Longitudinally slidable steel-concrete anti-lifting connecting member and construction method thereof

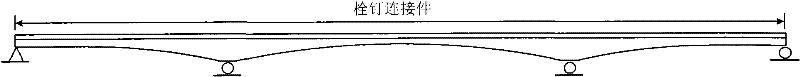

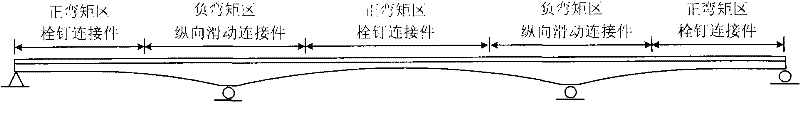

A technology for concrete and connectors, which is applied in the direction of load-bearing elongated structural components, building components, bridge parts, etc., can solve the problems of vertical resistance to separation and lifting of concrete slabs, which cannot be effectively solved, and the lack of negative bending moment areas. It is only resistant to lifting but not sliding new connectors, and the long-term performance and durability of concrete slabs are unfavorable, so as to improve long-term mechanical performance, improve local stability, and reduce compressive stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, structure of the present invention, construction process are described further.

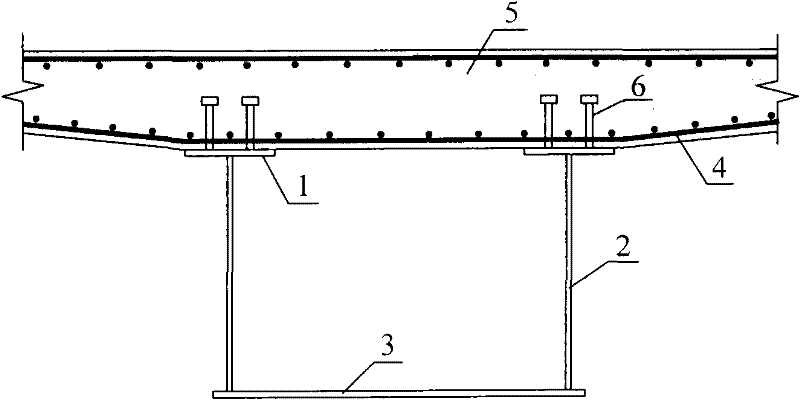

[0027] Such as Figure 4 and Figure 5 As shown, the steel girder is composed of upper flange plate 1, web plate 2 and bottom plate 3, and the concrete bridge deck is composed of steel bars 4 and concrete 5 in the plate. The connector provided by the present invention is used to connect the steel girder and the concrete bridge deck, and is composed of channel steel 7 and bolts 8, the channel steel 7 is pre-embedded in the concrete bridge deck, and the bolt 8 passes through the channel steel 7 and the bolt 8. The upper flange plate 1 of the steel beam connects the channel steel 7 with the upper flange plate 1 of the steel beam. The shape of the upper flange plate hole 9 of the steel beam that the bolt 7 passes is oval (such as Figure 6 As shown), the long axis is along the longitudinal bridge direction, and the bolts can slide longitudinal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com