Steel plate shear wall structure suitable for high-rise/super high-rise buildings in high-seismic-intensity regions

A steel plate shear wall and high-rise building technology, applied in the direction of load-bearing elongated structural components, building components, building structures, etc., can solve problems such as sacrifice and difficulty, and achieve enhanced strength, convenient production, and template saving. effect of quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

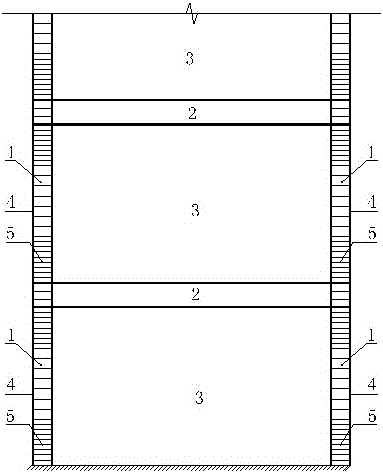

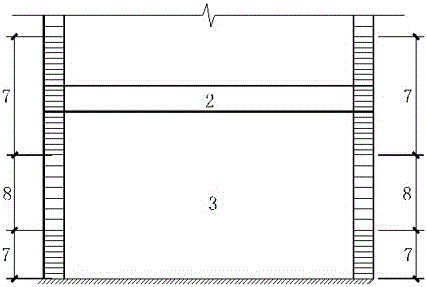

[0012] Such as figure 1 As shown, the present invention is a steel plate shear wall structure suitable for high-rise / ultra-high-rise buildings in high-intensity areas, using steel PEC columns instead of ordinary steel frame columns, and consisting of H-shaped PEC columns 1, frame beams 2, and built-in steel plates 3 .

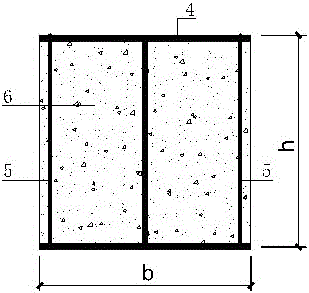

[0013] Such as figure 1 , figure 2 As shown, the H-shaped steel PEC column is a composite column with high strength and most of the rigidity is covered with concrete. The H-shaped steel PEC column is composed of section steel 4, tie bars 5 and concrete 6; The area of concrete 6 is Ac, the material strength of H-shaped steel 4 is Fs, and the axial compressive strength of concrete 6 is Fc, then the strength of H-shaped steel PEC composite column 1 is P=(1.2~1.7) (FsAs+FcAc); H-shaped steel PEC composite The rigidity of the column 1 is 1.4~1.8 times that of the H-shaped steel column 4; the tie bar 5 is welded between the upper and lower flanges of the H-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com