A kind of automatic production process of graphene electronic conductive paste

A technology of electronic conduction and production technology, which is applied in the direction of conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., which can solve the problems of affecting the normal use of electronic equipment, unstable electrical conductivity, and reduced electrical and thermal conductivity and other problems, to achieve the effects of convenient and rapid production and processing, stable electrical conductivity, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

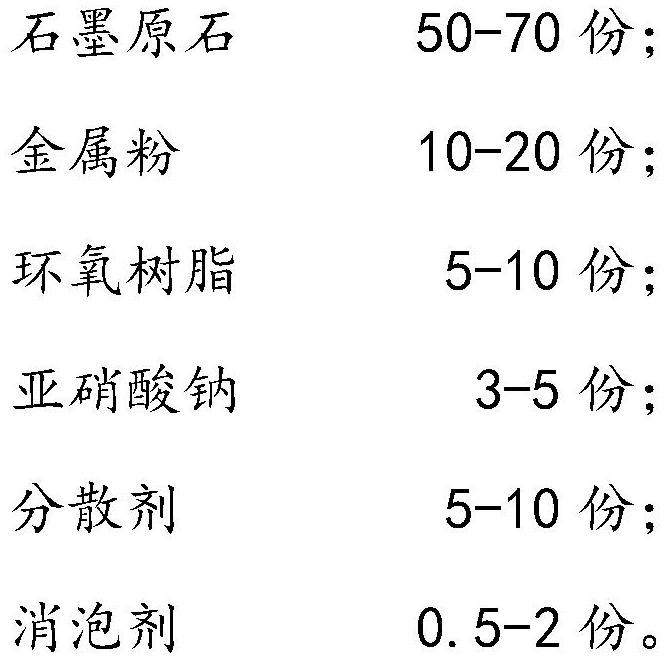

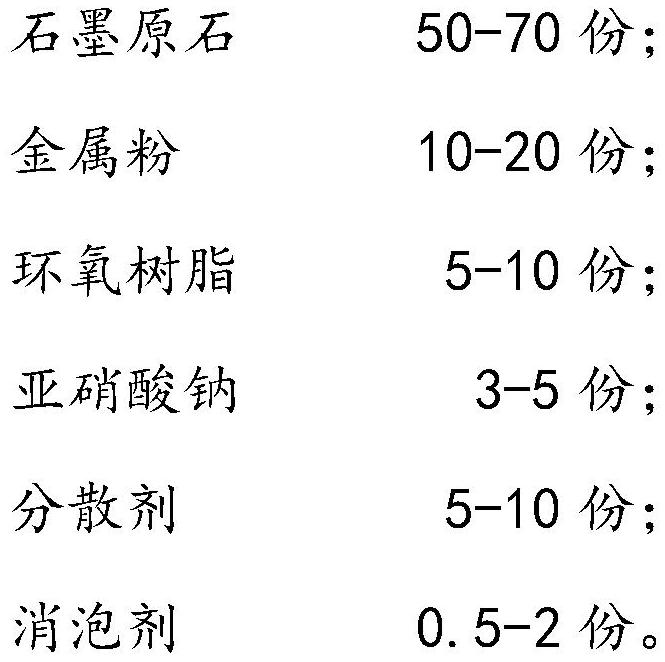

[0028] Embodiments of the present invention provide a graphene electronic conductive paste, comprising the following raw materials:

[0029]

[0030] The raw materials for forming the conductive paste are configured according to the following proportions: 63 parts of graphite rough, 10 parts of metal powder, 10 parts of epoxy resin, 5 parts of sodium nitrite, 10 parts of dispersant and 2 parts of defoamer.

[0031] An automated production process for graphene electronic conductive paste, comprising the following specific steps:

[0032] S1. 63 parts of graphite raw stones are preliminarily crushed by crushing equipment, and then the crushed graphite raw stone particles are repeatedly ground by a grinder to obtain graphite powder, and the prepared graphite powder is sieved and dried multiple times;

[0033] S2. Mix the graphite powder prepared in S1 with 10 parts of metal powder, and use a stirring device to stir and mix for 60 minutes. After the graphite powder and metal po...

Embodiment 2

[0044] This embodiment is based on the first embodiment: by adjusting the ratio of graphene electronic conductive paste raw materials, and carrying out related tests, its electrical conductivity and related properties are as follows:

[0045] The raw materials for forming the conductive paste are configured according to the following proportions: 55 parts of graphite rough, 20 parts of metal powder, 8 parts of epoxy resin, 5 parts of sodium nitrite, 10 parts of dispersant and 2 parts of defoamer.

[0046] Its production and processing technology includes the following specific steps:

[0047] S1. 55 parts of graphite raw stones are preliminarily crushed by crushing equipment, and then the crushed graphite raw stone particles are repeatedly ground by a grinder to obtain graphite powder, and the prepared graphite powder is sieved and dried multiple times;

[0048] S2. Mix the graphite powder prepared in S1 with 20 parts of metal powder, and use a stirring device to stir and mix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com