Base material cutting and forming equipment for photovoltaic cell panel processing

A photovoltaic cell panel and forming equipment technology, applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve the problems of photovoltaic cell panel base material deviation, influence on cutting, uneven force, etc., and achieve high cutting stability , Uniform force and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

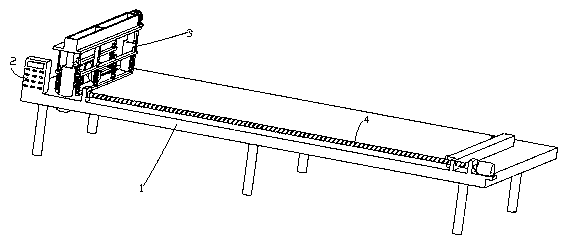

[0034] like figure 1 and figure 2 As shown, a base material cutting and forming equipment for processing photovoltaic panels in this embodiment includes a workbench 1, a control structure 2, a cutting structure 3 and a pushing structure 4, and the workbench 1 is located below the blade of the cutting motor 311 A cutting groove 11 is opened, and a control structure 2, a cutting structure 3 and a pushing structure 4 are arranged on the workbench 1. The control structure 2 is electrically connected to an external power supply, and the control structure 2 is respectively connected to the driving motor 32, the pushing motor 42, and the electric push rod. 31 is electrically connected with the cutting motor 311, and the control structure 2 and the cutting structure 3 are arranged on the right side of the pushing structure 4, and the pushing structure 4 includes a straight plate 41, a pushing motor 42, a second threaded rod 43, a T-shaped block 44, a third Threaded rod 45, push plat...

Embodiment 2

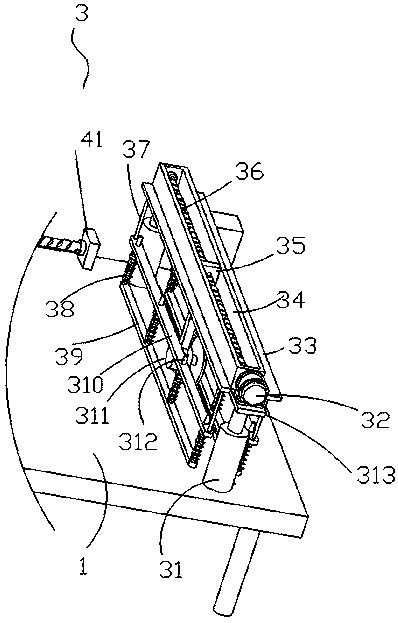

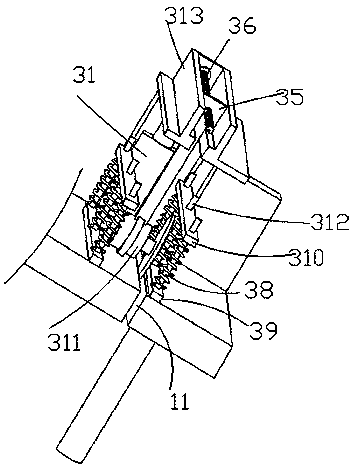

[0036] Embodiment two is a further improvement on embodiment one, as figure 1 and image 3As shown, the cutting structure 3 includes an electric push rod 31, a drive motor 32, a limit slider 35, a first threaded rod 36 and a cutting motor 311, the electric push rod 31 is fixedly connected to the workbench 1, and the top of the electric push rod 31 is fixedly connected There is a top plate 313, and the top plate 313 is fixedly connected with the drive motor 32 through a fixedly connected mounting frame. The rod 36 is fixedly connected to the output end of the drive motor 32, the first threaded rod 36 is threadedly connected with a limit slider 35 that fits and slidably connects with the limit chute 34, and the bottom of the limit slider 35 is fixedly equipped with a cutting motor 311 , the output end of the cutting motor 311 is fixedly connected with a cutting blade, and the electric push rod 31 of the cutting structure 3 drives the top plate 313 to move, and the top plate 313...

Embodiment 3

[0038] Embodiment three is a further improvement on embodiment one, as figure 1 , 3 As shown in 4, the left and right outer walls of the top plate 313 are fixedly connected with an outer plate 33, the top of the outer plate 33 is fixedly connected with a straight rod 37, the bottom of the straight rod 37 is fixedly connected with a connecting plate 310, and the bottom of the connecting plate 310 is fixedly connected with a slide bar 312 , the bottom of the slide bar 312 is fixedly connected with a pressure plate 39, and a compression spring 38 is fixedly connected between the pressure plate 39 and the connection plate 310, and the pressure plate 39, the slide bar 312 and the compression spring 310 in the cutting structure 3 cooperate with each other to facilitate the pressure plate 39 Pressing the base material processed by the photovoltaic cell panel can avoid sliding on the cutting of the base material processed by the photovoltaic cell panel, so that the cutting stability o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com