Metal part production and forming process for aviation field

A molding process and technology for metal parts, applied in the field of metal parts production and molding process, can solve problems such as affecting the plasticity of casting alloys, and achieve the effect of ensuring residual temperature, uniform heating, and avoiding local overburning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

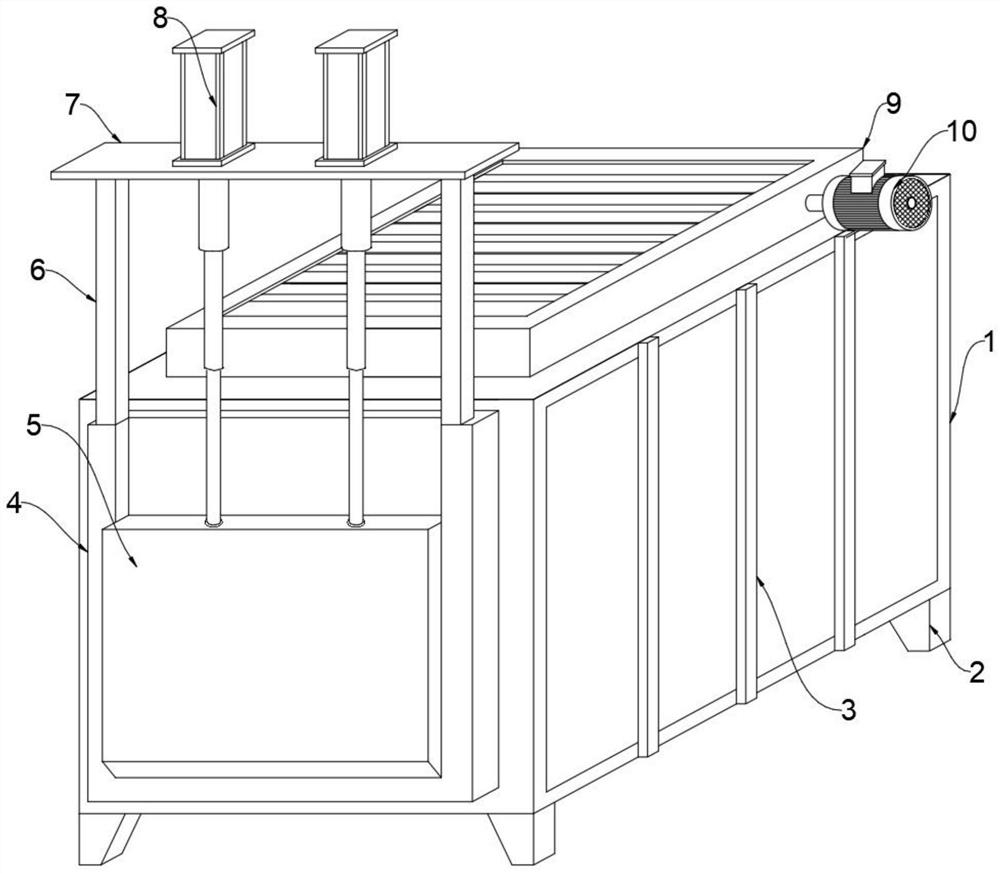

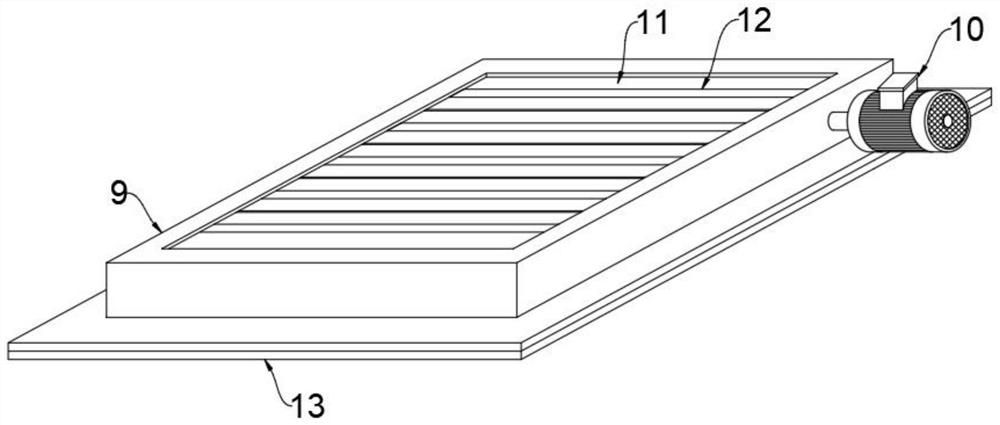

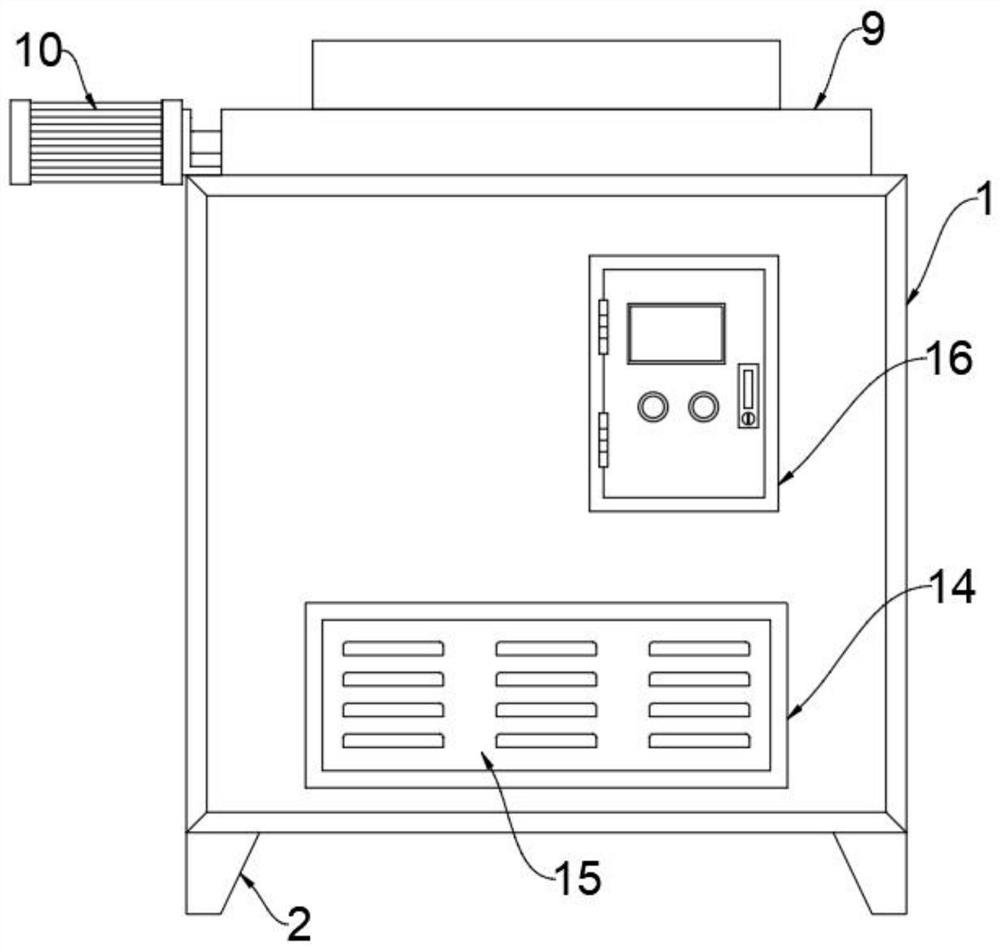

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0037] see Figure 1-7 , an embodiment provided by the present invention: a production and molding process of metal parts used in the aviation field, comprising the following steps:

[0038] Step 1: Prepare titanium ingots, reduce the titanium ore to pure titanium tetroxide by chlorination and distillation, and refine the pure titanium tetroxide into sponge titanium raw materials by vacuum separation. After removing impurities, the electrodes are welded into titanium ingots with a side length of 500mm;

[0039] Step 2: End surface pretreatment, cleaning one end surface of the titanium ingot, spraying an anti-oxidation coating after completion, and writing the ingot n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com