Panel paint-spraying device for compact shelving production

A technology of compact shelves and panels, which is applied in the field of compact shelves, can solve the problems of lack of cleaning mechanism, inability to clean dust and other debris, and affect the spraying quality of panel painting devices, so as to achieve good painting effects and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

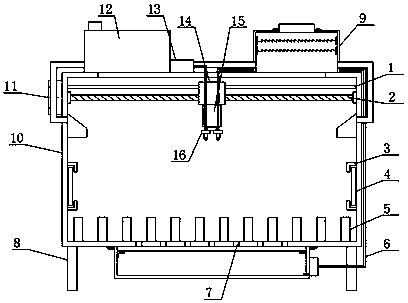

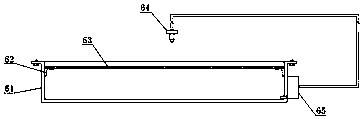

[0021] see Figure 1-Figure 3 , the present invention provides a technical solution: a panel paint spraying device for the production of dense racks, comprising a paint spray box 10, one end of the upper surface of the paint spray box 10 is welded with a paint box 12, and one side of the paint box 12 is connected with a paint pump 13 through a pipeline , the output end of the paint pump 13 is provided with a paint spraying pipe 16, the paint spraying pipe 16 is a cuboid structure, the lower surface of the paint spraying pipe 16 is arranged with several nozzles at equal intervals, the top of the paint spraying box 10 is welded with a drive motor 11, and the drive motor 11 The output end is welded with a limit screw rod 2, and one end of the limit screw rod 2 is provided with a limit slider 14. When in use, the limit slider 14 can move laterally along the limit screw rod 2, and the top of the limit screw rod 2 is provided with a The limit rod 1 corresponding to the limit slider ...

Embodiment 2

[0026] see Figure 1-Figure 4 , on the basis of Embodiment 1, in order to make the paint spraying device more environmentally friendly to use, in this embodiment, preferably, the two ends of the paint spraying box 10 are provided with adsorption plates 4, and the inner wall of the paint spraying box 10 is provided with adsorption plates. 4 corresponding to the first limiting member 3, in this embodiment, preferably, the first limiting member 3 is fixedly connected with the paint spray box 10 by welding, the material of the adsorption plate 4 is activated carbon, and there are several An adsorption through hole, when in use, absorbs the peculiar smell generated by the painting device during work through the adsorption plate 4, preventing the painting device from emitting a large amount of peculiar smell when in use, thereby making the painting device more environmentally friendly to use;

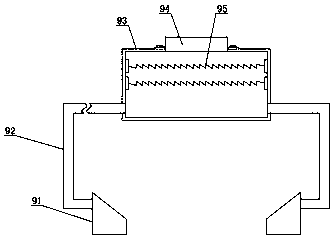

[0027] In order to make the paint spray box 10 more reliable to use, in the present embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com