Sound production device

A technology of sound-generating device and shell, which is applied to frequency/directional characteristic device, microphone, transducer shell/cabinet/support, etc., can solve the problem of affecting vibration and sound, not vibrating and sounding, and vibrator not being able to do immersive sound, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

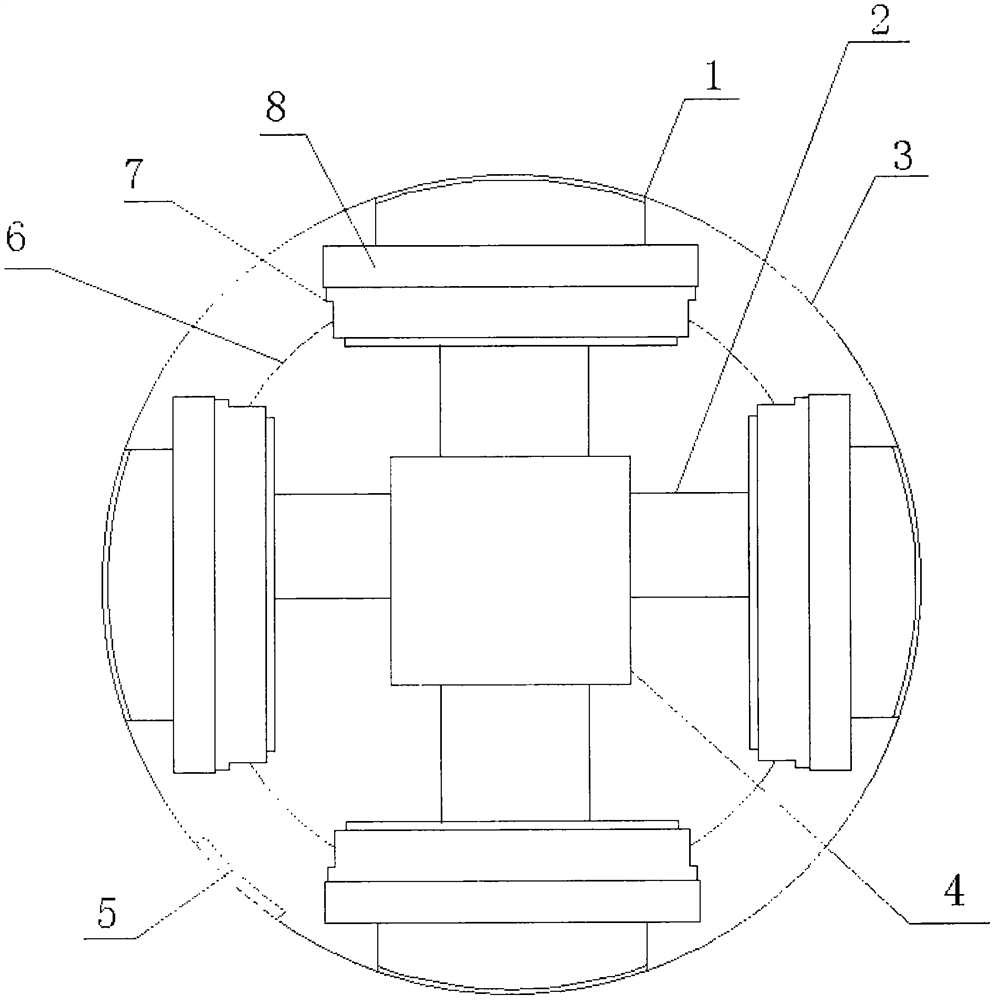

[0009] exist figure 1 In the shown embodiment, a vibration ring (1), a signal connection line (2), a vibration housing (3), an adapter (4), a seal (5), an inner support frame (6), and a shock absorbing sleeve are provided. (7), driver (8).

[0010] Implement a kind of sounding device of the present invention, comprise vibrating housing (3) and vibrating ring (1), vibrating ring (1) is fixedly connected in vibrating housing (3), vibrating ring (1) is fixedly connected driver (8), driver ( 8) The shock-absorbing sleeve (7) is fixedly connected, the shock-absorbing sleeve (7) is fixedly connected to the inner support frame (6), the inner support frame (6) is installed in the vibration shell (3), and the inner support frame (6) is installed with The connection adapter (4), the adapter (4) is connected to the signal connection line (2).

[0011] In a sound generating device implementing the present invention, the driver (8) is electrically connected to the power amplifier board t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com