Steel-concrete frame structure, wall body structure and passive house

A frame structure and wall structure technology, applied to walls, building components, building structures, etc., can solve problems such as thermal bridges and insulation layer inconsistency, and achieve the effects of long service life, good integrity, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

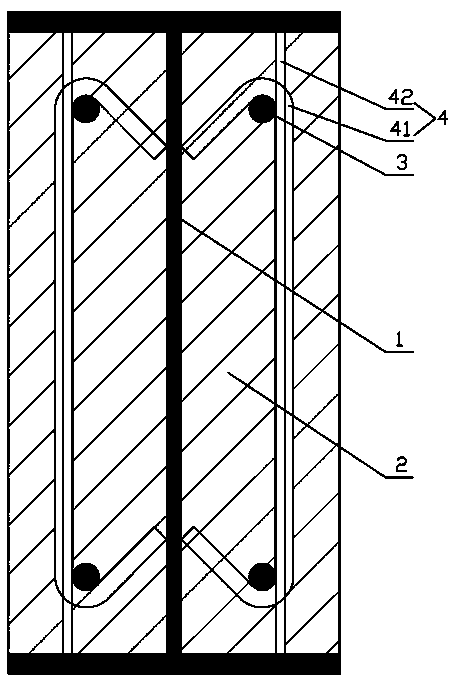

[0046] This embodiment provides a steel-concrete frame structure, such as figure 1 As shown, it includes H-shaped steel 1, and structural steel bars are arranged between the upper and lower flanges of the H-shaped steel 1. The structural steel bars include several transverse steel bars 3 and longitudinal steel bars 4, and the longitudinal steel bars 4 include the first longitudinal steel bars. 41 and the second longitudinal reinforcement 42, the two ends of the first longitudinal reinforcement 41 are respectively bent and fixed on two adjacent transverse reinforcements 3, one end of the second longitudinal reinforcement 42 is connected with the H-shaped steel 1 The upper flanges are connected, and the other end of the second longitudinal reinforcement 42 is connected with the lower flange of the H-shaped steel 1 . Concrete 2 is filled between the upper and lower flanges of the above-mentioned H-shaped steel 1, so that the above-mentioned H-shaped steel 1, structural steel bars...

Embodiment 2

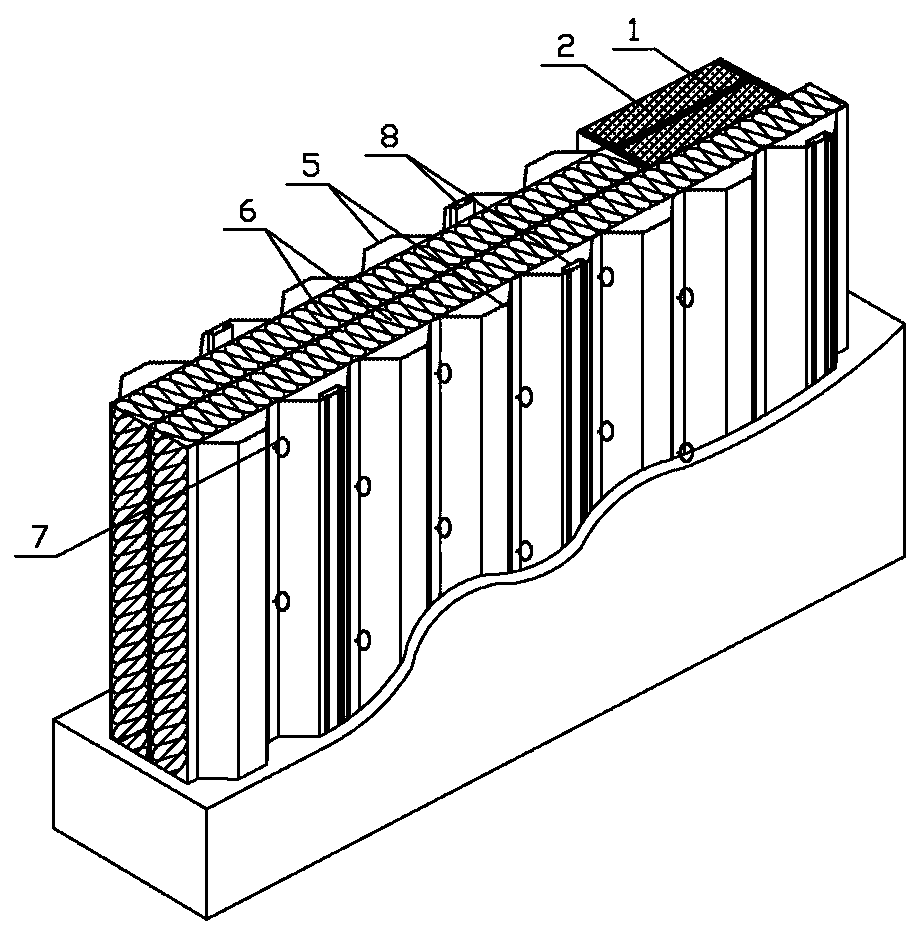

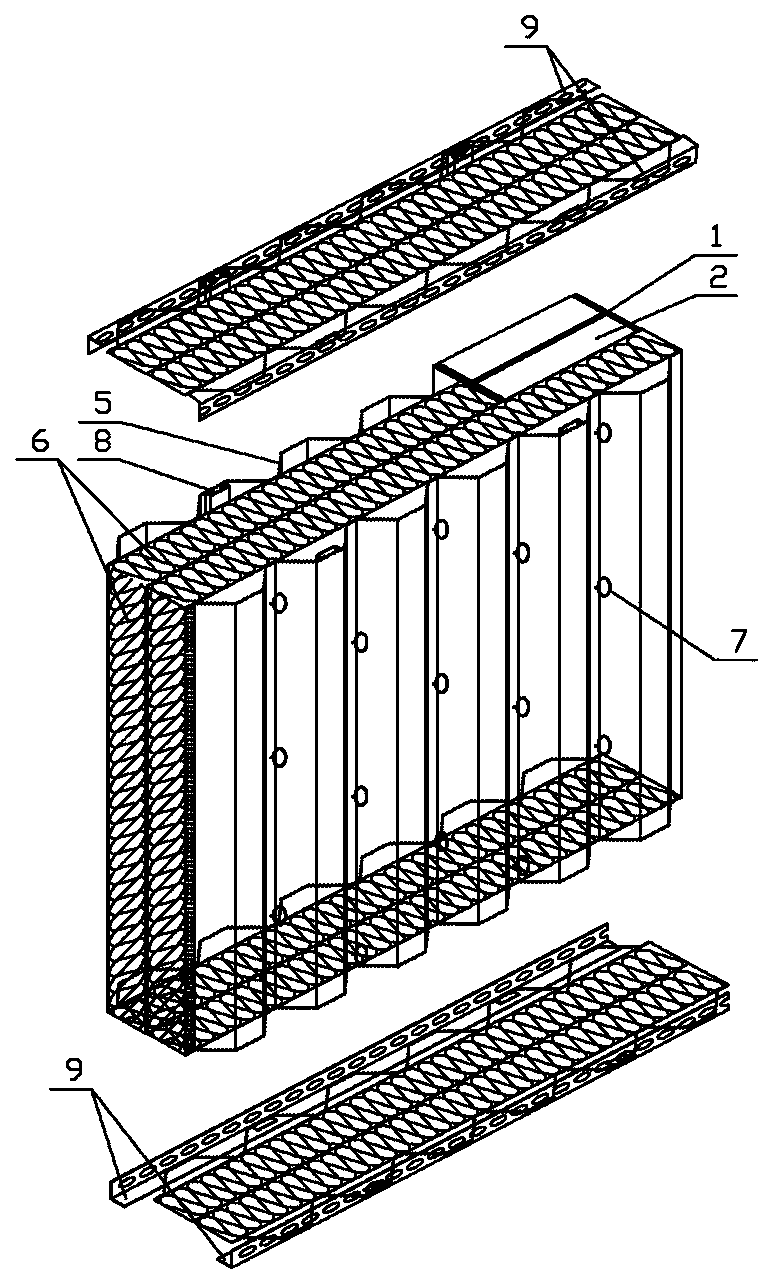

[0048] This embodiment provides a wall structure, such as Figure 2 to Figure 4 As shown, it includes the steel-concrete fabricated frame structure provided in the first embodiment above, at least two corrugated steel meshes 5 arranged at horizontal intervals, thermal insulation and sound insulation layers 6 and anchors 7, and the thermal insulation and sound insulation layers 6 are arranged on adjacent Between two corrugated steel meshes 5, two adjacent corrugated steel meshes 5 are fixedly connected by the tie member 7, and the steel-concrete fabricated frame structure can be embedded in two adjacent corrugated steel meshes. between net 5. The external wall insulation layer of traditional passive houses is made on the outside of the wall, which is also 200mm thick. The total thickness of the wall reaches 450mm. The thickness of the above-mentioned hollow inner mold wall is only 360mm, which is only 80% of the thickness of the traditional wall. Through the perfect combinatio...

Embodiment 3

[0058] This embodiment provides a passive house, including the wall structure of the second embodiment. Passive house surface and ground insulation materials can be paved with high-density graphite polystyrene boards with staggered double-layers to solve waterproof and moisture-proof, so that they can be integrated with the insulation layer of the external wall to ensure the continuity and stability of the external insulation layer of the building. The airtightness meets the characteristics of high thermal insulation and high airtightness of passive house buildings. The roof of the passive house can be installed with a solar water heating system to meet the needs of domestic water; laying solar photovoltaic panels to provide electricity to meet the electricity consumption of lighting and other household appliances; Perform constant temperature treatment, and then ventilate the interior space of the building through the fresh air and heat recovery system, so that it can reach a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Ripple height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com