Wicker basket assembly line type efficient paint spraying equipment

An assembly-line, spraying equipment technology, applied in spray booths, spraying devices, liquid spraying devices, etc., can solve problems such as limiting the spraying efficiency of equipment and inability to spray paint, and achieve the effect of saving spraying raw materials, reducing waste, and high spraying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

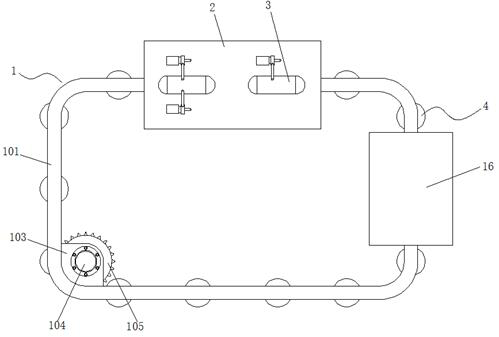

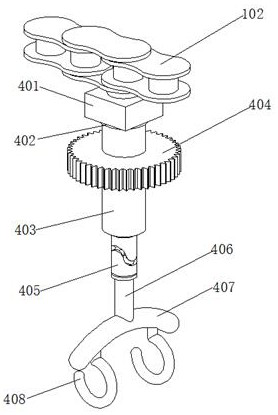

[0037] Embodiment 1 has introduced a kind of wicker basket assembly line formula high-efficiency painting equipment, with reference to the attached figure 1 , its main structure includes a closed suspension conveyor chain 1, a paint spray box 2 and two paint tanks 3. Wherein, the closed suspension conveyor chain is the prior art, mainly including the chain frame 101, and the chain frame 101 is arranged in a rectangular closed loop, and the lower surface of the chain frame 101 is provided with a conveyor chain 102, and a corner of the chain frame 102 is provided with Fixed plate 103, fixed plate 103 is provided with drive motor 104, and the sprocket wheel 105 that matches with transmission chain 102 is connected on the output shaft of its drive motor 104 lower end, can realize whole closed suspension by controlling the opening and closing of drive motor 104 Conveyor chain 1 running or stopping.

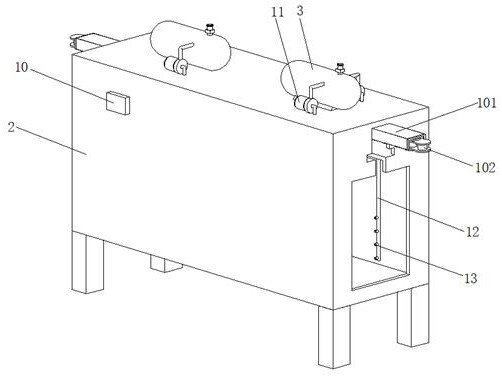

[0038] Reference attached figure 2 , the corresponding two ends of the paint sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com