Corrugated steel pipe reinforced concrete column

A technology of reinforced concrete columns and reinforced concrete beams, which is applied in the field of corrugated steel pipe reinforced concrete columns and building structural components, which can solve the problems of unfavorable guarantee of construction quality and mechanical performance, complex and prominent construction of steel pipes that are easy to buckle, and stress on beam-column connection nodes Complicated problems, to achieve superior mechanical properties, reduce construction temporary measures, increase the effect of local stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

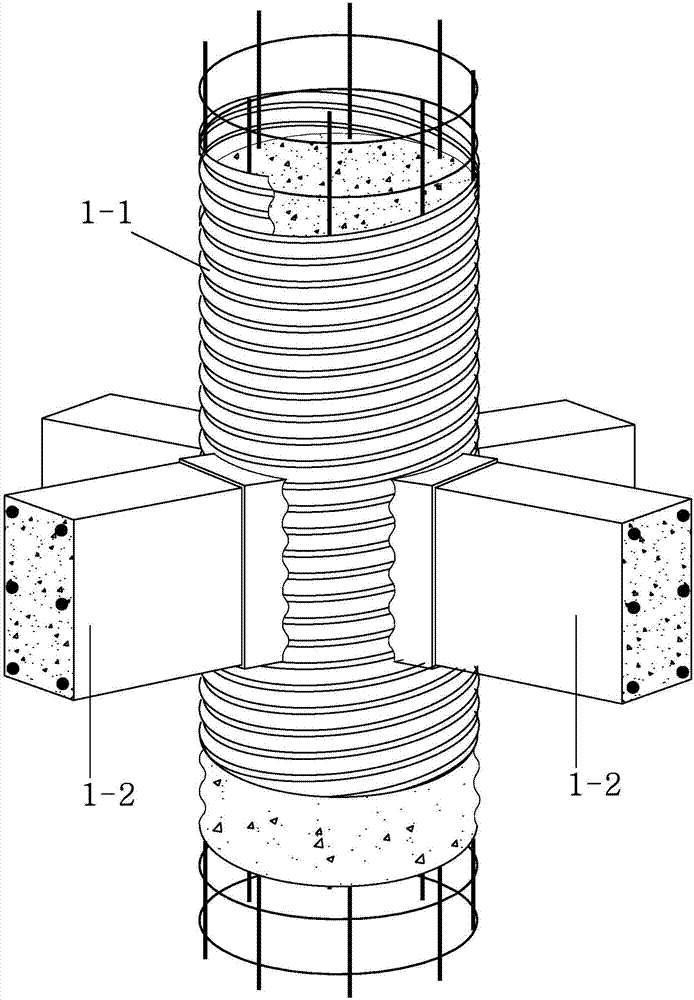

[0023] Specific implementation mode one: combine Figure 1 to Figure 7 Describe this embodiment, a corrugated steel pipe reinforced concrete column of this embodiment, it includes a column body 1-1 and two reinforced concrete beams 1-2, the two reinforced concrete beams 1-2 are perpendicular to each other to form a plane, and the Said plane is horizontally installed on the vertical column 1-1;

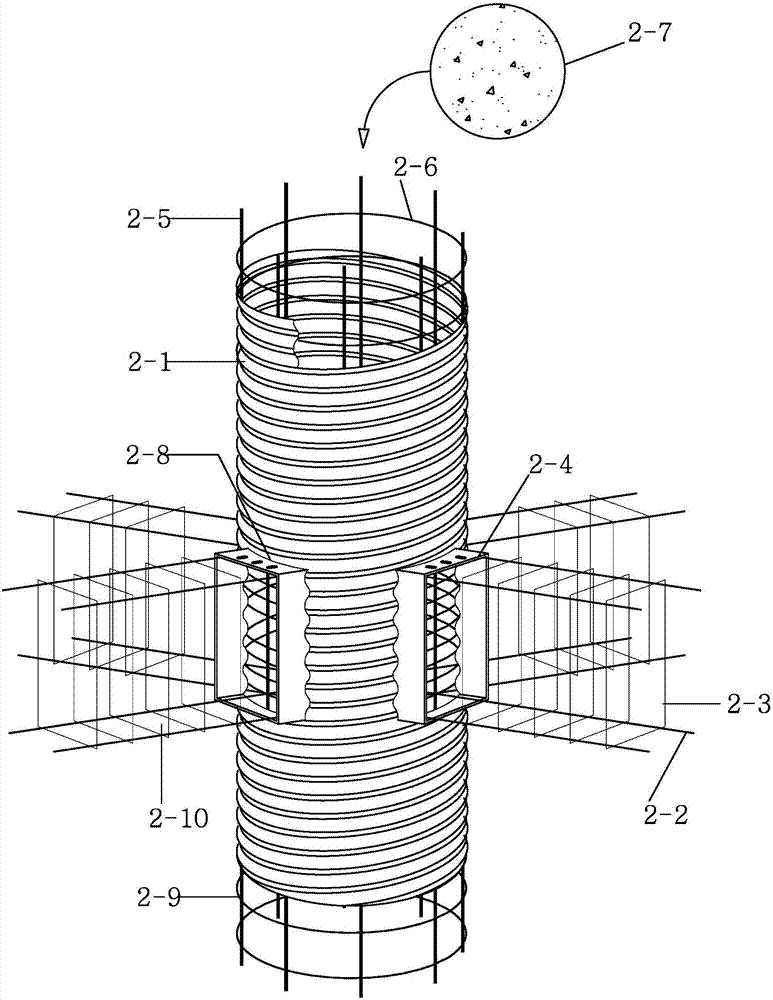

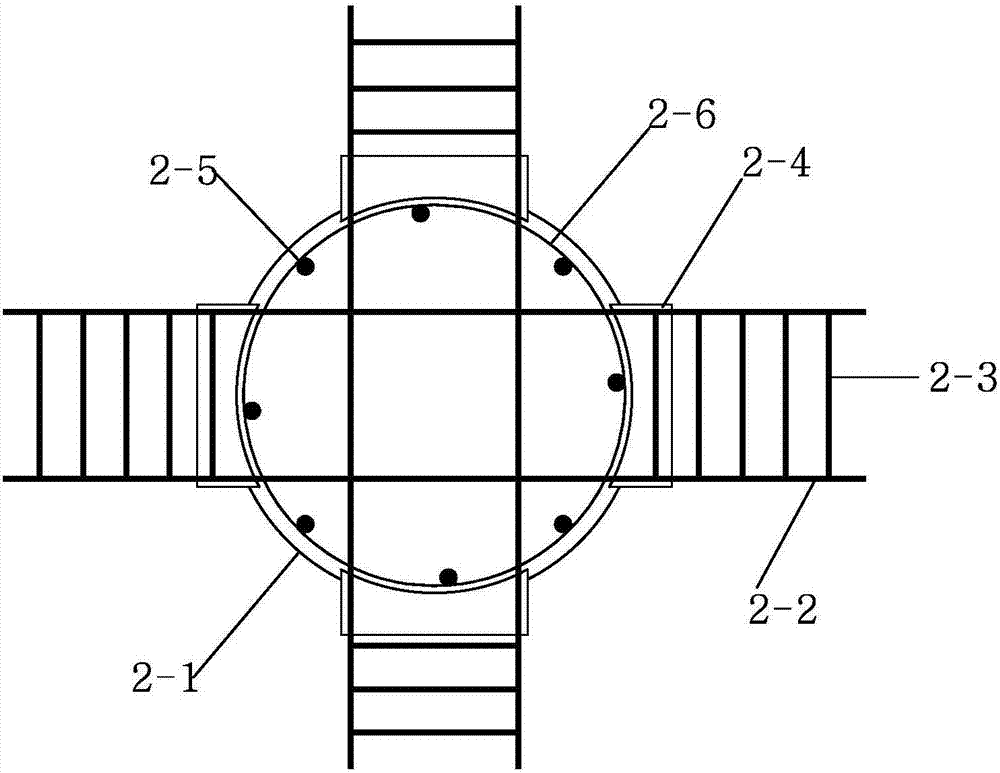

[0024] The column 1-1 includes a corrugated steel pipe 2-1, concrete 2-7 and a reinforcement cage 2-9 inside the column. The corrugated steel pipe 2-1 is provided with four corrugated steel pipe reserved holes 2-8 in a circular array along the outer circumference direction. The inner reinforcement cage 2-9 is installed in the corrugated steel pipe 2-1, and the concrete 2-7 is poured in the corrugated steel pipe 2-1;

[0025] Each reinforced concrete beam 1-2 includes a steel reinforcement cage 2-10 in the beam and two sets of guide steel plates. It is installed on two sets of guide s...

specific Embodiment approach 2

[0028] Specific implementation mode two: combination figure 2 Describe this embodiment, the reinforcement cage 2-9 in the column of this embodiment comprises a plurality of longitudinal reinforcement bars 2-5 in a column and a plurality of stirrup bars 2-6 in a column, and the longitudinal reinforcement bars 2-5 in a plurality of columns are vertically arranged in a circular array. Arranged vertically, multiple longitudinal steel bars 2-5 in the column are connected by multiple internal stirrup bars 2-6 installed from top to bottom. Such setting is convenient to provide a stronger guarantee for the corrugated pipe reinforced concrete column. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Specific implementation mode three: combination figure 2 Illustrate this embodiment, the reinforcement cage 2-10 in the beam of this embodiment comprises a plurality of beam longitudinal reinforcements 2-2 and a plurality of beam middle stirrups 2-3, and a plurality of beam longitudinal reinforcements 2-2 are arranged in a rectangle. The longitudinal steel bar 2-2 of the root beam is connected by a plurality of stirrup bars 2-3 in the beam to form a reinforcement cage 2-10 in the beam. Such setting ensures the stability and firmness of the beam structure. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com