Mandrel for forming liquid paper can

A paper can and liquid technology, applied in the field of forming mandrels of liquid paper cans, can solve the problems of environmental pollution, consumption of iron and aluminum, etc., and achieve the effects of reducing production costs, reducing use and waste, and simplifying production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

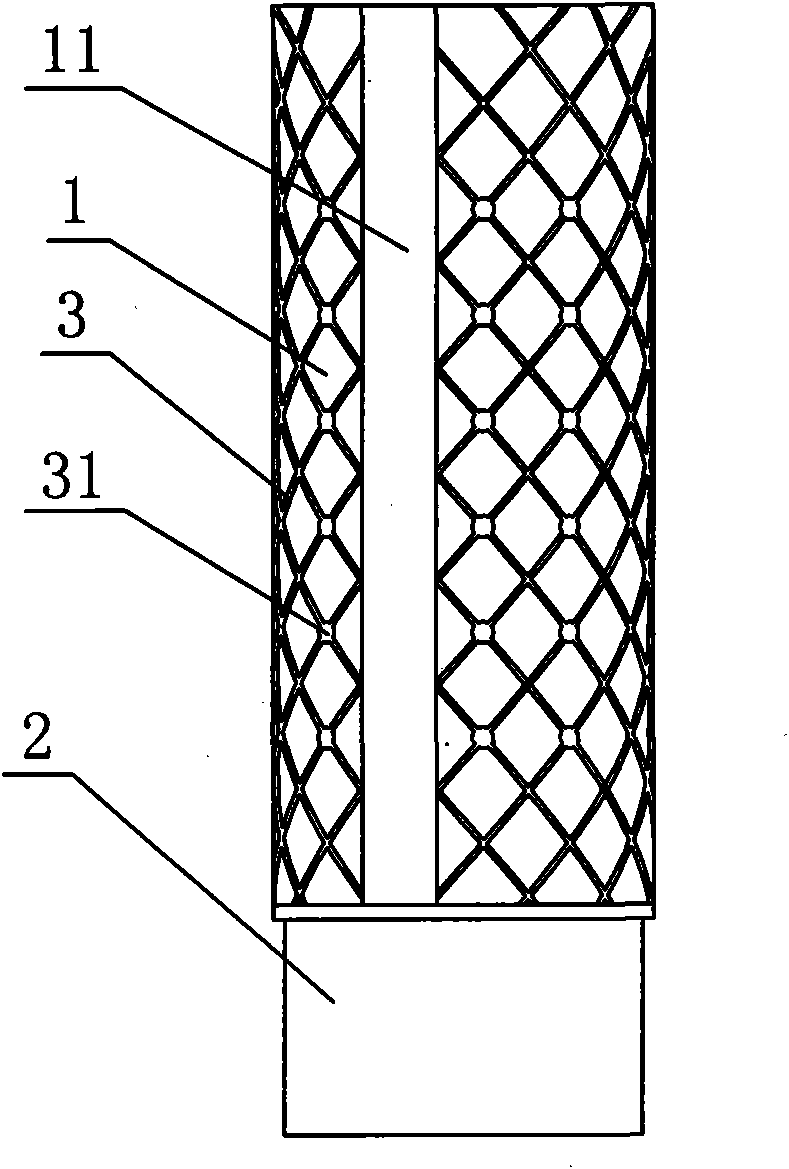

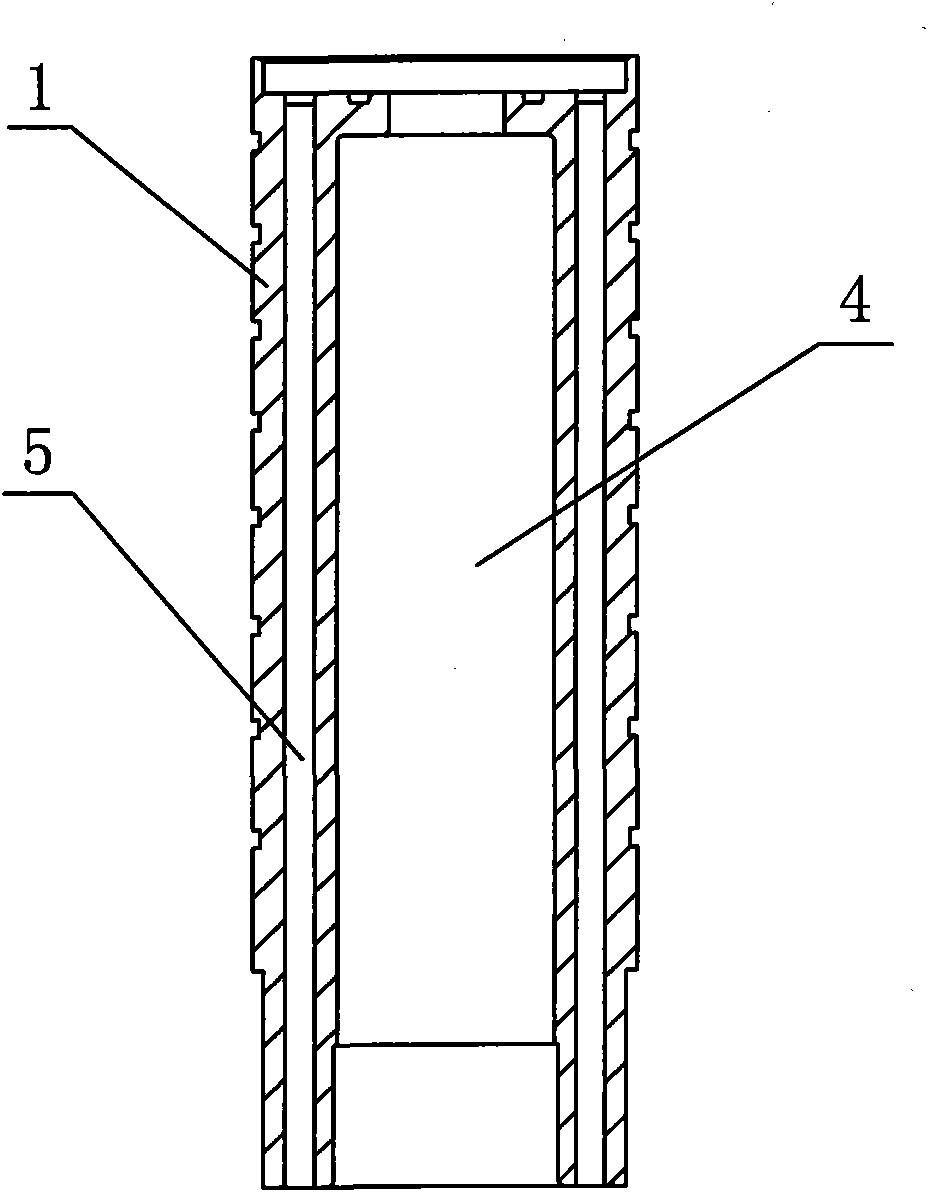

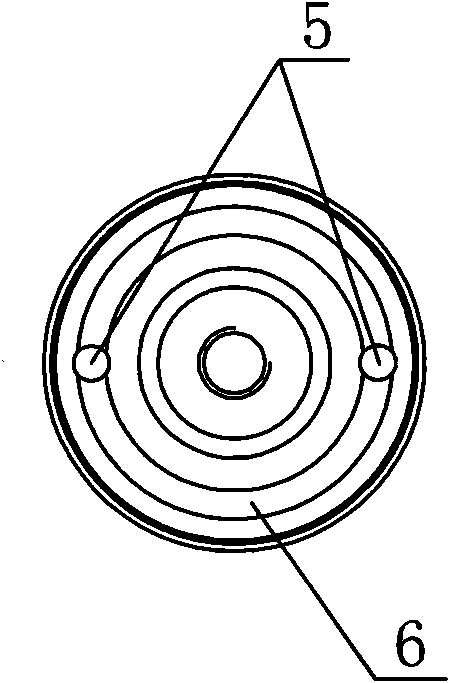

[0018] As shown in the figure, a forming mandrel of a liquid paper tank includes a main body 1 coated with Teflon on the outer surface and provided with a demoulding taper and a fixed end 2 integrally connected to the lower end of the main body 1, and the outer surface of the fixed end 2 A positioning plane 21 is provided on the surface, and the outer surface of the main body 1 is provided with concave air extraction grooves 3 evenly distributed in a mesh shape and a sealing surface 11 for side sealing, and the main body 1 is provided with an axial through hole 4, The air extraction groove 3 is provided with an air extraction hole 31 communicating with the axial through hole 4, and the main body 1 is provided with two axial water passages 5, and the upper end surface of the main body 1 is provided with a pipe connecting the two water passages 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com