Temperature-resistant composite color water-based ink applied to helmets

A water-based ink and compound color technology, applied in ink, applications, household appliances, etc., can solve the problems of color running, large color difference, etc., and achieve the effects of improved performance, convenient production and processing, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiments of the present invention provide a temperature-resistant composite color water-based ink applied to helmets, including the following specific components:

[0032] Temperature-resistant water-based ink

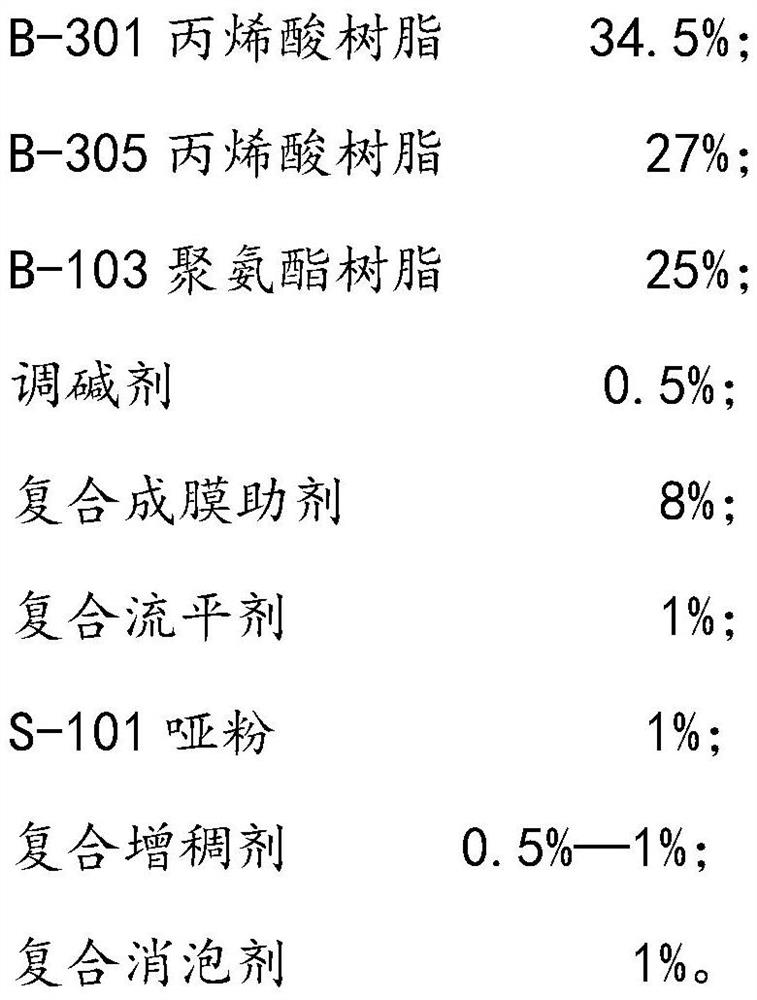

[0033] Water-based ink varnish, composed of the following components by mass percentage:

[0034]

[0035] Temperature-resistant composite color water-based ink

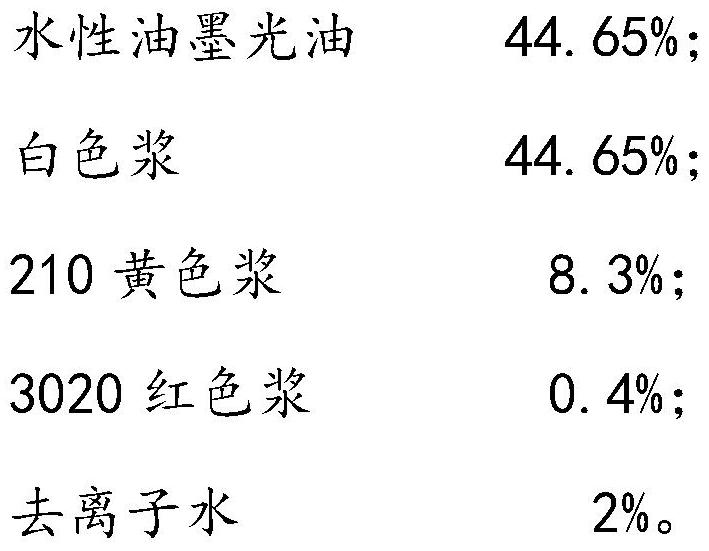

[0036] A. Orange ink consists of the following components by mass percentage:

[0037]

[0038]

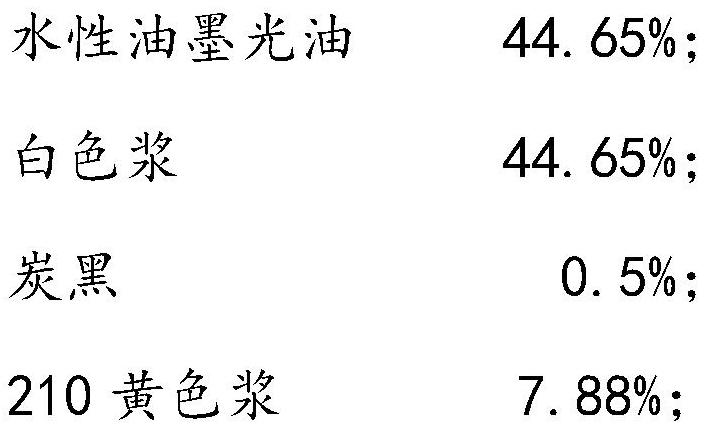

[0039] B. Gray ink consists of the following components by mass percentage:

[0040]

[0041] The temperature-resistant composite color water-based ink is made of temperature-resistant water-based ink as the base material, plus different color pastes and deionized water.

[0042] A preparation method for a temperature-resistant composite color water-based ink applied to a helmet, comprising the following specific steps:

[0043] S1. Mix 34.5% B-301 acrylic resin, 27% B-305 acrylic resin,...

Embodiment 2

[0050] In this embodiment, on the basis of Embodiment 1, the proportioning is carried out according to the following specific components:

[0051]

[0052] The above-mentioned raw materials are prepared according to the following steps:

[0053] Add to the mixer in order, stir evenly, stir for 3-5 minutes at each step to make it fully blend, add the defoamer and stir for 10 minutes, and the speed of the mixer is controlled within 1000r / min.

[0054] Use the prepared water-based varnish, add color paste, and compare the color of the sample. The mass composition ratio is as follows:

[0055] orange:

[0056]

[0057] grey:

[0058]

[0059]

[0060] Under the test of 260X1min for orange and gray, obvious discoloration was observed, and the two sides of the PC sheet showed different colors.

Embodiment 3

[0062] In this embodiment, on the basis of Embodiment 1, the proportioning is carried out according to the following specific components:

[0063]

[0064] The above-mentioned raw materials are prepared according to the following steps:

[0065] Add in order, stir evenly, and stir for 3-5 minutes each step to make it fully blended. After adding the defoamer, stir for 10 minutes. The speed of the mixer is controlled within 1000r / min.

[0066] Use the prepared water-based varnish, add color paste, and compare the color of the sample. The mass composition ratio is as follows:

[0067] orange:

[0068]

[0069] grey:

[0070]

[0071] Under the test of 260X1min in orange and gray, moderate color migration is observed, and its effect is better than that of Example 2, but it still cannot reach the model effect;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com