Longitudinal shear nonresistant perforated steel plate anti-pulling connecting piece and construction method thereof

A technology of connectors and steel plates, which is applied to bridge parts, bridge materials, bridges, etc., can solve the problems of unfavorable effects of structural stress, and achieve the effects of improving long-term mechanical performance, simple structure, and rapid construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, structure of the present invention, construction process are further described as follows.

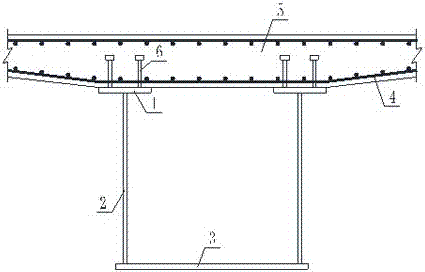

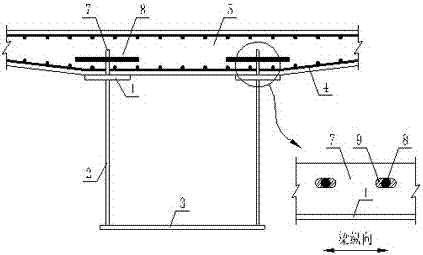

[0029] Such as image 3 As shown, the steel beam is composed of upper flange plate 1, web plate 2 and bottom plate 3, and the concrete slab is composed of concrete slab reinforcement 4 and concrete 5. The anti-pull connecting piece of longitudinal non-shear opening steel plate of the present invention is used to connect steel beams and concrete slabs, and is composed of a steel plate 7 with a long hole and a penetrating steel bar 8, the penetrating steel bar 8 passes through the long round hole of the steel plate 7, and the penetrating steel bar 8. Both sides of the part in the oblong hole are filled with elastic material 9, and elastic material 9 can adopt foamed plastics or rubber. The steel plate 7 with oblong holes is welded on the upper flange plate 1 of the steel girder, and its length direction is longitudinally arranged al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com