Box-section column of corrugated steel web-concrete filled steel tube flange combination

A technology of corrugated steel webs and steel tube concrete, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of increasing the comprehensive cost of the project, increasing the construction cost, and the loss of resistance of the steel column, so as to reduce the comprehensive cost of the project and improve the fire resistance , The effect of reducing the thickness of the web

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

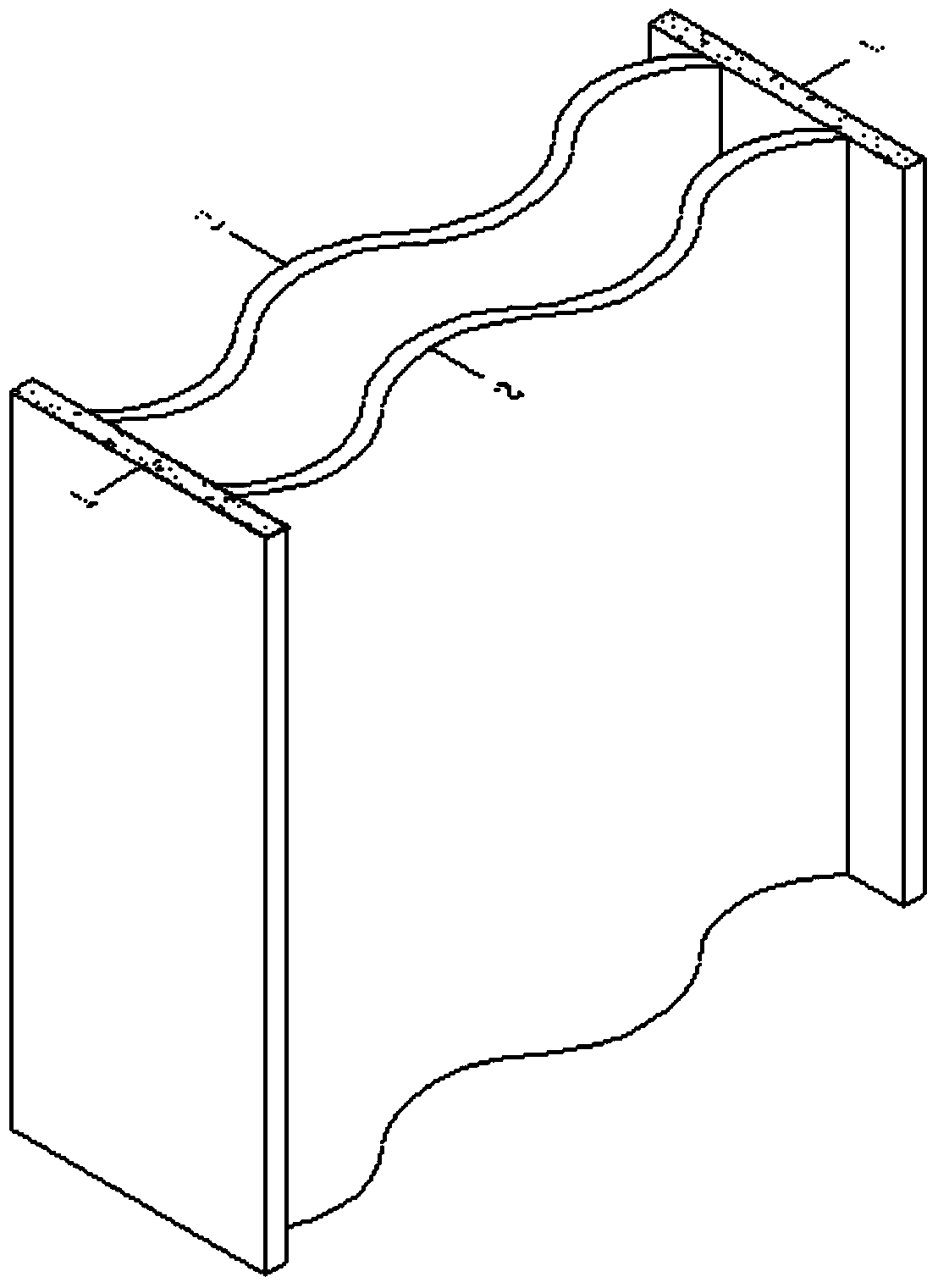

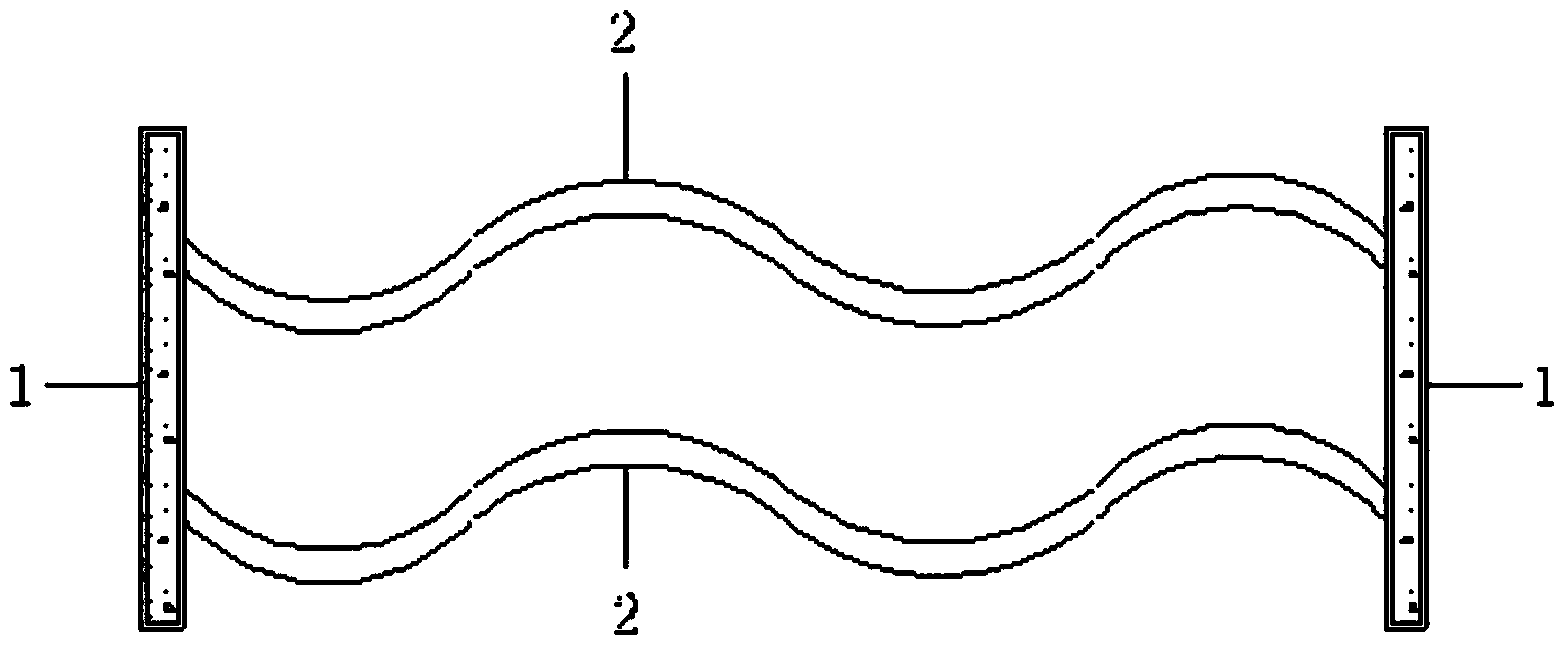

[0023] Such as figure 1 and 2 Shown: a corrugated steel web-concrete steel tube flange composite cross-section box column, which is composed of two webs and two flanges connected together to form a box structure, the web is corrugated steel web 2, corrugated The steel web 2 has periodically repeated corrugated sides perpendicular to the length direction of the member, and the non-corrugated sides of the corrugated steel web 2 are welded to both ends of the width of the flange, the flange is the steel pipe concrete flange 1, and the steel pipe concrete The flange 1 includes the steel pipe and the concrete inside it, and the concrete is self-compacting concrete. The form of the corrugated steel web 2 is curved, broken line or trapezoidal.

[0024] In the present invention, the steel pipe, the corrugated steel web and its welding are usually pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com