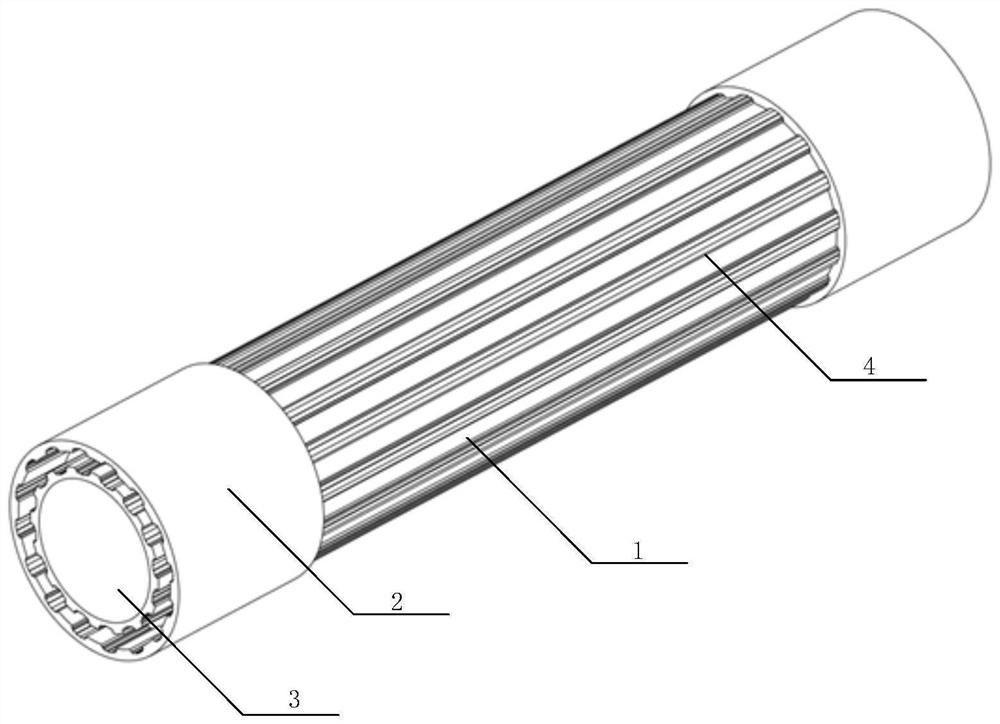

Component and joint integrated composite material pre-tightening force longitudinal fractal tooth connecting device

A composite material and connecting device technology, which can be applied to slender elements, building elements, etc., can solve the problems of opening holes or teeth, unable to fully exert the bearing capacity of the composite material pipe, increasing the weight of the composite material pipe, etc. The friction surface area, improving the bearing capacity of the joint, and avoiding the effect of secondary processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0037] Example 1

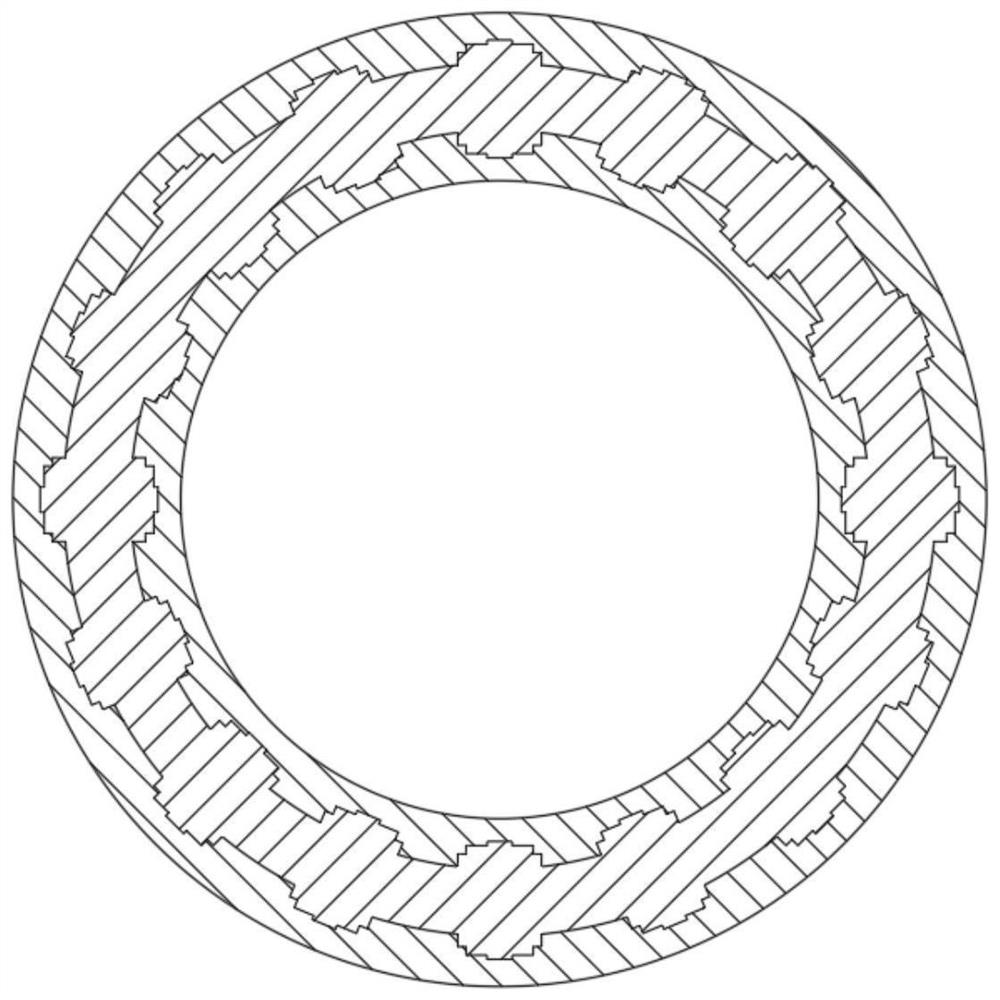

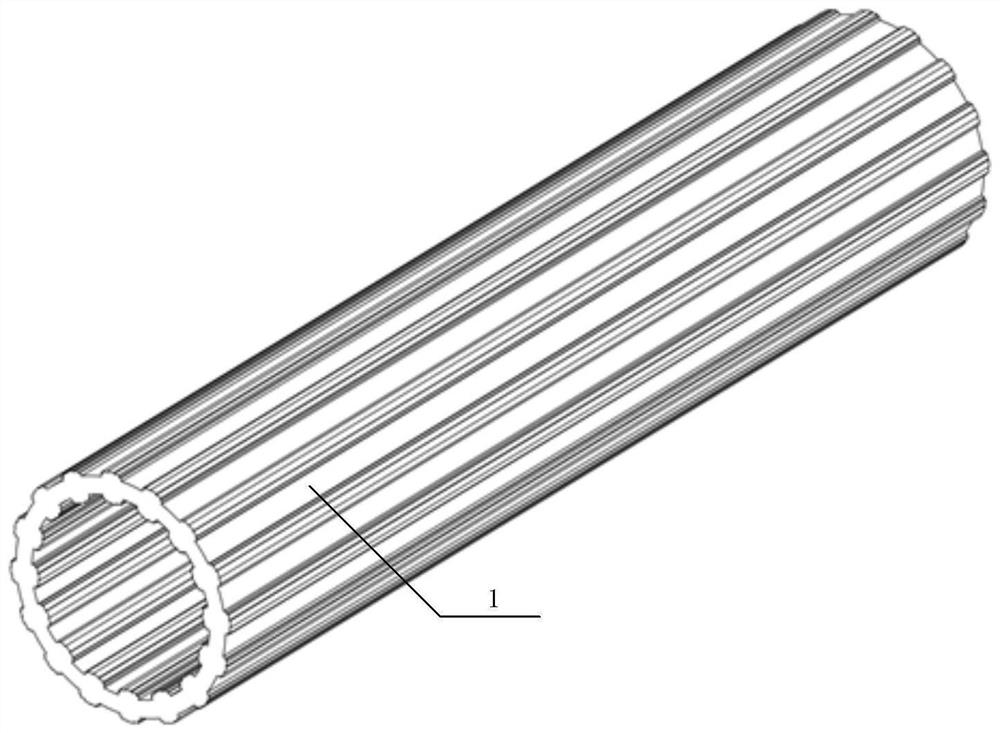

[0038] Inner and outer metal sleeves, pultruded composite tubes. The wall thickness of the composite tube is 8mm, and the thickness of the inner and outer metal sleeves is 6mm. Three-stage teeth evenly distributed along the circumference were prepared on the inner wall of the outer metal sleeve, and the depth and thickness of the teeth were 1.5 mm, 1 mm and 0.5 mm respectively. In order to match the local compressive bearing capacity of the joint with the bearing capacity of the connection, the number of longitudinal teeth prepared on the outer metal sleeve in the circumferential direction is 16, and the teeth are evenly distributed along the circumferential direction. Three-stage teeth evenly distributed along the circumference are prepared on the outer wall of the inner metal sleeve, and the geometric dimensions of the teeth are the same as those of the outer metal sleeve. When the composite material tube is pultruded, the longitudinal parting teeth matc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com