Paint spraying device for wooden pole

A technology of wooden poles and clamping devices, which is applied in spraying devices, spray booths, etc., can solve problems such as high labor intensity, uneven painting, and impact on health, so as to improve work efficiency, reduce the discharge of harmful substances, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

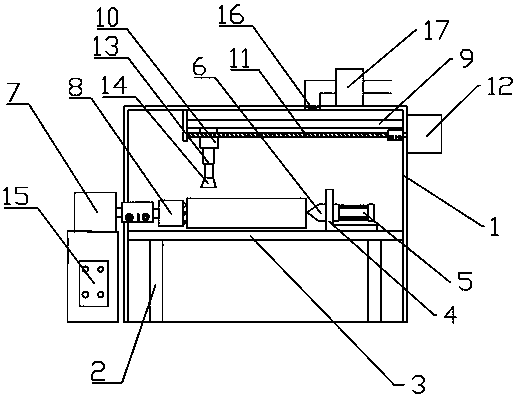

[0016] Such as figure 1 As shown, it includes a box body 1 with an openable front panel. The lower part of the box body 1 is provided with a clamping device, and the upper part of the box body 1 is provided with a painting device. The clamping device includes a support frame 2, The upper end of the support frame 2 is fixed with a guide rail 3, the guide rail 3 is slidably connected with a mounting seat 4, the hydraulic cylinder 5 is fixed on the mounting seat 4, and the output end of the hydraulic cylinder 5 is connected with a push rod 6, It also includes a rotating motor 7, the output shaft of the rotating motor 7 is connected with a push rod two 8 facing the push rod one 6, and several tapered protrusions are symmetrically formed on the front end surface of the push rod two 8; The painting device includes a slide rail 9 fixed on the top of the box body 1 and parallel to the guide rail 3, both ends of the slide rail 9 are provided with limit blocks, and the slide rail 9 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com