Method and device for monitoring drilling depth and the drilling speed of mine down-the-hole drill

A technology of drilling depth and down-the-hole drilling rigs, which is applied in the field of mine drilling monitoring, and can solve the problems of low accuracy and manual monitoring of drilling depth that cannot be monitored in real time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

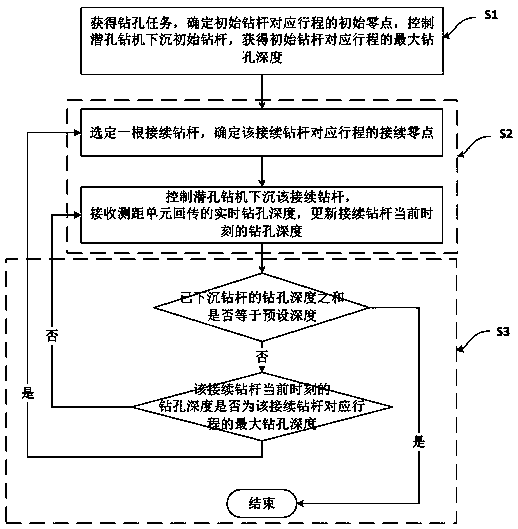

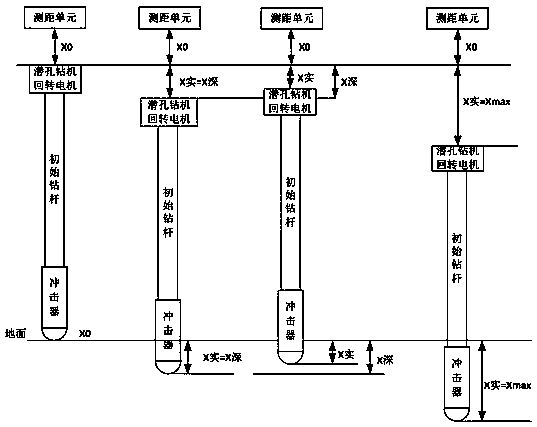

[0035] Embodiment 1: as attached figure 1 , 2 As shown in , 5, the method for monitoring the drilling depth and drilling speed of the mine down-the-hole drilling rig includes a down-the-hole drilling rig, an impactor, a distance measuring unit for detecting the drilling depth and at least one drill rod, and the method includes:

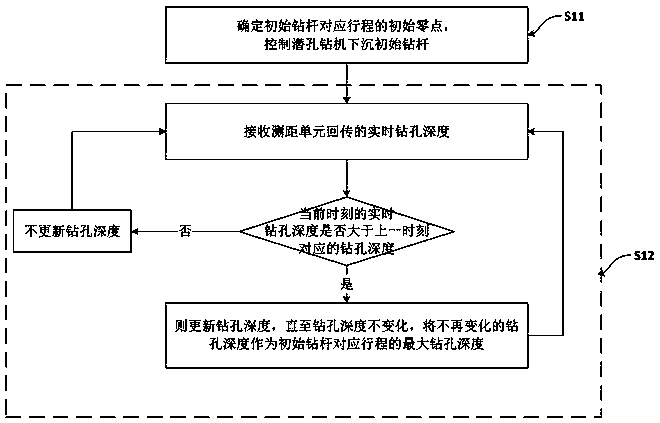

[0036] S1, obtain the drilling task, and determine the initial zero point X of the stroke corresponding to the initial drill rod 0 , control the down-the-hole drilling rig to sink the initial drill rod, and obtain the maximum drilling depth X corresponding to the stroke of the initial drill rod max , where the initial zero point X 0 is the initial distance between the rotary motor of the down-the-hole drilling rig and the distance measuring unit when the bottom of the impactor is in contact with the ground, and the maximum drilling depth is X max is the maximum value of the stroke corresponding to the initial drill pipe;

[0037] S2, select a conn...

Embodiment 2

[0058] Embodiment 2: as attached Figure 6 As shown, the drilling depth and drilling speed monitoring device of the mine down-the-hole drilling rig includes:

[0059] The initial drill rod control unit obtains the drilling task and determines the initial zero point X of the stroke corresponding to the initial drill rod 0 , control the down-the-hole drilling rig to sink the initial drill rod, and obtain the maximum drilling depth X corresponding to the stroke of the initial drill rod max , where the initial zero point X 0 is the initial distance between the rotary motor of the down-the-hole drilling rig and the distance measuring unit when the bottom of the impactor is in contact with the ground, and the maximum drilling depth is X max is the maximum value of the stroke corresponding to the initial drill pipe;

[0060] The connecting drill rod control unit selects a connecting drill rod and determines the connecting zero point X of the stroke corresponding to the connecting ...

Embodiment 3

[0062] Embodiment 3, as attached figure 1 As shown in the storage medium, a computer program that can be read by a computer is stored on the storage medium, and the computer program is configured to execute the method for monitoring the drilling depth and drilling speed of a mine down-the-hole drilling rig during operation.

[0063] The storage medium mentioned above may include, but not limited to, various media capable of storing computer programs such as USB flash drives, read-only memories, removable hard disks, magnetic disks, or optical disks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com