Reciprocating jaw type crusher for sintered bricks

A jaw crusher, reciprocating technology, applied in grain processing, etc., can solve problems such as environmental pollution, increased production costs, and a large amount of dust, and achieve the effects of improving the operating environment, improving crushing efficiency, and increasing utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

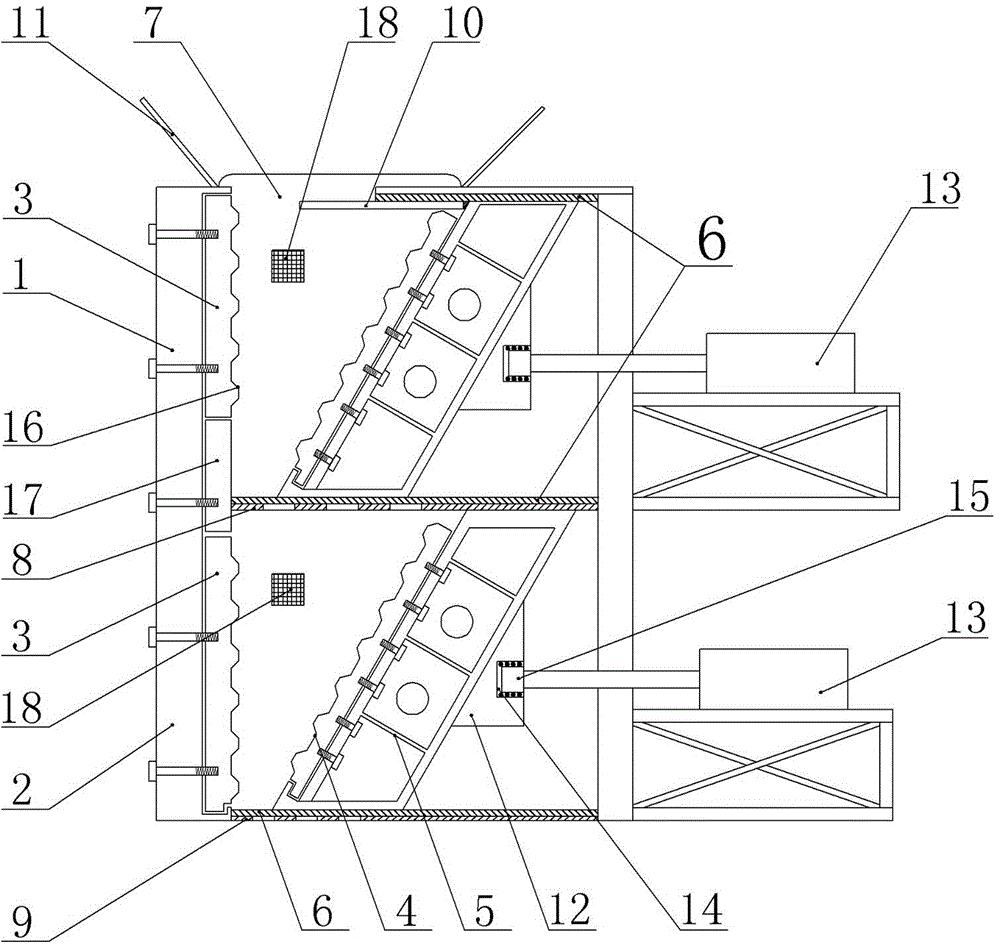

[0028] Embodiment two: see figure 1 , the structure of this embodiment is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the static jaw plate 3 in the crushing chamber 1 is a vertically split structure, and it also includes a belt There are point-type static jaw plates 17 of point-type crushing jaws evenly distributed on the bottom plate in a dot shape, and the static jaw plate 17 is located at the lower part of the static jaw plate with the tooth-type crushing jaws 16 .

[0029] In the present invention, the function of the crushing bin body 1 is to preliminarily crush the sintered bricks, and the discharge particle size is 30-40 mm.

[0030] ①Setting and function of the static jaw plate: According to the requirements for the discharge particle size, and fully considering the characteristics of high porosity and low strength of the sintered brick, the crushing chamber body and the static jaw plate adopt a split ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com