Method for preparing organic net membrane

A technology of organic omentum and inorganic membrane, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problem of less application of surface interface, etc., and achieve the effect of simple and easy experimental operation, optional materials and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation of embodiment 1, tetraphenylporphyrin (TClPP) omentum

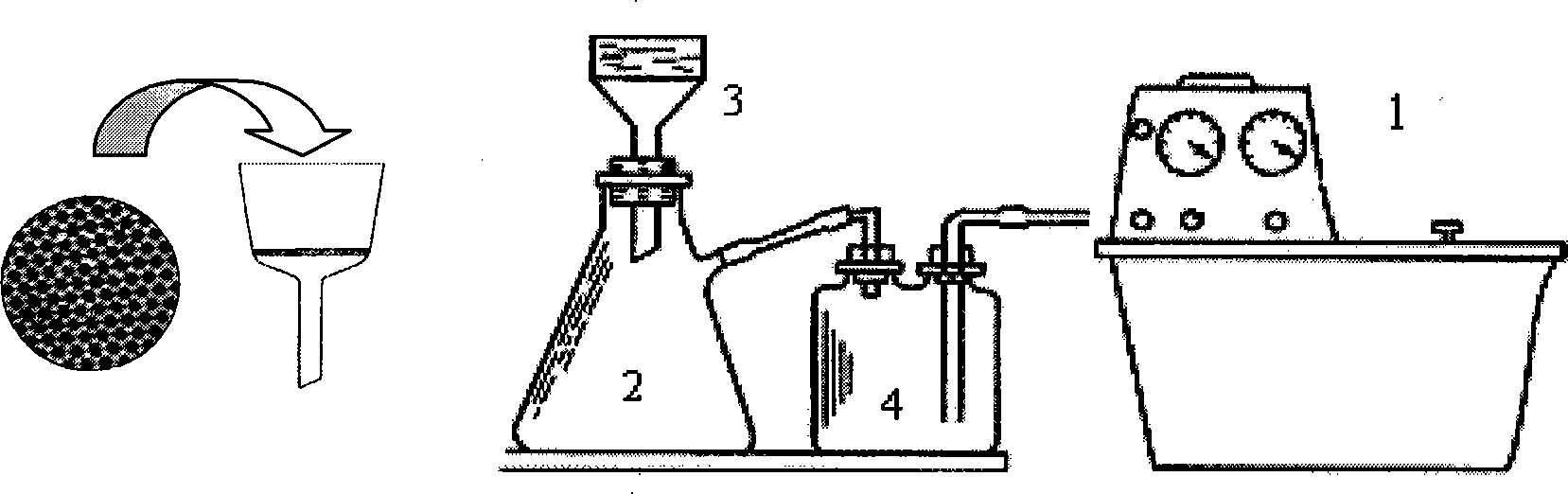

[0035] A porous alumina template (whatman) with a pore size of 200nm after hydrophilic and hydrophobic treatment was pasted horizontally in a sand funnel, and the sand funnel was externally connected to a suction filter bottle. Add a saturated concentration of tetraphenylporphyrin solution (solvent: dichloromethane) dropwise to the template, stop every time the template is soaked, continue to drop after the solvent evaporates, and repeat for 20 cycles. During the dropwise addition, suction filtration under reduced pressure was maintained at a constant pressure, and the pressure was 0.04 MPa. After the end, wait for the solvent to fully volatilize, take out the template adsorbed with tetraphenylporphyrin, and dry it under nitrogen to obtain a tetraphenylporphyrin omentum covering the surface of the porous alumina template.

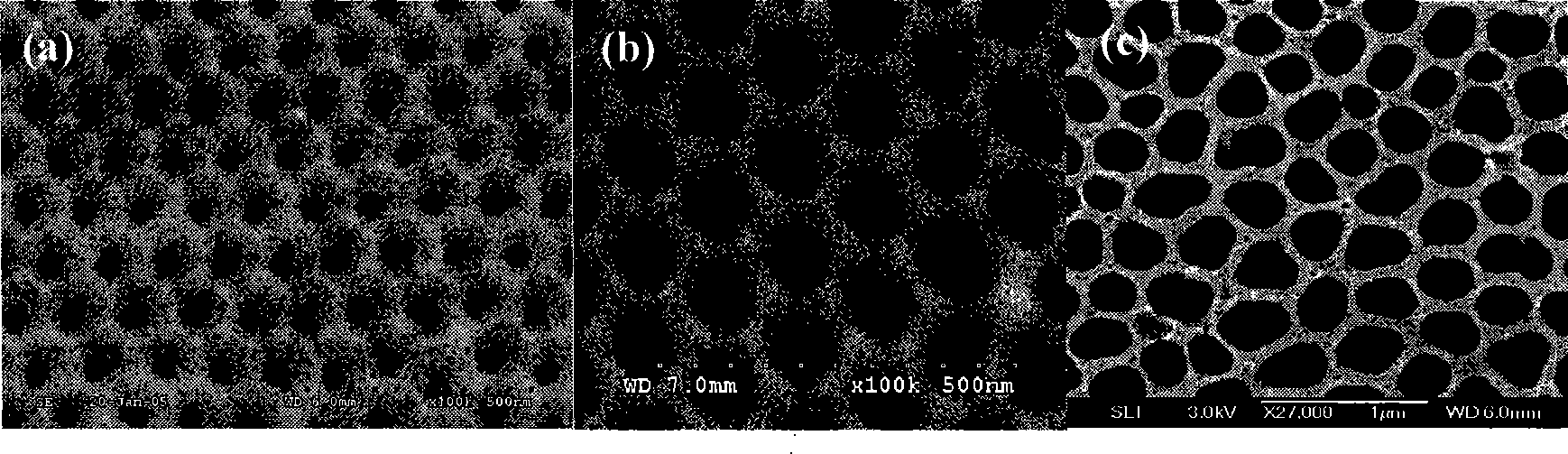

[0036] Electron microscopy was performed after annealing in nitrogen atmosp...

Embodiment 2

[0038] Embodiment 2, preparation tetraphenylporphyrin omentum

[0039] The porous alumina template with a pore size of 50nm after hydrophilic and hydrophobic treatment is horizontally pasted in the sand funnel, and the sand funnel is connected with a suction filter. On the template, repeatedly drop the concentration of 10 -3 M tetraphenylporphyrin solution (solvent: dichloromethane), with an interval of 2 minutes, repeated 10 cycles. During the dropwise addition, suction filtration under reduced pressure was maintained at a constant pressure, and the pressure used was 0.03 MPa. After the end, wait for the solvent to fully volatilize, take out the template adsorbed with tetraphenylporphyrin, and obtain a tetraphenylporphyrin omentum covered on the porous alumina template.

[0040] Electron microscopy was performed after annealing in nitrogen atmosphere.

[0041] Scanning electron microscope images of the obtained samples are shown in Figure 4 . It can be seen from the fig...

Embodiment 3

[0042] Embodiment 3, preparation tetraphenylporphyrin omentum

[0043] A porous alumina template with a pore size of 100nm after hydrophilic and hydrophobic treatment is pasted horizontally in the sand funnel, and the sand funnel is externally connected to a suction filter. On the template, repeatedly drop the concentration of 10 -3 M tetraphenylporphyrin solution (solvent: dichloromethane), with an interval of 2 minutes, repeated 10 cycles. During the dropwise addition, suction filtration under reduced pressure was maintained at a constant pressure, and the pressure used was 0.03 MPa. After the completion, wait for the solvent to fully volatilize, take out the template adsorbed with tetraphenylporphyrin, and obtain a tetraphenylporphyrin omentum covering the surface of the porous alumina template.

[0044] Electron microscopy was performed after annealing in nitrogen atmosphere.

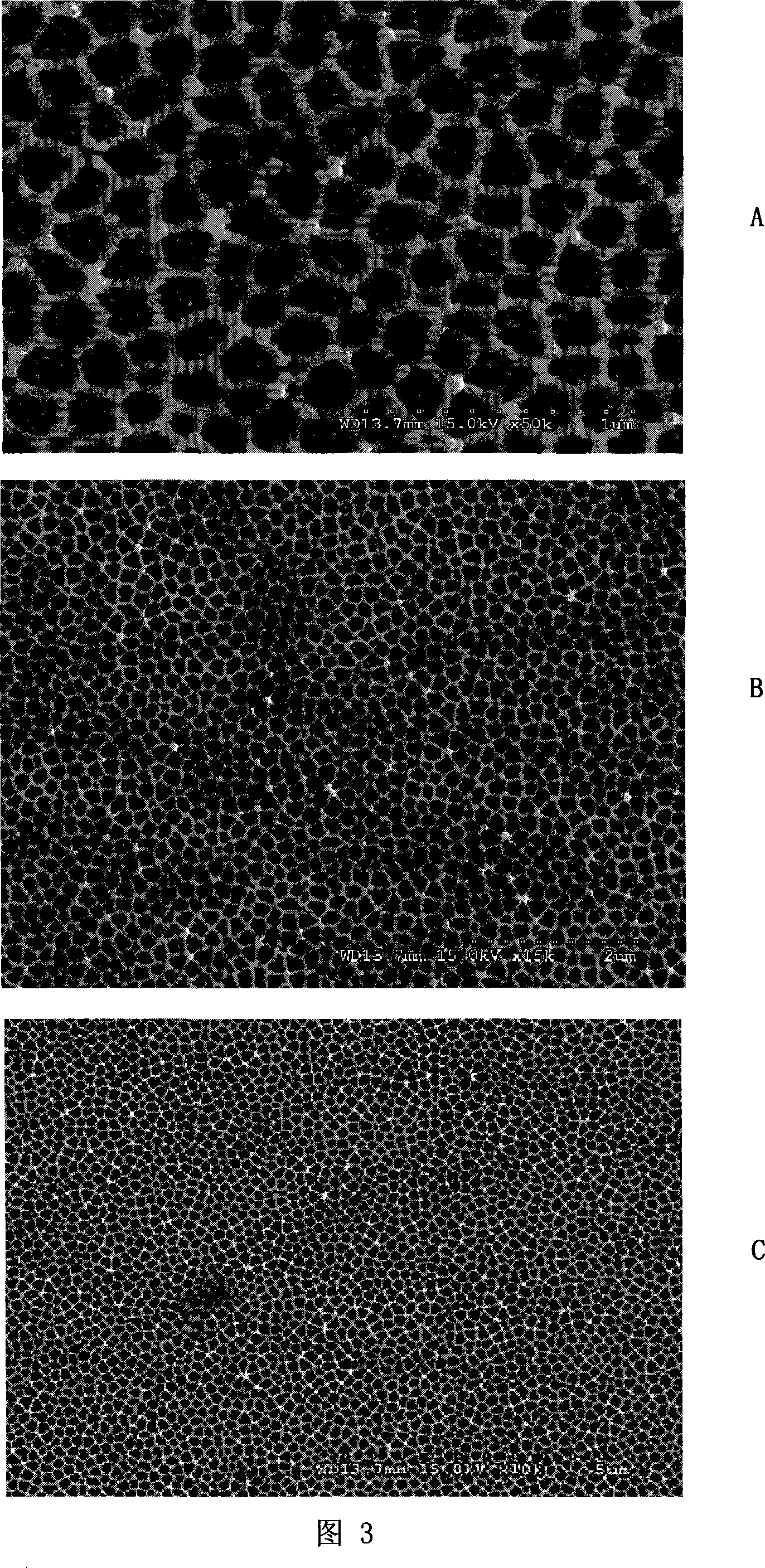

[0045] Scanning electron microscope images of the obtained samples are shown in Figure 5 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com