Corrugated web steel column with cross-shaped section

A technology of corrugated webs and corrugated steel webs, applied in the field of new structures, can solve the problems of increasing steel consumption, increasing project comprehensive cost, increasing construction cost, etc., to improve stable bearing capacity, reduce comprehensive project cost, and reduce comprehensive The effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

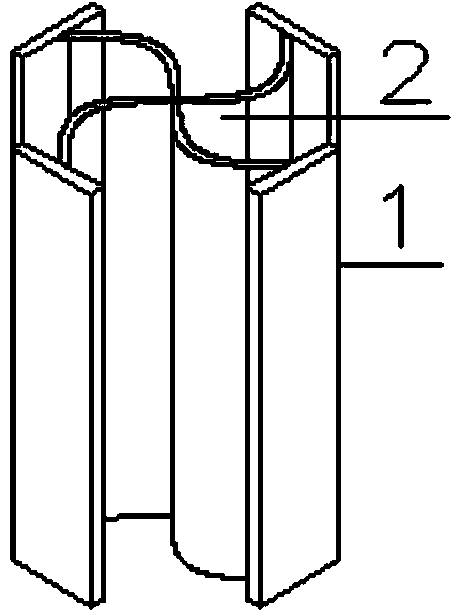

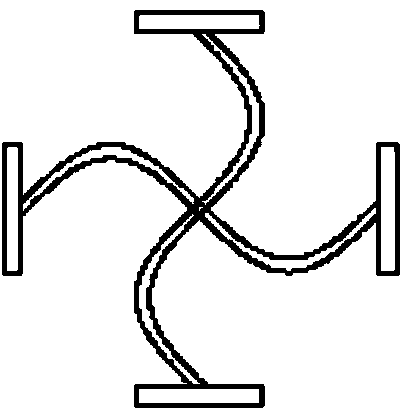

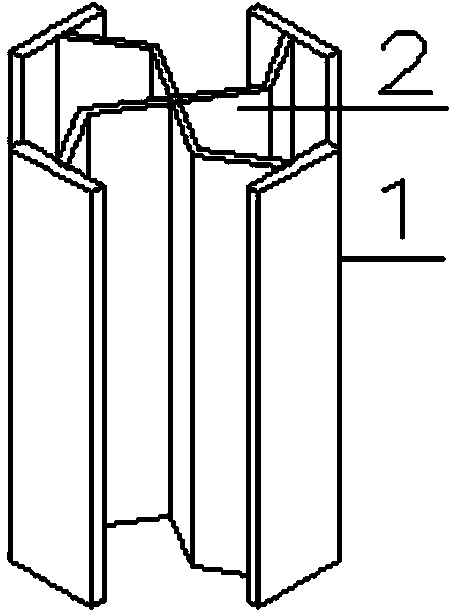

[0025] like Figure 1-6 Shown: a corrugated web cross-section steel column, including corrugated steel web 2 and flat steel plate flange 1, which is welded by one piece of corrugated steel web H-shaped steel and two pieces of corrugated steel web T-shaped steel or four pieces The corrugated steel web is welded by T-shaped steel or three pieces of corrugated steel web 2 and four pieces of flat steel plate flange 1 are welded and combined. The connection point of corrugated steel web 2 and flat steel plate flange 1 is located At the midpoint of the width, the form of the corrugated steel web 2 is curved, broken line or trapezoidal. The various forms of the corrugated steel web 2 require at least one wave width.

[0026] It should be pointed out that those skilled in the art can make some improvements and modifications without departing from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com