numerical Control Machine Tool to Eliminate Height Position Difference

A technology of numerical control machine tools and processing methods, applied in the direction of program control, computer control, general control system, etc., can solve the problems of not supporting advanced processing modes, unable to solidify numerical control programs, time-consuming and labor-intensive, etc., to reduce the number of programming and manage risks, Facilitate the arrangement of production tasks and improve the efficiency of CNC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] An embodiment of the present invention will be further described below in conjunction with the drawings.

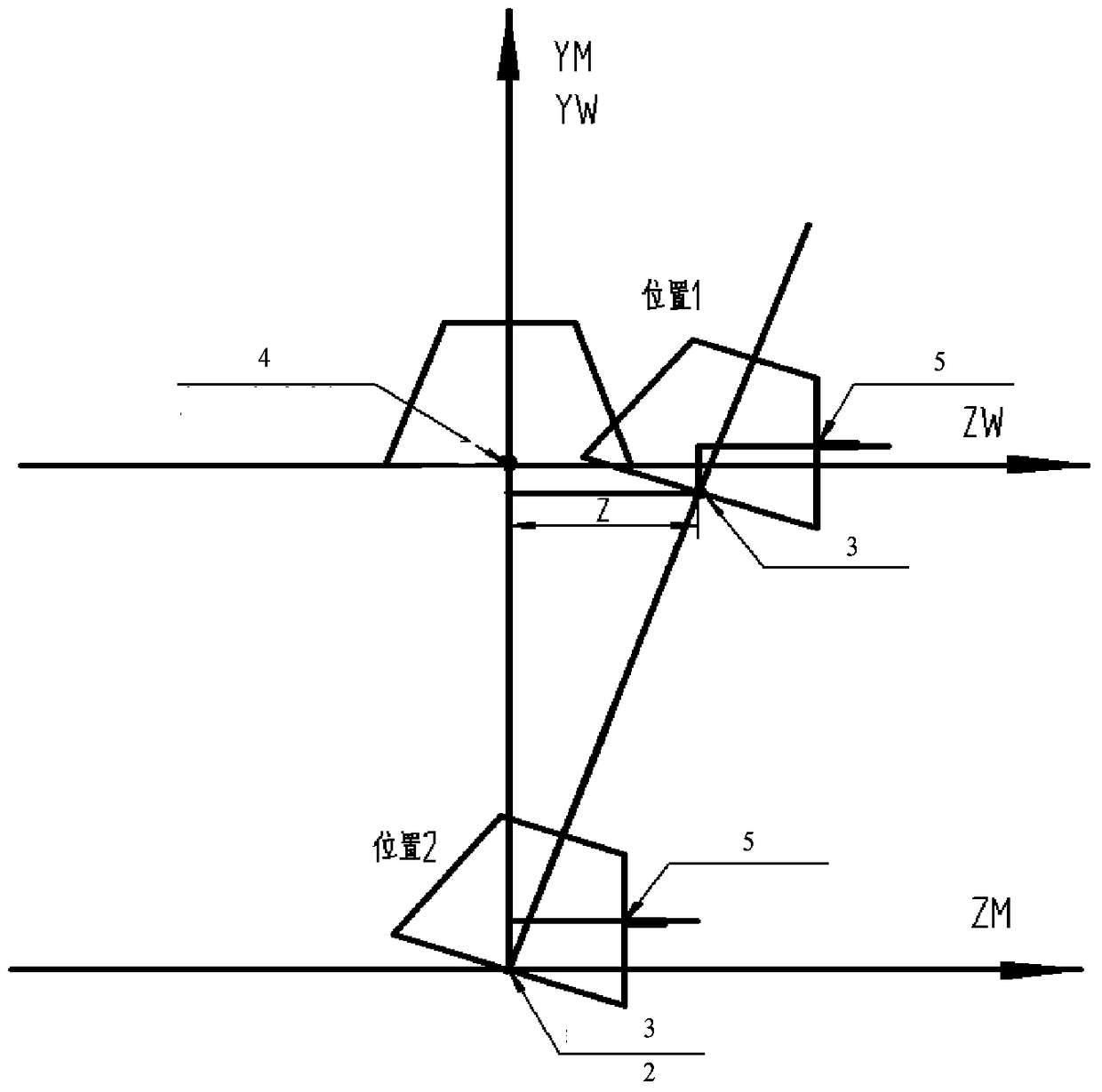

[0018] In the embodiment of the present invention, such as figure 1 As shown, after the part rotates the same angle at position 1 (flip origin) and arbitrary position 2, the tool position in the machining path is the same relative to the part's programmed coordinate zero point, which is only different from the origin of the machining coordinate system G54. The difference between them can realize that the CNC program has nothing to do with the fixture and the turning height; in the figure, 2 represents the turning point, 3 represents the programming coordinate zero point, 4 represents the processing coordinate system G54, and 5 represents the tool processing position;

[0019] In the embodiment of the present invention, the numerical control machine tool processing method that eliminates the difference in height position is used to configure a Siemens numerical control sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com