Shearing machine for steel grating plate

A steel grating and shearing machine technology, which is applied in the direction of shearing devices, shearing machine equipment, and knives used in shearing machine devices, can solve the problems of inconvenient adjustment of knives and knives, damage of saw blades, and low production efficiency And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

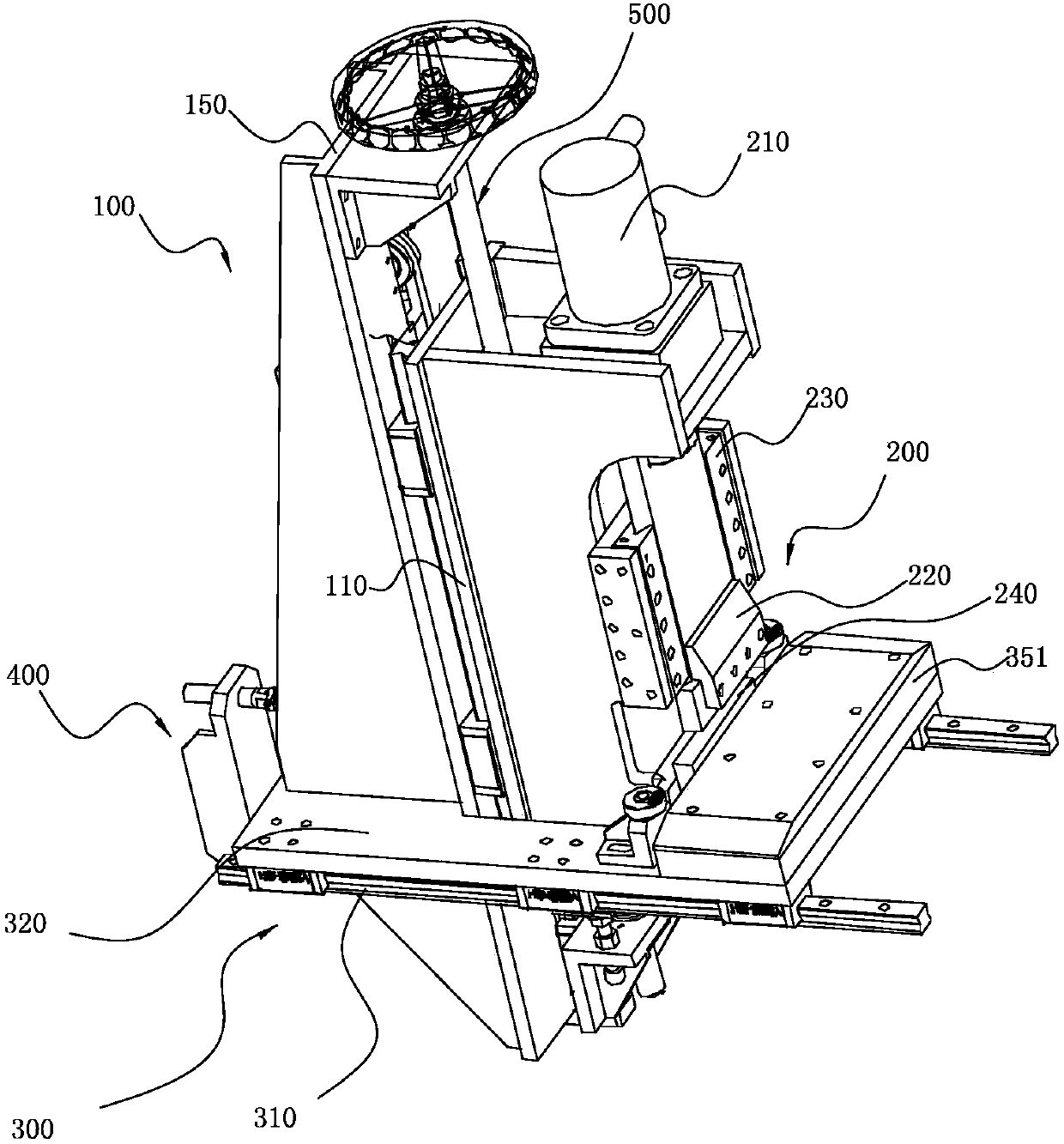

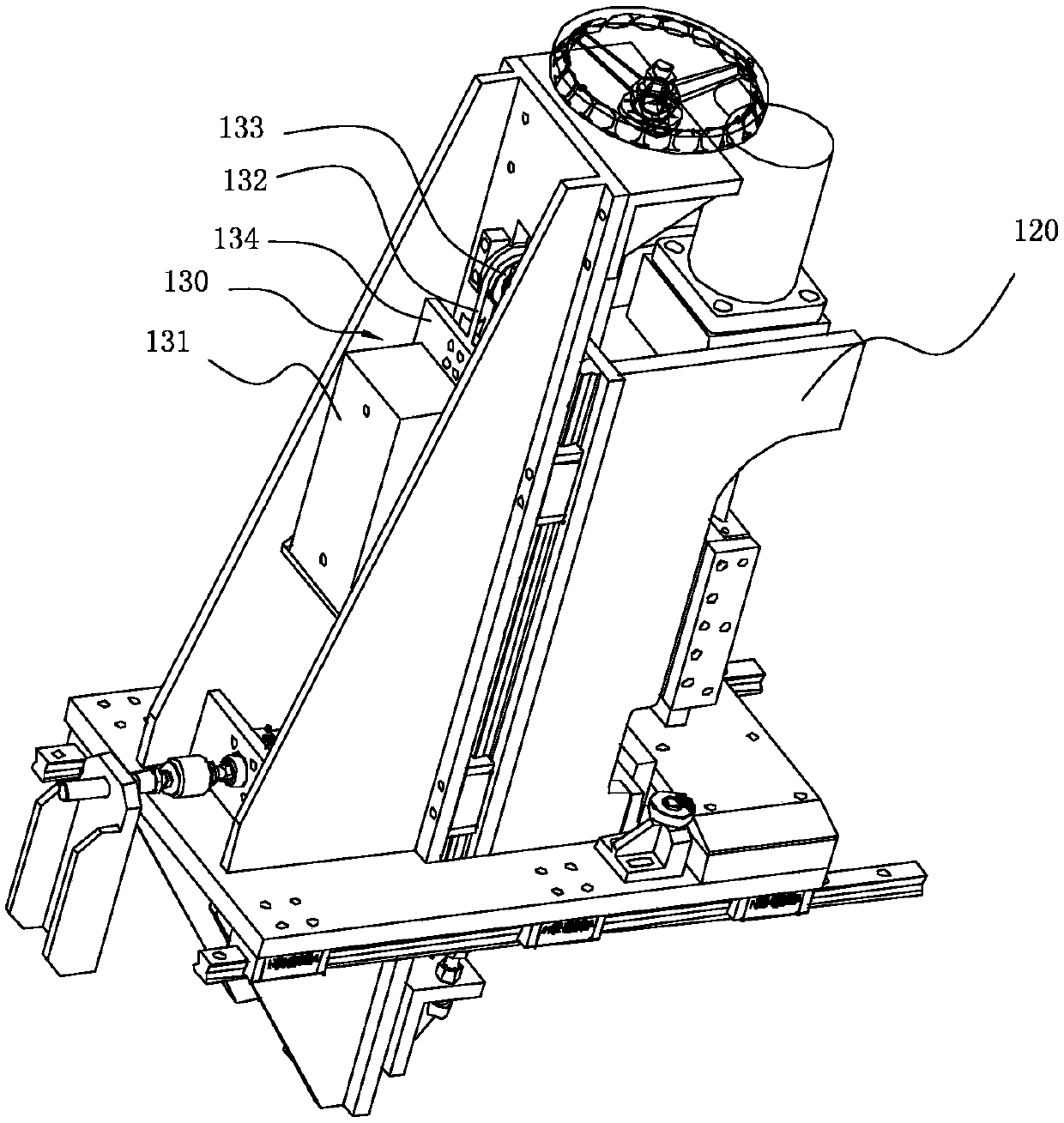

[0026] Please refer to Figure 1-Figure 4 , a steel grating shearing machine according to the present invention, which includes a knife holder seat 100 , a cutter assembly 200 , a support seat 300 , a transverse adjustment assembly 400 and a screw adjustment assembly 500 .

[0027] The knife holder seat 100 is used to fix the cutter assembly 200 .

[0028] The cutter assembly 200 includes an oil cylinder 210, an upper cutter 220 driven by the oil cylinder 210, a guide seat 230 guiding the upper cutter 220, a slidable lower cutter 240 and a lower cutter arranged on the knife rest seat 100. The knife guide rail 250, the oil cylinder 210 and the guide seat 230 are all fixed on the knife rest seat 100; the oil cylinder 210 drives the upper cutter 220, and the upper cutter 220 slides on the guide seat 230, and the upper cutter 220 slides on the guide seat 230. The cutter 220 moves up and down on the guide seat 230 and is guided by the guide seat 230 , and the lower cutter 240 slid...

Embodiment 2

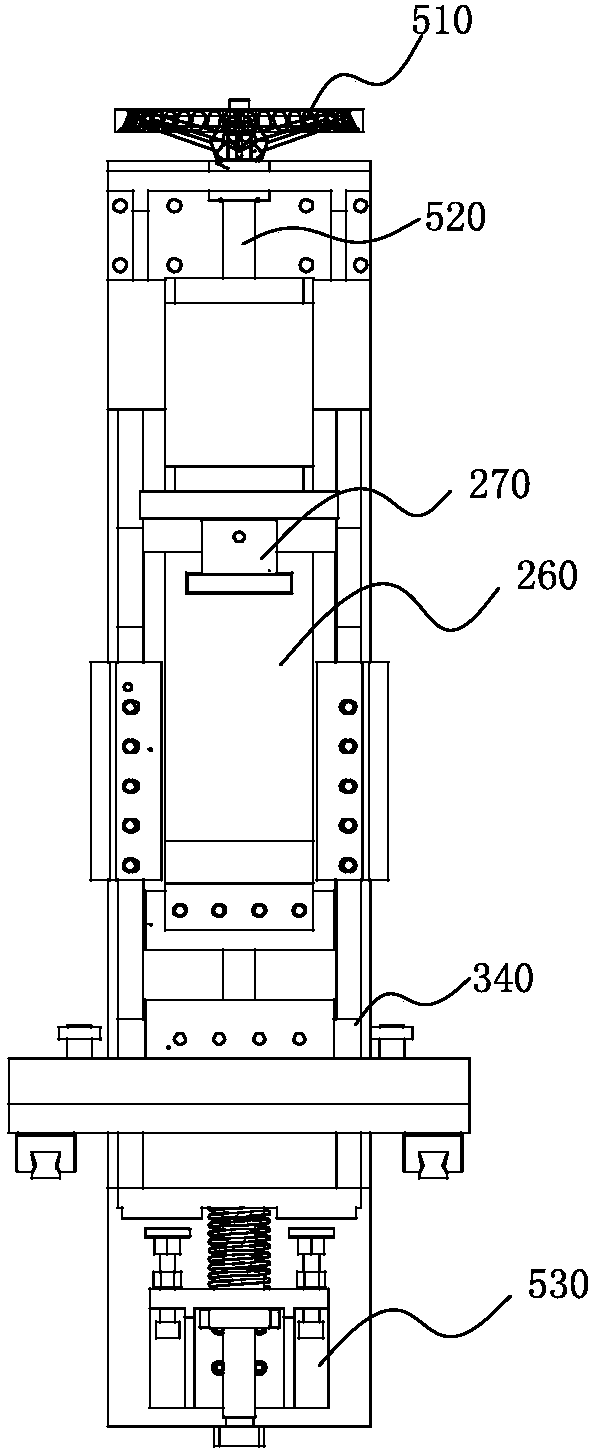

[0040] according to Figure 1-Figure 4 , the working principle of a steel grating shearing machine, the steel grating is placed on the upper surface of the steel grating guide block 350, and the two ends of the steel grating guide block 350 have inclined surfaces, and the inclined surfaces and the steel grating guide block The upper planes intersect so that the steel grating can smoothly come to the upper surface of the steel grating guide block or withdraw from the upper surface of the steel grating smoothly.

[0041] The steel grating is cut by the cutter assembly 200, and the oil cylinder 210 in the cutter assembly 200 drives the oil cylinder joint 270, and the oil cylinder joint 270 drives the upper cutter 220 to slide down and press the steel grating. At this time, Continue to pressurize the oil cylinder 210 until the upper cutter 220 and the steel grating are relatively stationary. Now, the lower cutter 240 begins to cut upwards, and the lower cutter 240 takes the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com