Self-stress adjustable concrete filled steel tubular column

A technology of concrete-filled steel tube columns and concrete columns, which is applied in the direction of columns, pier columns, pillars, etc., to achieve the effects of eliminating rust, simple structure, and improving airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

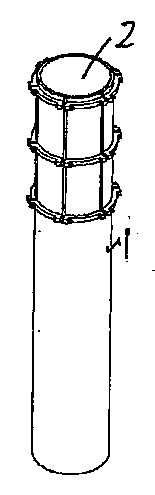

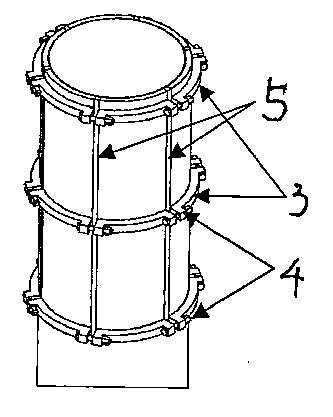

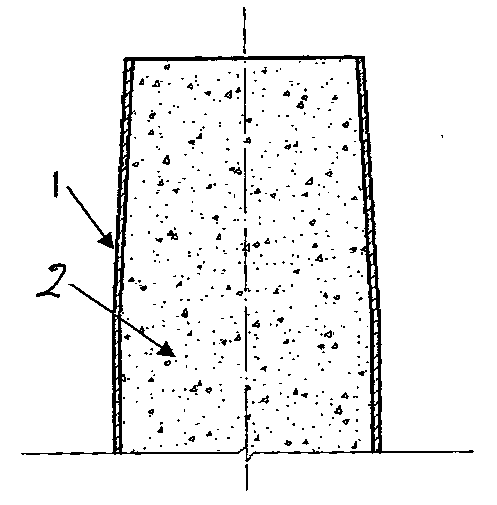

[0023] A self-stress adjustable concrete-filled steel pipe column, which includes a steel pipe 1 with symmetrical longitudinal slots on the upper part, and a core concrete column 2 inside the steel pipe; a number of transverse reinforcing ribs 3 are arranged on the outer surface of the steel pipe to hold the steel pipe tightly, and bolts are used between adjacent ribs Linked with the nut 4, the longitudinal slots of the steel pipe are sealed with a highly elastic polymer material filling strip 5, and the cylinder surface divided by the slot on the upper part of the steel pipe shrinks inwardly when the adjacent ribs are tightened by bolts, eliminating the void area 6.

[0024] The longitudinal slot is located at the upper third of the height of the steel pipe.

[0025] There are multiple layers of transverse reinforcing ribs, and each layer of transverse reinforcing ribs is composed of a plurality of ribs, and the connection between two adjacent ribs is located at the longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com