Bottom cover sealing device for liquid paper can

A paper can and bottom cover technology is applied in the field of bottom cover sealing devices of liquid paper cans, which can solve the problems of iron and aluminum consumption, environmental pollution, etc. The effects of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

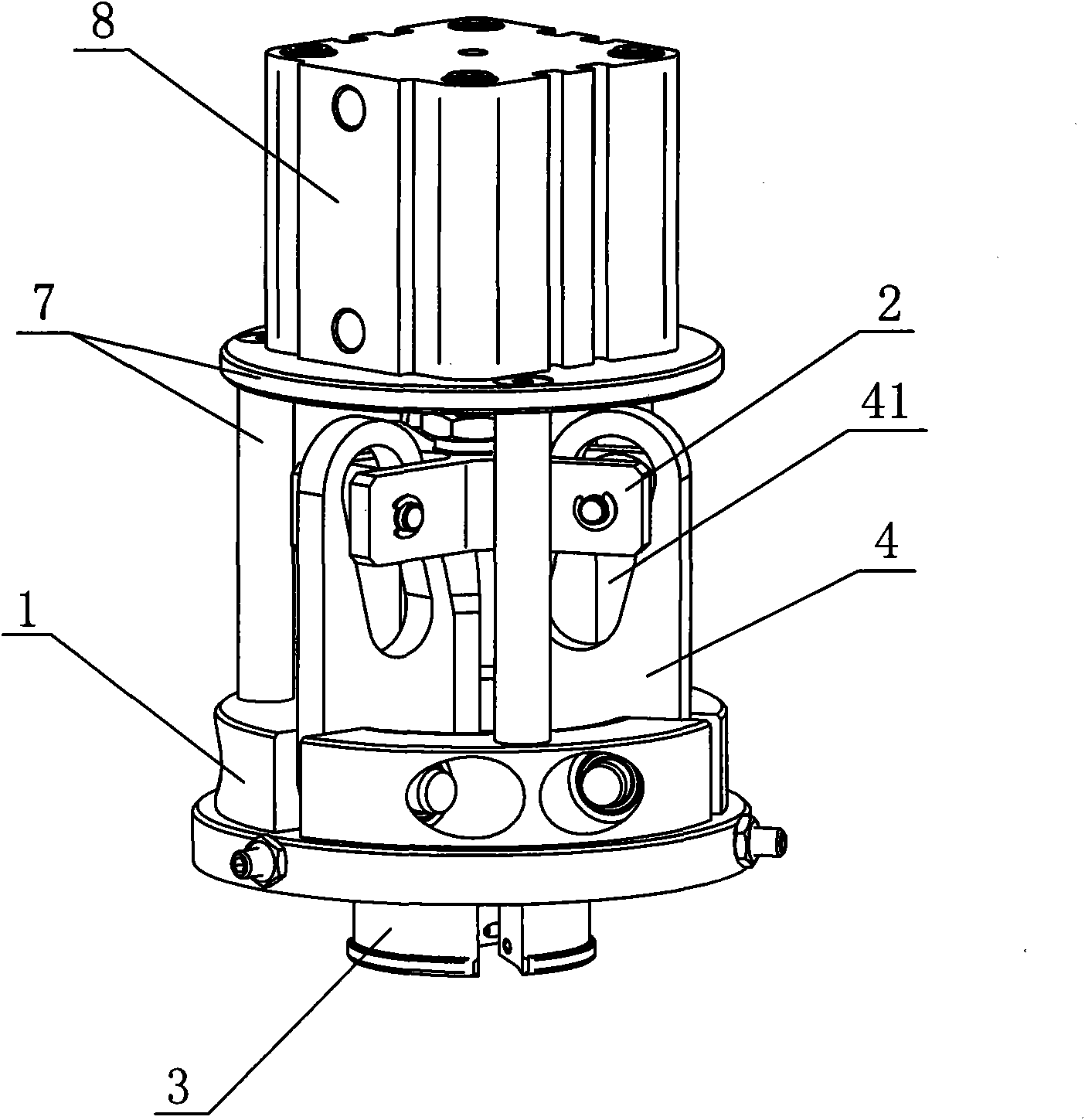

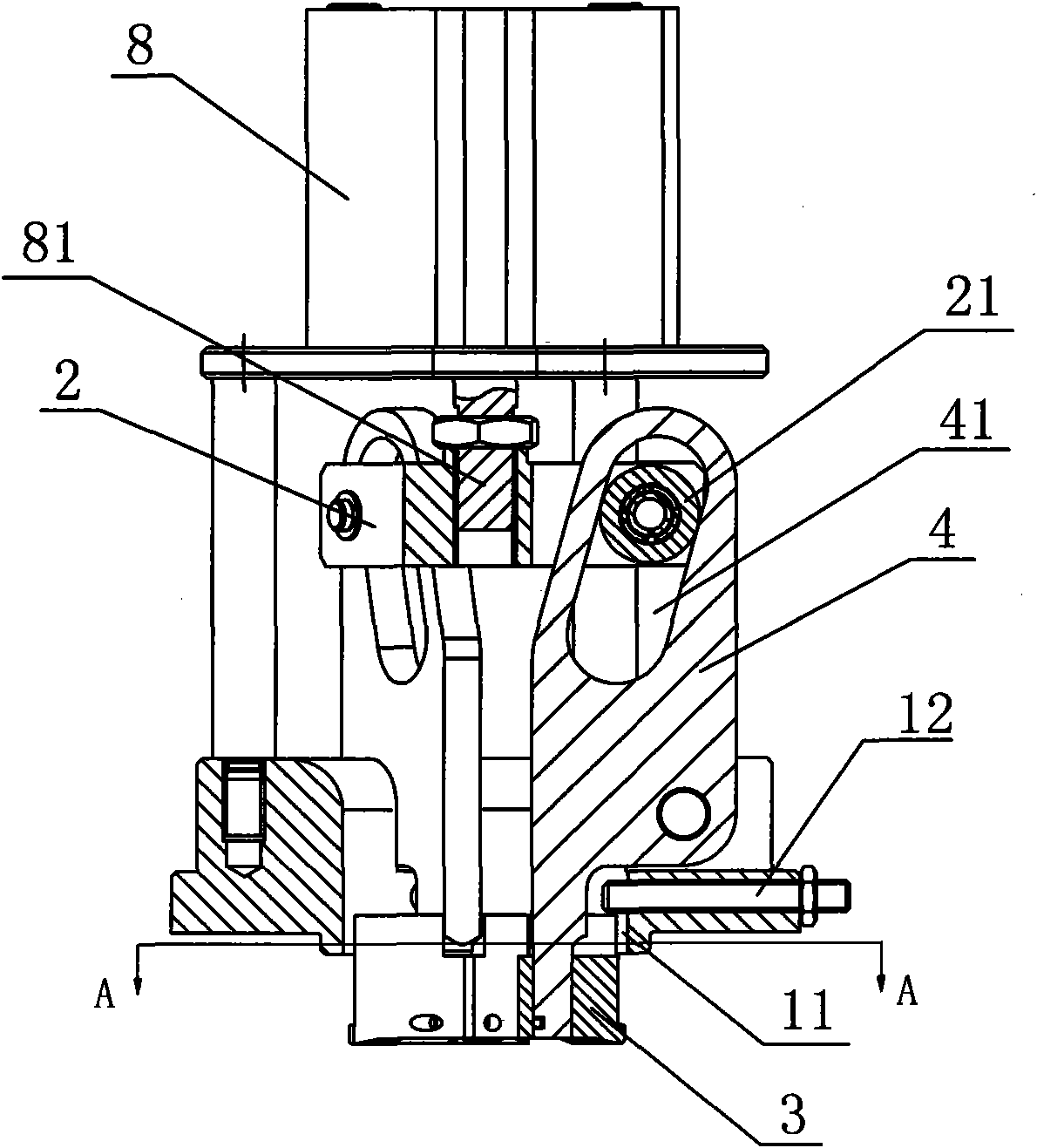

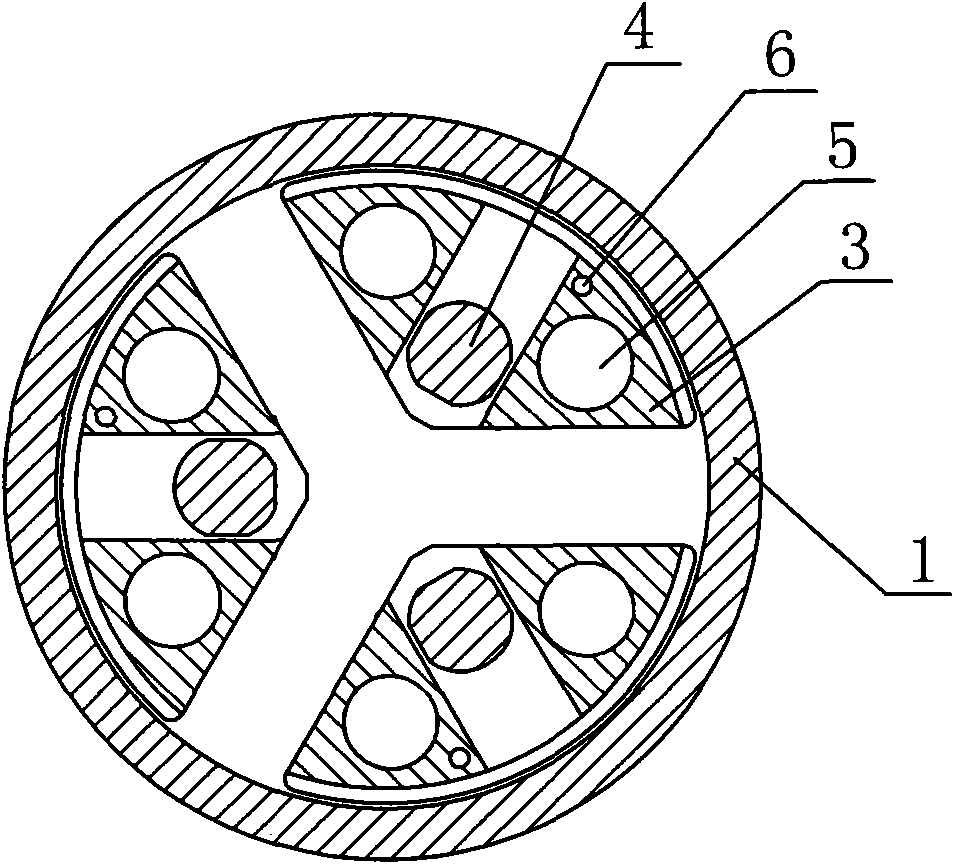

[0013] As shown in the figure, a bottom cover sealing device for liquid paper cans includes a base 1, a driving block 2, three sealing blocks 3 that can be assembled into a circle and three rotating arms 4, and the sealing block 3 is fixed inside A heater 5 and a sensor 6 are arranged, a support 7 is fixedly connected to the base 1, a cylinder 8 is fixedly arranged on the support 7, the drive block 2 is fixedly connected with the drive shaft 81 of the cylinder 8, the rotating arm 4 is evenly distributed around the drive shaft 81 and the shaft Connected to the base 1, the upper end of the rotating arm 4 is provided with a chute 41 inclined inwardly from top to bottom, the drive block 2 is fixedly provided with a connecting pin 21, the connecting pin 21 passes through the chute 41, and the base 1 is provided with Through hole 11, the lower end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com