Compound plastic forming equipment, die transposition mechanism thereof and positioning method for die transposition mechanism

A plastic forming and mold technology, applied in other manufacturing equipment/tools, forming tools, metal processing equipment, etc., can solve the problems of unstable quality, affecting product accuracy, unreliability, etc., to improve manufacturing accuracy and product quality, improve The effect of product accuracy and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

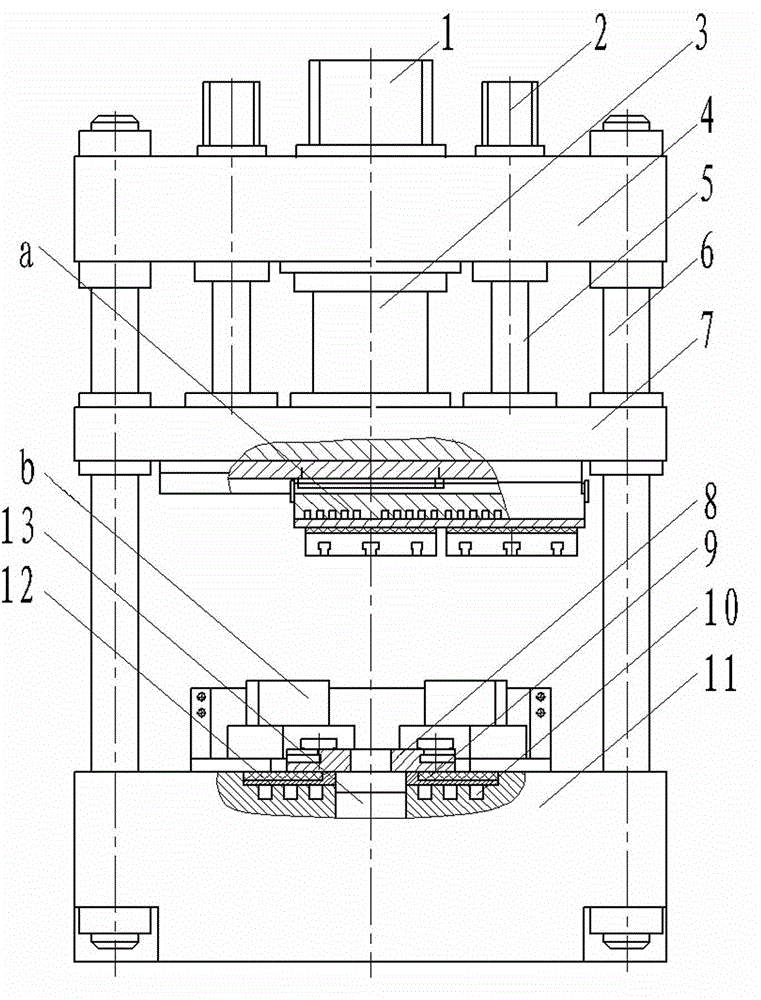

[0033] An example of composite plastic forming equipment in the present invention is Figure 1~Figure 11 As shown, it is a compound extrusion forming equipment for automobile hub, which adopts the basic frame of common hydroforming equipment, such as figure 1 As shown, its main structure includes a column 6, an upper beam 4 fixedly arranged on the upper and lower ends of the column 6, a lower beam 11 and a movable beam 7 slidingly matched with the column 6, and the upper beam 4 is fixedly provided with a main cylinder 1 and an auxiliary cylinder. 2. Two auxiliary cylinders 2 are arranged symmetrically on both sides of the main cylinder 1 in the radial direction. The main cylinder piston 3 of the main cylinder 1 and the auxiliary cylinder piston 5 of the auxiliary cylinder 2 are both connected to the movable beam 7 for driving the movable beam 7 up and down. sports.

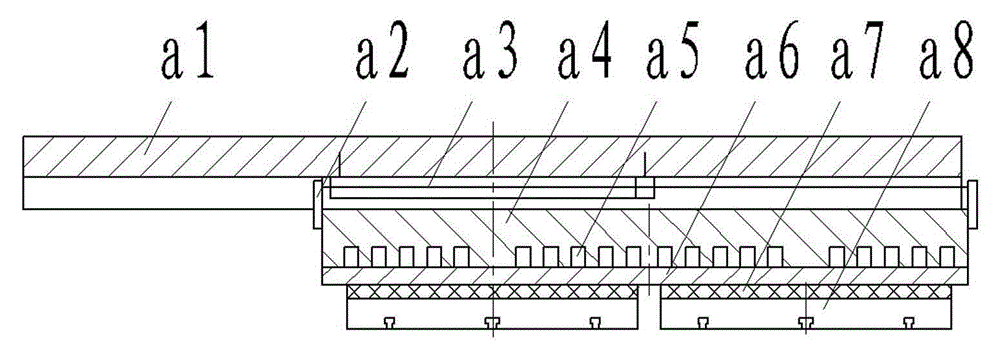

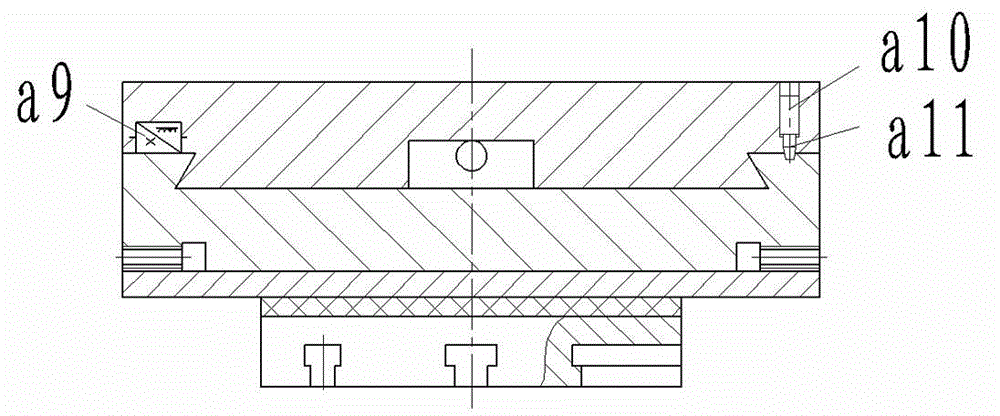

[0034] An upper mold assembly and a lower mold assembly are respectively arranged on the movable beam 7 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com