Patents

Literature

33results about How to "Rapid production and processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

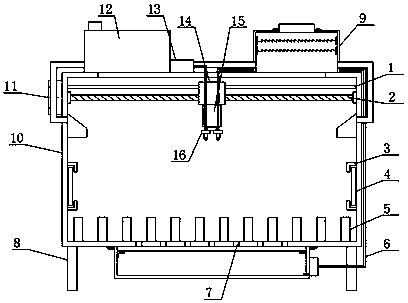

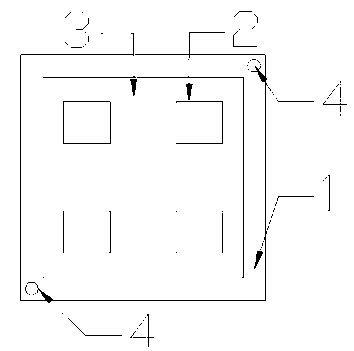

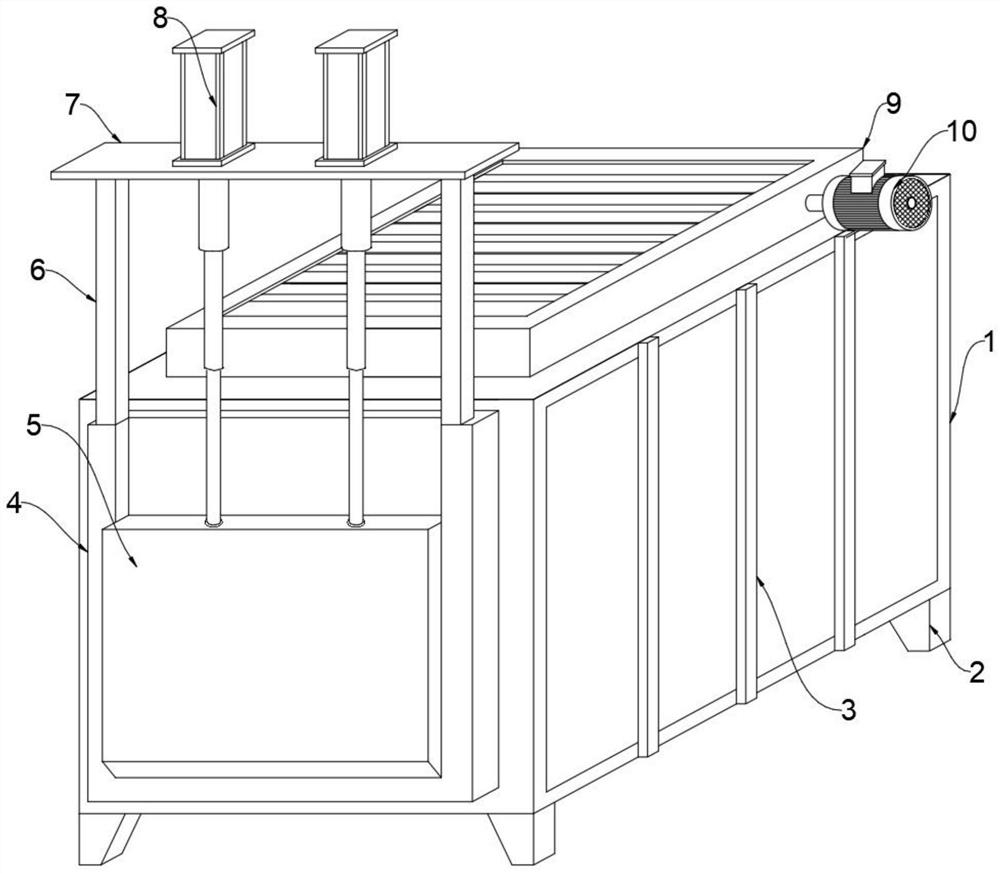

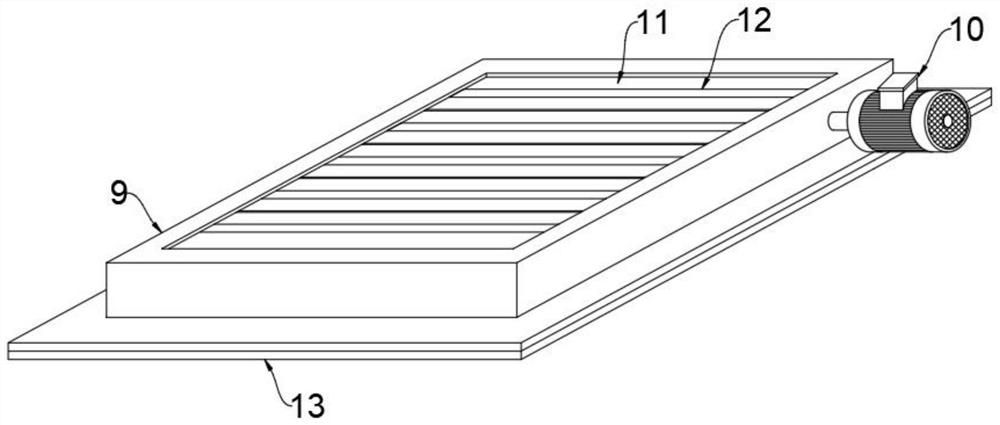

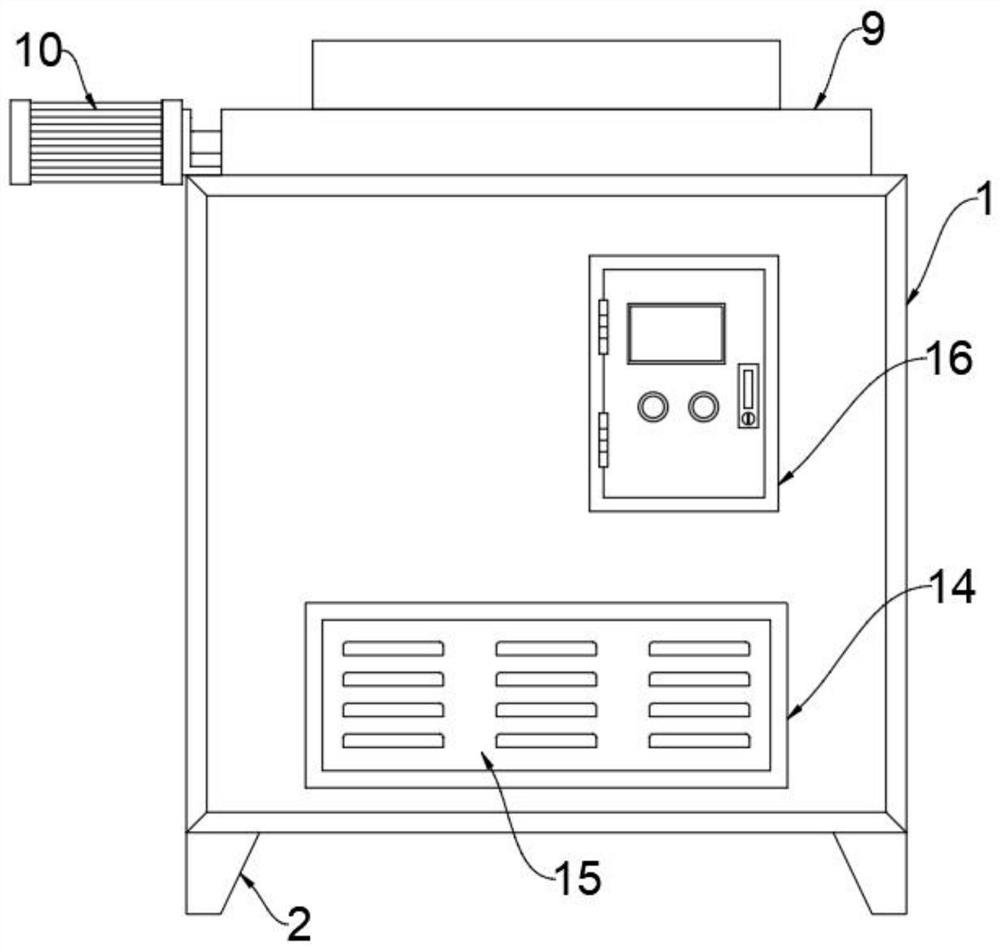

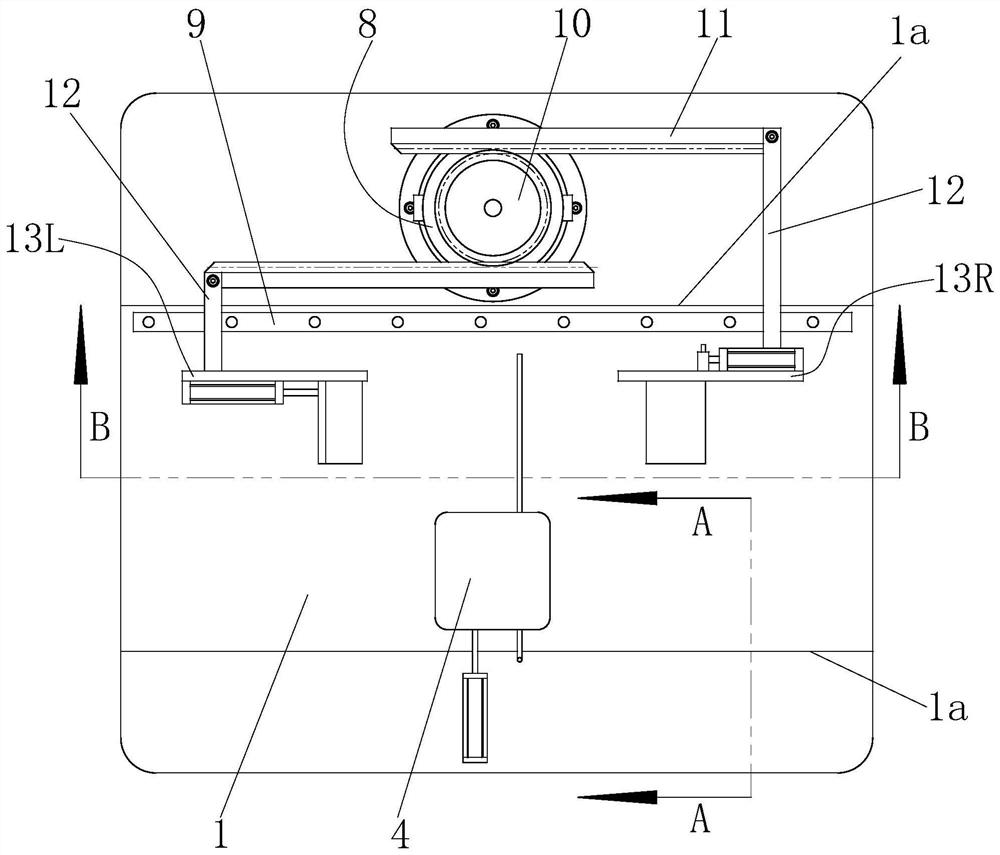

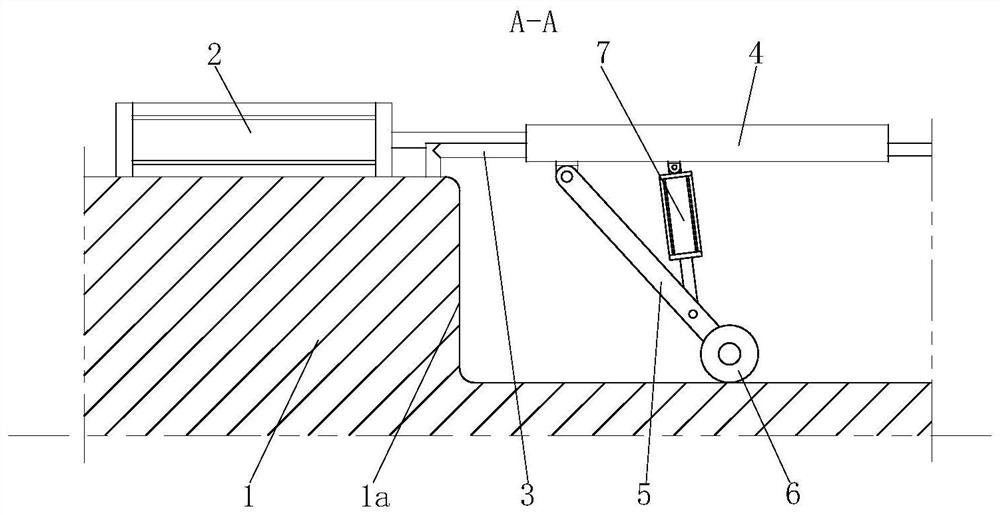

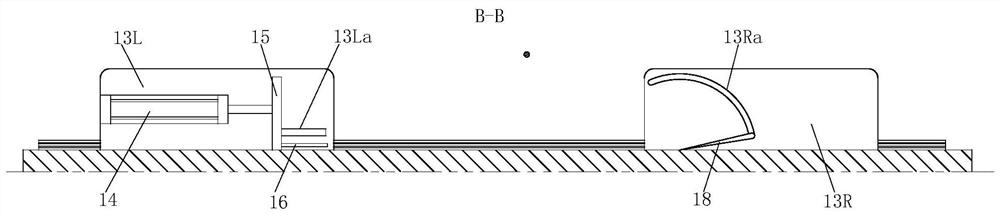

Panel paint-spraying device for compact shelving production

InactiveCN110227630AGood paint effectRapid production and processingPretreated surfacesLiquid spraying apparatusDrive motorWater spray

The invention discloses a panel paint-spraying device for compact shelving production, and belongs to the technical field of compact shelving. The panel paint-spraying device for compact shelving production comprises a paint spraying box, wherein an oil paint box is arranged at one end of the upper surface of the paint spraying box; an oil paint pump is arranged on one side of the oil paint box; apaint spraying pipe is arranged at the output end of the oil paint pump; a drive motor is arranged at the top end of the paint spraying box; a limiting screw rod is arranged at the output end of thedrive motor; a limiting slide block is arranged at one end of the limiting screw rod; a limiting rod corresponding to the limiting slide block is arranged above the limiting screw rod; and an electrictelescopic rod corresponding to the paint spraying pipe is arranged on the lower surface of the limiting slide block. According to the panel paint-spraying device for compact shelving production provided by the invention, when in use, the upper surface of a panel is flushed through the water spraying pipe, so that impurities such as dust remained on the surface of the panel can be removed so as to be prevented from influencing the spraying quality of the paint spraying device; and secondly, the device can be used for adjusting the position of the paint spraying pipe, so that a paint sprayingeffect on the panel through the paint spraying device is good.

Owner:JIANGXI EQUIP INDAL GROUP GREAT INSURANCENT

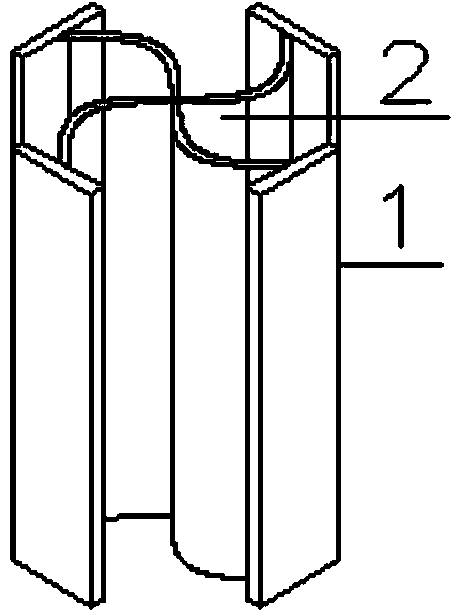

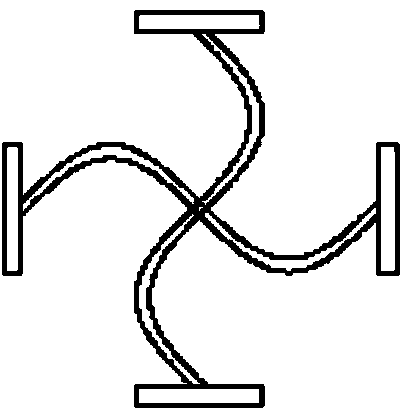

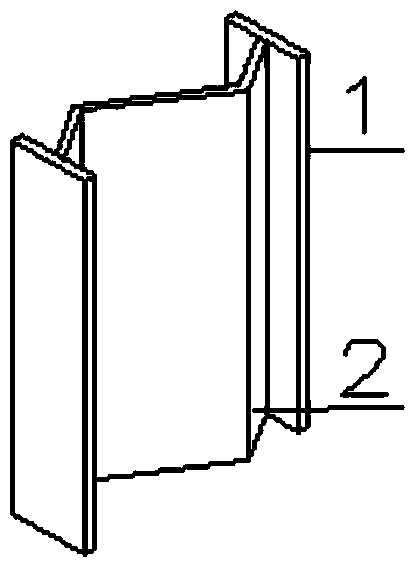

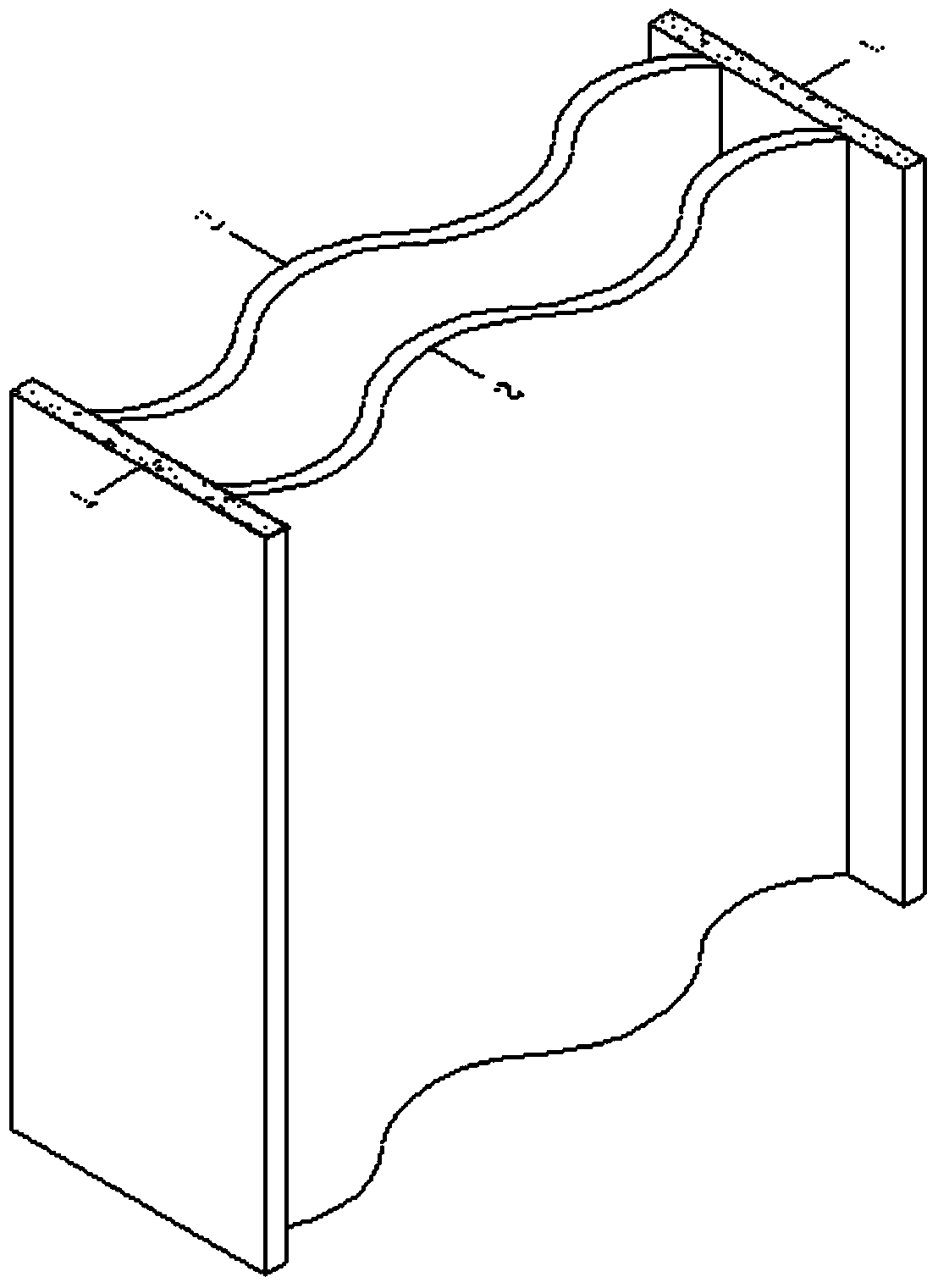

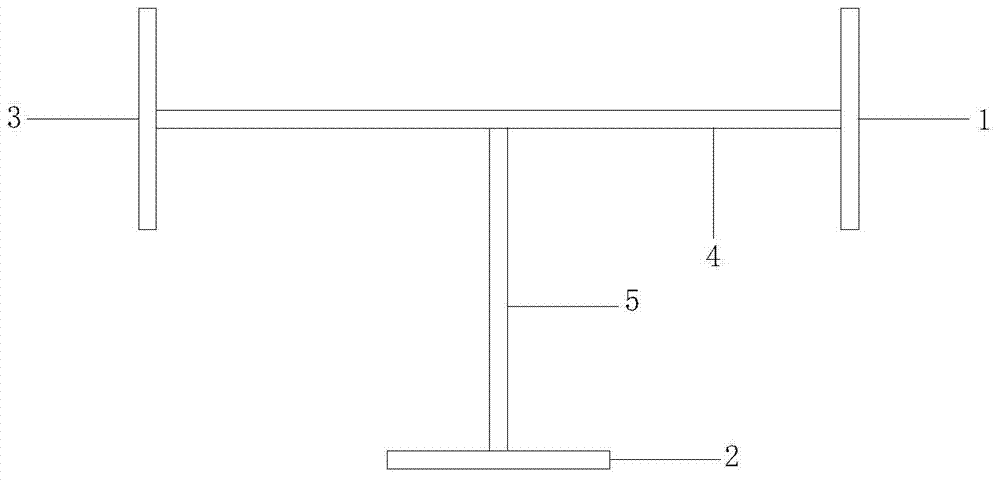

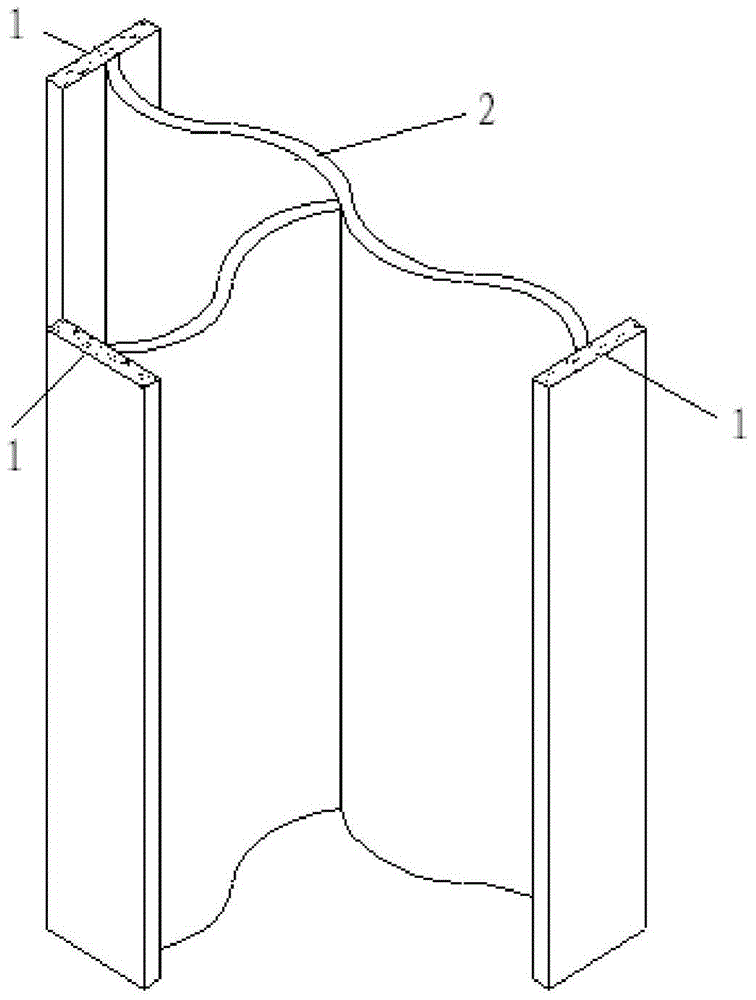

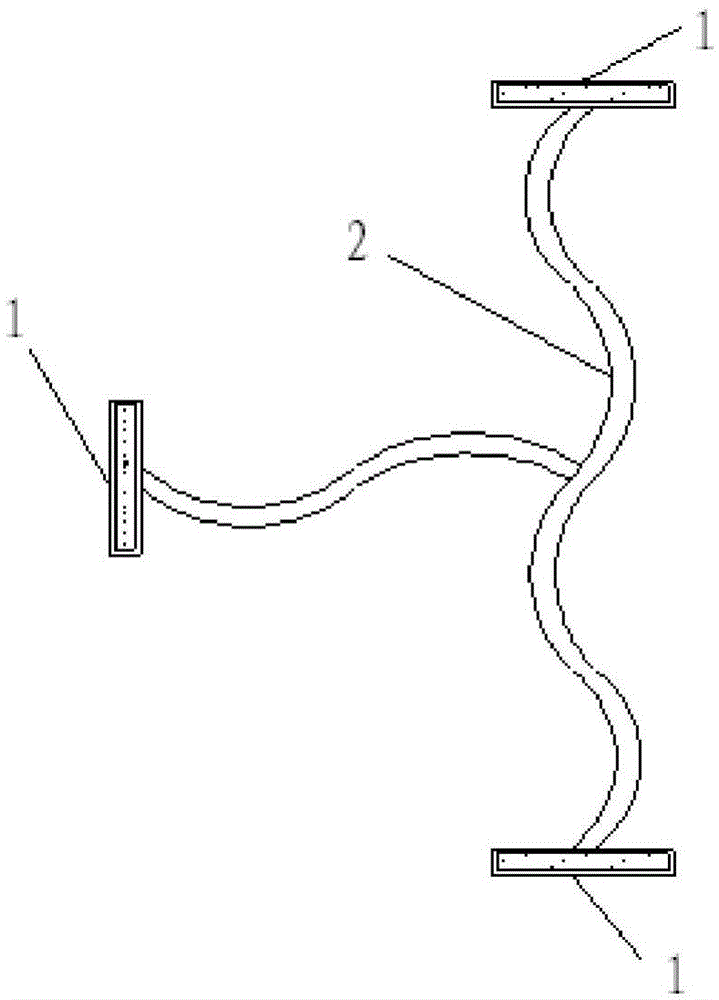

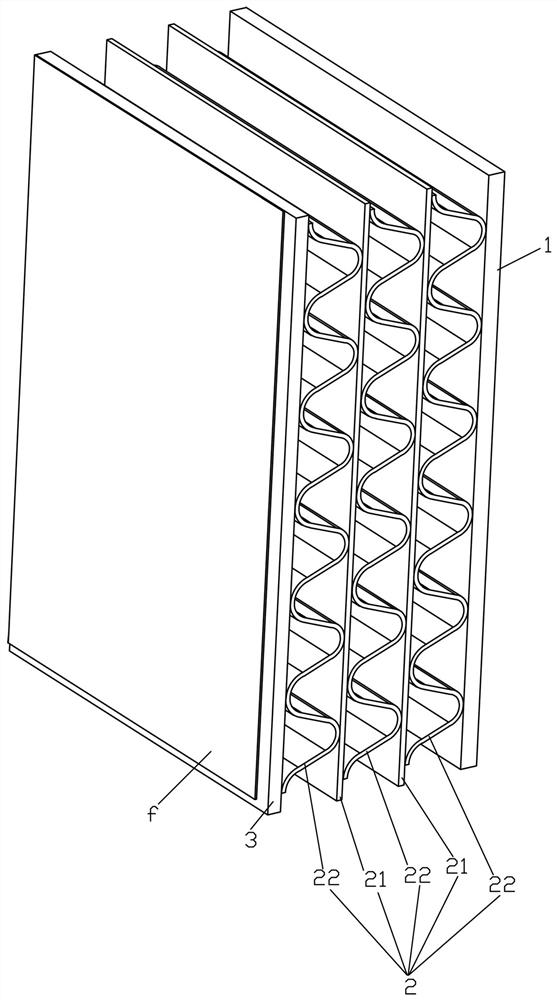

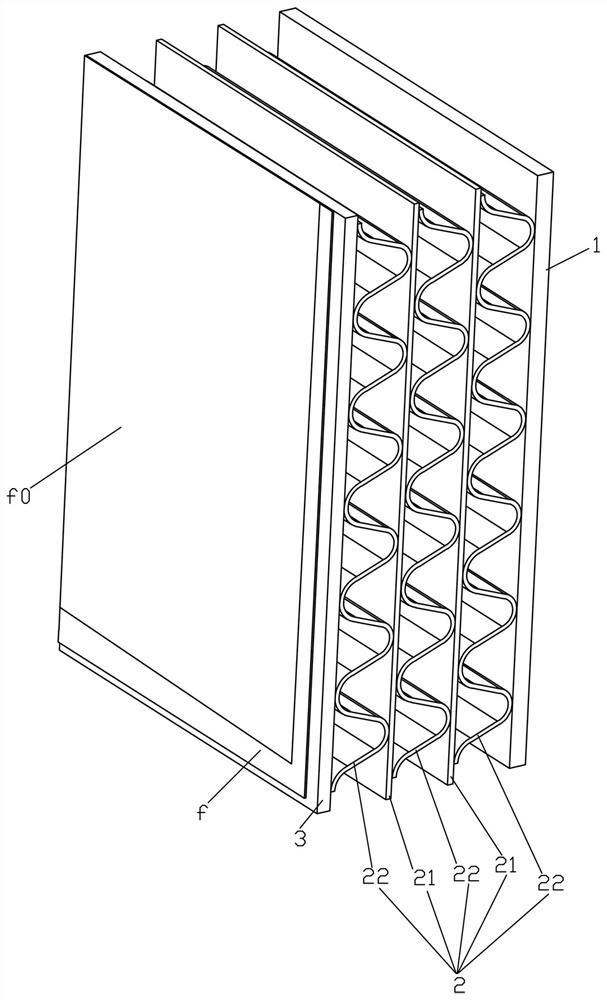

Corrugated web steel column with cross-shaped section

InactiveCN103835437AReduce usageSection composition is reasonableStrutsPillarsEngineeringSteel columns

The invention discloses a corrugated web steel column with a cross-shaped section. The corrugated web steel column comprises corrugated steel webs and plain plate flanges and is formed by welding an H-shaped corrugated web steel and two T-shaped corrugated web steel or welding four T-shaped corrugated web steel or welding three corrugated steel webs and four plain plate flanges, wherein the connection points of the corrugated steel webs and the plain plate flanges are in the middle of the width of the plain plate flanges, and the corrugated steel webs are curved, folded or trapezoidal. The steel column is reasonable in section composition, has good mechanical properties, high bearing capacity, good ductility, excellent anti-seismic property and simple structure, is convenient and fast to produce and process, saves steel and is low in cost.

Owner:NANJING UNIV OF TECH

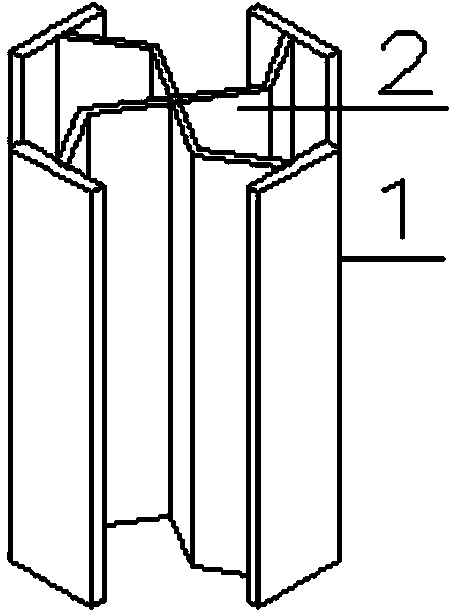

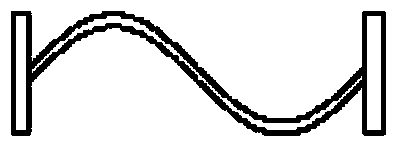

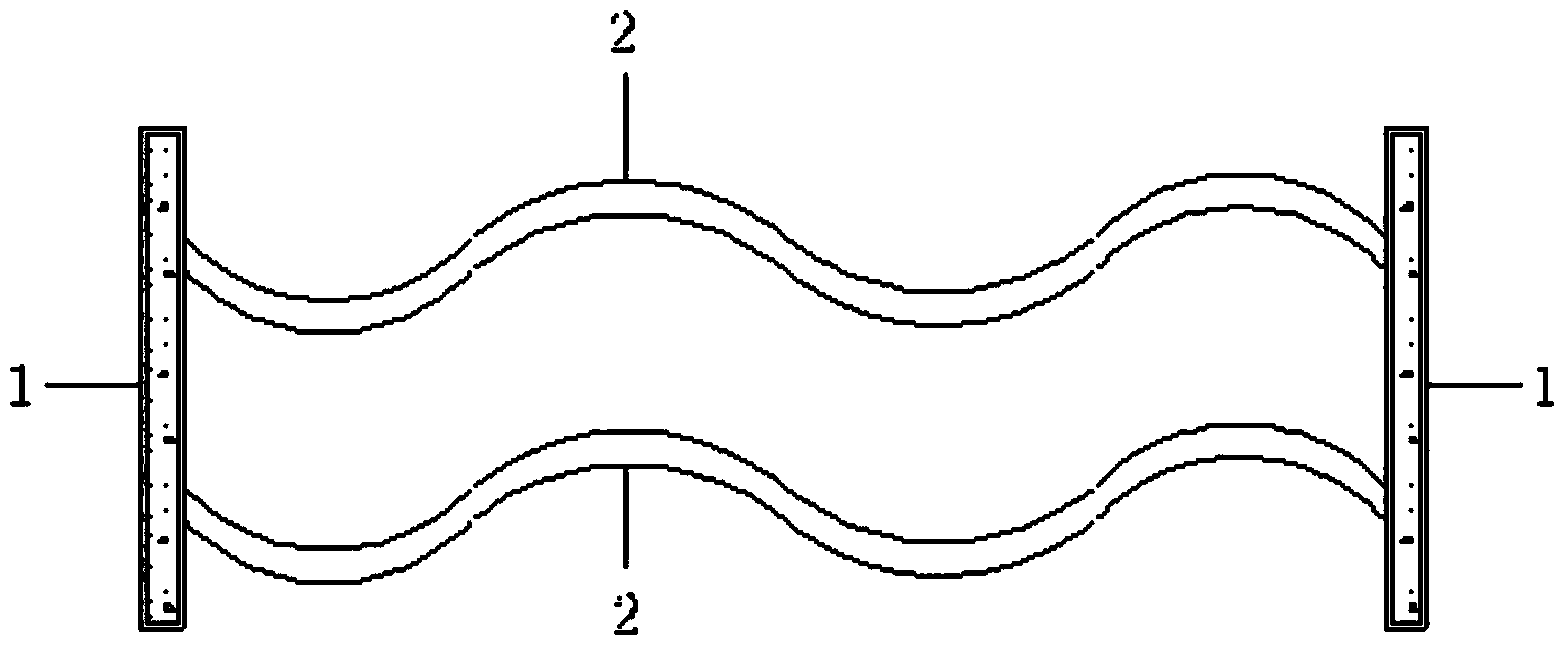

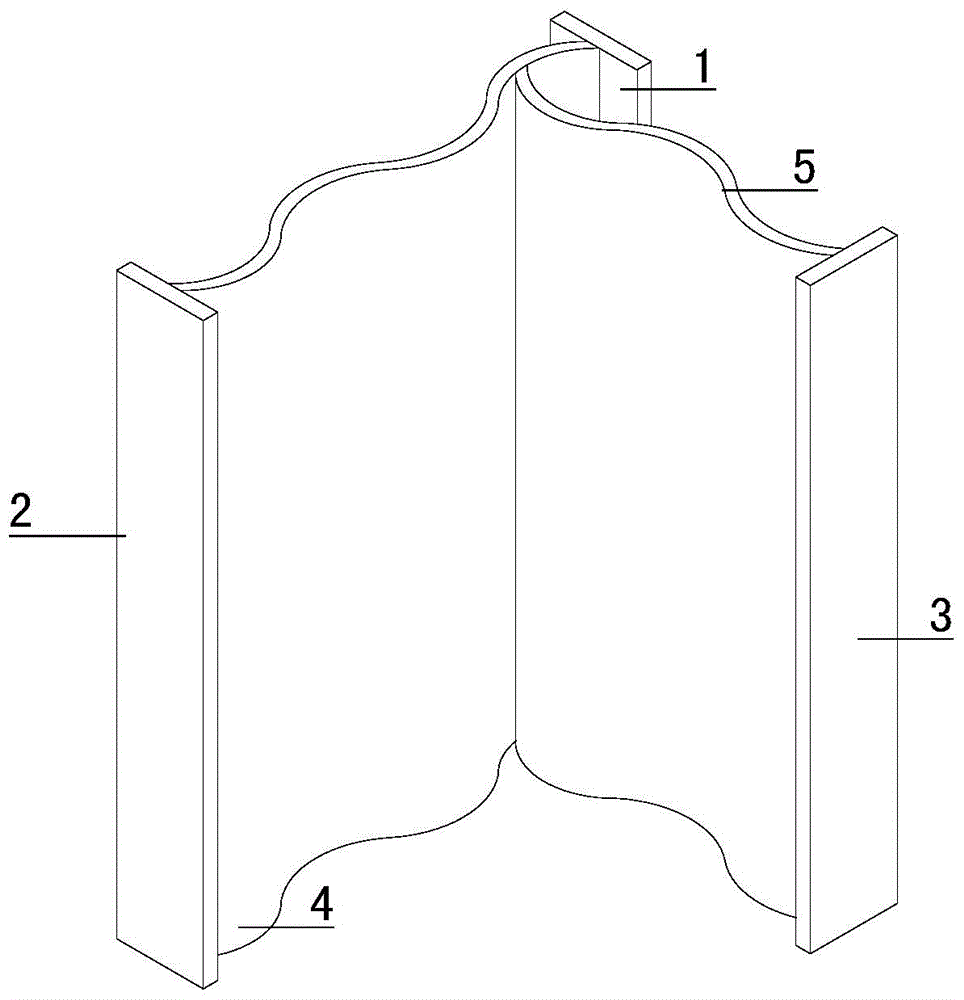

H-shaped corrugated web steel column

InactiveCN103835438AReduce usageSection composition is reasonableStrutsPillarsEngineeringSteel columns

The invention discloses an H-shaped corrugated web steel column. The H-shaped corrugated web steel column comprises a corrugated steel web and two plain plate flanges, wherein the corrugated steel web is arranged between the two plain plate flanges; the connection points of the corrugated steel web and the plain plate flanges are in the middle of the width of the plain plate flanges; the corrugated steel web is curved, folded or trapezoidal. The steel column is reasonable in section composition, has good mechanical properties, high bearing capacity, good ductility, excellent anti-seismic property and simple structure, is convenient and fast to produce and process, saves steel and is low in cost.

Owner:NANJING TECH UNIV

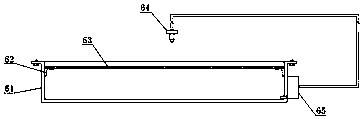

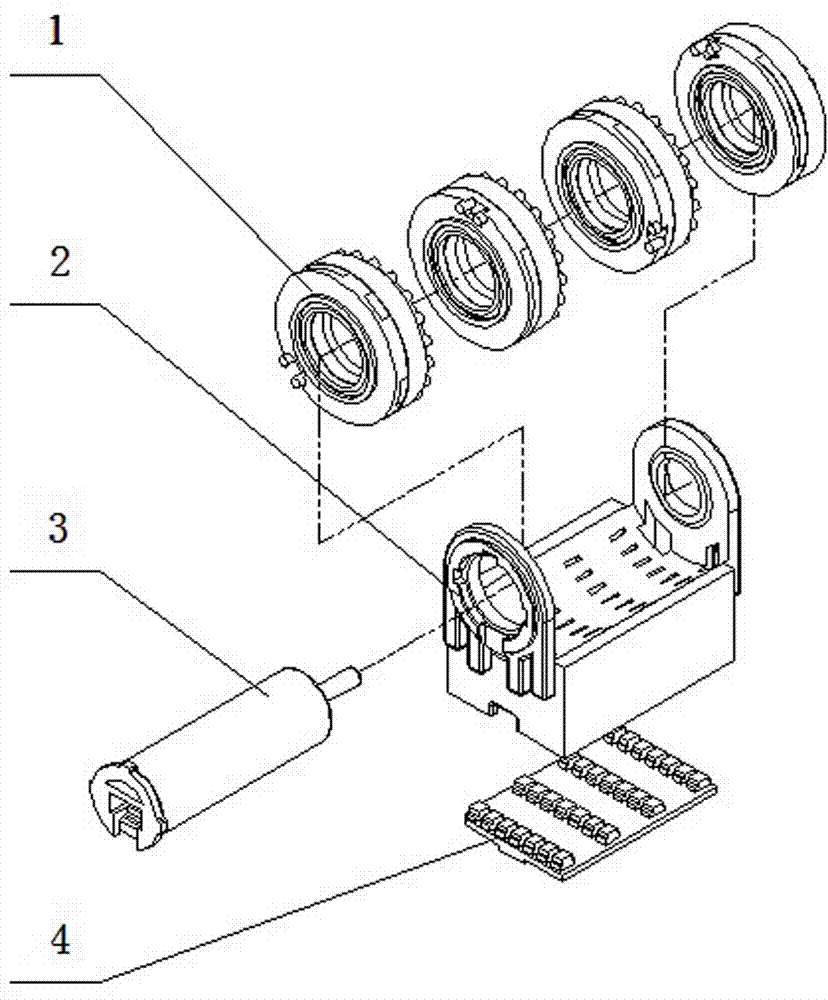

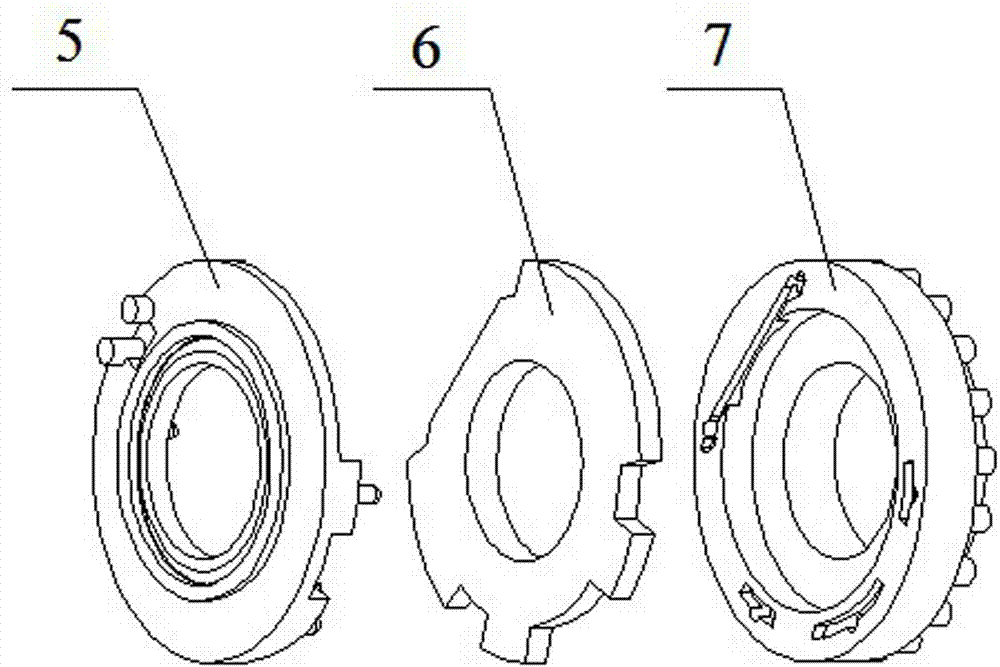

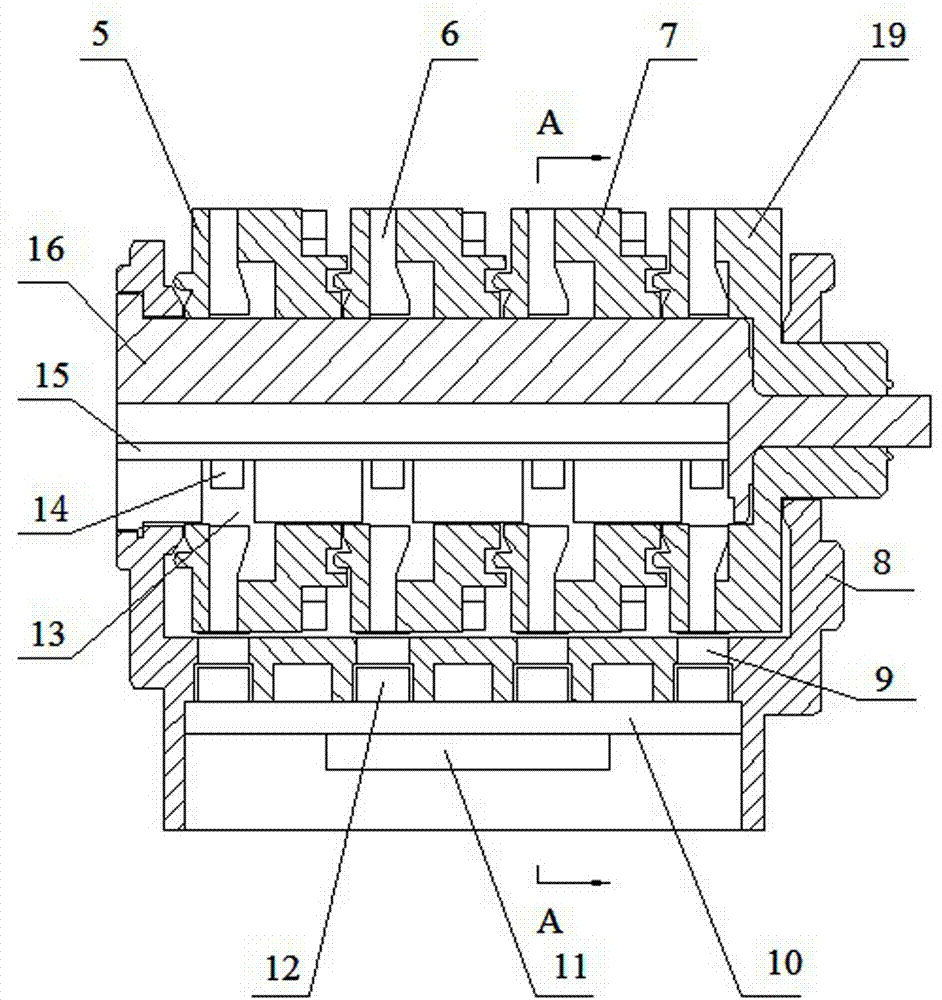

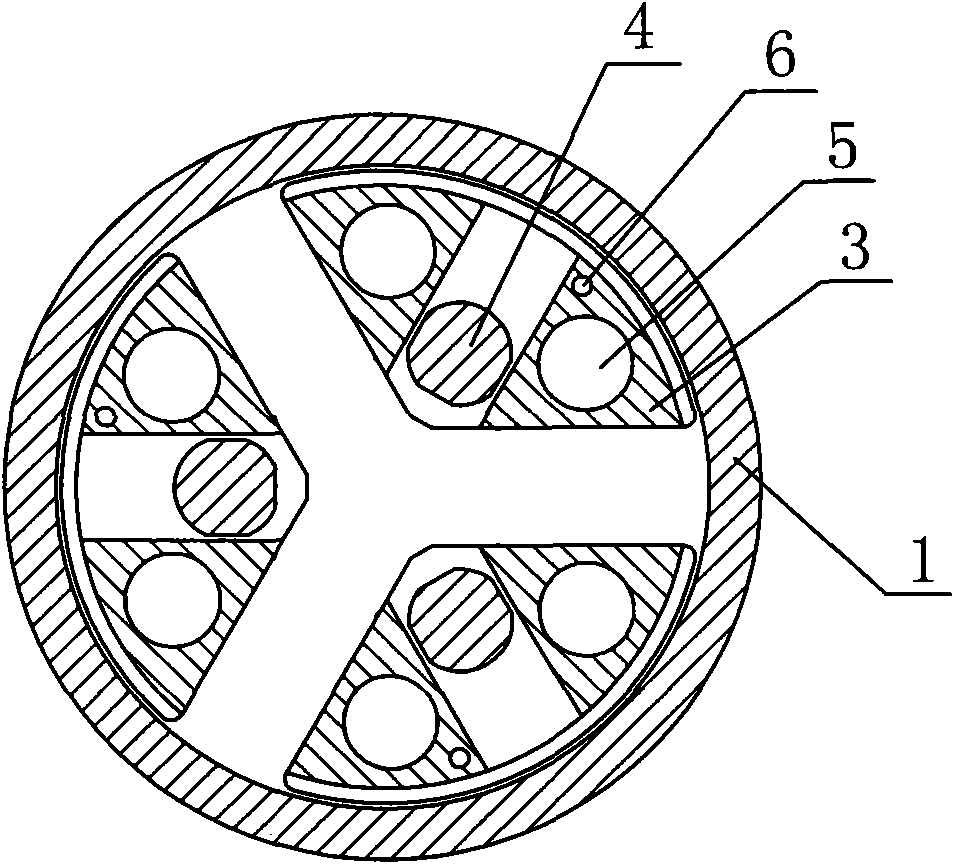

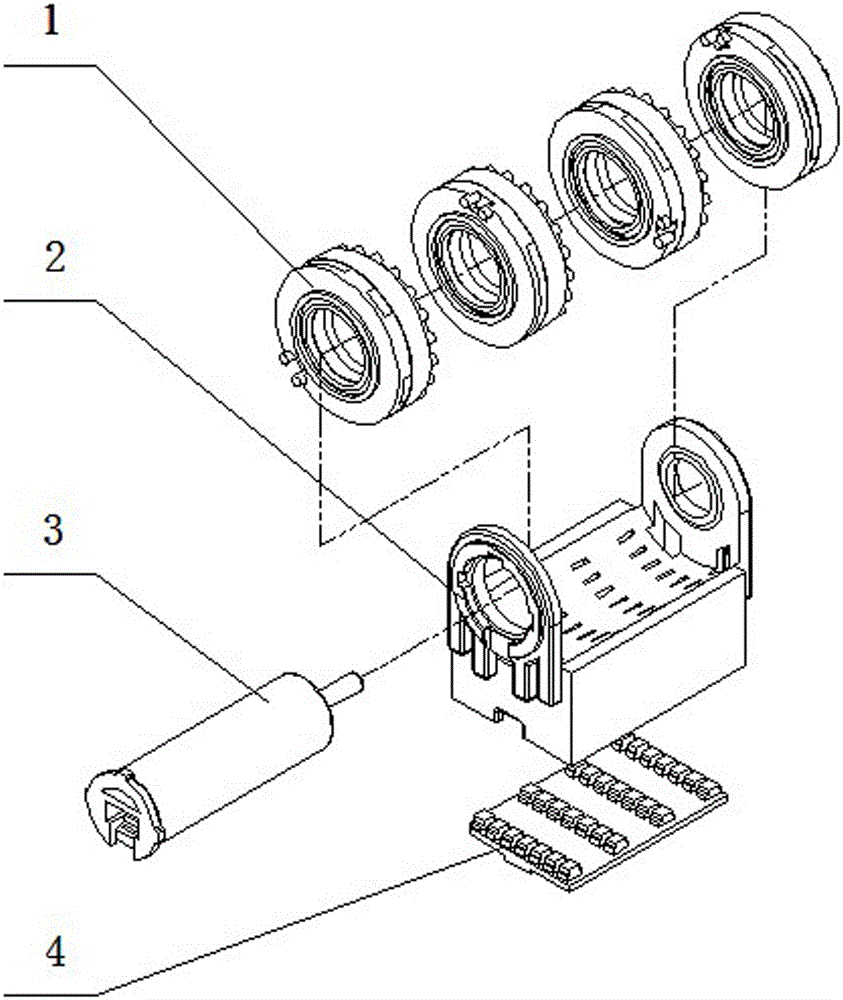

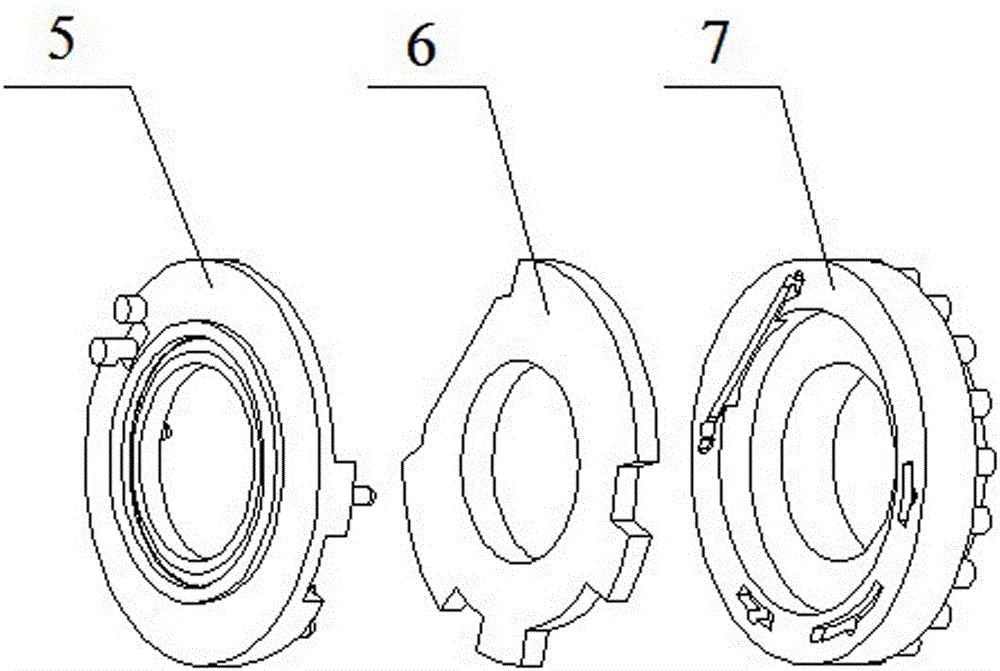

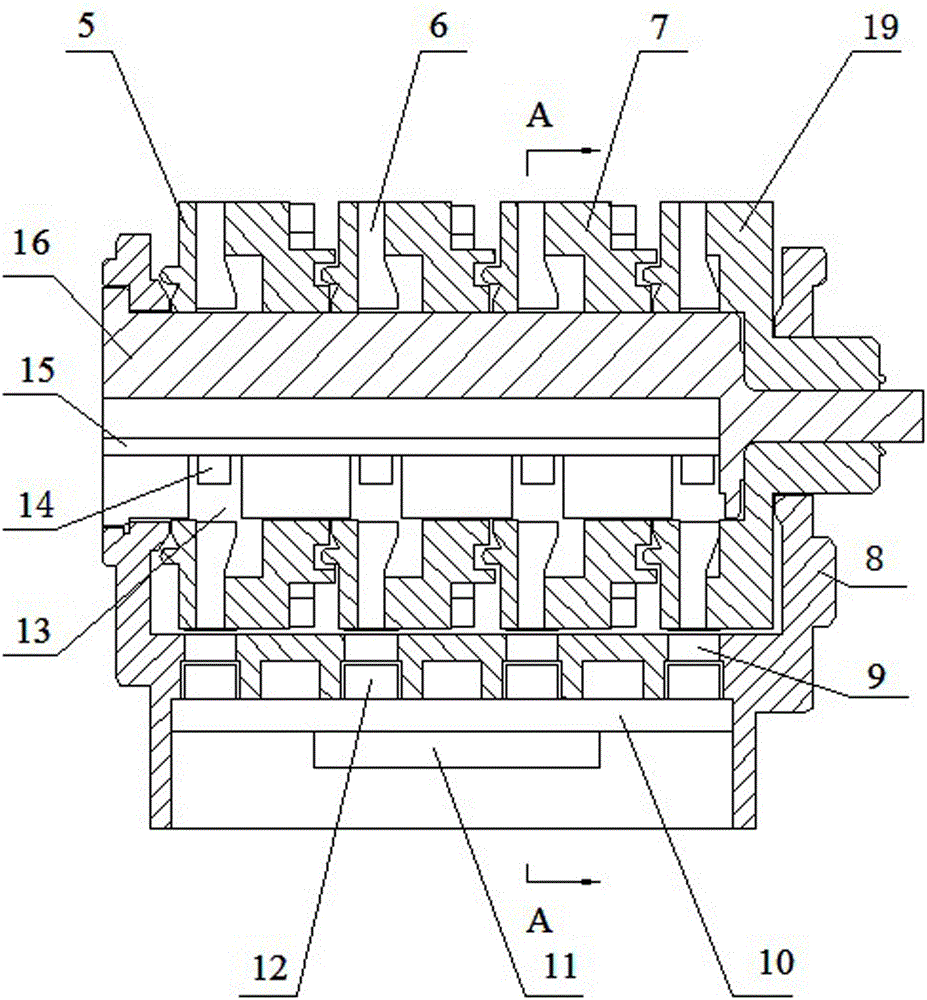

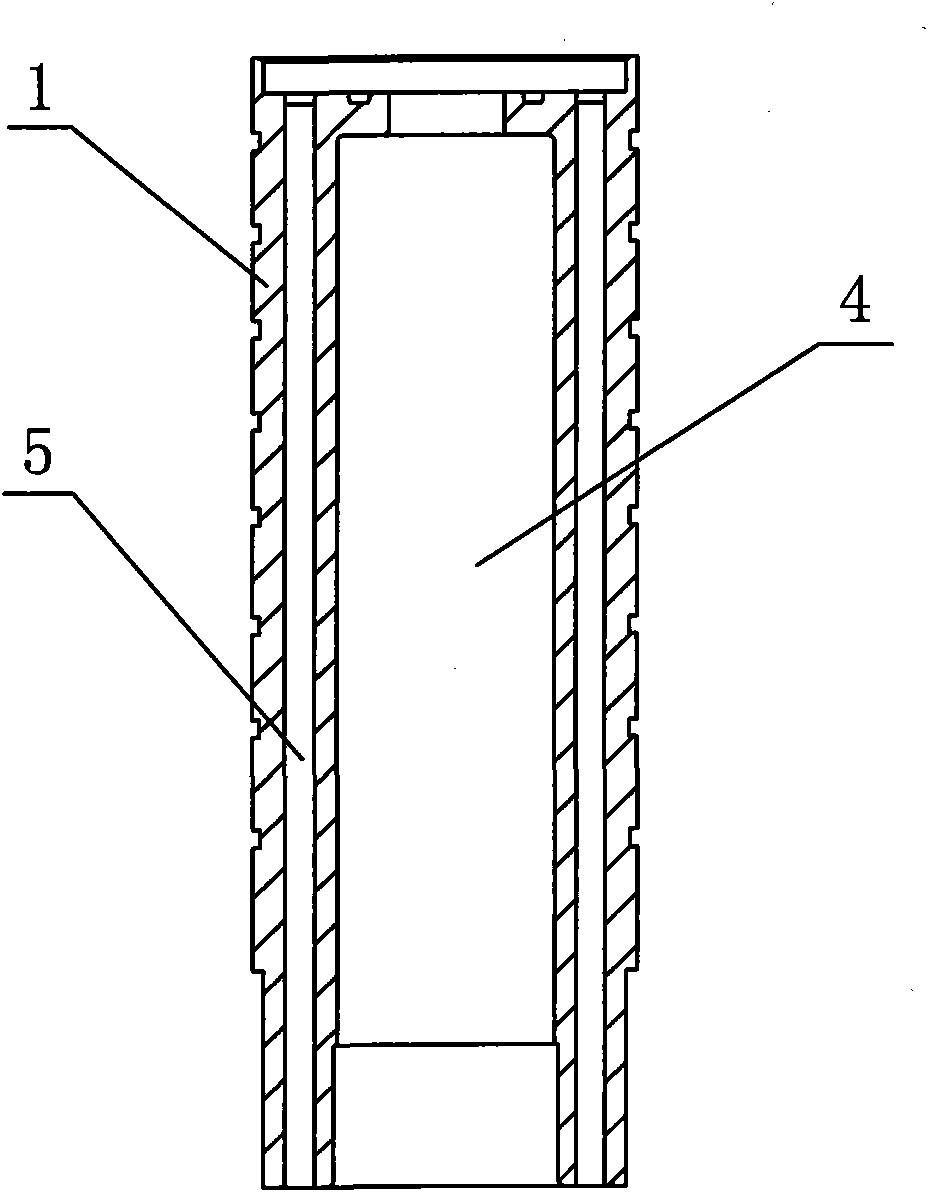

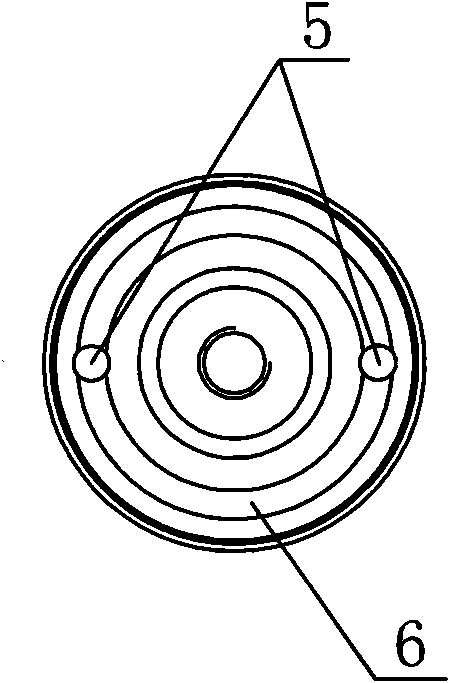

Electric signal counting photoelectric direct-reading device for remote transmission instruments

InactiveCN103499357ASmall refraction effectReduce the effect of refractionConverting sensor outputLight guideOptical axis

An electric signal counting photoelectric direct-reading device for remote transmission instruments solves the problems of large quantity of elements, poor antijamming capability and large error rate and the like of the existing photoelectric direct-reading device. The device comprises a light guide assembly with a decoder and a coded word wheel group assembled on the light guide assembly by a lighting shaft assembly; the technical key points are that each coded word wheel in the coded word wheel group is formed by integrally splicing a left light shielding wheel body, a right light shielding wheel body and a transparent wheel body; a light transmitting wheel disk groove of the transparent wheel body is matched and spliced with laterally arranged bosses of the left and right light shielding wheel bodies; a light receiving tube in a light guide hole of the light guide assembly converts an optical signal sent from a lighting tube of the lighting shaft assembly into an electric signal to be decoded by a decoding chip, so a radial light ray transmission path starting from the lighting shaft assembly, to the coded word wheels, the light guide assembly, and the decoder in sequence is formed. The electric signal counting photoelectric direct-reading device for the remote transmission instruments is reasonable in structural design, high in measuring precision, low in error rate, strong in antijamming capability, suitable for various environments and machining and production in batch and low in production cost.

Owner:沈阳蓝海灵豚投资有限公司

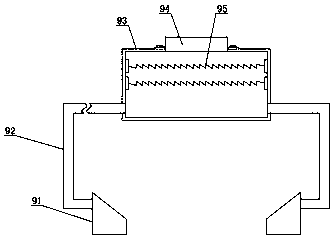

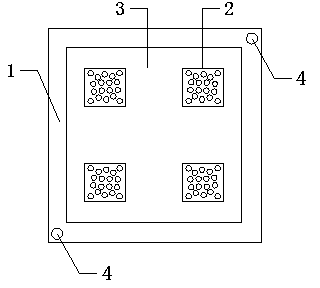

High concentrated photovoltaic cell bonding and printing steel mesh with positioning function

InactiveCN103342044APrecise positioningImprove yieldFinal product manufactureScreen printersMetallurgySolder paste

The invention relates to a high concentrated photovoltaic cell bonding and printing steel mesh with a positioning function, and belongs to the technical field of solar photovoltaic power generation. The high concentrated photovoltaic cell bonding and printing steel mesh with the positioning function comprises a frame, a printing hole array, a stainless steel sheet and a positioning hole, wherein the stainless steel sheet is fixed on the frame, and the printing hole array is formed in the stainless steel sheet in an engraving mode. After solder paste on the printing hole array is heated and melted, a concentrating photovoltaic cell sheet tightly adheres to a region through the solder paste and will not move or deviate; the concentrating photovoltaic cell can be more accurately positioned by the positioning hole, and therefore the percent of pass of products is improved; production and processing can be faster conducted, and therefore production efficiency is improved.

Owner:成都聚合科技有限公司

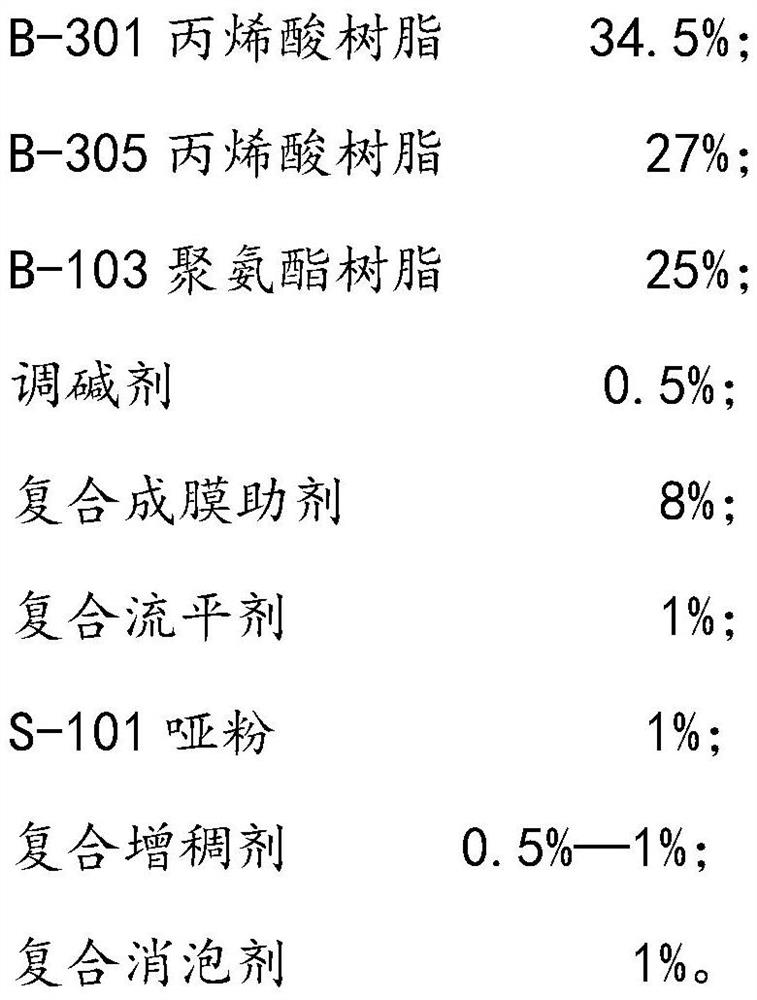

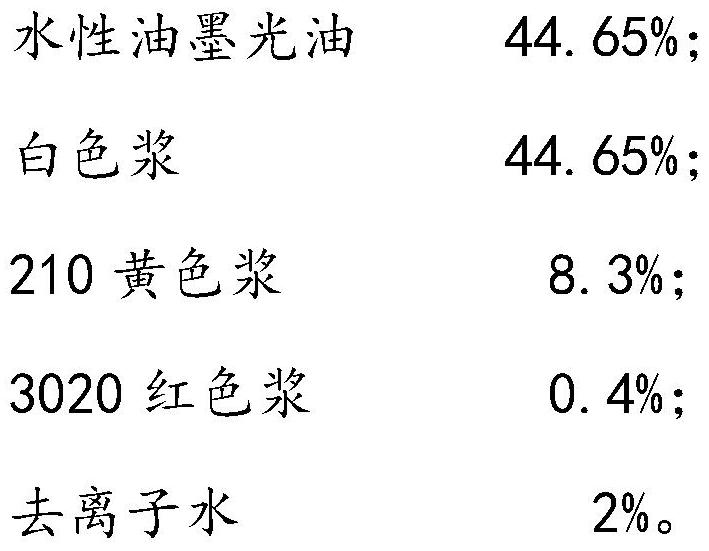

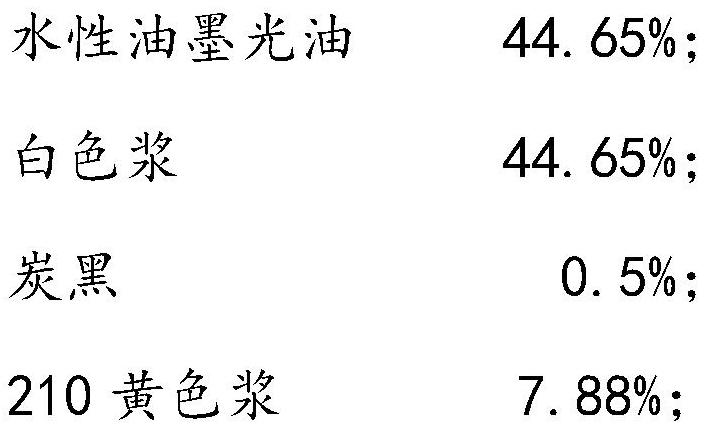

Temperature-resistant composite color water-based ink applied to helmets

The invention provides temperature-resistant composite color water-based ink applied to helmets, and relates to the technical field of fine chemical engineering and coating industries. The temperature-resistant composite-color water-based ink applied to the helmets comprises the following specific components: temperature-resistant water-based ink and water-based ink varnish, wherein the water-based ink varnish comprises the following components in percentage by mass: 34.5% of B-301 acrylic resin, 27% of B-305 acrylic resin, 25% of B-103 polyurethane resin, 0.5% of an alkali adjusting agent, 8%of a composite coalescing agent, 1% of a composite leveling agent, 1% of S-101 matt powder, 0.5%-1% of a composite thickening agent, and 1% of a composite antifoaming agent. According to the temperature-resistant composite color water-based ink, A, an orange ink is composed of the following components in percentage by mass: 44.65% of water-based ink varnish. The water-based ink varnish prepared by adopting the formula is used as a main material of the composite ink, and the temperature-resistant composite color water-based ink is compounded by adding color pastes with different colors and deionized water, so that the problem of color bleeding in the blister process is effectively solved, and the overall performance of the composite ink is greatly improved.

Owner:深圳市方润环境科技有限公司

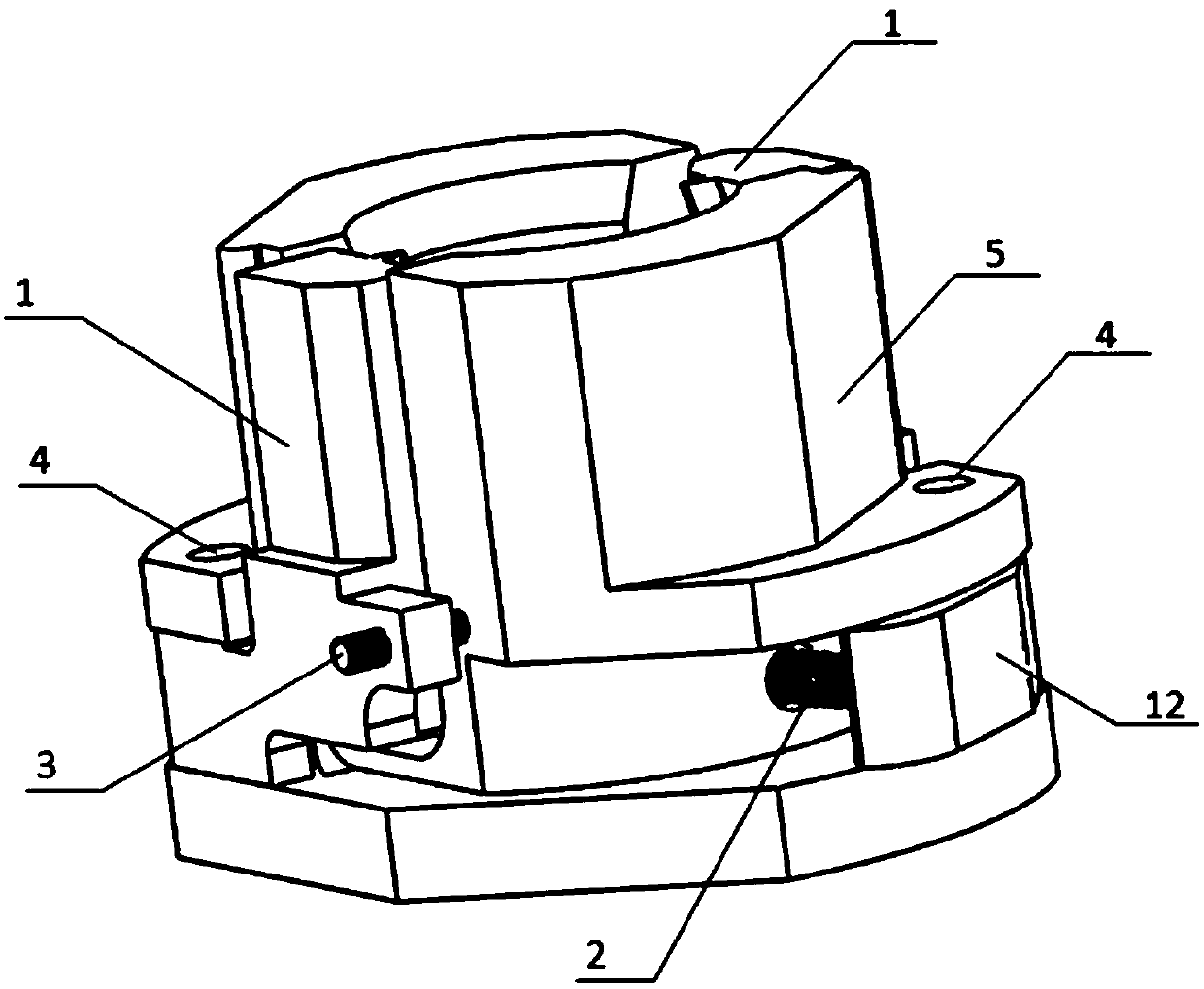

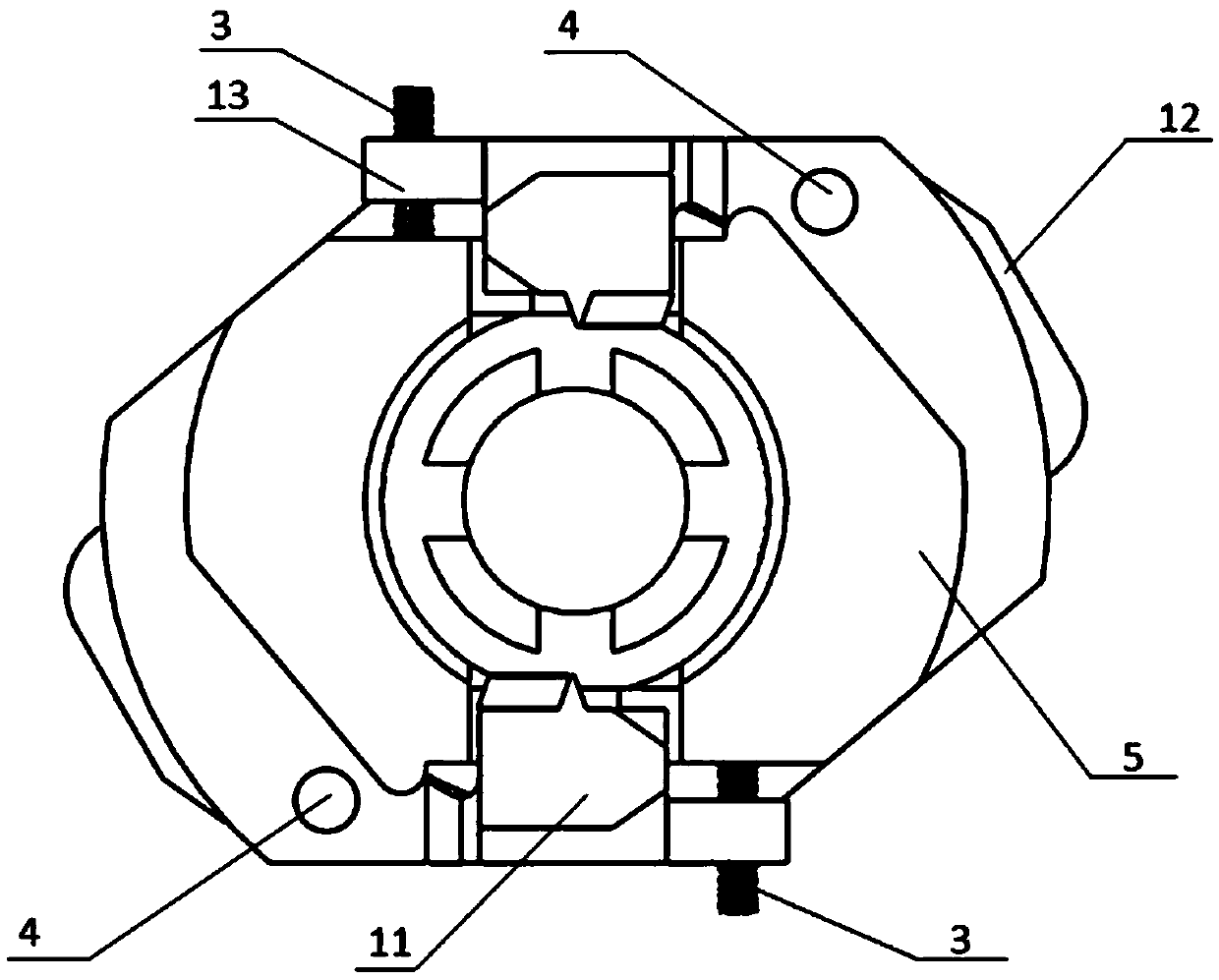

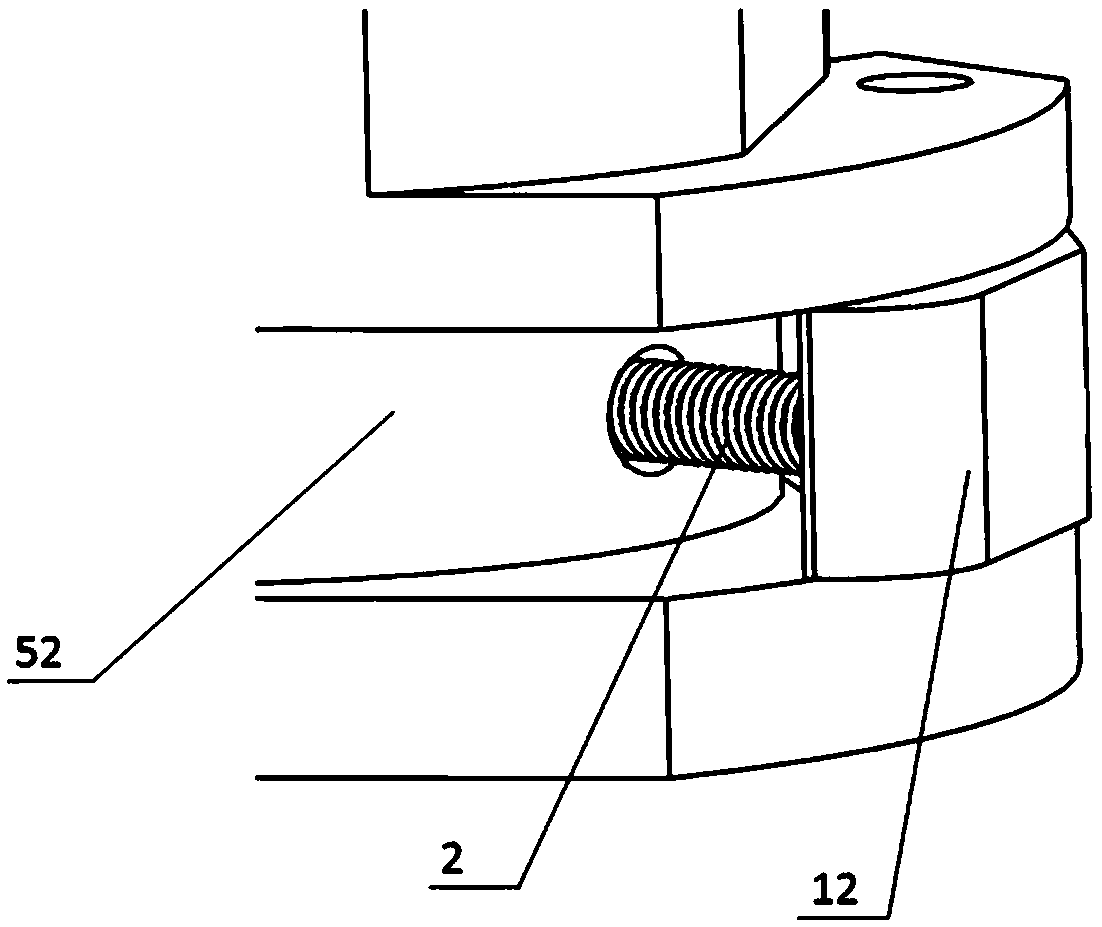

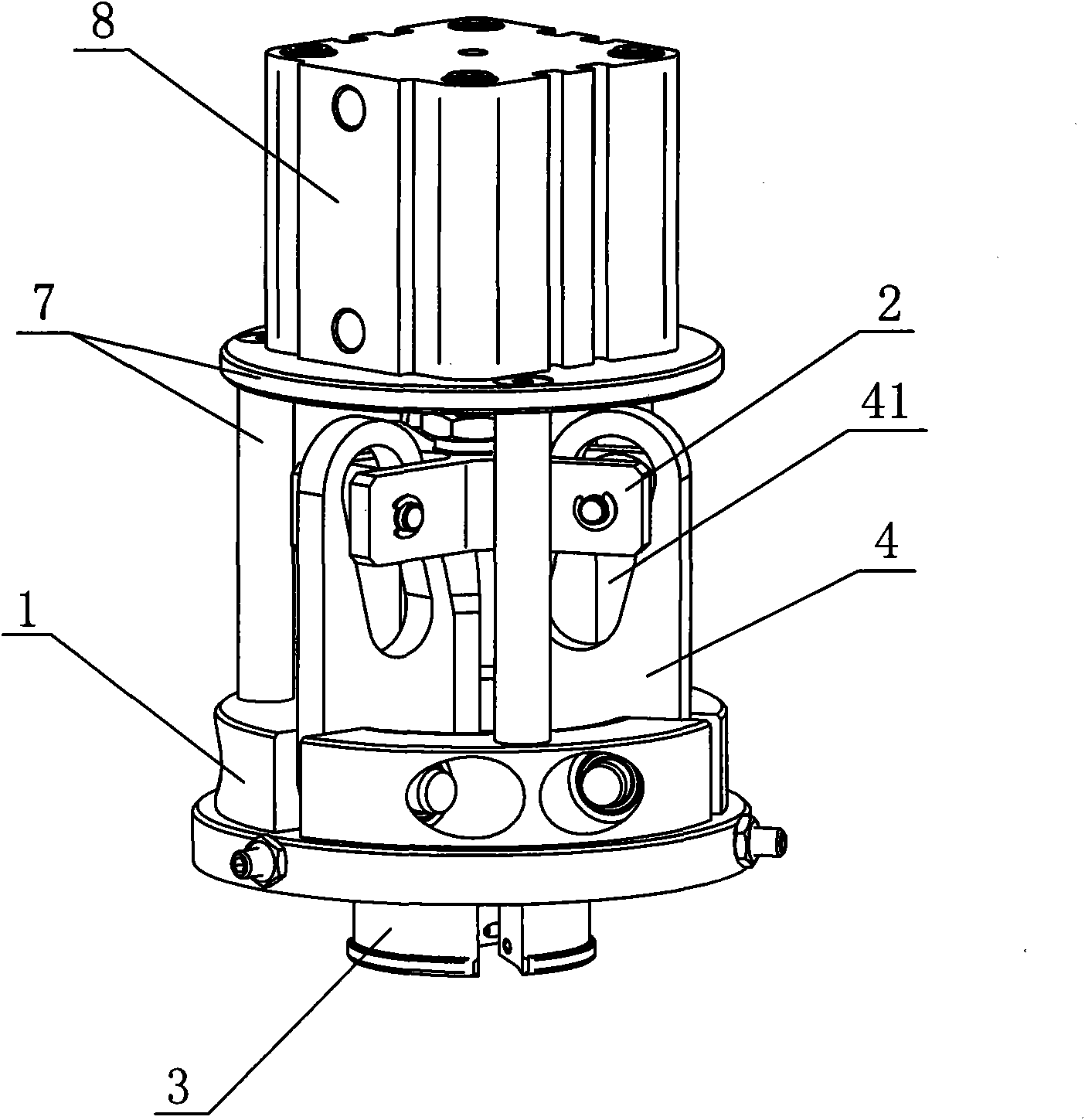

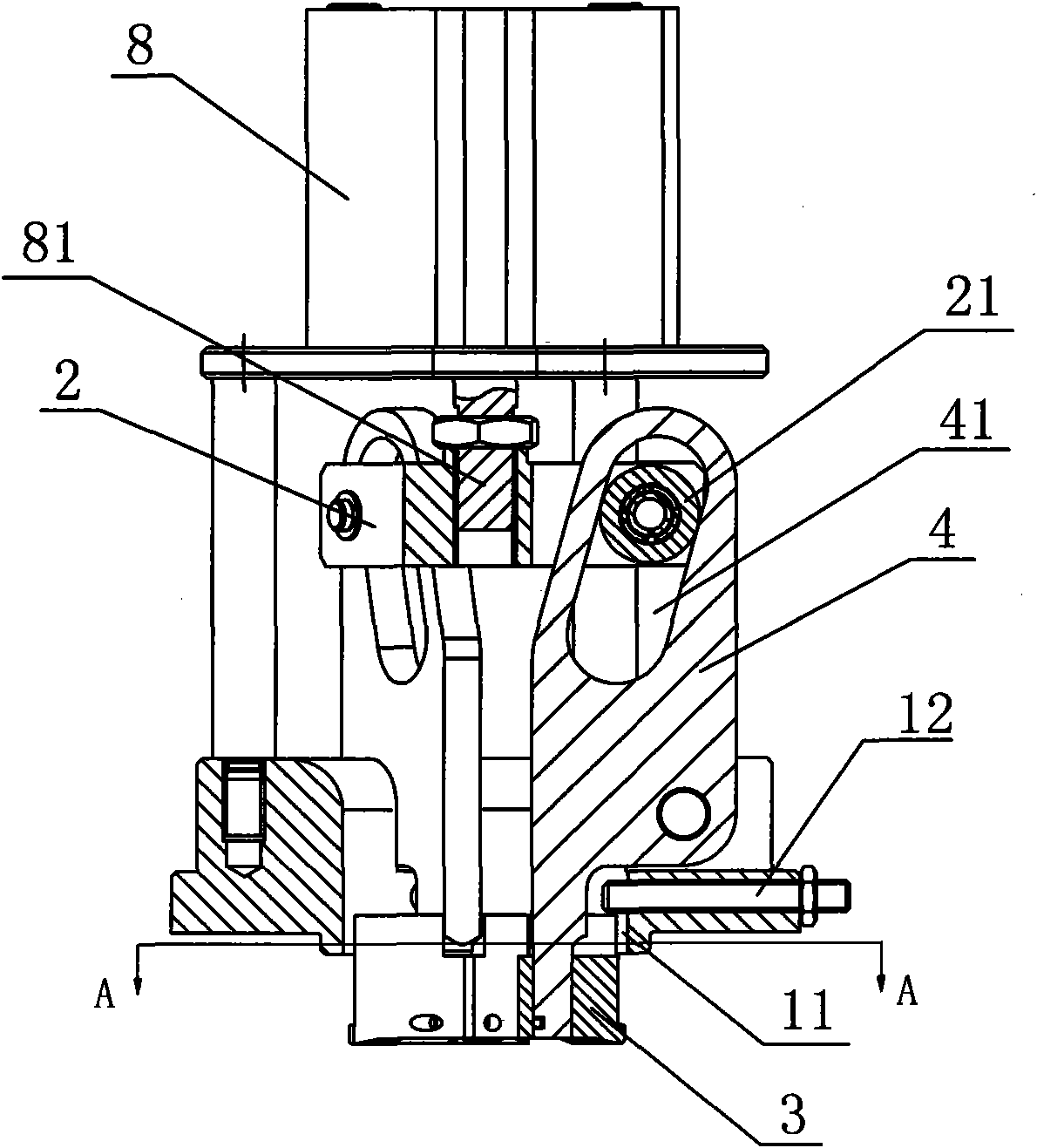

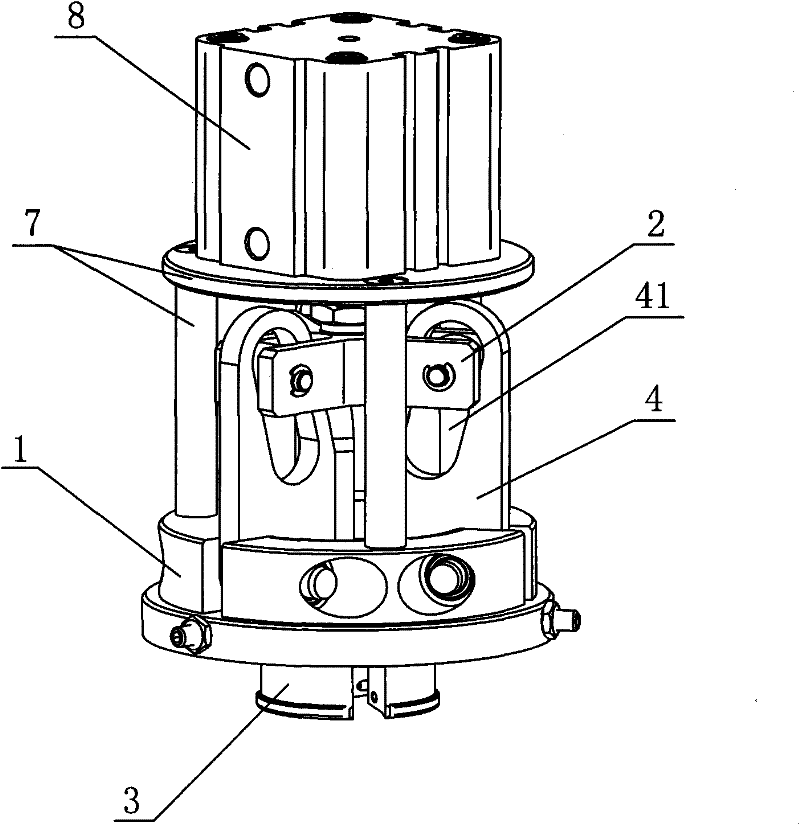

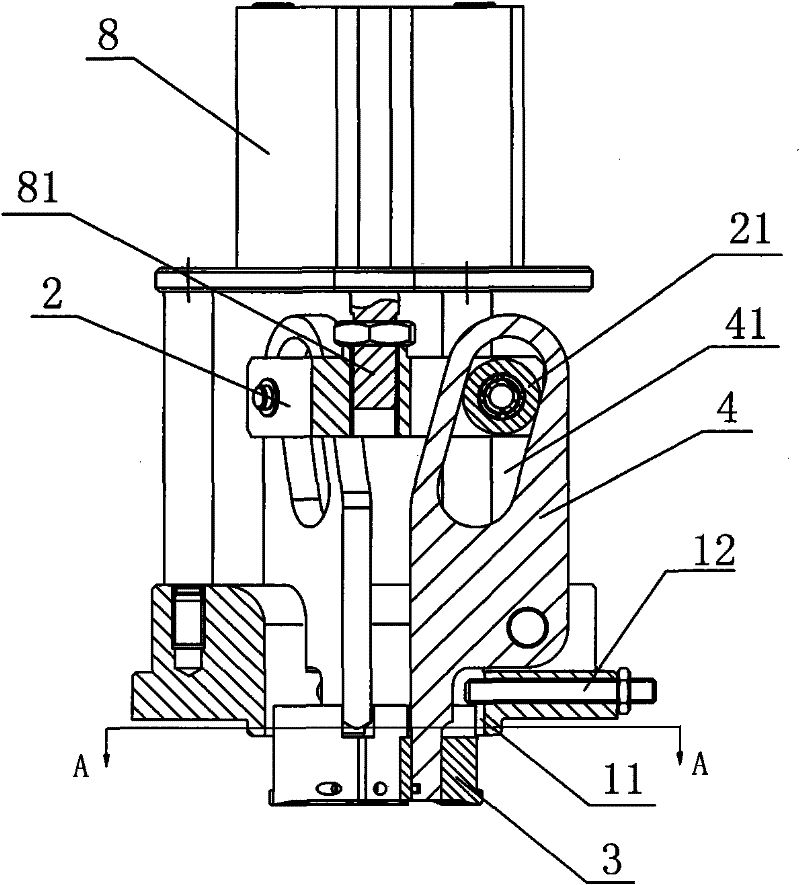

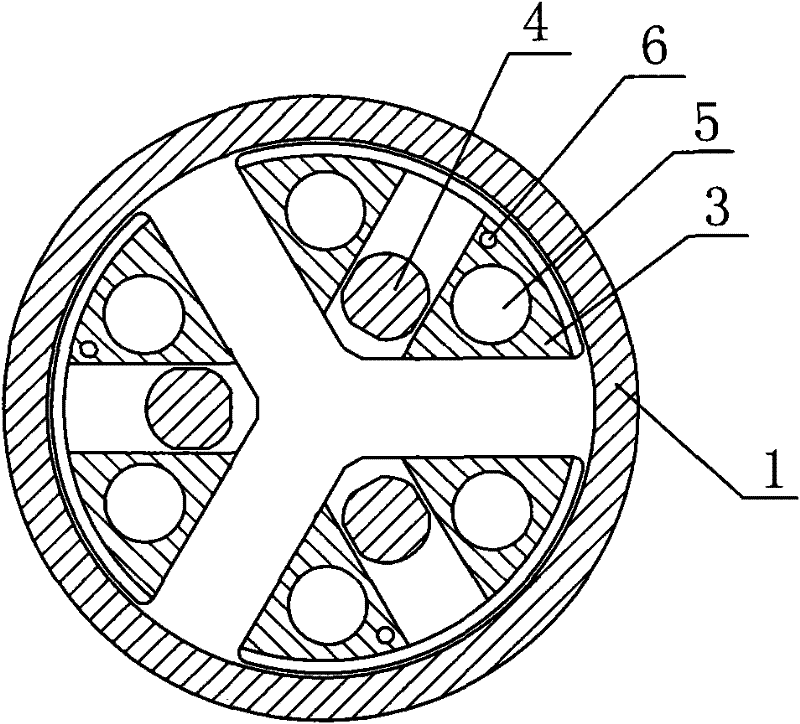

Honing clamp for planetary gears

PendingCN109623625APrevent up and down displacementSimple structureHoning machinesGrinding work supportsGear wheelEngineering

The invention provides a honing clamp for planetary gears. The honing clamp comprises two gear retaining plates and a clamp base, and the gear retaining plates are detachably connected into the clampbase; each gear retaining plate comprises a baffle, wherein the inner surface of the baffle is provided with a bulge; the clamp base comprises a gear placement table and two arc-shaped enclosing plates, and the two arc-shaped enclosing plates which are distributed in a center symmetry mode are fixedly connected to the outer side of the gear placement table; and the outer surface of the gear placement table is wrapped with the two arc-shaped enclosing plates, two opening grooves are formed between the two arc-shaped enclosing plates, and the two baffles are located in the opening grooves between the two arc-shaped enclosing plates correspondingly. According to the honing clamp for the planetary gears, fast positioning upward moving and motion blocking functions of the planetary gears can beachieved, and the honing process of the planetary gears is quickly completed.

Owner:天津天海同步科技有限公司

Box-section column of corrugated steel web-concrete filled steel tube flange combination

InactiveCN104328867AImprove mechanical performanceImprove the stable bearing capacityStrutsPillarsSteel columnsSteel tube

The invention discloses a box-section column of a corrugated steel web-concrete filled steel tube flange combination. Two webs and two flanges are connected to form a box-shaped structure, wherein the webs are corrugated steel webs; the periodically repeated corrugated edges of the corrugated steel webs are perpendicular to the length direction of a component; the non-corrugated edges of the corrugated steel webs are welded to the two width ends of the flanges; the flanges are concrete filled steel tube flanges including steel tubes and concrete in the steel tubes; the concrete is self-compacting concrete. According to the box-section column of corrugated steel web-concrete filled steel tube flange combination disclosed by the invention, the structural behavior of the box-section column of existing flat webs is improved and the comprehensive cost of the project is not increased significantly, so that the box-section column of corrugated steel web-concrete filled steel tube flange combination can be applied widely in projects.

Owner:NANJING UNIV OF TECH

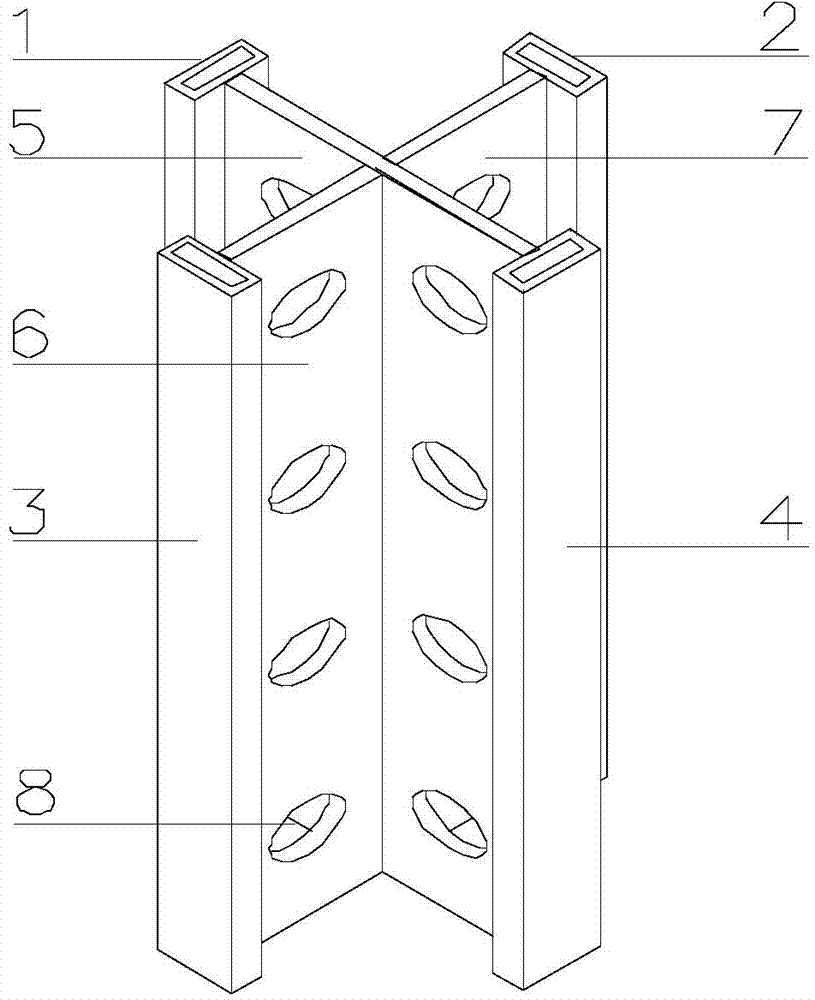

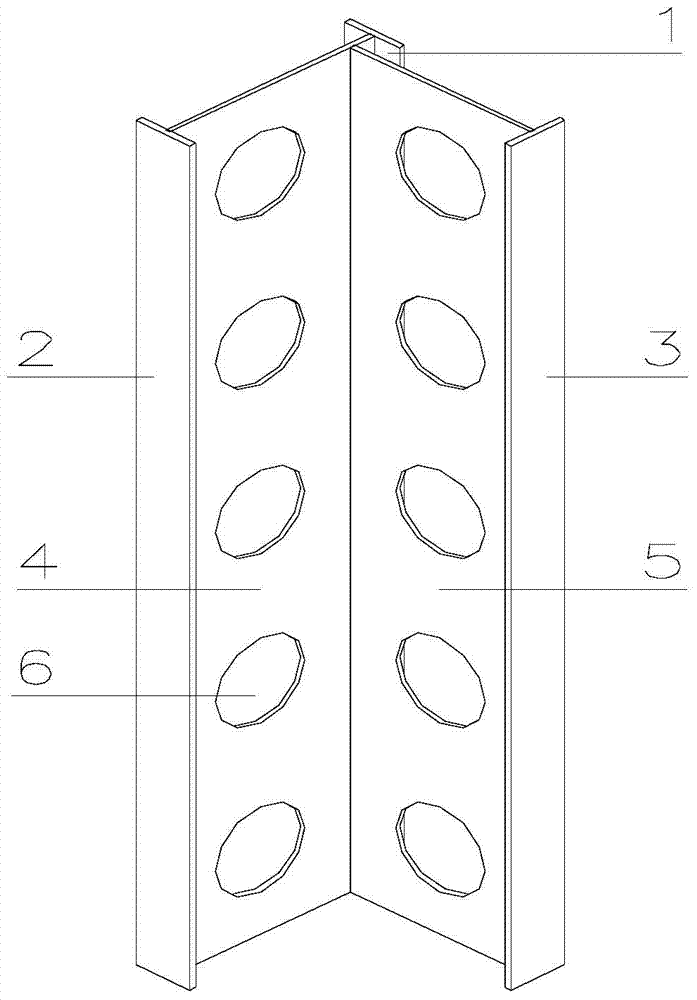

Honeycomb-shaped web crossed-section special-shaped steel column

InactiveCN104234314AReasonable section compositionImprove mechanical propertiesStrutsPillarsButt jointHoneycomb

The invention discloses a honeycomb-shaped web crossed-section special-shaped steel column. The honeycomb-shaped web crossed-section special-shaped steel column comprises a first rectangular steel pipe flange, a second rectangular steel pipe flange, a third rectangular steel pipe flange, a four rectangular steel pipe flange, a first steel web, a second steel web and a third steel web; the first steel web, the second steel web and the third steel web are connected together to form a crossed component; the first steel web, the second steel web and the third steel web are honeycomb-shaped steel webs of which the middles are provided with web holes; each of the first steel web, the second steel web and the third steel web respectively consists of two steel plates of which the edges are provided with notches; the steel plates are welded by butt-jointed seams to form the honeycomb-shaped steel webs. According to the invention, the structural behaviors of the conventional solid-web special-shaped steel column with a crossed section and the conventional trussed web member special-shaped steel column with a crossed section are improved without obviously increasing the comprehensive cost of the construction, so that the honeycomb-shaped web crossed-section special-shaped steel column is widely applied to in the construction.

Owner:NANJING UNIV OF TECH

Camel special-purpose compound nutritive block for lapping and production method thereof

InactiveCN105918636ASolve the problem of fat lossImprove palatabilityFood processingAnimal feeding stuffSelenium methionineManganese

The invention relates to a camel special-purpose compound nutritive block for lapping and a production method thereof. Each 1kg of the block for lapping comprises 1.5-3% of molasses, 10-15% of urea, 5-9% of bentonite, 5-10% of zeolite, 55-65% of table salt, 5-9% of calcium hydrogen phosphate, 1-2% of magnesium sulfate, 5-10% of detoxicated rapeseed cake, 0.02-0.08% of zinc-amino acid chelate, 0.0001-0.0002% of selenium methionine, 0.03-0.06% of manganese methionine, 0.0001-0.0004% of cobalt methionine, 0.07-0.08% of iron methionine and 0.01-0.02% of copper methionine. The camel special-purpose compound nutritive block for lapping has good palatability and good absorbency, is rich in nutrient elements suitable for camel absorption, supplies nutrients suitable for camel absorption and solves the problem of camel weight reduction caused by seasonal nutrition imbalance. The camel special-purpose compound nutritive block for lapping is prepared from easily available raw materials. The production method is simple and fast.

Owner:新疆畜牧科学院饲料研究所

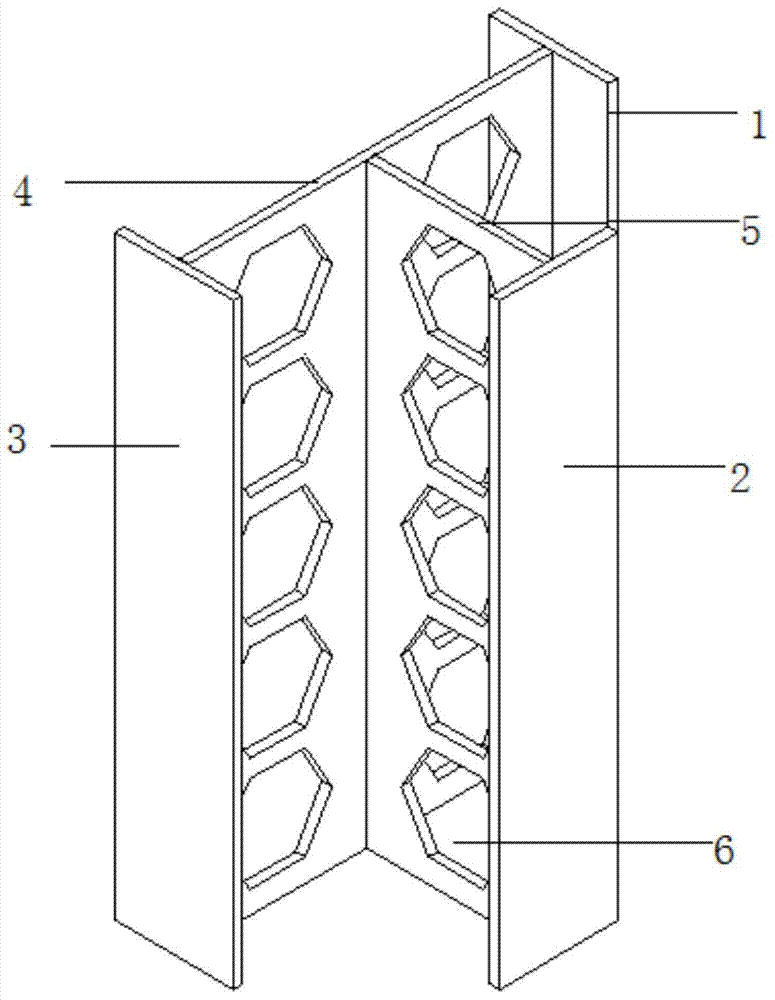

Honeycomb-shaped web special-shaped steel column with T-shaped section

InactiveCN104234309AReasonable section compositionImprove mechanical propertiesStrutsPillarsSheet steelResidence

The invention discloses a honeycomb-shaped web special-shaped steel column with a T-shaped section. The honeycomb-shaped web special-shaped steel column with the T-shaped section comprises a first plain steel plate flange, a second plain steel plate flange, a third plain steel plate flange, a first steel web, a second steel web and holes; one side edge of the second steel web is perpendicularly connected with the middle part of the first steel web, and the other side edge of the second steel web and two side edges of the first steel web are respectively connected with the first plain steel plate flange, the second plain steel plate flange, the third plain steel plate flange together to form the special-shaped steel column with the T-shaped section; the first steel web and the second steel web are honeycomb-shaped webs of which the middles are provided with the holes; each of the first steel web and the second steel web respectively consists of steel plates of which the edges are provided with notches; the steel plates are welded by butt-jointed seams to form the honeycomb-shaped webs. According to the invention, the structural behavior of the special-shaped steel column is improved without obviously increasing comprehensive cost of the construction, so that the special-shaped column structure is more widely applied to multi-storey and high-rise residences.

Owner:NANJING UNIV OF TECH

Bottom cover sealing device for liquid paper can

The invention discloses a bottom cover sealing device for a liquid paper can. The device is characterized by comprising a base and at least two sealing blocks which can be spliced into a circle mutually, wherein the sealing blocks are provided with a heater and a sensor; and the base is provided with a drive device for driving the sealing blocks to expand outwards or contract inwards. The device has the advantages that: a bottom cover and a paper can filled with a liquid beverage are sealed to replace a pop can by using the device so as to reduce the use and the waste of metal resources and reduce production cost and environment pollution; and moreover, the production and the processing are simple, convenient and rapid.

Owner:乐美机械(宁波)有限公司

Machining method for complex MIM part

PendingCN111992722ARapid processing and productionEfficient processing and productionTransportation and packagingMetal-working apparatusProduct inspectionMachining process

The invention discloses a machining method for a complex MIM part. The method comprises the following steps of S1, raw material inspection, S2, mixing and injection molding, S3, sintering machining, S4, deep machining treatment, and S5, product inspection and packaging, specifically, carrying out randomly selecting and inspecting on all products, and packaging the randomly selected products afterthe randomly selected products meet the qualified rate of 100%, and storing the packaged products in a shipment warehouse. According to the machining method for the complex MIM part, firstly, a raw material is detected, and defective products are avoided; the metal powder raw material and a binder are uniformly mixed and injected into a mold for molding so as to quickly obtain rough blank workpieces; the rough blank workpieces are combined and sintered to obtain a sintered workpiece; and then the sintered workpiece is subjected to deep machining treatment, so that production and machining of the product are rapidly and effectively completed, the whole production and machining process is scientifically designed and treated, and machining and production of the complex MIM part can be effectively completed.

Owner:苏州卓米智能制造科技有限公司

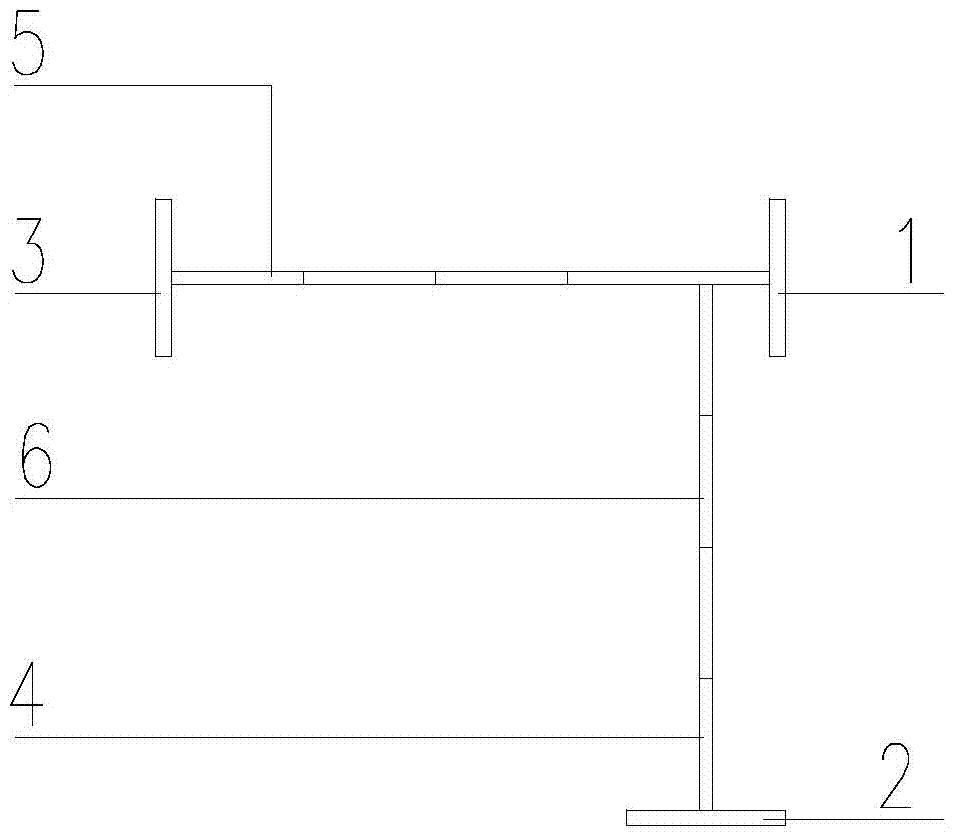

Corrugated steel web plate-steel pipe concrete flange combined section T-shaped column

InactiveCN104405085AImprove mechanical performanceImprove local stabilityStrutsPillarsSteel columnsHigh rise

The invention discloses a corrugated steel web plate-steel pipe concrete flange combined section T-shaped column which is formed through welding web plate H-shaped steel and web plate T-shaped steel or welding two web plates and three flanges, wherein web plates are corrugated steel web plates which are curvilinear, polygonal-shaped or trapezoid; the periodically repeated corrugated edges of the corrugated steel web plates are perpendicular to the length direction of a member; the non-corrugated edges of the corrugated steel web plates are respectively welded with the middle points in the width directions of the flanges; the flanges are steel pipe concrete flanges; the steel pipe concrete flanges comprise steel pipes and concrete in the steel pipes; the concrete is self-compacting concrete. According to the corrugated steel web plate-steel pipe concrete flange combined section T-shaped column, the stress performance of a conventional solid web type specially-shaped steel column and the stress performance of a truss type web member specially-shaped steel column are improved, and the comprehensive manufacturing cost of engineering is not obviously increased, so that a specially-shaped column structure can be widely applied to multiple high-rise buildings.

Owner:NANJING UNIV OF TECH

Special solar energy high power spotlighting steel mesh with positioning irregular holes

InactiveCN104290436AImprove product yieldRapid production and processingFinal product manufactureScreen printersSolder pasteMaterials science

The invention relates to a special solar energy high power spotlight steel mesh with positioning irregular holes and belongs to the technical field of solar photovoltaic electricity generating. The special solar energy high power spotlight steel mesh with the positioning irregular holes for the solar energy comprises a frame, a stainless steel piece, an irregular array hole and a positioning hole; the stainless steel piece is fixed on the frame; the irregular array hole and the positioning hole in the same size are engraved on the stainless steel piece. According to the special solar energy high power spotlight steel mesh with the positioning irregular holes, a spotlighting photovoltaic battery piece is tightly adhered to an area after solder paste on the irregular array hole is heated and melted; the positioning hole can accurately position the spotlighting photovoltaic battery piece to improve the product yield; production and manufacturing can be performed rapidly and the production efficiency is improved.

Owner:KUNSHAN KEDE NEW ENERGY TECH

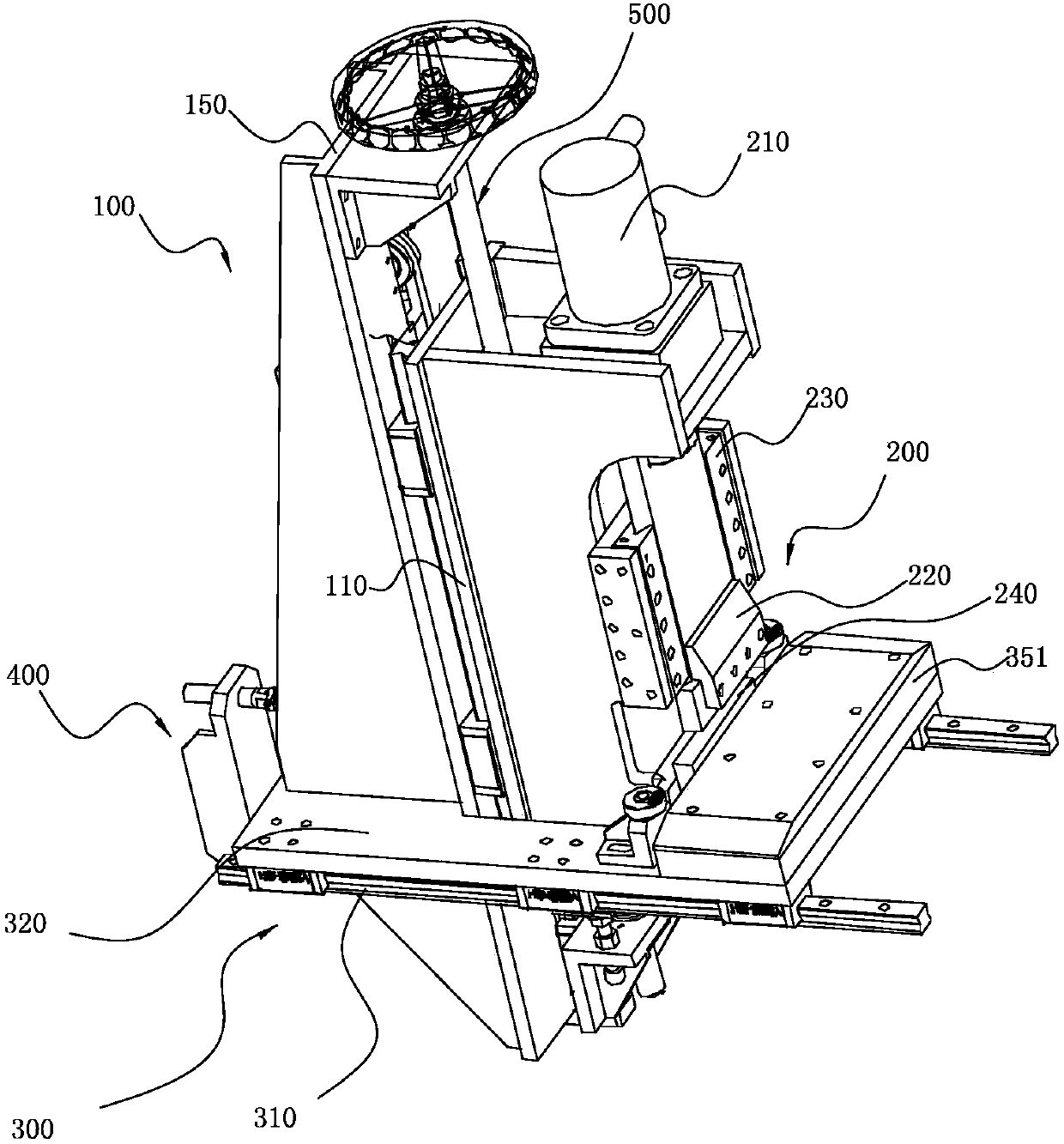

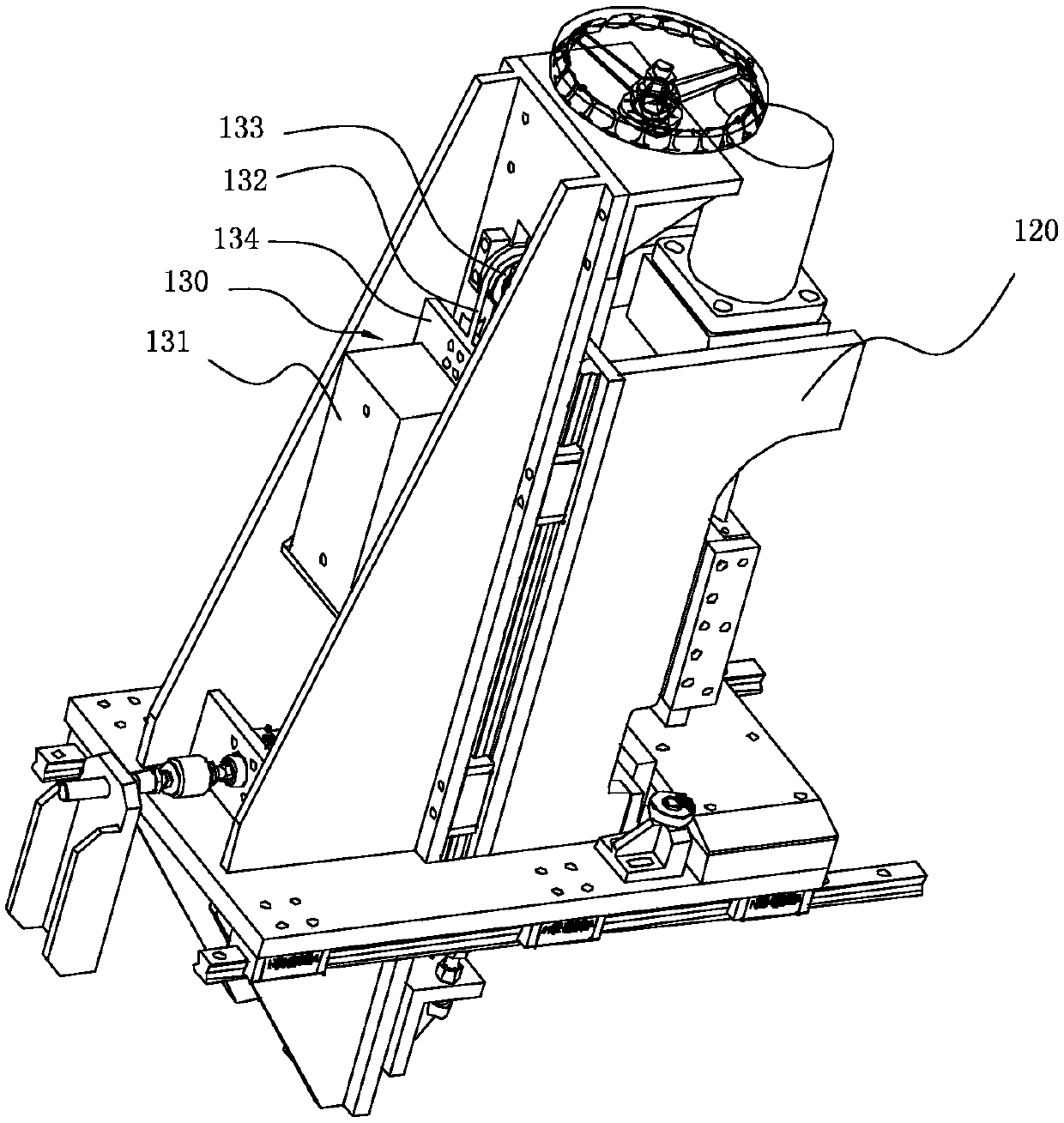

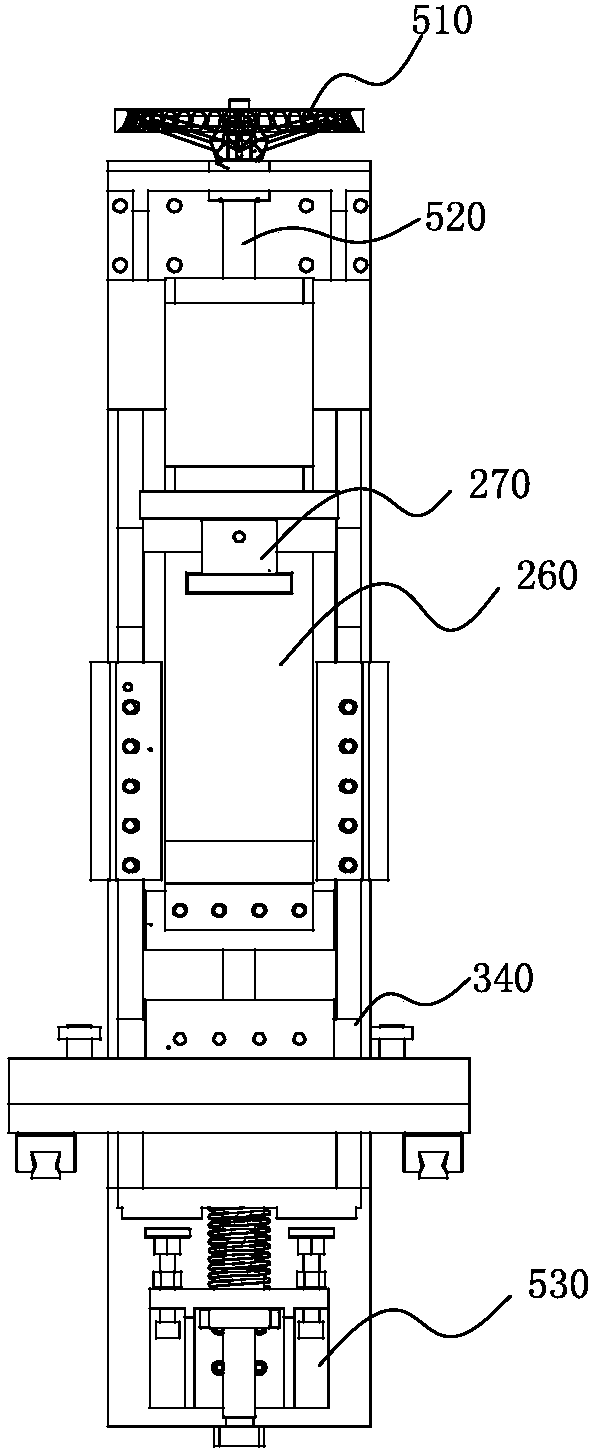

Shearing machine for steel grating plate

PendingCN107914037AAdjustable cutting heightAdjustable lateral clearanceShearing machinesShearing toolsGratingEngineering

The invention discloses a shearing machine for a steel grating plate. The machine comprises a cutter holder seat, a cutter assembly, a supporting seat, a transverse adjusting assembly and a lead screwadjusting assembly, wherein the cutter assembly comprises an oil cylinder, an upper cutter which is driven through the oil cylinder, a guide seat for guiding the upper cutter, a slideable lower cutter, and a lower cutter guide rail which is arranged on the cutter holder seat; the oil cylinder and the guide seat are fixed to the cutter holder seat; the supporting seat comprises a transverse guiderail, a supporting plate and a first vertical guide rail; the transverse adjusting assembly is connected to the cutter holder seat; the lower end of the lead screw adjusting assembly is in contact with the lower cutter. The shearing machine for the steel grating plate is simple in structure, stable to work, and accurate in cutting; the upper cutter is used for pressing and positioning the steel grating plate and can be matched with the lower cutter to cut the steel grating plate; few working steps are carried out, so that the production and processing can be quickly performed; and meanwhile, transverse gaps of the upper cutter and the lower cutter can be adjusted; and the cutting height of the lower cutter can be adjusted.

Owner:NINGBO XINZHOU RESISTANCE WELDER

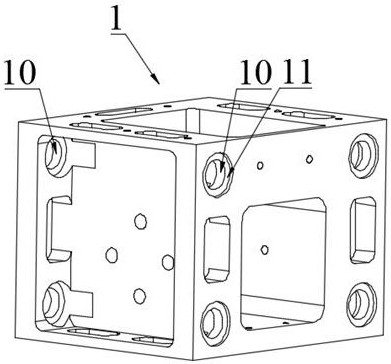

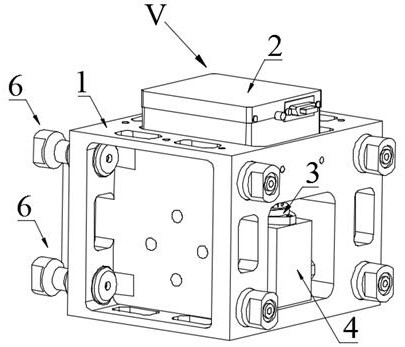

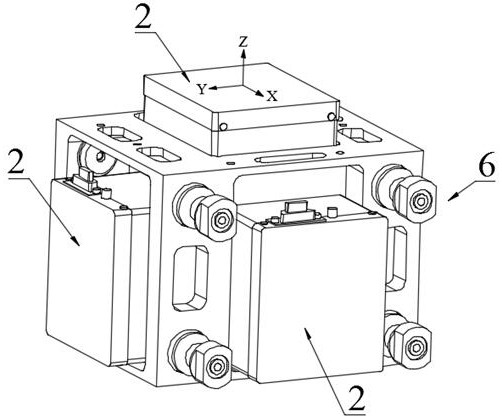

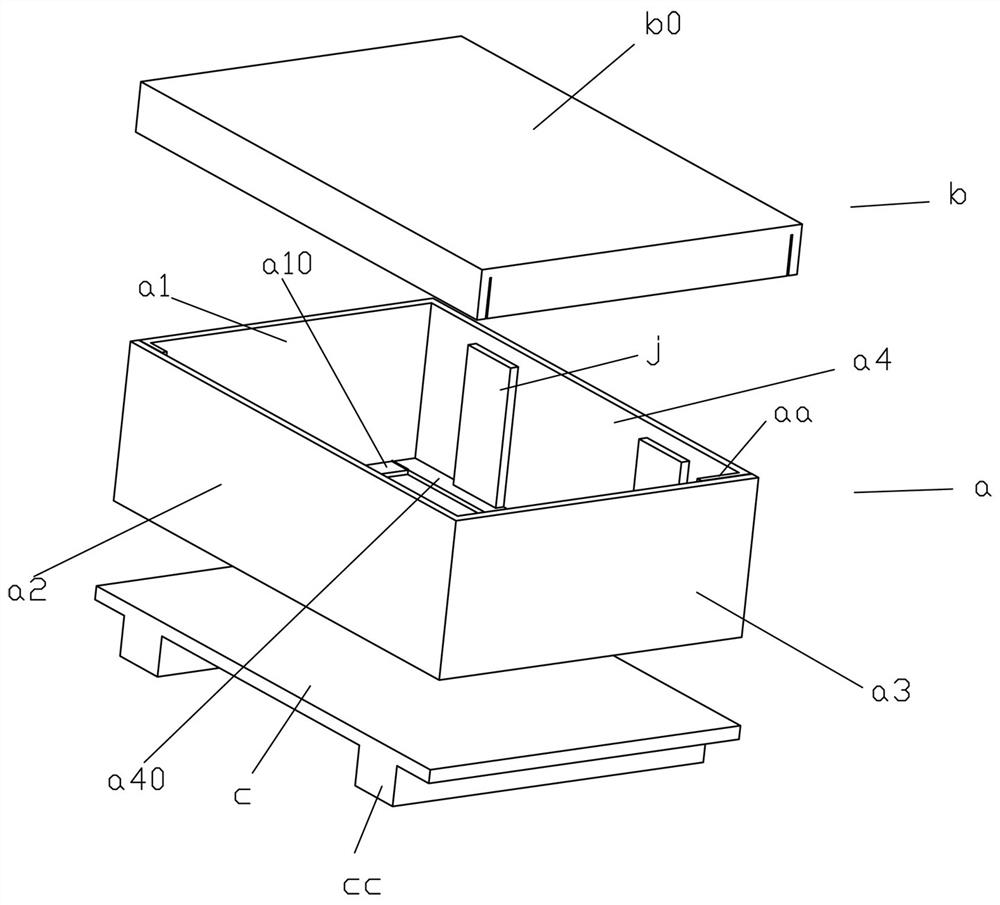

A Laser Gyro Strapdown Inertial Navigation

ActiveCN109186600BRegular and concise structureRapid production and processingNavigation by speed/acceleration measurementsAccelerometerEngineering

The invention discloses a laser gyro strapdown inertial navigation system, which includes an installation frame, and the installation frame is used for fixed installation of three laser gyro and three accelerometers, and is characterized in that: the overall shape of the installation frame is rectangular Shaped structure; the rectangular body-shaped structure is concave in the middle of any three sides of the four sides in the horizontal circumferential direction and is formed with an X-direction laser gyro installation groove, a Y-direction light gyro installation groove and an accelerometer installation Groove, the accelerometer installation groove can accommodate three accelerometers and provide them for fixed installation; the middle position of any one of the top surface or bottom surface of the rectangular body-shaped structure is concavely formed with a Z-direction laser gyro installation groove. The laser gyro strapdown inertial navigation system of the present invention has the advantages of regular and simple structure, small volume, high compactness and lighter weight.

Owner:CHONGQING QIANWEI SCI & TECH GRP

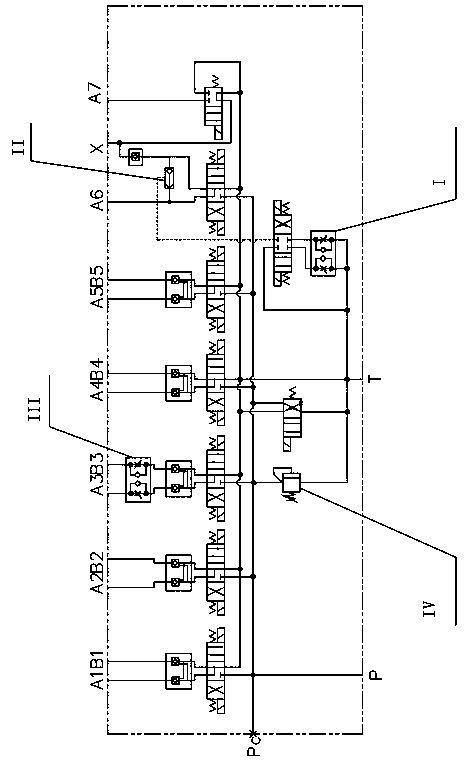

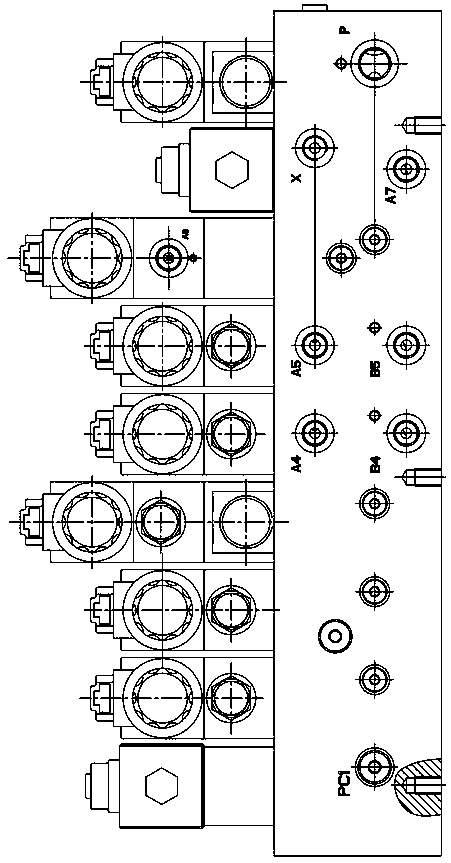

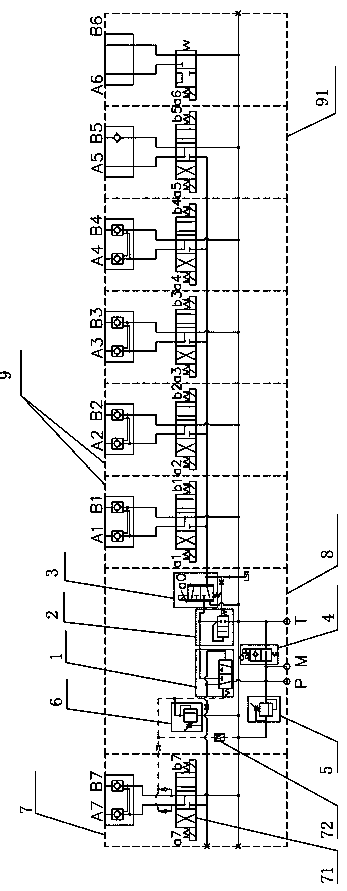

Hydraulic control system for environmental sanitation sweeper

PendingCN110617244ASave system energyReliable actionFluid-pressure actuator safetyServomotor componentsEnergy lossStreamflow

The invention discloses a hydraulic control system for an environmental sanitation sweeper. The hydraulic control system solves he problems that an existing sweeper system is large in energy loss, complex in structure, poor in synchronous performance and incapable of realizing modularization. The hydraulic control system comprises a suction valve set, an oil inlet and return valve set, and a working valve set, wherein the oil inlet and return valve set comprises a main oil inlet, an oil return opening, a pressure compensation valve, a diverter valve, a proportional solenoid valve and a main overflow valve; the pressure compensation valve is used for realizing the flow distribution, and is used for completing the composite action of a suction of the suction valve set and an actuating mechanism of the working valve set; the diverter valve is used for meeting the flow except the working requirement for low-pressure unloading; and the proportional solenoid valve is used for realizing control of the output flow so as to control the speed of the actuating mechanism of the working valve set. The hydraulic control system has the advantages that rapid and large-scale production and processing can be achieved, modular production and assembly can be achieved, organizing production is facilitated, the structure is simple, the assembly is facilitated, the action is reliable, the system energy consumption is small, the synchronization performance is good, service life is long, and the like.

Owner:SHENGBANG GRP +3

Electric signal counting photoelectric direct reading device for remote transmission instrument

InactiveCN103499357BSmall refraction effectReduce the effect of refractionConverting sensor outputInterference resistanceOptical axis

An electric signal counting photoelectric direct-reading device for remote transmission instruments solves the problems of large quantity of elements, poor antijamming capability and large error rate and the like of the existing photoelectric direct-reading device. The device comprises a light guide assembly with a decoder and a coded word wheel group assembled on the light guide assembly by a lighting shaft assembly; the technical key points are that each coded word wheel in the coded word wheel group is formed by integrally splicing a left light shielding wheel body, a right light shielding wheel body and a transparent wheel body; a light transmitting wheel disk groove of the transparent wheel body is matched and spliced with laterally arranged bosses of the left and right light shielding wheel bodies; a light receiving tube in a light guide hole of the light guide assembly converts an optical signal sent from a lighting tube of the lighting shaft assembly into an electric signal to be decoded by a decoding chip, so a radial light ray transmission path starting from the lighting shaft assembly, to the coded word wheels, the light guide assembly, and the decoder in sequence is formed. The electric signal counting photoelectric direct-reading device for the remote transmission instruments is reasonable in structural design, high in measuring precision, low in error rate, strong in antijamming capability, suitable for various environments and machining and production in batch and low in production cost.

Owner:沈阳蓝海灵豚投资有限公司

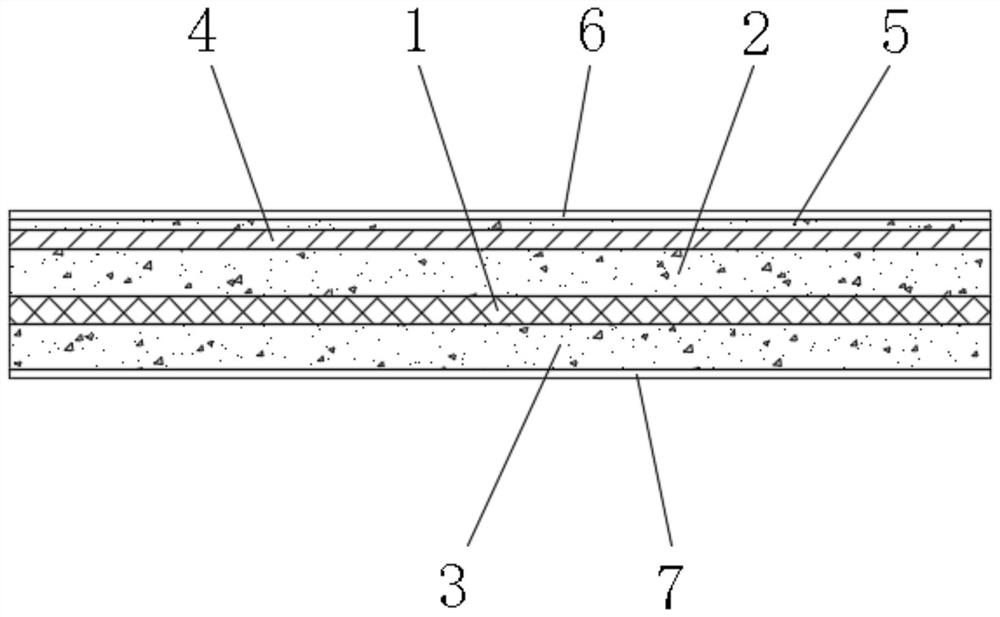

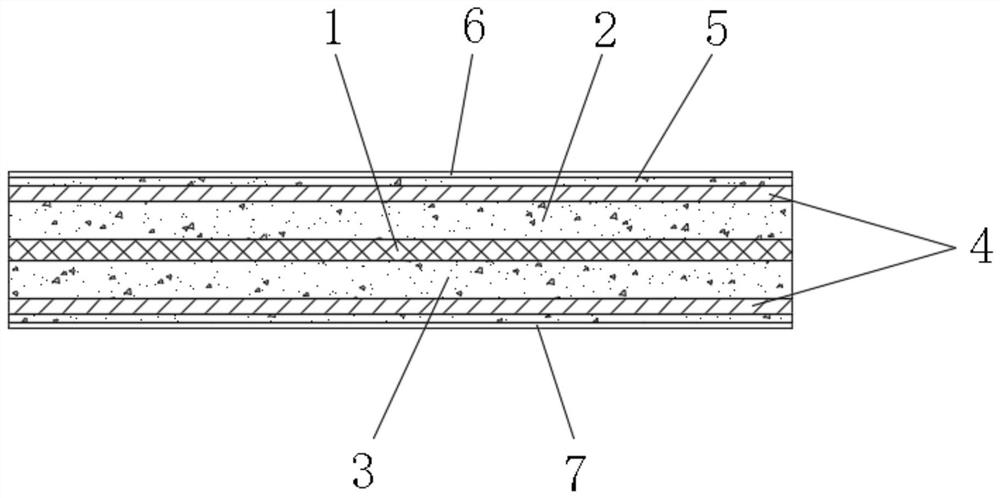

Preparation method of SBS modified asphalt energy-saving thermal-insulation waterproof coiled material

ActiveCN112026298ARapid production and processingSave manpower and material resourcesSynthetic resin layered productsGlass/slag layered productsPolyesterAsphalt

The invention provides a preparation method of an SBS modified asphalt energy-saving thermal-insulation waterproof coiled material, and relates to the technical field of preparation of energy-saving thermal-insulation waterproof coiled materials. The SBS modified asphalt energy-saving thermal-insulation waterproof coiled material comprises a first SBS modified asphalt layer and a second SBS modified asphalt layer which coat the upper surface and the lower surface of a framework layer, a high-temperature-resistant fireproof layer is bonded to the upper surface of the first SBS modified asphaltlayer, and a surface SBS modified asphalt layer is arranged on the upper surface of the high-temperature-resistant fireproof layer; an upper surface isolating membrane layer and a lower surface isolating membrane layer are respectively arranged on the outer surfaces of the surface SBS modified asphalt layer and the second SBS modified asphalt layer; and the framework layer is formed by compoundingand processing thin steel wires and a polyester base. By designing the three SBS modified asphalt layers, the waterproof performance of the thermal-insulation waterproof coiled material can be greatly improved, the high-temperature-resistant fireproof layer is arranged between the two SBS modified asphalt layers, the high-temperature-resistant and sun-proof performance of the thermal-insulation waterproof coiled material can be greatly improved, and the thermal-insulation waterproof coiled material is worthy of vigorous popularization.

Owner:山东坤岳防水材料股份有限公司

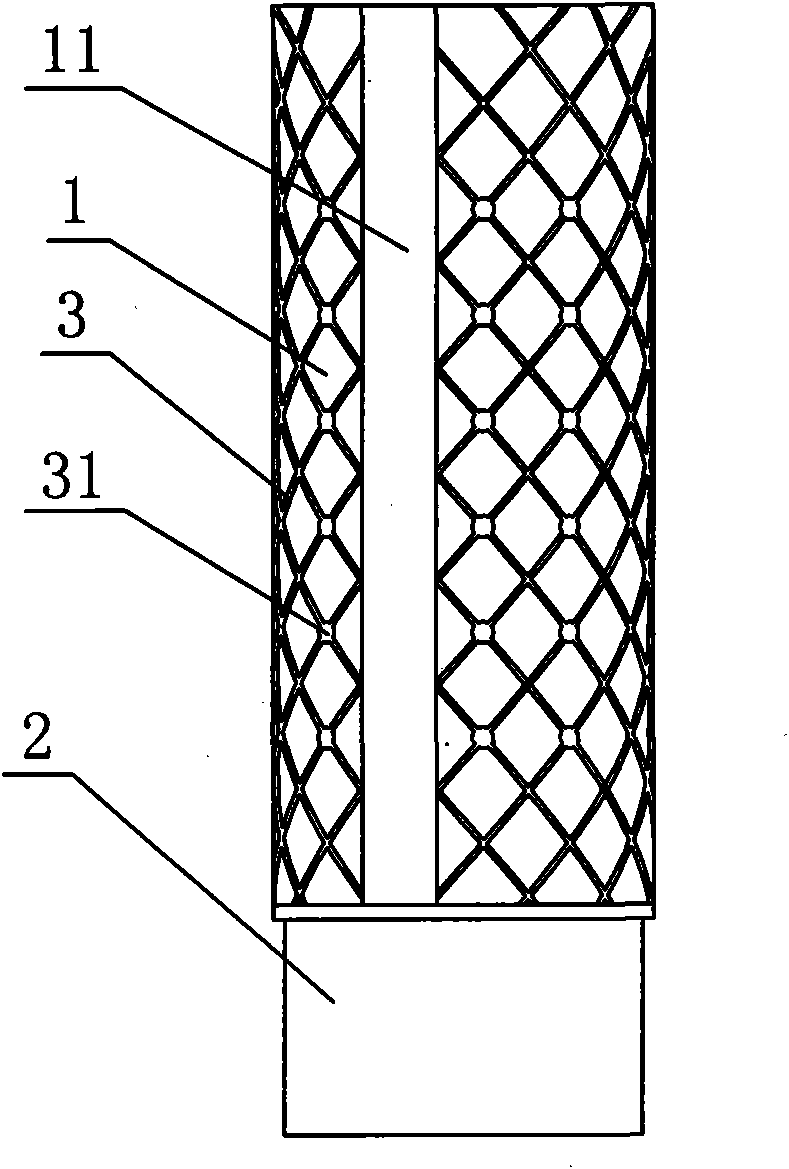

Honeycomb-shaped web special-shaped steel column with L-shaped section

The invention discloses a honeycomb-shaped web special-shaped steel column with an L-shaped section. The honeycomb-shaped web special-shaped steel column comprises a first plain steel plate flange, a second plain steel plate flange, a third plain steel plate flange, a first steel web, a second steel web and holes; one side edge of the second steel web is perpendicularly connected with the edge of the first steel web, and the other side edge of the second steel web and two side edges of the first steel web are respectively connected with the first plain steel plate flange, the second plain steel plate flange, the third plain steel plate flange together to form the special-shaped steel column with the L-shaped section; the first steel web and the second steel web are honeycomb-shaped webs of which the middles are provided with the holes; each of the first steel web and the second steel web respectively consists of two steel plates of which the edges are provided with notches and the shapes are the same; every two corresponding steel plates are welded by a butt-jointed seam to form one honeycomb-shaped web. According to the invention, the structural behaviors of the conventional solid-web special-shaped steel column with an L-shaped section and the conventional trussed special-shaped steel column with an L-shaped section are improved, and the comprehensive cost of the construction is controlled.

Owner:NANJING UNIV OF TECH

Mandrel for forming liquid paper can

InactiveCN101870184AReduce the use effectReduce wastePaper/cardboard wound articlesPulp and paper industryAluminum foil

The invention discloses a mandrel for forming a liquid paper can. The mandrel is characterized by comprising a main body of which the external surface is coated with a high-temperature-resistant material and a fixed end which is integrally connected to the lower end of the main body, wherein the external surface of the main body is provided with an inward concave air exhaust groove and a sealing surface for sealing a side edge; an axial through hole is formed in the main body; the air exhaust groove is provided with an air exhaust hole which is communicated with the axial through hole; and a cooling device is arranged in the main body. The mandrel has the advantages that: a paper-plastic composite material with an aluminum foil layer can be wound into a paper tube through the mandrel, and a top cover, a bottom cover and the paper tube are heated, pressurized and sealed by subsequent processing to form the liquid paper can capable of replacing a pop can, so that the usage and wastage of metal resources are reduced, the production cost and environmental pollution are also reduced, and production and processing are simple, convenient and quick; and the cooling device is arranged in the main body, so that the mandrel can keep constant temperature, and PE on the surface of the paper-plastic composite material is prevented from melting due to overhigh temperature of the mandrel.

Owner:乐美机械(宁波)有限公司

Bottom cover sealing device for liquid paper can

The invention discloses a bottom cover sealing device for a liquid paper can. The device is characterized by comprising a base and at least two sealing blocks which can be spliced into a circle mutually, wherein the sealing blocks are provided with a heater and a sensor; and the base is provided with a drive device for driving the sealing blocks to expand outwards or contract inwards. The device has the advantages that: a bottom cover and a paper can filled with a liquid beverage are sealed to replace a pop can by using the device so as to reduce the use and the waste of metal resources and reduce production cost and environment pollution; and moreover, the production and the processing are simple, convenient and rapid.

Owner:乐美机械(宁波)有限公司

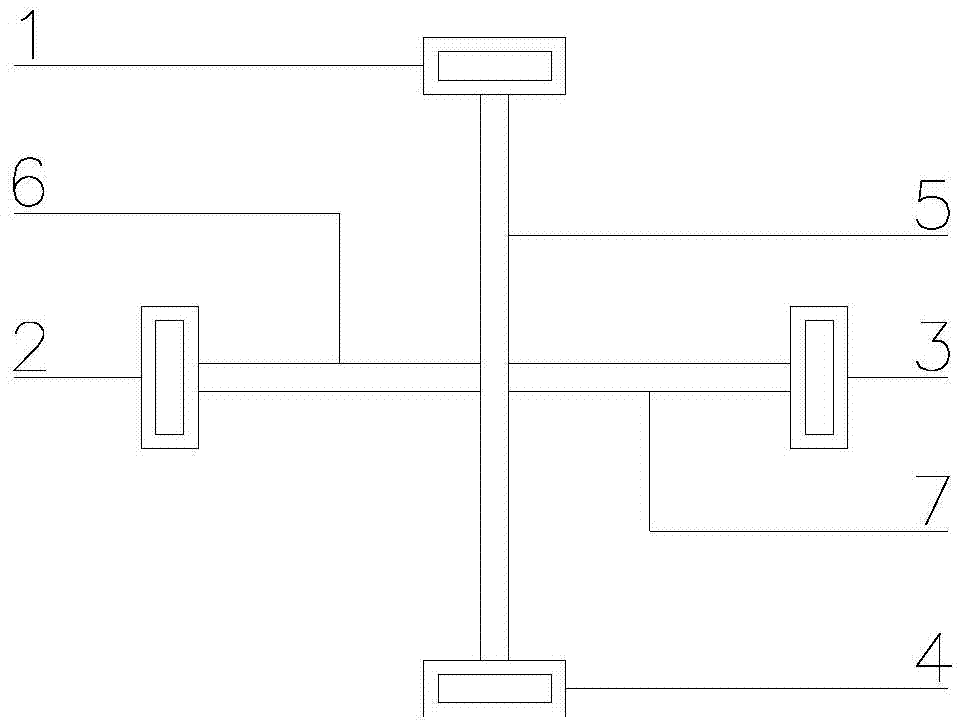

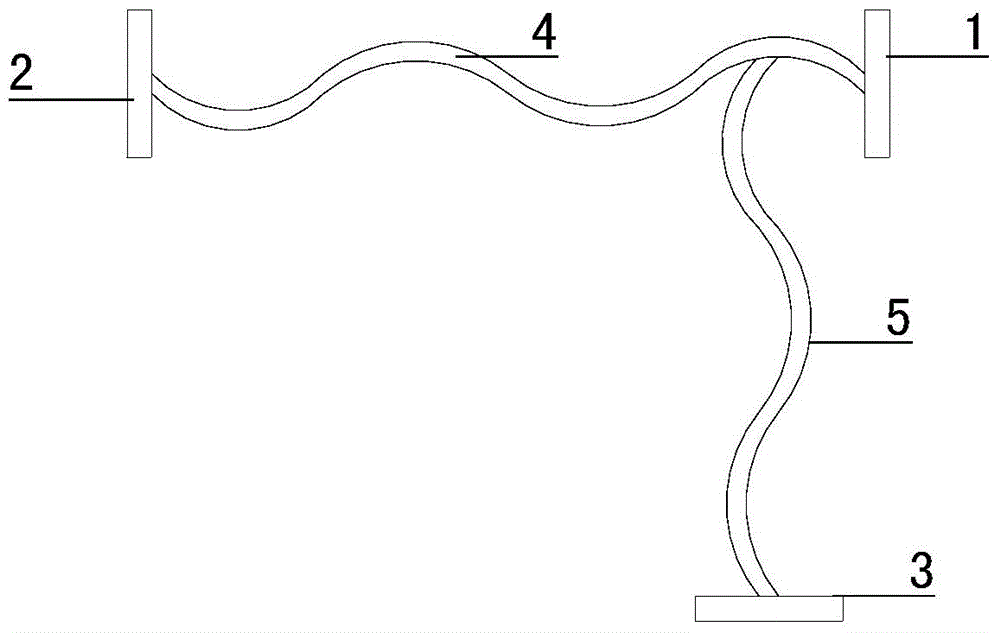

Corrugated web plate L-shaped section specially-shaped steel column

InactiveCN104405080AReasonable section compositionImprove mechanical propertiesStrutsPillarsEngineeringSteel columns

The invention discloses a corrugated web plate L-shaped section specially-shaped steel column. The corrugated web plate specially-shaped steel column comprises a flat steel plate flange I, a flat steel plate flange II, a flat steel plate flange III, a steel web plate I and a steel web plate II, wherein one side edge of the steel web plate II is perpendicularly connected with the edge of the steel web plate I so as to form the specially-shaped steel column with the L-shaped section; the steel web plate I and the steel web plate II are corrugated steel web plates; the corrugated steel web plates are curvilinear, polygonal-shaped or trapezoid; the periodically repeated corrugated edges of the corrugated steel web plates are perpendicular to the length direction of a member; the non-corrugated edges of the corrugated steel web plates are respectively welded with the middle points in the width directions of the steel plate flange I, the steel plate flange II and the steel plate flange III. According to the corrugated web plate L-shaped section specially-shaped steel column, the stress performance of an existing L-shaped section specially-shaped steel column is improved, and the comprehensive manufacturing cost of engineering is not obviously increased, so that the corrugated web plate L-shaped section specially-shaped steel column can be widely applied to the engineering.

Owner:NANJING TECH UNIV

Metal part production and forming process for aviation field

ActiveCN113458717AGuaranteed performanceGuaranteed residual temperatureProcess efficiency improvementAviationEmergency treatment

The invention discloses a metal part production and forming process for the aviation field, relates to the technical field of metal part production and manufacturing, and aims to solve the problems that in the heating stage of a casting, if equipment breaks down, no emergency treatment measures exist, and the alloy plasticity of the casting is easily affected in the existing metal part production and forming process for the aviation field. The process comprises the following steps of, 1, preparing a titanium ingot, reducing titanium ore into pure titanium tetroxide through chlorination and distillation, refining the pure titanium tetroxide into a sponge titanium raw material by virtue of vacuum separation, removing impurities, and obtaining the titanium ingot through electrode welding; 2, carrying out end face pretreatment, specifically, cleaning one end face of the titanium ingot, spraying an anti-oxidation coating after cleaning is completed, and marking an ingot number; and 3, carrying out pretreatment on the titanium ingot, placing the face, with the ingot number, of the titanium ingot on an adsorption base of a cleaning and spraying all-in-one machine, and fixing the titanium ingot to the adsorption base through suction force generated by a vacuum generator.

Owner:苏州市锐意金属制品有限公司

Manufacturing method of pulp-molded stainless steel forming die

InactiveCN112238209AEasy to produceEasy to processFoundry mouldsFoundry coresSS - Stainless steelHeating furnace

A manufacturing method of a pulp-molded stainless steel forming die comprises the steps: injecting a wax liquid into a cavity formed between an upper die nut and a lower die nut, forming, by the curedwax liquid, a wax female die, and then drilling the wax female die manually, wherein a plurality of dense filtering holes can be formed in the wax female die; soaking the wax female die with the drilled holes in a high-temperature-resistant liquid material to form a protective layer on the outer surface of the wax female die, then placing the wax female die with the protective layer attached to the surface in a heating furnace to be heated, melting the wax female die inside, enabling the melted wax female die to flow out of a liquid flowing channel, and then fully casting a stainless steel liquid into the protective layer; then conducting natural cooling and curing; and finally, removing the outer protective layer, wherein the left cured stainless steel is the stainless steel forming diewith a plurality of dense filter holes. The whole manufacturing process is simple, convenient in production and processing and low in cost, the stainless steel forming die is produced and processed ina simplified manner effectively, and the production efficiency is improved.

Owner:向孙团

Rolling table for making rice noodle

ActiveCN110946166BGuaranteed tasteEasy to processDough processingHydraulic cylinderClassical mechanics

The invention relates to a noodle rolling table for making rice noodles, comprising a noodle rolling table, a one-way propeller is installed at the front of the noodle rolling table, and a noodle rolling device is connected to the one-way propeller; Two-way propeller; the two-way propeller is respectively connected to the limiting component and the overturning component. The one-way propeller includes a No. 1 hydraulic cylinder and an L-shaped guide rod that are all fixedly installed on the noodle rolling table; the No. 1 hydraulic cylinder is connected with a hanging plate that is slidably matched with the guide rod. The invention has a high degree of automation, and the dough is automatically rolled and folded alternately, so that the dough can be rolled for many times, which saves manpower and ensures the taste of rice noodles, and also facilitates the production of rice noodles. The effect of rapid mass production and processing of rice noodles.

Owner:芜湖王玉珍食品有限公司

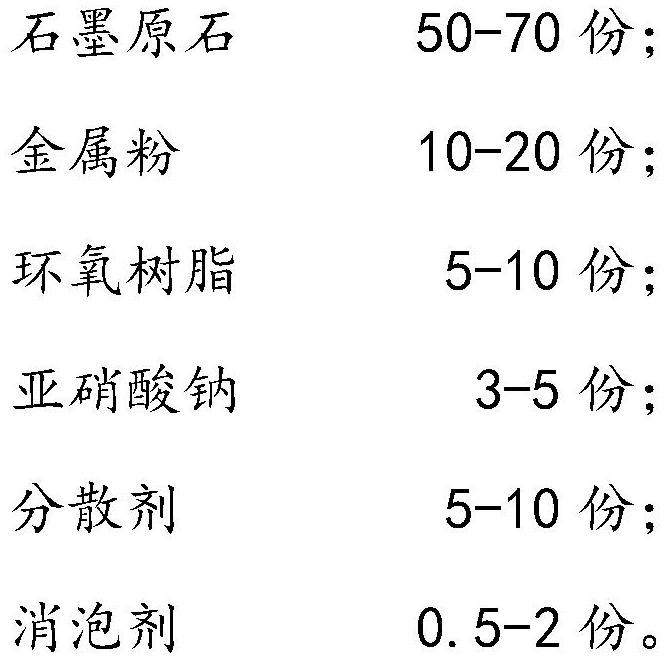

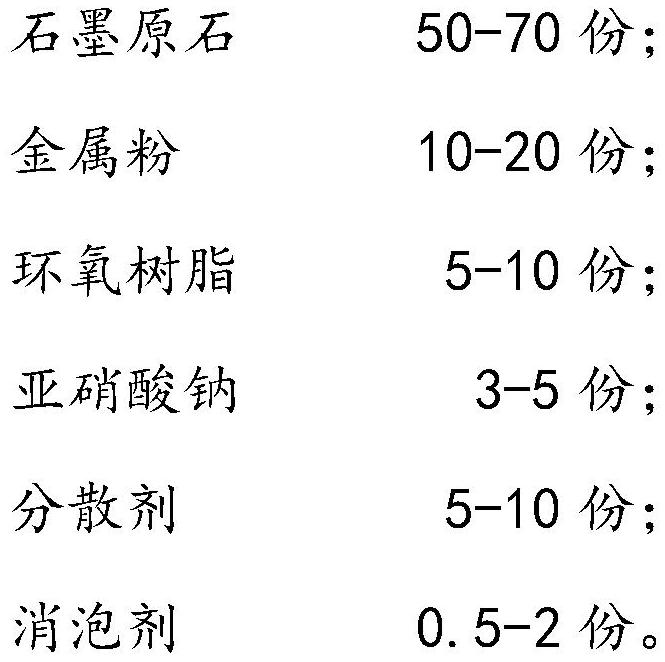

A kind of automatic production process of graphene electronic conductive paste

ActiveCN112885500BExtended service lifeImprove conductivityNon-conductive material with dispersed conductive materialCable/conductor manufactureEpoxyConductive paste

Owner:WUXI DONGHENGNEWENERGYTECHNOLOGYCO LTD

Waterproof and moisture-proof packaging box for elevator equipment

ActiveCN111776416BReduce usageReduce weightRemovable lids/coversRigid containersCardboardEngineering

The invention relates to the technical field of elevator packaging, in particular to a waterproof and moisture-proof packaging box for elevator equipment, which includes a box body with an opening facing upwards and a box cover with an opening facing down and capable of covering the upper opening of the box body. It includes a box bottom and a box body installed on the upper side of the box bottom. Both the box body and the box cover are corrugated cardboard bodies, which are suitable for elevator packaging.

Owner:HUZHOU YAODONG PACKING CO LTD

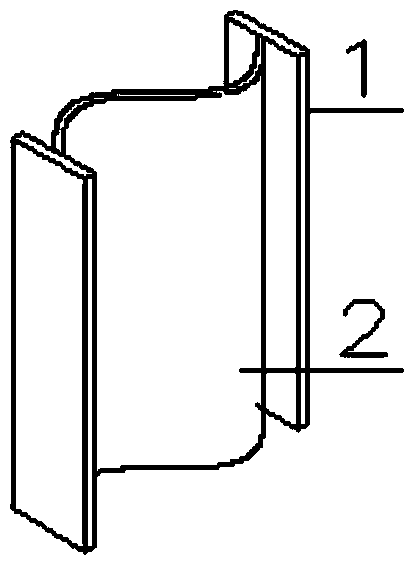

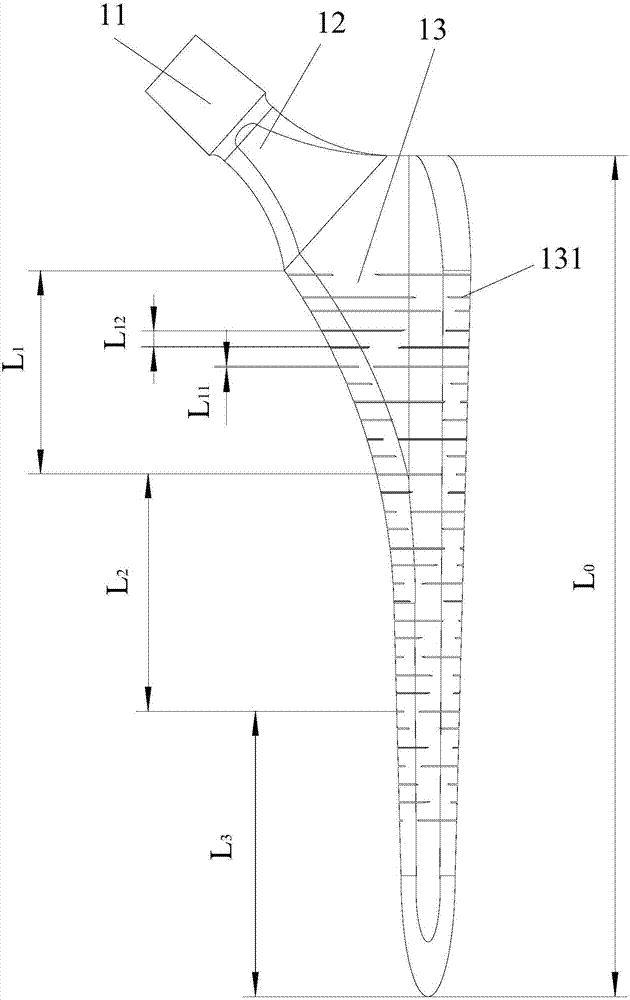

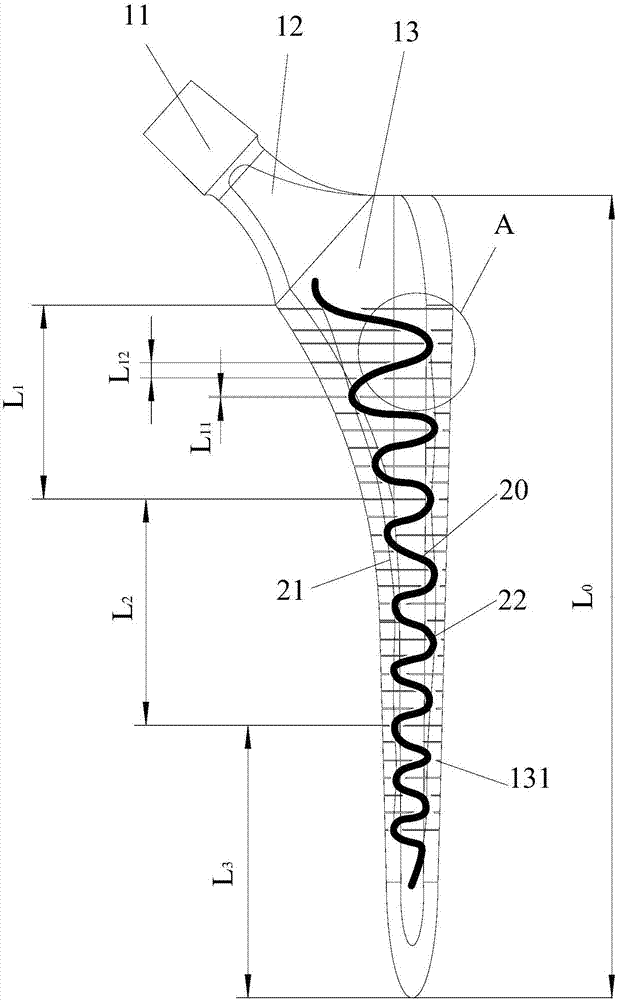

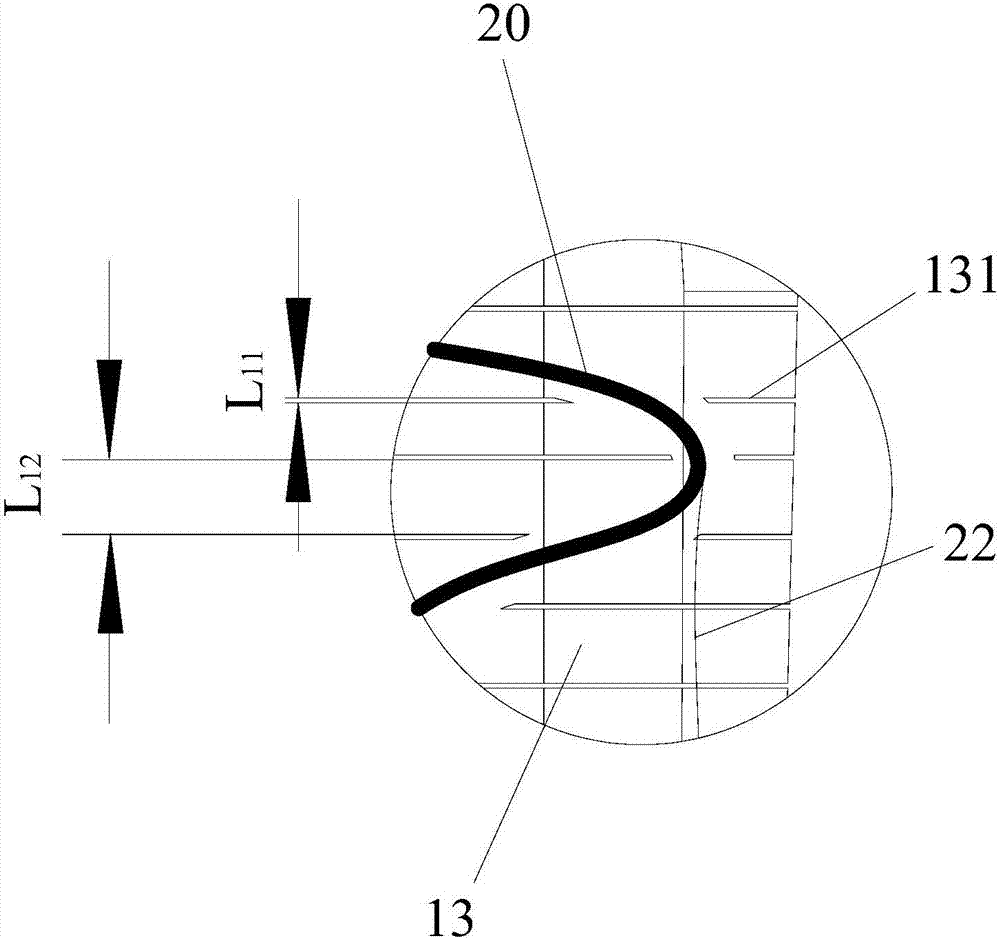

Low-elastic modulus femoral stem

ActiveCN107080606ALow elastic modulusSimple manufacturing processJoint implantsFemoral headsNeck partsFemoral stem

The invention provides a low-elastic modulus femoral stem which comprises a head, a neck part and a stem body. The low-elastic modulus femoral stem further comprises an elastic structure integrally formed in the stem body; the extending direction of the elastic structure is consistent with that of the stem body. The technical scheme of the invention effectively solves the problem of complicated manufacturing process of the low-elastic modulus femoral stem in the prior art.

Owner:BEIJING AKEC MEDICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com